It is Sunday, 18:57, 15/01/2023

Well, sorry in advance because this Project Log will take some time, a lot of time, in fact.

Worse yet is that right now I'm sick as heck and I can barely step out of bed, I'm taking care of myself, so don't worry lads.

Well, this Project Log didn't go as I expected to go, but I don't think I will be able to actually text any of the options presented here for the next weeks or so.

Because I still need to make a program that translates the motion captured into something useful.

Some problems:

Anyway, to begin with, I strongly suggest that you watch the following video of the Hacksmith channel:

They made a lot of mistakes that I honestly would have done as well, in fact, I think I would have done worse than that.

I was thinking on literally buying 10 thousand brazilian bucks of stuff after finding a side job (around an entire year), but thinking about it now, it feels like it would be a really big mistake.

Not to crap on them, but I feel like they should have started with a small plastic prototype before going to the real thing.

I mean, maybe they wouldn't have bursted their budget if they thought and analysed all the problems more throughouly... Like with a smaller prototype.

They literally had to change the hydraulic cylinders and the servo valves 2 or 3 times because they didn't considered the weight and the mechanical disadvantage these things would be under, like, they litearlly took something that is a heavy metal tool and it broke multiple times.

Probably in the recordings and inner discussions were much more complex and better thought out than what it looks like in the final cut that went to youtube.

And all of these problems makes me think:

If these professionals took an entire year slamming their heads on this project, how much f*cked I am?

They used the method of attaching an encoder on the rotating joints in order to control it with inverse kinematics, however, as you could see, know its position is not the same as knowing the force applied.

Which gave me the idea (that I already had, but I forgot) of using the Piezoeletric buzzers as pressure sensors.

And also using 9dof motion sensors, which confused me, but as said in this answer on Stackexchange, it seems like it is an super reduntant position sensor.

And I was thinking of using that on the limbs of the Mech while also using rotary encoders, so I can have a better idea where everything is.

The problem with all of that is the cost.

Sure, the 9dof motion sensors are somewhat cheap (around 50 reais or 10 dollars), but the processing unit that they had to use... hmmmm

Anything that is meant for processing and controlling robots is absurdly expensive, something as silly as a raspiberry pi can reach thousands of Reais.

Of course, I can always f*ck around and find out with cheaper computers, but even then, I don't know how much will cost.

The controls:

As I have shown in my other project, the DIY Full-body VR Rigid Haptic Piezoelectric Suit, I have bought some time ago around 100 units of really small piezoelectric buzzers that I can convert to piezoeletric sensors.

Well, once I get better, I will try to wire them in an attempt of controlling a VR hand, since, after all, both projects are interlinked somehow.

... And if I can virtually control something as sensitive and precise as the movements of the hands in a rigid suit, I definitely can do that to the rest of my body.

The problem is... How?

Of course, it would be a crime if I didn't mentioned the ideas that dekutree64 gave.

Basically, he suggested to use a 3d printed plastic exoskeleton from a project in hackaday itself and use both the 9dof motion sensors and/or the fluid/movement of linear actuators (hydraulic or mechanical).

Being honest, the reasons that I want to use rigid piezoelectric suit is completly for safety reasons and haptic sensory, but the idea he gave is much more simpler and easier to build.

The only problem is that I don't know (yet) how to fit this exoskeleton for motion capture inside the cramped mech, you would need to make something to control the thing.

The first thing that comes to my mind is the "motion capture cockpit" of the Avatar franchise, buch as you could see, you need a lot of space.

But... Now that I think of it...

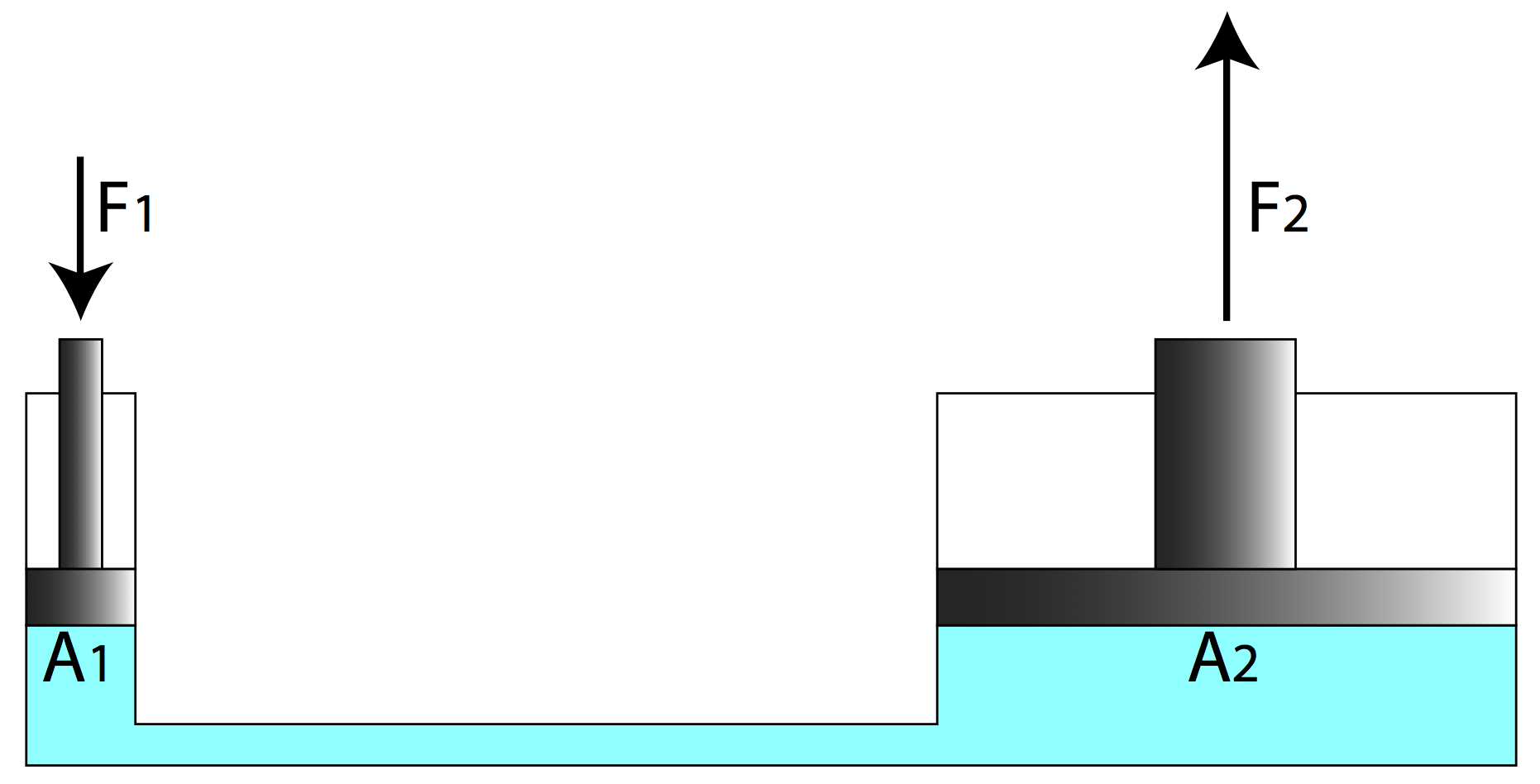

Maybe you would be able to control the pressure applied the same way a gas spring works!

Even though you have a little bit of moving room (or a lot, depending on how you make it), you could easily verify the pressure applied!

Wait...

Actually not, I totally forgot that it is hard as frick to measure the pressure of a pneumatic cylinder, how one would do that with the gas spring?

Maybe if you had instead a hydraulic gas spring where the pressure generated by your body movement would press the spring of a hydraulic accumulator, and then you could measure the force and speed applied accordingly to the time it took to move the spring and motion encoder a certain distance/force.

Maybe using the example above of hydraulic Pascal's principle and the springs bellow:

Actually, I don't even need to use spring or piezoeletric sensors, I could simply use a scale/weight sensor.

And these have its precision already garanted unlike the piezoeletric buzzers.

But I still could use the buzzers for haptic feedback (lies I tell to myself in order to feel less stoopid).

Dunno if this was obvious for you, but for me, it was mind blowing.

I just woke up and I'm feeling waaay better, I feel that maybe I'm not sick anymore.

Anyway, a problem that I overlooked is the same problem thaat every scale has:

If you're familiar with using scales, you know that when you put something over it, it takes some time to precisely calculate the weight (the arm is in front of the display, but you know what I mean).

Which could be a significant problem, and maybe a deal breaker, but I can only suppose that maybe with a better quality weight sensor and/or separating the weight values, you could make something that goes less crazy.

On the "separating the weight values", what I mean is:

If you apply a 500 gram force to the sensor, and it always goes crazy up to 700 grams, then you could, for example, make 500 to 700 grams to be the threshold values for the same force.

So the arm of the mech doesn't go crazyly up and down while the sensor tries to precisely measure the weight.

And if you really want to go absolute precision, you could use precision gauges.

And you can make a lot of different configurations using it:

In this video, it is shown a robot arm with 3 electronic gauges (I think it is for the 3 axis) in order to show off (and calibrate the robot arms) its precision.

Now that I searched a little bit more, maybe I was overthinking all the problems, to be honest...

As shown in the video bellow, even piezoelectric are good enough sensors for force/pressure/weight detection, the only problem is that piezoelectric devices are more sensitive to vibration, which wouldn't be good if you're inside a walking mech.

I also found this video that seems quite interesting, I don't think you would be able to translate that into movement, but you could use this matrix as a "skin" around the mech so it can make a simulation of touch.

Besides, I think that would be really useful for robotics in general.

You could even make a prosthetic with haptic feedback without the insane costs that those companies normally applies.

I will try to disassemble a precision scale I already have in order to take the load cell and then text it.

However, no matter the type of motion capture suit, I still need to make a software that can translate the captured motion of the pilot's body into a virtual motion.

Of course, there is a cheaper and easier way to do that:

The problem is: the pilot doesn't have the space to move around.

Well, giving a try on thinking in a solution using the already readly used solution to motion capture, I could put the cameras directly pointed to the body and transmit the little movements into the program so it could generate some kind of movement.

Of course, I could just go Avatar Mech Suit crazy and make a giant box with arms and legs where the pilot is suspended by elastics inside of it.

But it would need a lot of space, and a lot of space, means that I need a lot of material to keep the pilot safe; and a lot of material, means a lot of weight; and a lot of weight means a lot of energy going to waste.

Would be something like a bungee trampoline (the name of this thing), plus this thing bellow:

I just think this video is kinda funny because it literally shows the mech suit user k*lling people while it plays an "heroic feels good" music in the background.

I mean, couldn't you use other scenes, any scene besides that one?

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.