Sunday 09:28, 04/12/2022

Well, I just woke up and my brain is still on low energy mode, lol.

So, after sleeping like a rock and taking some really useful notes with dekutree64, I decided to lay my options on the table again.

I'm having a hard time trying to find a 1 ton Mckibben muscle that isn't made of Vectran and Kevlar (I wonder why ¬ ¬).

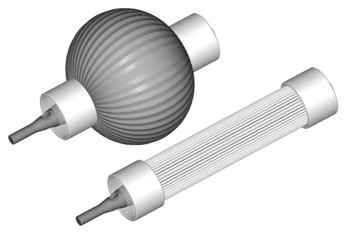

In this video of the channel HackSmith, they make McKibben muscles using steel braiding and rubber balloons. I don't really know where that kind of rubber balloon can be bought, but I will try to find on google shopping.

During 4:47 they show that an 1 inch braided stainless steel pneumatic McKibben muscle (I will use hydraulic, by the way) that accordingly to that goofy look green screen, it lifts 205lbs/92,9Kg, around 100 kg for 1 inch, so I would "only" need 10 of those.

But I'm still watching (re-watching, because let's be honest, every nerd has seen this video), and I'm trying to figure out how much pressure they use.

Well, I finished it and they don't say in any moment, but I can assume that it is around 0,7mpa, or 101,5 PSI, or 6,9 bars (nice).

Edit: I was rewatching today (2 days later) and at 2:44, they show a pressure gauge that stays at more or less 100 PSI or 5-6 bars. So I was right. lol

Also, I saw this question on quora asking "what would happen if you filled half of the artificial muscle interior with something solid".

And basically, it would still apply the same amount of force, but with less fluid. This means that if I filled the interior with plastic (or whatever other material), the muscles wouldn't weight as much as if they had liquid inside.

Maybe I could put a partially filled balloon inside, so it gives a little bit of spring action.

(Also, for some reason when I hyperlinked the phrase to the quora page, it froze the hackaday website and I had to rewrite a bunch of stuff).

So, taking into consideration the 3D sketch I made on Project Log 6 (I updated the 3D model, by the way, I forgot to add some muscles), we can count how many 1 ton group of artificial muscles we would need:

There are 10 Stewart Platforms with 6 muscles each, plus 4 muscles on each arm arms, plus 2 more on each thigh, so we have 72 muscle bundles (without the hands).

So I would need 720 large McKibben muscles, and pretending each is 30 cm long, I would need 216 meters of 1 inch tubing and braiding. Well, better than the 4,4 km. than my previous calculation.

Well, not that much...

You know, the price is proportional to the amount of rubber used, you know (I didn't, because I'm a idiot)? So... I can only find the prices around 20-40 Reais per meter. So 4400-8800 Reais for 220 meters...

LUCKILY I found out that 1-2 inches flat hoses are quite cheap, I can easily find 40 meters for 15 reais, what would be 0,37 brazilian cents per meter. Which would cost 81 reais for 220 meters.

I would need to "just" cramp that beast into a 1-3 inch braided sleeve, and since these can't escape, they would inevitably expand the braided sleeve sideways (I think).

And yes, I think one could use the flat hose alone, since it is flat and once the water pressure increases, it expands radially.

But I don't know how much it contracts compared to an actual McKibben muscle, probably not much.

Also, I don't necessarily need to braided sleeve that normally you see being used on McKibben, one could actually just make one braid using the "chinese finger trap" braid. Even Festo used that method in one of their products to increase contraction up to 45%. But I can't find the PDF again (not that it explained how to do it, just showed the product).

And I say that because braiding can cost up to 20 Reais per meter, and I can't afford that y-y.

I can just buy fabric tapes (like synthetic silk) and use that to make the braids, although I would still need to make everything by hand...

Also, this "solves" another problem that was in my mind when looking for materials:

Once I read a really useful article about a new type of pneumatic muscles, and one of the problems they were trying to solve was exactly about the expansion process.

The expansion of the inner tube and its friction with the outer sleeve diminished a little bit of the efficiency of the artificial muscle.

Just found it: "Third–Generation Pleated Pneumatic Artificial Muscles for Robotic Applications: Development and Comparison with McKibben Muscle".

For some reason I couldn't find the method of fabrication, but basically, they use a specific tissue with a linear triangular "wave", and on the inside of each "wave" they insert a wire of some material.

It is quite simple to make, but not in great quantities.

Also, I can't find the damn pdf anymore with the fabrication method explained. I always download a lot of scientific articles and pdfs "to read later", but now that I have almost 10 gigabytes of this crap I can't find anything anymore.

There are McKibben artificial muscles that are made from ripstop fabrics, and that's something that completely flew over my head while I was writing these Project Logs:

Just using fabrics instead of tubes, that is cheaper (I think) and easier to find.

The only problem is that I need to make the tubing... By hand.

I mean, if I can find a supplier that turns them into tubes with an automatic sewing machine... Or a "melting machine", since these are normally made from polymers.

Let's look at first article: "Simple, Low-Hysteresis, Foldable, Fabric Pneumatic Artificial Muscle".

"Fig. 1. Left: The fPAM (Fabric Pneumatic Artificial Muscle) in a depressurised, folded state. Center: The depressurised, extended state (ε = 0). Right: The pressurized, contracted state as it lifts a 2.3 kg mass. The 30 cm long muscle (without compressor or end fixture) has a mass of only 1 g, and a peak contraction of about 30% when unloaded. Ruler is 30.5 cm long for reference."

Well, this is in the same proportion of size, force and inner pressure as the multifilament Mckibben muscle I showed on Project Log 7, this time however, they've made a endurance test, and this baby can endure thousands upon thousands of cycles of contraction and lifting.

So it is very much working under the threshold for resistance and forces, this mean redundancy and endurance. :)

Now the hard part is finding out how much fabric I need to lift 1 ton. They show how they made this FPAM, but I couldn't find any information on the width of the space cut.

"Fig. 3. Series of photos illustrating fPAM fabrication.

A) Cut fabric at a 45◦ bias.

B) Lay strip of fabric with double-sided tape down its center.

C) Fold top half of fabric over, lengthwise, onto the double-sided tape. Apply thin bead of silicone adhesive along edge of fabric.

D) Fold bottom half of fabric over and adhere to applied silicone adhesive.

E) Apply pressure and wait for adhesive to cure.

F) Evert tube to remove tape and complete manufacturing. Scale bars denote 5 cm."

"Scale bars denote 5 cm", I can't make heads of this, but I will assume the width of the strip in the B figure is more or less 5 cm, lol.

Anyway, I don't think it will be a good idea to use this, it is too time consuming to make this happen, I will keep searching for Fabric McKibben muscles.

Also, I totally forgot about this, but there is a printable pneumatic muscle (that can be used as a hydraulic one that can be mass produced easily as well.

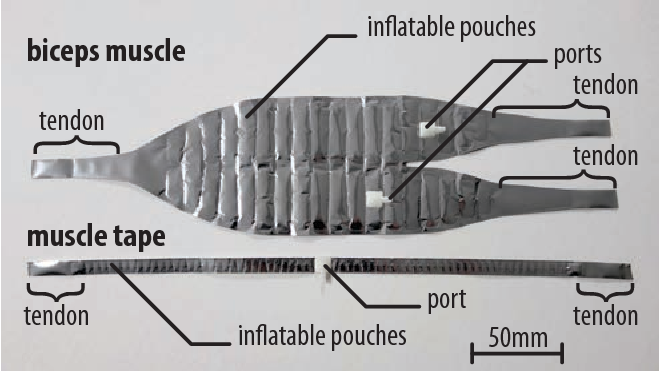

Article is: "Printable pneumatic artificial muscles for anatomy-based humanoid robots".

Well, I'm kinda tired right now, so I will see if it is cheaper later.

Edit:

I'M BACK LESGOOO

Normally I find PET foil bobbins laminated with aluminium foil, just like in the paper. These costs 100-250 meters for 100-200 brazilian bucks.

So, around 2 brazilian bucks per meter, not bad.

The thing is, that these bobbins width is not really the same as the final muscle fiber. The muscles are 5cm in width and 13cm in length.

One example I can find is 250 meters long with 32 of width, so in total, we would have 6,4 muscle fibers by dividing it.

So, having muscle fibers of 30 centimeters length dividing by 250 meters we would have 833 fibers, multiplied by 6, 4998 fibers with 30cm in total. And since every fiber can lift 1-2 kg, we would have the capacity of lifting 9996 kg from 250 Reais of aluminium plated PET sheets.

Although the flat hose McKibben would merely cost 81 reais (15,52 dollars) for all the 220 meters of material, since I need 25 reais for each 1 ton muscle bundle, I would need 1800 reais for all 72 muscle bundles.

Of course, the price can change based on the price of the foil and the type of foil. I tried exactly the type of foil used on the article, if you could find another type of foil that is cheaper than this, I would love to hear, because I really don't wanna make 300 meters of chinese finger trap by hand. lol

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.