I picked up a box of t-nuts that range from 6-10 mm and that are the full 22 mm thickness of my bench top.

Then after carefully laying out all my tools in an optimal arrangement I marked, drilled and installed the t-nuts. The idea is to hold everything securely, but still be able to quickly remove a tool, if I need it somewhere else. In particular, the miter saw has a separate stand, and I may need to use it on a project or two.

I took my hose reel appart and modified it so the hose pulls from the bottom rather than the top. This should reduce the stress on the drawer since I'm pulling in line with the drawer slides.

I then marked and drilled a 50 mm hole thorough the drawer, and mounted the reel to the drawer with t-nuts. This will allow me to use the compressor without needing to open the drawer. The compressor is just resting in the drawer for now and I plan on setting it up so I can quickly lift it out of the drawer if I need to take it with me.

It all fits in well together, and with everything tucked back it does not stick out into the shop much at all. I mounted the miter saw right at the front of the bench so that I could place wood in front of the bandsaw, without having to reach really far across to still access the band saw. That has a downside of the miter saw sticking quite a bit into the room, when not turned to a 45 degree. I've already bashed my head on this once, we will see if this was a bad idea or not.

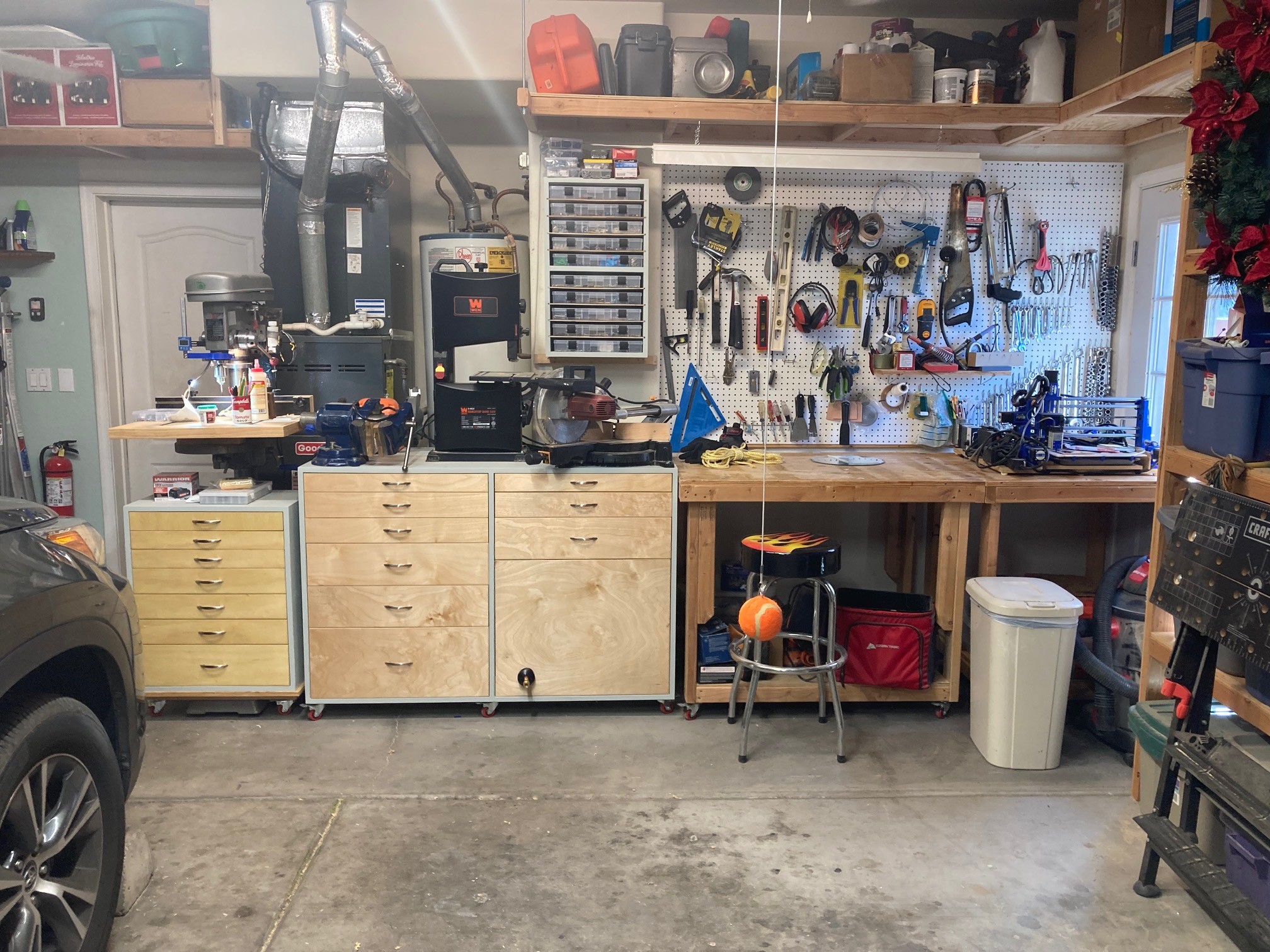

I quickly put the shop back together. It looks very nice to me! I still need to move all the tools into the various drawers. And I need to sort out the power situation. I want to have a single power cord sticking out of the back of the bench that controls every tool. And I would like some quick disconnect in the drawer so I can unplug the compressor without fishing cords around. And I want a way to turn the compressor on/off from outside of the drawer

I also want to add some sound absorbing material to the compressor drawer, and add in a latch to hold it closed while pulling on the hose. And I need to find a way to straighten up the face of the drawer. The 1/2" plywood I used for it is already warping, and i was not smart enough to back it with a large piece of MDF to help stabilize it. I will probably come up with something that also allows me to hold a spare hose for the compressor so it serves more than one purpose.

One issue I'm having is that it is relatively difficult to roll this around. Once you get it rolling it continues just fine. But changing directions or steering is difficult. I think the top bearing on my wheels is not really up to the load and that makes it a bit sticky. I have a set of 3" casters I could swap out for these 2" casters, I may do that if it gets worse. I figure there is about 200 pounds on the 6 casters right now, and I expect another 100 or so pounds of tools in here. These casters should be able to hold 800 pounds, if there claims are correct.

Now that I'm done with this second cart, it is also time to sort through my scrap wood pile. I hate throwing away wood, but there are only so many 2" wide pieces of MDF a person needs!

My hope is to get this all cleaned up and packed away this weekend. I probably will need a little more time to sort through the power and sound isolation, but I can knock out the cleanup at least. It will be nice to have my shop put back together and get rid of the boxes of stuff.

I still have a whole other project organizing the drawers. I have plans to bring some 3D printing in to help, but I also just want to take the time to really sort it out intelligently. I have never had a really well organized shop before, and I'm itching for it.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.