It is Wednesday my dudes, 16:11, 11/01/2023

Well, after much frustration with myself and a lot of thinking, I finally came to the conclusion that I cannot properly design an endoskeleton that demands highly engineering knowledge.

And therefore, I will try to make it the simplest way I can come up with, but I cannot garantee it will withstand the 1 ton threshold.

Of course, you can simply choose to use composite materials such as carbon fiber, fiber glass or wood+resin (or ultra high performance air-concrete).

But, like I said, quality is also not a garantee when you make composite materials by yourself. Specially when you're building something to withstand 1 ton of weight.

You could also use solid steel (or aluminium 6061/7072) rods with 9cm in diameter and 30cm in length, but it will still weight around 2 tons (or 600 kg if you use aluminium).

Henceforth, with all this said, let's get this bread.

Off-topic:

Well, I guess off-topic topics are now a thing, since I can't just shut up myself.

I forgot to actually right what I had in mind, lol.

So... What I was trying to say:

Pulse jet engines are a simple but extremely powerful type of engine, however, these have some defects.

These aren't as fuel efficient as Turbine Jet engines of similar size/thrust, but they have superior thrust-to-weight ratio and are incredibly simple to make.

(this guy sells his PulseJet projects, by the way).

However, as you may not know (just like I did), pulse jets actually aren't detonation engines.

These actually work with deflagration.

The difference between deflagration and detonation would be something like the difference between a flamethrower and a explosive.

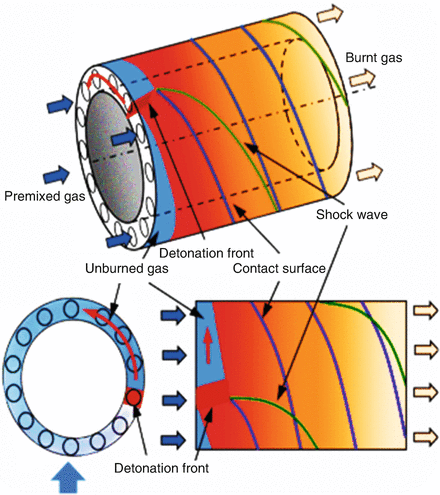

Anyway, the thing is that there actually are detonation engines, that work by supersonic detonation.

And as you could see, there are rotating detonation engines, which, as you could see in the video above, use a rotating wave of detonation that pulses the air in a spiral just like the blades of a Turbine Jet Engine.

So, a turbine jet engine without moving parts.

My mind just blew away with such concept.

The thing is, that if you put obstacles in a tube in which a deflagration reaction is happening, it actually becomes a detonation wave.

Who would guess that obstructing a wave would make it go faster?

So... If you use a Pulse Jet engine that turns into a pulsed detonation engine and then stack a lot of those in a circle, and then ignite them in a rotating succession... You get a rotating detonation engine.

Maybe.

I couldn't find any examples like this.

Maybe you would need to reintroduce fuel in the pulsed detonation chamber in order to make it work better, but... Who knows?

Image took from the article: "Review on the Research Progresses in Rotating Detonation Engine".

So, if you put enough of those in a mech...

Would you be able to rocket thrust around like in the games/animes/movies?

The Endoskeleton Bones:

Well, like I should have done since the beginning, I will use trusses made out of wood.

I mean, it was so simply and in front of me all this time, I could've just used them.

Here it is what I mean:

See these metal plates? These are called brackets, so you can literally "just' take a plate of metal and go using both as a holder for nuts and bolts and as a structural reinforcement.

Not to mention that Oak wood can have the density of 0.82 g cm-3, meaning that, even if you were to use solid Oak wood rods with 10cm in diameter and 30cm in length, the entire structure would still weight just 247kg.

... Wait...

Waaaait...

Wait, even if I use solid Oaks as an endoskeleton, then why should I waste time desinning the damn truss structure?

I mean...

I could have done this since the beginning...

Just using wood...

And I could even cut the wood in different shapes, so I could make a knee or a shoulder bone structure...

By the way, 2 meters of wood beams/columns range greatly in price, but normally it costs 10 reais (2 dollars) per meter, and since we need around 38,4 meters of this thing, you may need 400 Reais (77 dollars) for the entire damn body.

It was so simple.

The solution was in front of me all along.

bruh.

Anyway guys, it seems that the endoskeleton structure is more or less complete...

This means now that I will break my head over motion capture.

Now the real headache starts.

By the way, I received another answer saying that a 15cm in diameter and 3mm in thickness steel tube would be able to withstand these forces.

Which would be cheaper and lighter but... How to be sure?

I just give up on trying to figure out on my own... Wood it is.

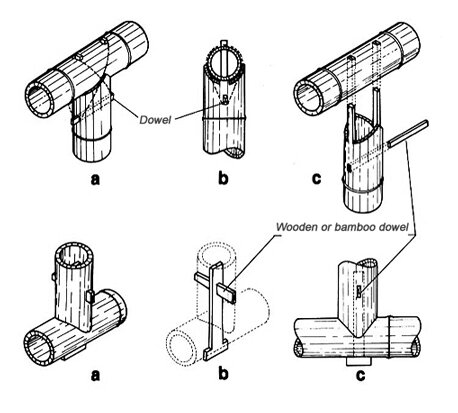

By the way, you could make trusses with rope (made of metal or not) and other elements:

I took this pic above from this article: "Bamboo Joints and Joinery Techniques".

This last one I took from this article: "Bamboo Trusses with Low Cost and High Ductility Joints".

One could also use the hypnotising japanese woodworking techniques:

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

lol, you just keep hitting all my interests :) As you can probably tell from my milling machine, I love precision woodworking. It will be interesting to see how this design works out. It will probably work well for the legs, but aluminum is probably better for the arms since they need to handle torsional stress as well, and that tends to cause splitting. Though you could reinforce it in some way (spiral wrap in carbon fiber, or drill a bunch of holes and glue in dowels... but dowels are surprisingly expensive).

Use glue rather than hardware connections when possible. Stronger and lighter and cheaper. And when you do need hardware near the ends of pieces, glue cross grain reinforcements to the sides to prevent holes from splitting.

This one makes me think of Escaflowne, with their sort of analog mechanical steampunk mechs :) That show was simultaneously awesome and kind of stupid.

Are you sure? yes | no

Funny enough I edited the project log and added a bunch of stuff, lol.

I see, thanks for the suggestion about the arms. But that makes me think: what if you insert aluminium rods on the oak "trunks"? Would it make any change?

Glue? Not doubting your knowledge, but can glue really withstand forces around 1 ton? :o

Escaflowne was really cool to watch, I can barely remember anything but the cool heavy metal soundtrack, lol

Are you sure? yes | no

I'm not sure what you mean by "insert aluminium rods on the oak "trunks""

Glue certainly can withstand 1 ton. It just depends on glue area and stress concentration. But since you can only glue side grain, it only has to match the splitting strength of the wood, which is not much compared to long grain strength.

Designing around grain direction is always the hard part of wood structures. That's why aluminum is such an awesome material, because it's strong in all directions at once while also being lightweight and easy to work with. Even carbon fiber has grain direction limitations. I mostly use it when the construction techniques are easier, rather than trying to save weight compared to aluminum. For example making a hollow aluminum bone that isn't a straight tube would be very difficult, whereas wrapping carbon fabric on a mandrel is easy. And my feather making techniques only work with fabrics.

Are you sure? yes | no