I was up half the night trying to think of where to go next with this project. Were getting to the point where big decisions need to be made and real money spent. So I thought I would get my ideas down on paper before they all fell out of my mind and I had to start over from scratch.

Looking at my new benches, I don't think I'm using the space I have effectively. I think I will take some of the scraps I have left and add in a shelf on the workbench. Maybe I can fit my screws and other smaller items on this shelf.

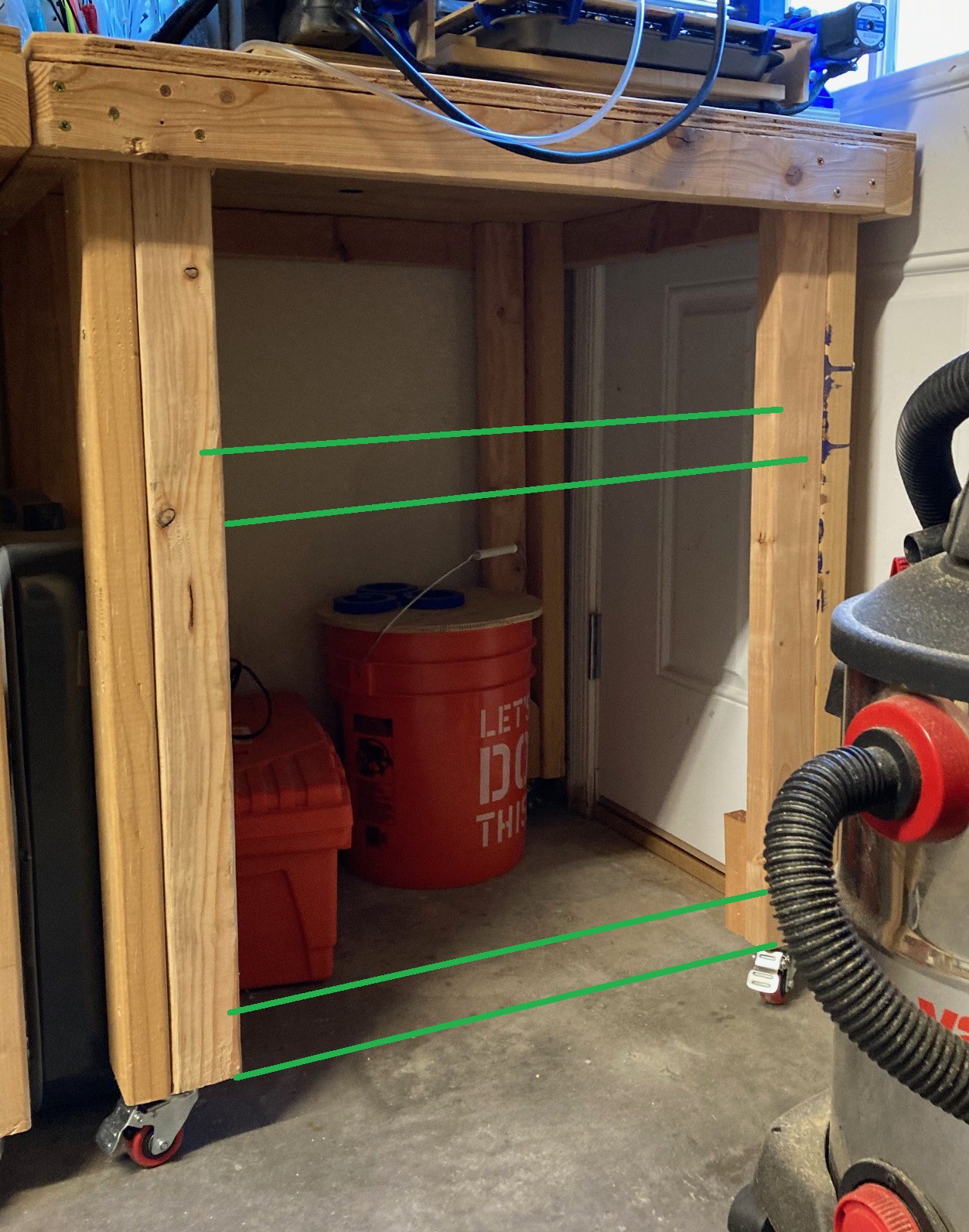

I left the CNC stand open at the bottom, partially because I had not decided what to do with the space and partially because I hoped to fit the shop vac in under the space. However the vac is huge and it is nearly impossible to fit anything around it and still make it free to roll in and out. Plus I have at least 6 different tools that really should use the vac and none of them will be placed near each other so the vac really should be out and free to roll around.

So I decided to take it out from under the stand and fill in the bottom and center with two shelves. I don't think I have enough plywood to cover all three shelves, I may have to break down and buy some more. I'm loathed to do this, but I suspect I will be using these stands for a good long while so it is not bad to invest a bit of money in them. This will let me get all of the various CNC jigs up and on the machine, and should provide a space to add in some filters for the laser and hopefully an enclosure as well.

For now I will tuck the shop vac in here next to the door. There is enough room here to still access stuff on the shelfs and it is easily rolled out of the way if needed. I have thought about finding a smaller vac, but there really are no compact (or quiet) vacs that still have enough suction that don't cost as much as a used civic. I think instead I will invest a bit in getting some better hoses for this vac so they are easy to wrap up and less gangly. The vac came with a very small and cheap hose (pictured here) and as an experiment I picked up a larger hose that is super stiff and almost impossible to work with. I also have a wide array of accessories, none of which are very useful. I think one nice long tube and wand for moping the floor and some sort of smaller nozzle with a brush for getting into crevises and the rest can pass on to good will. That way I can store everything on the vac and not have a jumble of things laying around to keep track of.

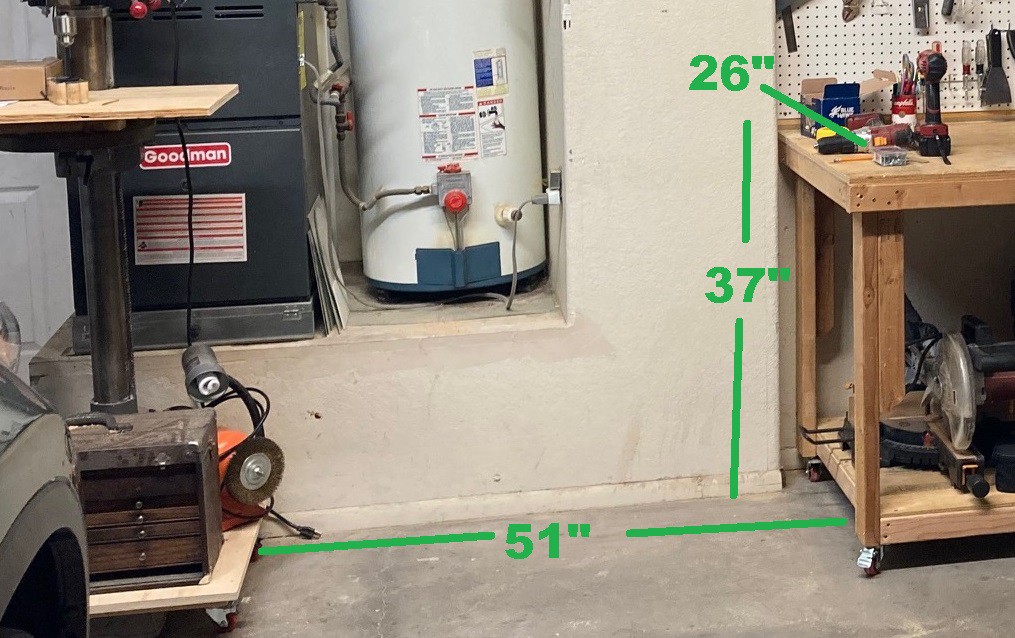

I have a space 51" wide, 26" deep and 37" tall to build my new cabinets. I could push the drill press out further into the space by the door if needed, and It is already sticking out about 3" so I could push it back flush with the wall if it turns out (unlikely) that I don't need all this space.

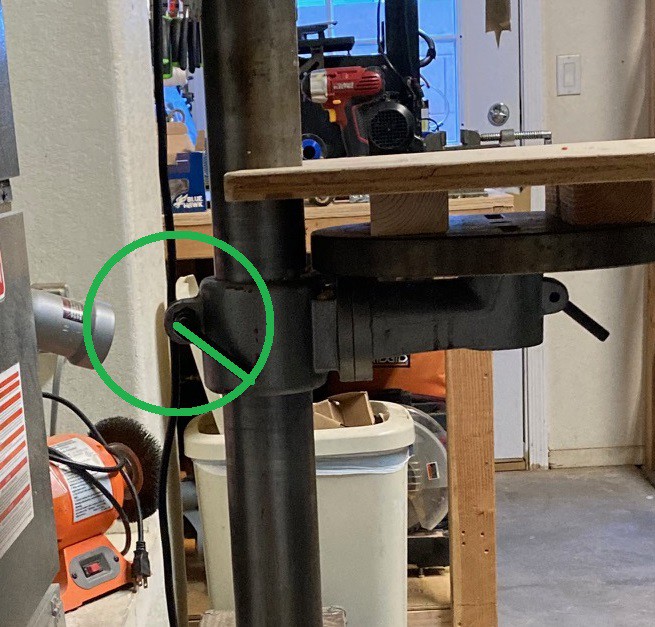

On the drill press there is a lever here on the left side that needs clearance to rotate. This works in conjunction with the lever on the right side to raise and lower the bed so it must be easily accessible.

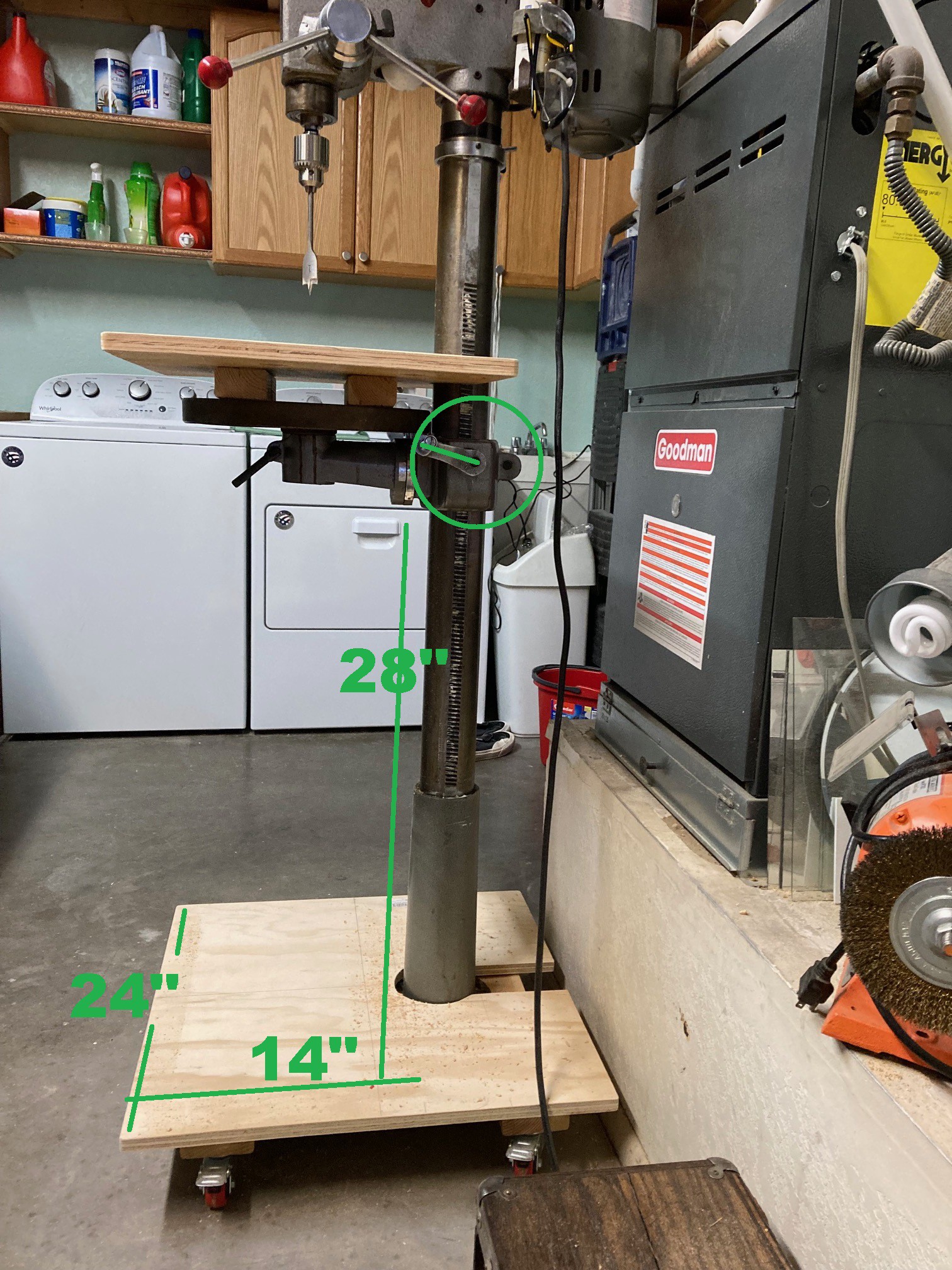

I put in the longest drill bit I have and lowered the bed so the bit just touched when the drill was plunged all the way down. That leaves a space 24" wide, 14" deep and 28" tall below the drill press table and in front of the column. I think I will make a series of drawers here to hold my drill bits and possibly my cordless drills as well. I don't think I will try to run the drawers past the edge of the column, there is just too much space lost there trying to close it off properly. Maybe I will make some open shelves on the back side or store clamps there. My longest clamps are too long to properly fit back there but maybe I can cut some slots in the top of the shelf to let the ends stick up. I may or may not put my grinder back there as well, however it does not look like it will be a good fit, and I would like it o be a continuous and flat surface so any dust from the drill press can be easily taken care of.

I spent quite a lot of time thinking about drawer slides. There are basically 4 types of slides I can work with. One is just using wood on wood like an old fashioned drawer. My small tool box uses this and it works ok for smaller drawers and it basically only cost time. The next up are the sheet metal slides you find on most (contractor grade) kitchen cabinets, these are relatively inexpensive, I can get twenty 22" slides for $100. There all we have in the house, and I have yet to see one fail or even really struggle with the weight. There not high quality but they are good enough. Next up is proper ball bearing side mounted slides, these can be had ten for $100 with a 22" depth. And finally the under mount ball bearing slides are five for $100 at 22" (for the non name brand units).

I'm going to need lots of drawers, I really want everything covered up so I'm not cleaning sawdust off of everything every time I'm cutting things. As much as possible I want to avoid open shelves. Ideally even the air compressor would be mounted in a drawer, both to keep it quieter and to make it simpler to remove if I need to carry it over to the car to fill up a tire. For those heavy drawers I will use some of the nice slides, but for most I think the cheap slides make a lot more sense. I don't see the point in spending more money on slides than wood for all these projects.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.