Sunday, 18/06/2023, 18:25

Soooo...

I don't even know why I'm writting this project log, I really don't think that I will have the money, nor the mental fortitude and determination to go through with this project, but for some reason, I keep going forward.

And the project log of today is about Hydrogen Fuel Cell Generators.

So, there are a crapton of hydrogen fuel cell types, and all of them have pros and cons.

The simplest, more efficient and easiest of them all is the Proton Exchange Membrane Fuel cells.

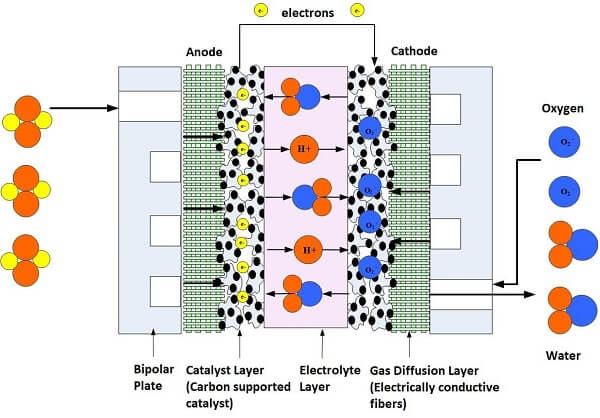

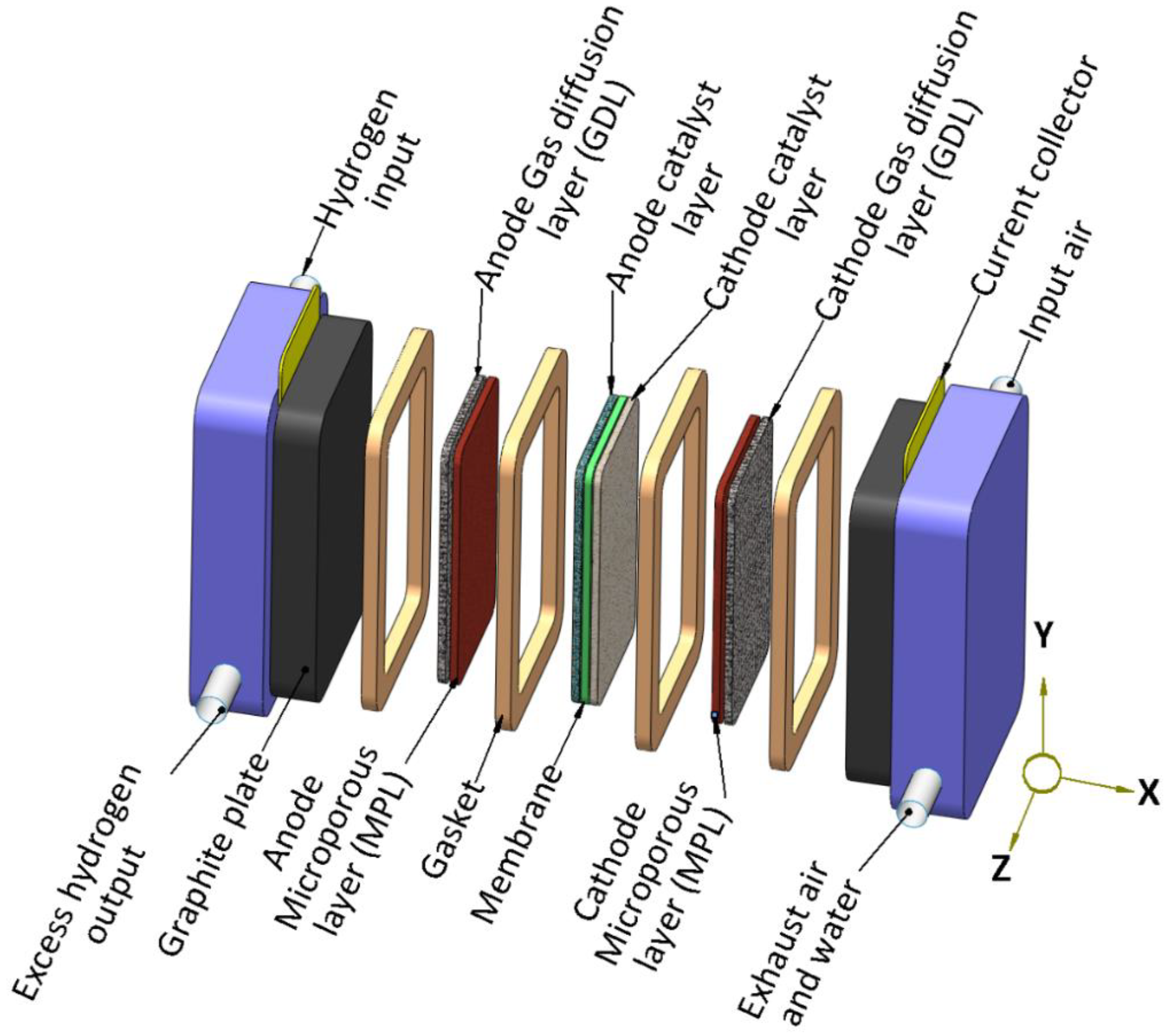

You simply put in sequence a current collector, an electrode (cathode or anode), then the Proton exchange membrane, then another electrode (cathode or anode), another current collector and bam, you have a fuel cell.

The problem is that EVERY SINGLE PIECE of EVERY TYPE of hydrogen fuel cells are expensive as fricking hell!!!

I thought the most expensive part was like, the platinum or something, but no, even if I was made out of gold I wouldn't be able to pay for something such as a fuel cell.

Nafion, the most common proton exchange membrane and commercially available costs 200 reais (40 dollars) for every 10 square centimeters!!!

A *single* membrane costs 200 reais (40 dollars) for a single cell. There are hundreds, if not thousands of fuel cells on an Hydrogen Fuel Cell generator.

Of course, the list goes on and on for every type of fuel cell, the Solid Oxide Fuel Cells are basically the same thing, but with ceramic materials replacing each part and running at 200ºC to 600ºC (or even more) of temperature to reach desirable efficiencies.

But my dude, even the ceramic materials are expensive as hell, the electrolyte/"proton exchange membrane" of a solid oxide fuel cell, the "yttria-stabilized zirconia (YSZ)" or whatever the hell this means costs around 200 reais (40 dollars) a single 5cm by 5cm square piece with 0.1mm of thickness!

(by the way, I saw some videos where people simply used Acrylic plastic as a proton exchange membrane on some home-school projects, but I don't know how well that would be for a fuel cell)

__________________________________________________________________

Obviously, there are some ways of "getting around of it", but I doubt any of these are as efficient as the commercially available options.

However, I don't want to be super efficient, I just want to be as efficient as a combustion engine (30% to 40% efficient), but the more I research about the subject (on google, lol), the more I understand that it really isn't that simple, and even a 30% efficiency from homemade materials is just asking too much.

Well, the best video I found about making a homemade proton exchange membrane was this one bellow. Although half of the video is him throwing chemical stuff after chemical stuff on the cloth in order to clean it and make it adhere to the proton exchange resin, which is the whole "heart" of the stuff.

One could use hydrogels to suspend the resin or something like that, but I don't know how an hydrogel wouldn't simply go down the drain in a hydrogen fuel cell...

This other video, however, kinda made me excited for the possibilities of an entirely castable hydrogen fuel cell.

You see, an "ion exchange membrane" is the same thing as a proton exchange membrane (somehow), and since you can use regular cement for it, maybe you could use refractory cement to make the entire thing and work at the same insane conditions of a regular Solid Oxide fuel cell.

Again, you "could", "maybe", the resin is the reason the membrane works, and the high temperatures may destroy it, even inside the brick.

(By the way, the idea would use resistor wires such as Kanthal and Nicrome, these are relatively cheap and chan reach thousands of degrees with relatively low wattages)

In the video the guy mixes the powdered Nafion plastic and mixes it with cement in order to use the cement as a single membrane in a solution of 3:1 of nafion and cement respectively.

However, even then you need a significant quantity of nafion and/or proton exchange membrane.

As far as I know it, clay pottery can be used as some kind of membrane in batteries, such as the clay pot battery. And the same can be said about plaster of paris.

Although I don't know how well it would work as a proton exchange membrane, neither as a hydrogen fuel cell membrane. Which is relevant, since you will be making water out of the reaction, and a plaster of paris membrane would just melt in the presence of water.

And the more I look into Hydrogen Fuel Cells, the more I get confused, because a lot of them are done in a really specific way. Some may have gas diffusion layers (GDL) for some reason, and others may have bipolar plates and current collectors, which I still don't understand why you would need both.

Why a gas difussion layer? Why a microporous layer? Aren't the cathode and anode already current collectors? What?

__________________________________________________________________

... In any way, you can use Nickel and/or Iron as the catalyst in the electrodes and maybe mix other substances that may be used in other types of fuel cells, such as silica, gadolinium, zinc oxide (known as zirconia), cerium (glass rated polishing powder), vulcan (carbon black, an specific type of carbon that is more electrically conductive), sodium silicate (for better heat resistance) and, the best of all, homemade graphene.

Yes, that "blood graphene" that is made with milk, with the proteins present on milk, more specifically. The guy made it using Whey protein powder and later made a bioplastic that was basically indestructible.

And graphene is said to be a great catalyst support material and an even greater reinforcement for concrete. Although, for the catalyst support I would guess that you need a lot of funky wunky chemistry stuff to make it work.

__________________________________________________________________

So the idea would be to take a really deep/long pot of any kind of material to be used as the casting mold.

Then, you would use Plaster of paris as the spacer for some parts, such as the gas parts, the tube connections and so on and then melt it with water after everything became solid.

Basically you would put the screw hose entrance on the extremities of the inside of the mold, put the plaster of paris already casted in a 3D printed shape (or simply carved shape) with or without the metal parts and then, after the whole thing is rock solid, you take out of the mold and melt the plaster of paris with water, which will leave the channels behind.

So, the order of casting would be:

Current collector cement mixture > Negative plaster channels > Electrode cement mixture > Proton Exchange membrane cement mixture > Electrode cement mixture > Negative plaster channels > Current collect cement mixture.

(not a cement fuel cell, but a valid example)

Every step you would obviously wait until the cement mixture of every layer is dry, which, I suppose, you would have weighted before hand so they are as even as possible and as thin as possible. Plus, what will be considered the cathode and anode will depend on which part you insert the oxygen/air and hydrogen gas.

The thing is: I don't know what should be used as current collector, or if using graphene from graphite on everything would cause short circuits (or dead short, or whatever it is called in english) everyhere, or what should be the cathode and anode (and oxygen/hydrogen channels respectively).

I'm suspecting that, although the idea would be great to simply cast an entire hydrogen fuel cell, you would still need gaskets or cement insulant/separation layers to avoid short circuits on the entire system.

I also don't have the money to buy everything necessary to test it out, in this case, the high pressure hydrogen gas tank.

I was thinking on buying a 1 liter 200 bar gas tank, connect to a complete cell and see how much electricity it would generate, and then I would more or less know the efficiency, since 1 liter of hydrogen at 200 bar (or any kind of pressure) would have an x value of electricity in total, and the amount of electricity you where able to generate from this liter would be y value, and thus, show you how much you've lost during the process.

However, I don't feel like I have the skills to pull this off.

Yes, it is a "simple" project, and yet, I don't feel confident to build and test it with all the necessary components... Just imagine an entire mech...

... Or I'm just being lazy?

... Or overly insecure due to my constant failures?

_____________________________________________________________________

Edit¹:

I just calculated the value of everything and basically, I would need around 50 reais (10 dollars) for every part, and since I would need around 10 to 14 components to make the cement hydrogen fuel cell, I would need around 500 to 700 reais (100 to 150 dollars).

Even in the "cheap", I still don't have the money to even try to make the dang cement hydrogen fuel cell.

The components would be:

- Graphite powder for graphene

- The proteins for mixing with the graphite for the making of graphene, such as the Whey powder that contains the bovine serum albumin (I only found egg albumin for food recipes) and lactoglobulins (that I also couldn't find pure), although I couldn't find many Whey Powder that explicitly said they contained these two proteins, the best bet would be "concentrated milk protein".

- Cement and/or refractory cement.

- Sodium silicate to make the cement even stronger and heat resistant, however, I do not know how much it would affect the performance/efficiency of the overral fuel cell.

- Nickel powder for the catalyst, however, I'm curious if super elastic Nitinol wire (an alloy with nickel and titanium) would work, these are cheaper than they sound (but the iron/nickel powder definitely aren't).

- Iron powder, because like nickel, iron is also used as a catalyst.

- A short Platinum or platinum coated wire for around 50 brazilian bucks (10 dollars), it won't be enough for the entire thing, but it could be somewhat useful.

- PVA glue with Polyvinyl alcohol (it won't work without it) for the proton exchange membrane.

- Maybe pure Polyvinyl alcohol to add extra to the mixture.

- Citric acid for the proton exchange membrane.

- Chitosan powder to mix with PVA, chitosan is a bioplastic that is normally sold as tea/natural treatment, but there are tons of papers/articles showing hydrogen fuel cells made using it, so in my smooth brain this made me think:

"Proton Exchange Membrane with PVA and citric acid + chitosan dissolved in PVA (because it needs to be dissolved in something) = better proton exchange membrane. - Conductive ink to be mixed in the electrodes for better electric conductivity between cells.

- PTFE insulating tapes for electrical insulating inside the thing.

- Kanthal resistor wire to test if the stuff would peform better at higher temperatures.

- Rust/oxidation resistance conductive wire to be used as current collectors in the cells, the cheapest I found was for electric fences, which are constantly exposed to the environment and need to keep its conductivity.

- Also, I heard that Polyimide (kapton) plastic and/or silica gel could be used as a high temperature Proton Exchange Membranes with limited efficiency compared to properly made PEM's...

But it could be tested, if you have the money.

All of the components are around 50 reais (10 dollars), some are just 20 reais (4 dollars), others are above 80 reais (16 dollars).

One or another are literally 100 reais (20 dollars) or more, depending where you buy it.

Also, if you where to make a really hot cement fuel cell, like 600 ºC or something like this, I would suggest to use heat resistant ceramic one-way valves (or "check-valves") to avoid the gases to go back from where they came from and go kaboom; Oh yeah, with so much heat you can just instantly combust your fuel. :|

And even a shell around the fuel cell made out of refractory cement.

The holes/channels could be made the same manner as I talked above the Project Log, with negative plaster cast and so on, so you could protect the rest of the equipment...

This also means that I can't really even start/complete this project, since it would be so fricking expensive in all aspects...

_____________________________________________________________________

Also, I saw this interesting "swiss roll fuel cell" that I thought it was quite interesting, I don't remember what fuel it uses, but It is not purely hydrogen and oxygen.

The article: "A Swiss-roll liquid–gas mixed-reactant fuel cell"

The article: "A Swiss-roll liquid–gas mixed-reactant fuel cell"

I also saw this one made out of ceramics, I wonder if it would work with this cement fuel cell.

Article: "A “Swiss-Roll” Fuel Reformer: Experiments and Modeling"

Maybe you could put the cement in a cloth and roll it around before it dried out? I mean, they do that for concrete cloth...

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.