First, each component is designed in the Fusion 360 software, using commercial bench presses as reference. That's also the case for the dimensions of our 3D printed bench press.

One of the challenges of our design was to ensure smooth movement for the shaft and tight joints between components. With that in mind, a pillow block bearing was added to the design and multiple holes for M5 and M8 screws. The 3D model also include hexagonal-shaped mouldings, where nuts are inserted in order to tighten the joints.

A C-shaped component was added later to press the bench press against a table. This component includes 2 handles and cushions to fulfill its mission.

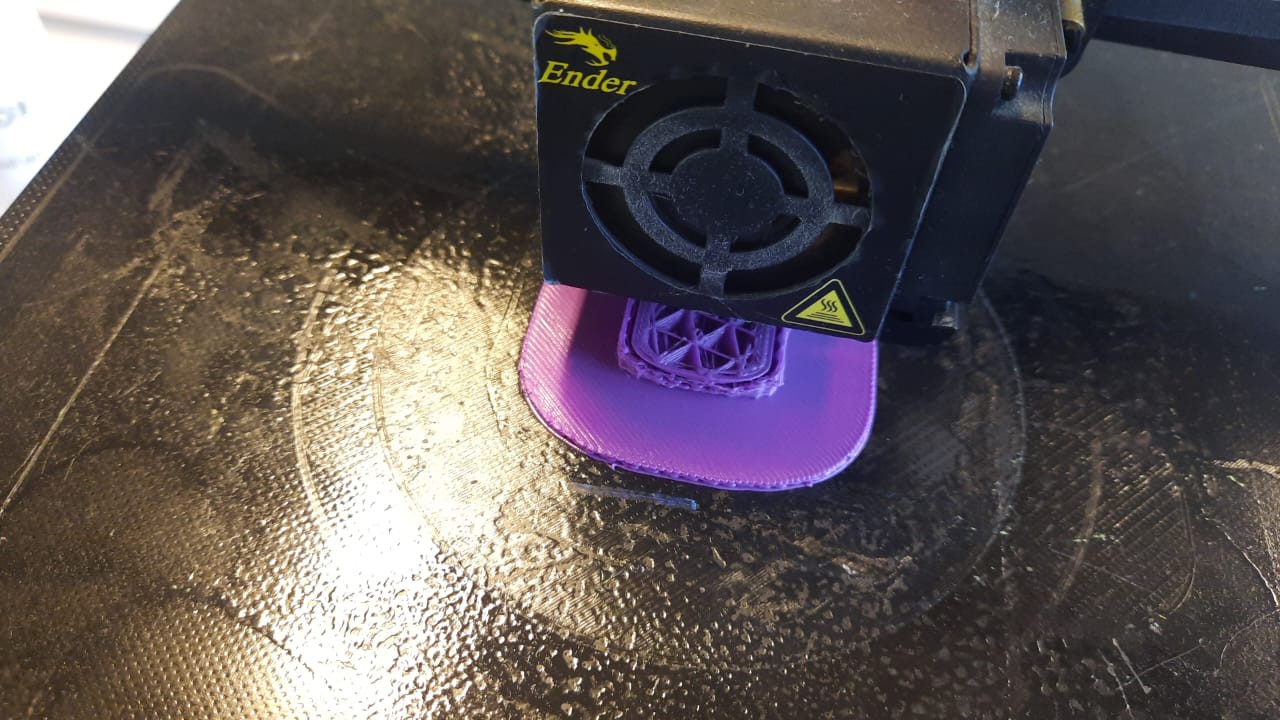

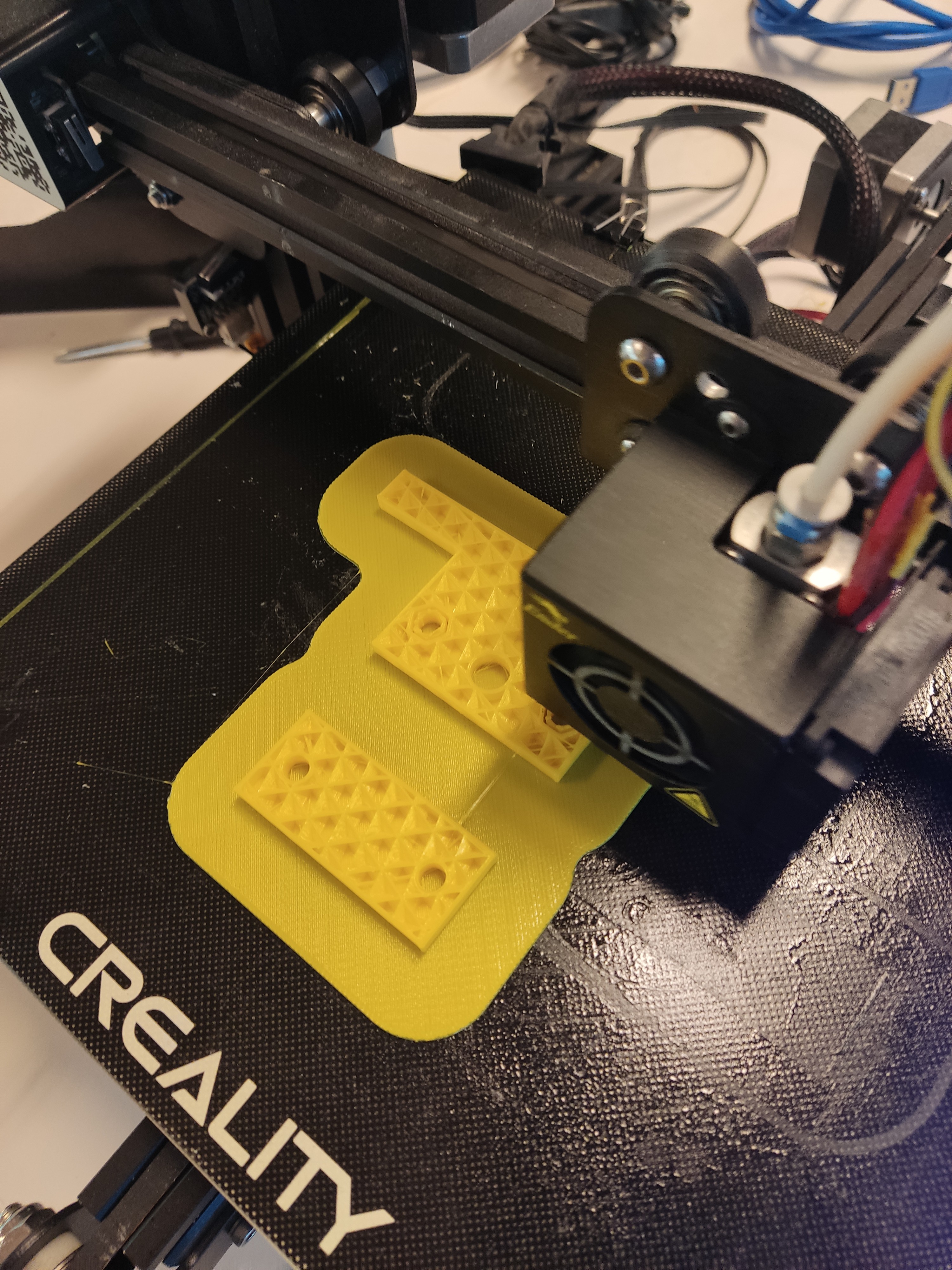

The 3D printing process starts using CREALITY Ender 3 printers. Recommended printing parameters for Ender 3 were chosen: bed temperature 60ºC and extruder temperature 210ºC. Also, default layer height was 20 mm and infill density chosen was 20%.

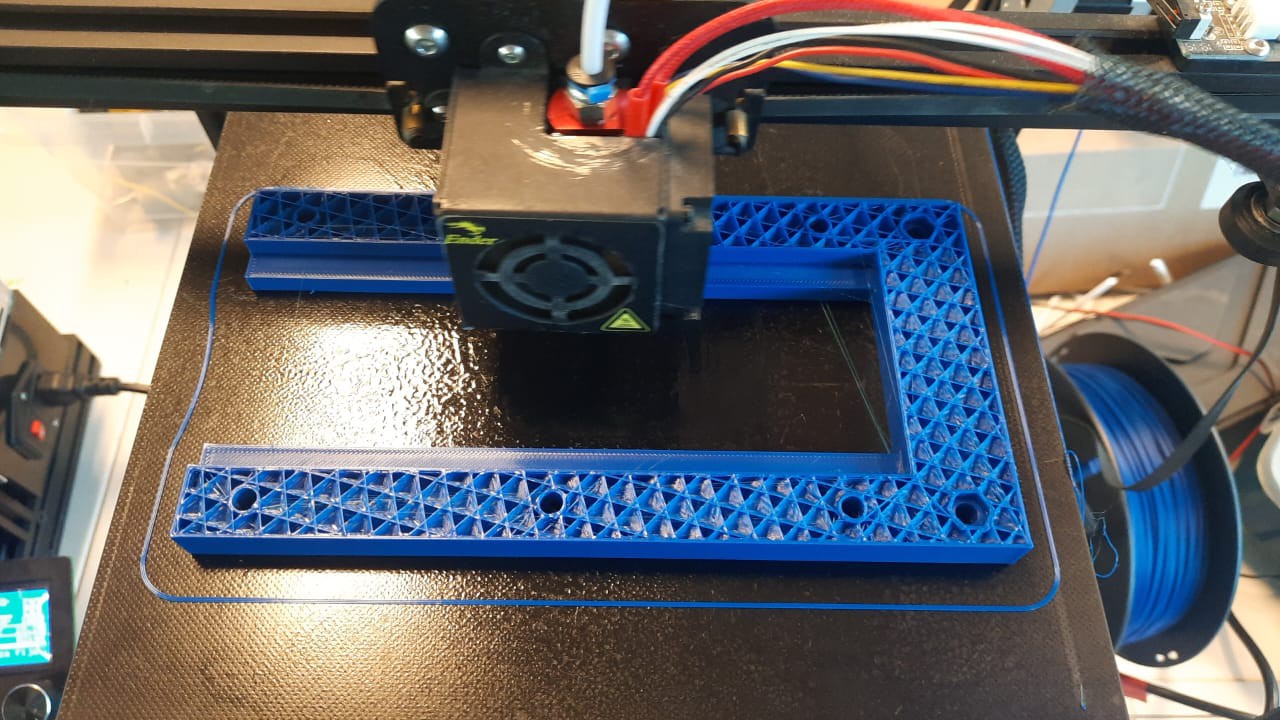

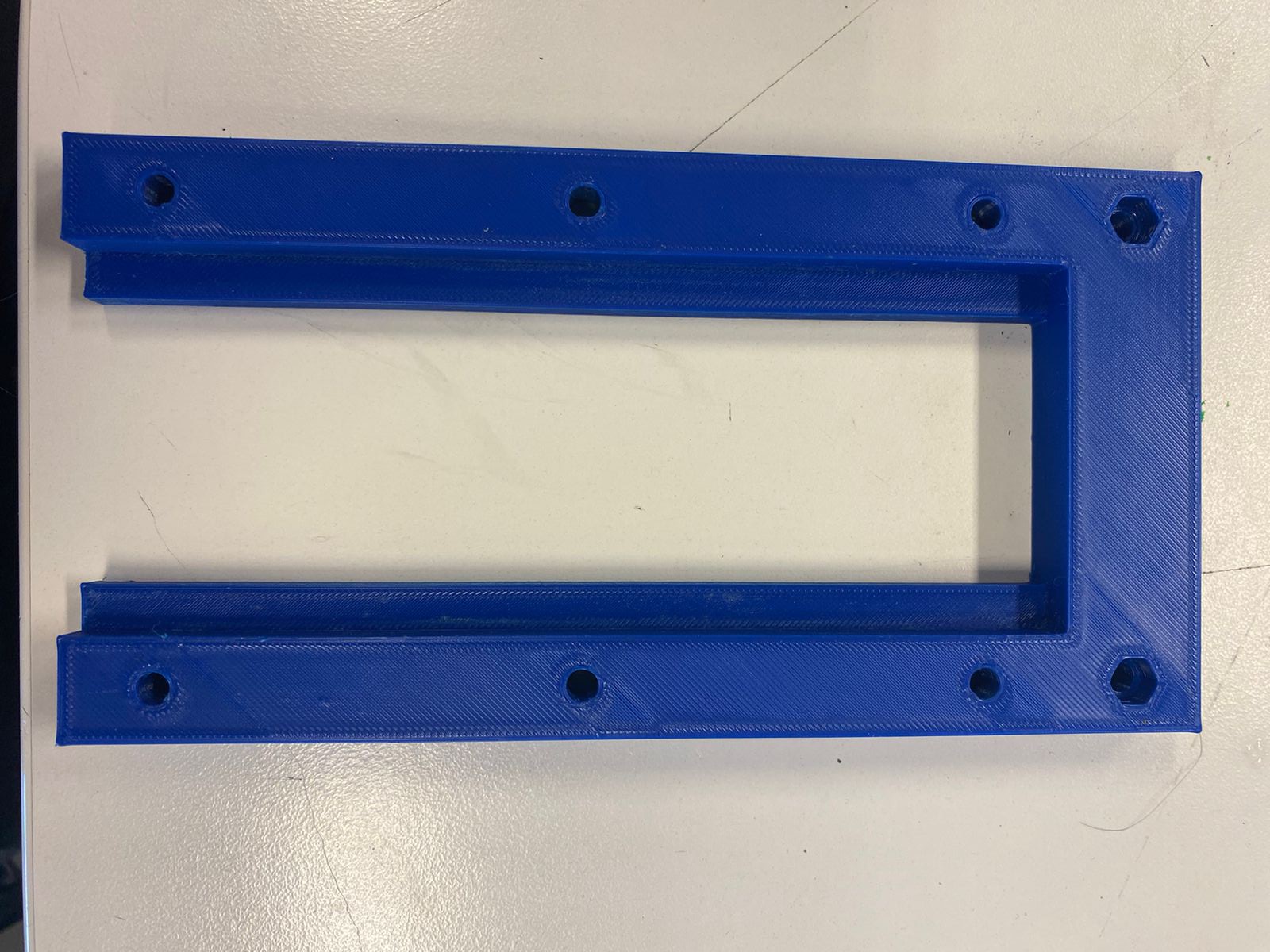

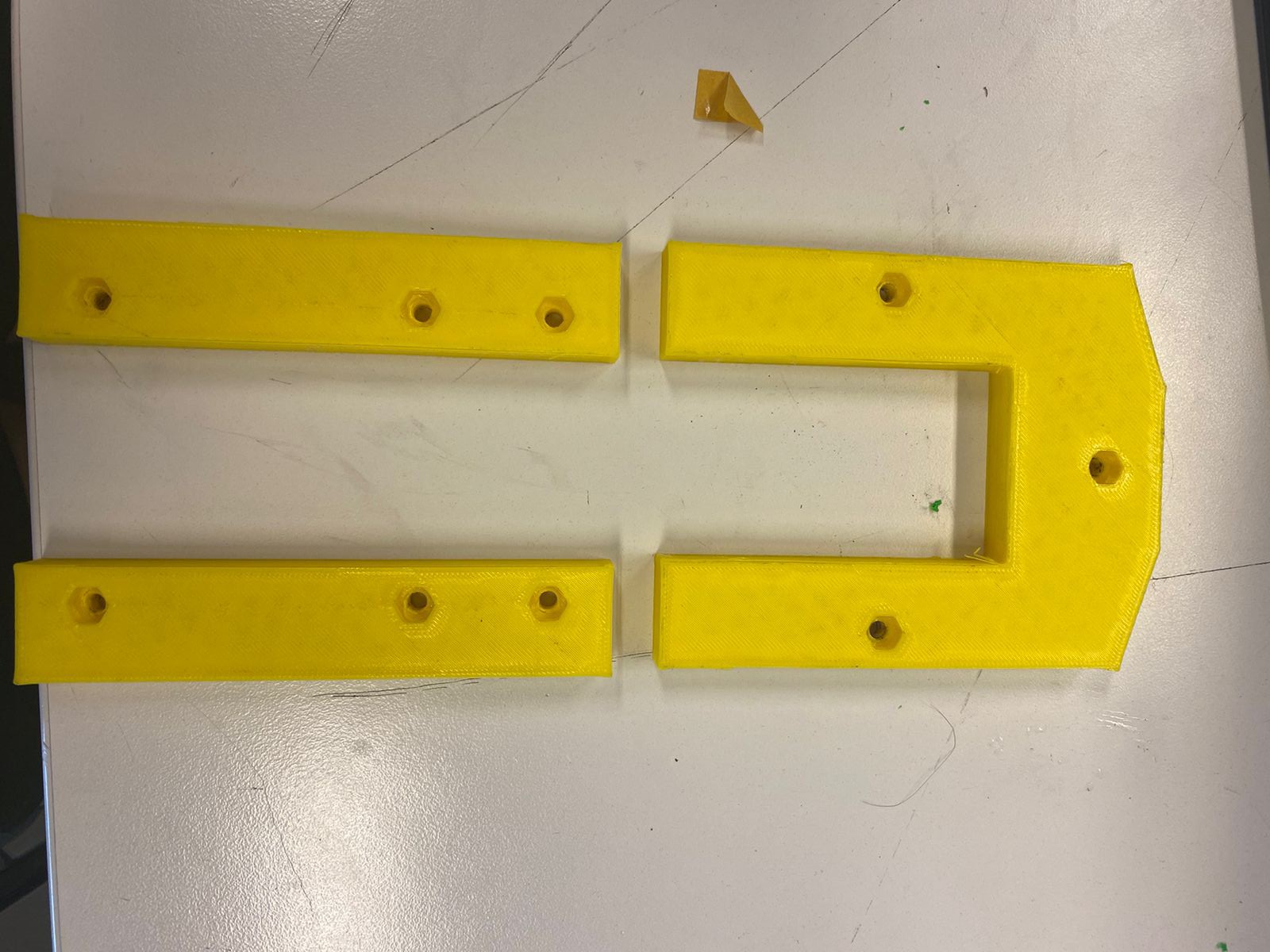

Rails

The first components printed were the rails.

Plate adhesion type: Skirt

The printing process of the rails lasted 5 hours and 49 minutes.

Total weight: 115 grams.

The resulting part is shown next.

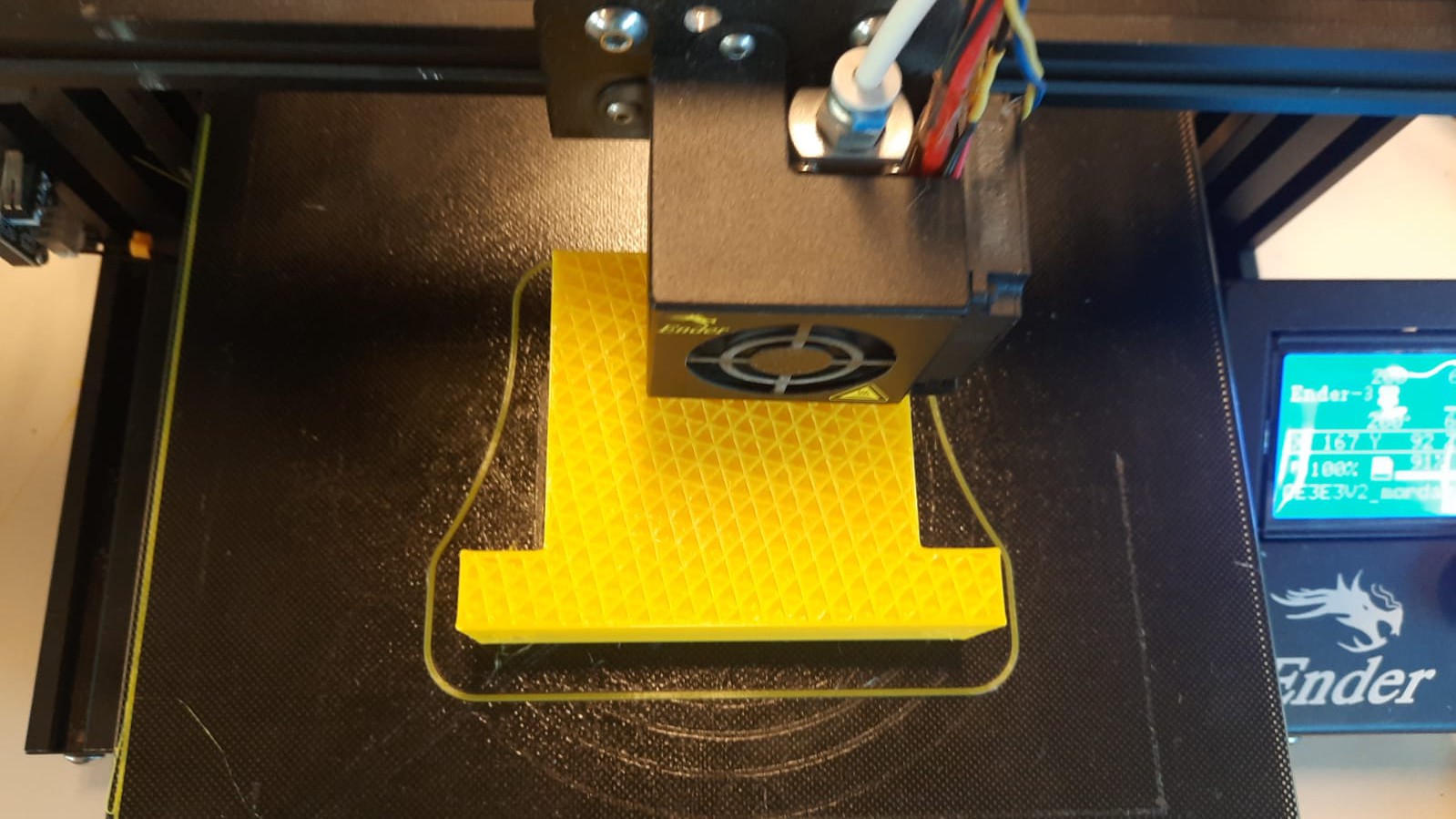

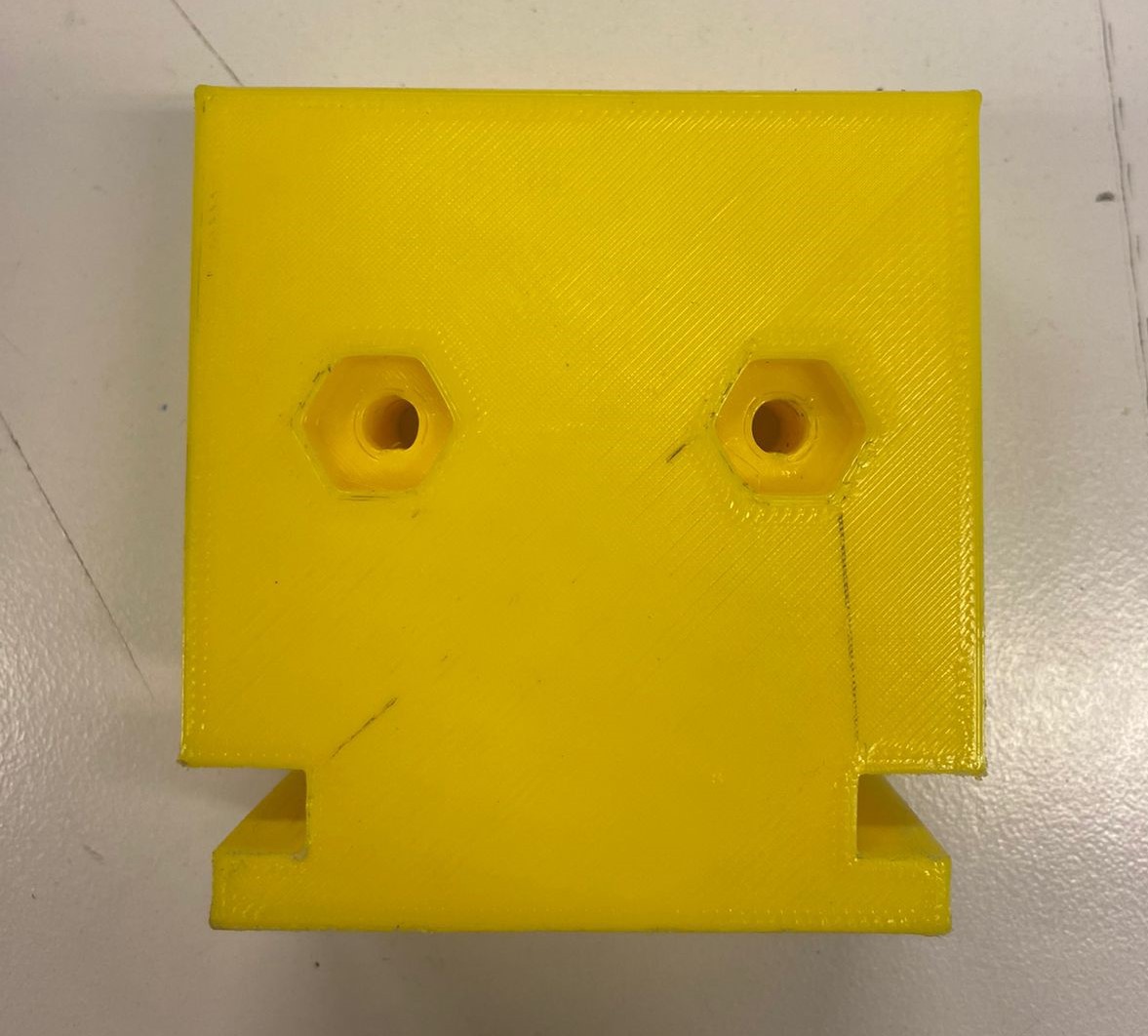

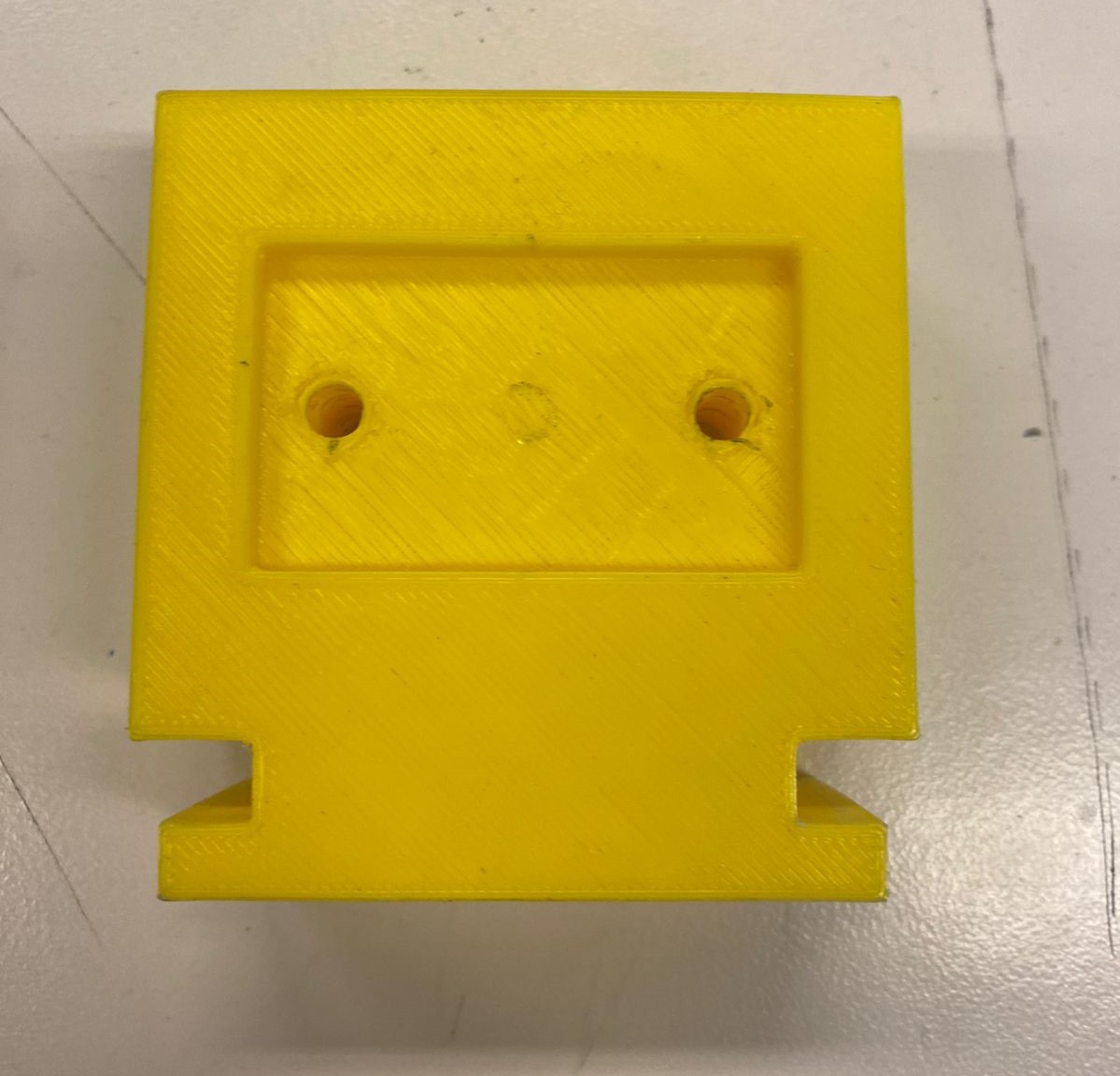

Fixed Jaw

The second component printed was the fixed jaw. It has the same parameters than the rails (which is the case for almost every component).

Printing time was 3 hours and 20 minutes.

Total weight: 78 grams.

The final product is shown next:

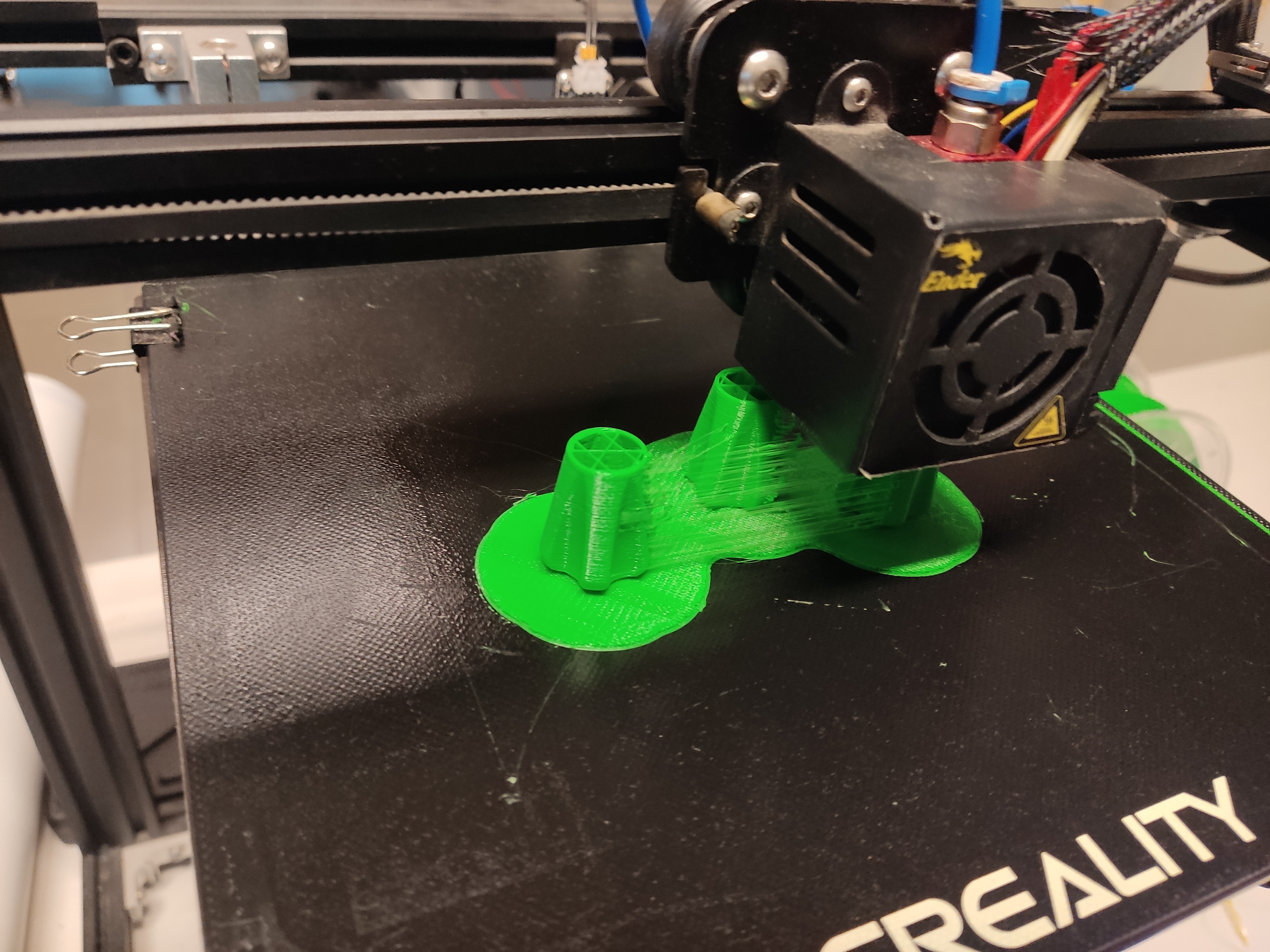

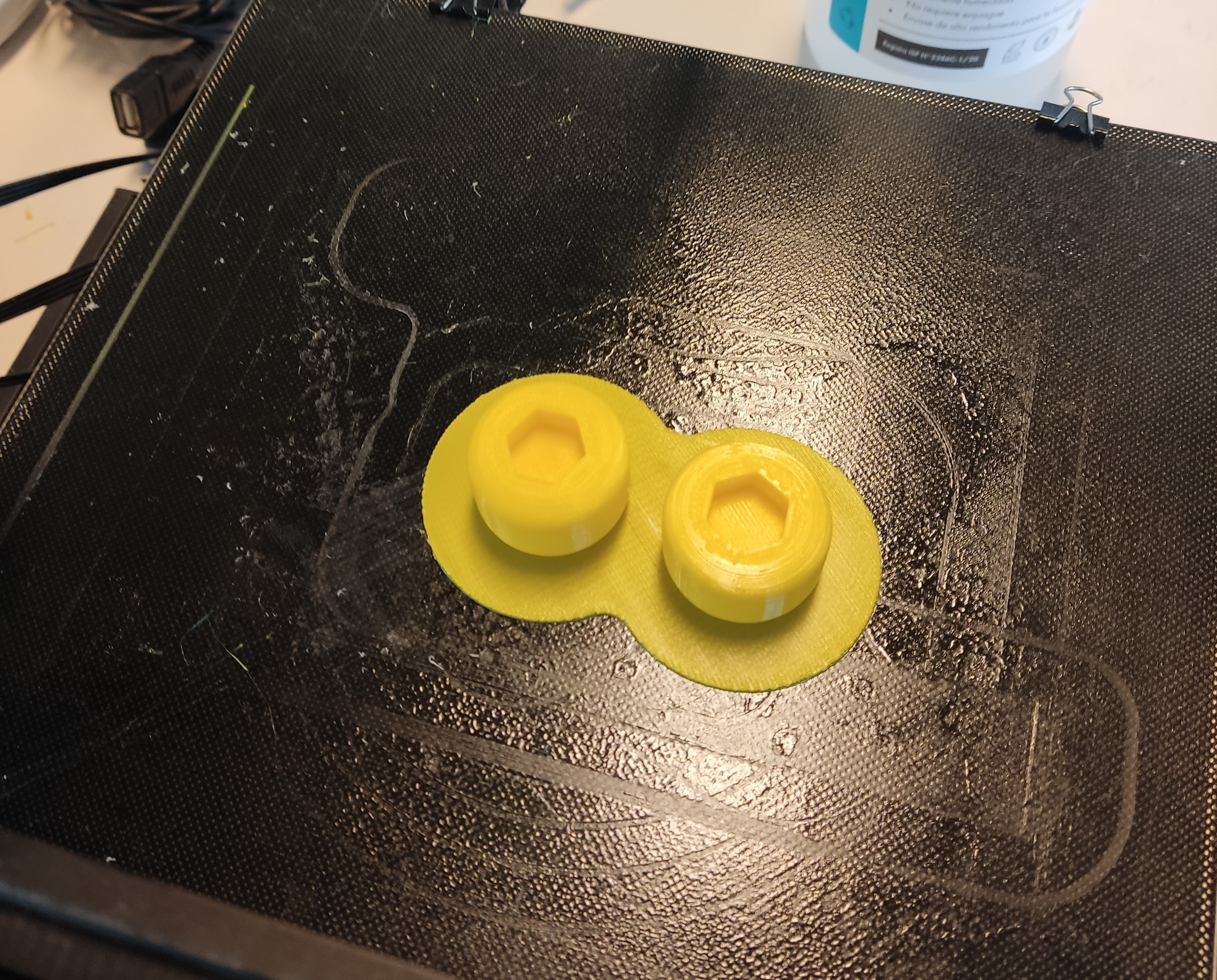

Handles

Three handles were printed at the same time. One for the main thread and the other two for the C-shaped component.

Plate adhesion type: raft.

Total printing time: 1 hour and 30 minutes.

Total weight: 17 grams.

Cushions

A first iteration of the design is shown.

The cushions were redesigned when the deadline was approaching. The hexagonal moulding was replaced by a slot in order to avoid displacements of the nut.

Plate adhesion type: raft

Total printing time: 1 hour and 24 minutes

Total weight: 18 grams

Moving Jaw

Plate adhesion type:

Total printing time: 3 hours and 20 minutes.

Total weight: 70 grams.

|  |

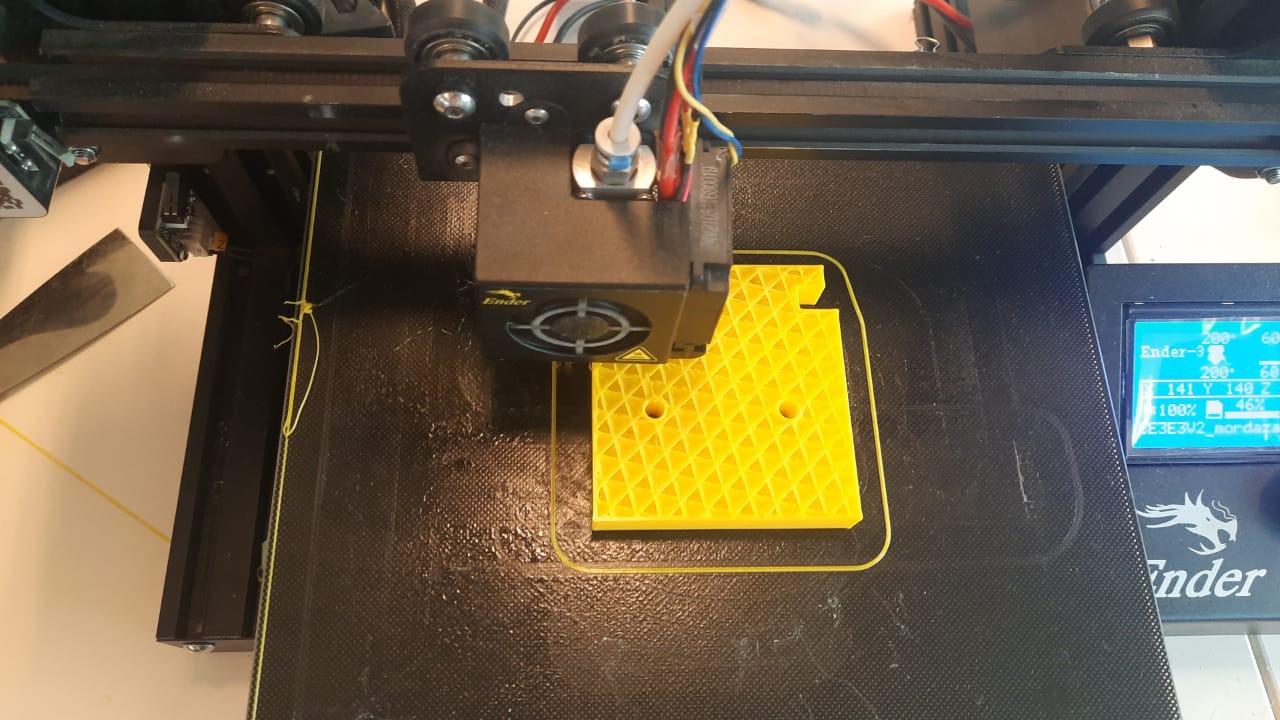

Base

Initially, the base was just a solid block component, but it was so big that it didn't fit in the printer's bed, so it had to be divided into 2. Also, a hole was made in the center in order to reduce printing time.

Plate adhesion type: Skirt.

Total weight: 123 grams.

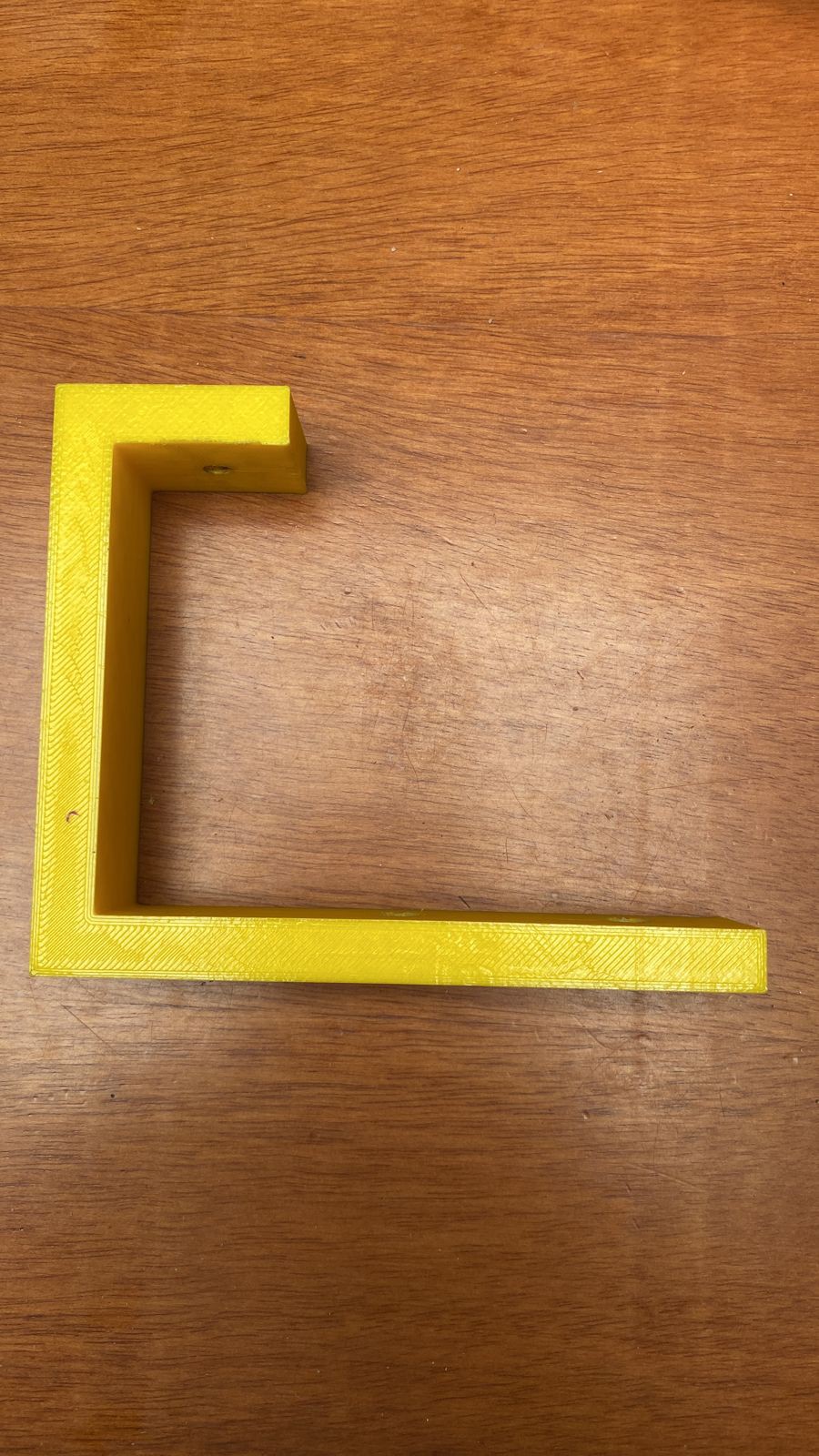

C-shaped support

Plate adhesion type: Skirt

Total printing time: 3 hours and 13 minutes

Total weight: 36 grams.

Nut thread box (and cover)

Box and cover were printed at the same time

Plate adhesion type: Raft

Total printing time: 3 hours and 27 minutes

Total weight: 42 grams.

We realized that a hole was missing on the cover part, so it had to be redesigned and reprinted. Also, covers for the nuts were needed.

Total printing time of the covers: 45 minutes

Total weight of the parts: 13 grams

Fernando

Fernando

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.