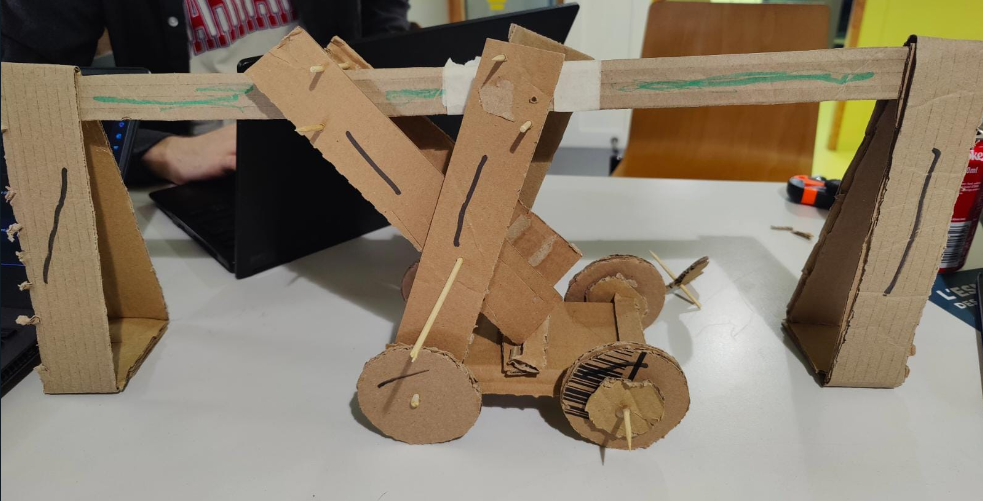

1st Protoype :

Our first prototype was made using cardboard and wooden sticks (and glue). As our project needed to be related to mechanical engineering, we had to look for "ingredients" that we liked about mechanical engineering so we could put them all together. With my teammates, our ingredients were : "The mouvement of rotation and the mouvement of lifting, the transmission of power that comes from a motor, the reaction of chain that you get with multiple gears combined together. So, we chose to go with a car and add a bridge to crossl gaps between two platforms. We were heavily inspired by a Youtube video showing the bridge car fully made out of lego :

To carry the bridge without having it dragging on the floor we used a system that kinda works like a lift table.

After 3 long hours of hardwork we were finally able to finish the cardboard protoype.

The bridge is supposed to slide upon the car until it reaches the other side of the platform. The car then lifts itself onto the bridge and slides across it before putting itself down. The bridge then sildes back to it's center of gravity and is wedged in place with the help of a small block.

Now the first step onto our next prototype was to decide what materials we would use for the different parts of the project. In the image below, the parts marked in black are supposed to be replaced with wood and the parts in green are supposed to be modelised and 3D printed if possible.

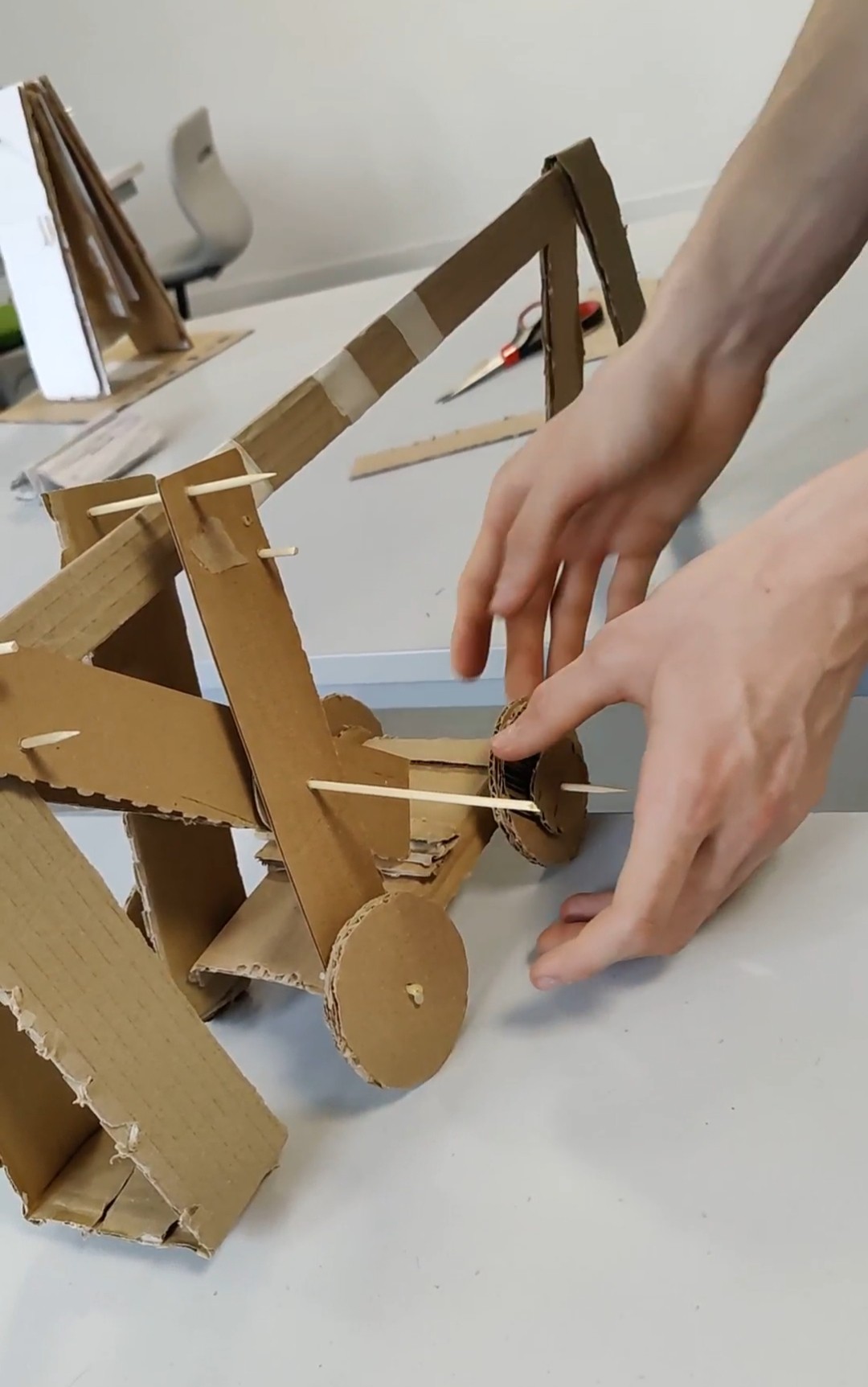

For our second model, we wanted to try using Legos to learn more about what we needed to do and take into account for a working model.

So, we decided to list all the constraints we encountered so we could be more aware of all technical difficulties.

Technical constraints:

It is necessary for the weight of the car to be well distributed so that once it is on the bridge, it is not unbalanced. In our first prototype, the battery was at the back, which meant that the center of mass was not in the center of the car. Therefore, we had to place the battery, which represents the majority of the car's mass, in the center.

The bridge must also be as lightweight as possible while maintaining good rigidity because when it is not in use, it represents unnecessary weight while the car is moving. We used a triangular structure for the legs to ensure minimal weight with good rigidity.

For the car's movement on the bridge, we had to find a way to connect the motor to the battery and also position the motor in an optimal configuration that does not obstruct the car and is sufficiently resistant.

For the scissor lift, we needed to find a system capable of supporting the weight of the bridge while limiting play in the joints.

In summary, we needed a car with minimal weight that would be strong enough to support the weight of a bridge above it.

Issues encountered:

The number of motors (in this case, 4) must be powered by a single battery, which results in power loss if everything is used simultaneously.

Having gears that are strong enough to allow for complete energy transfer.

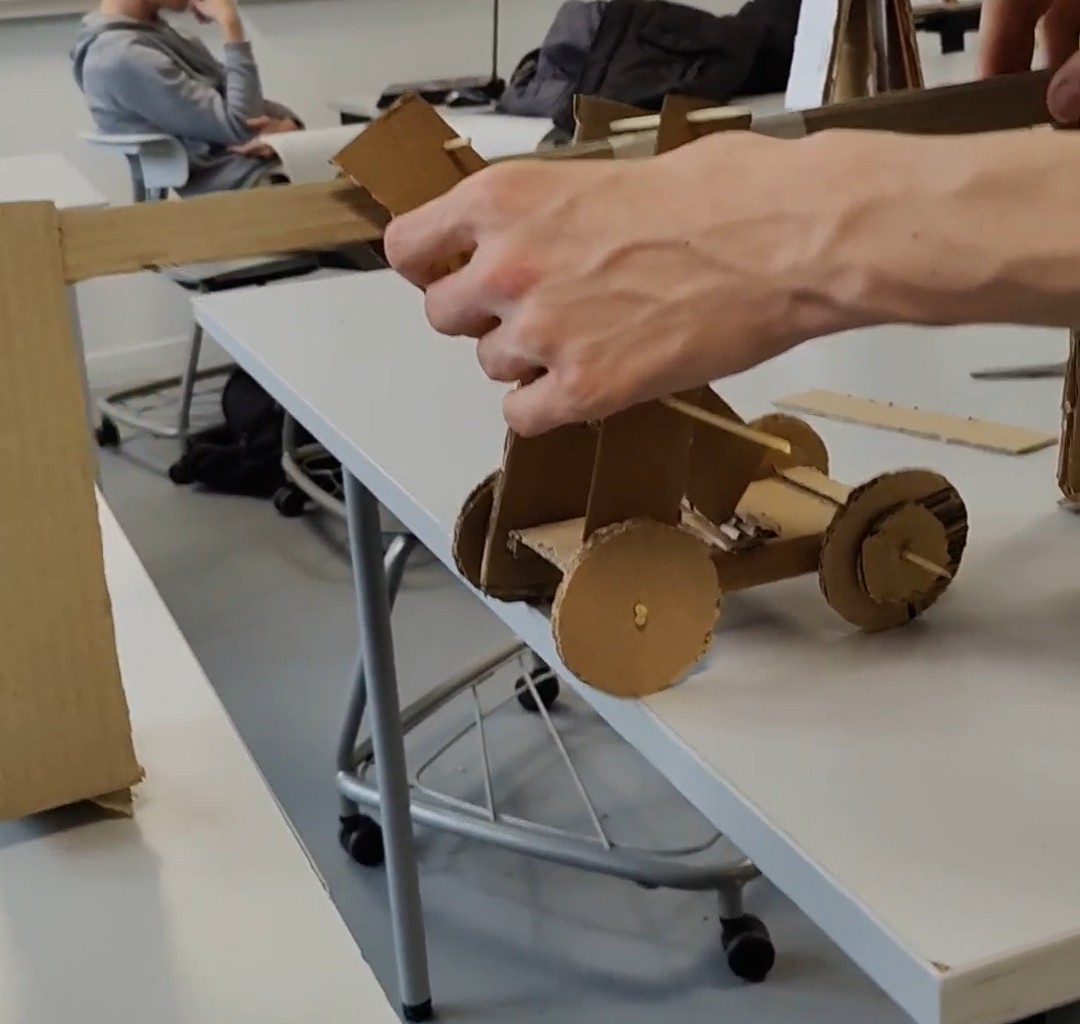

Here is a look at everything we've done so far.

The bridge

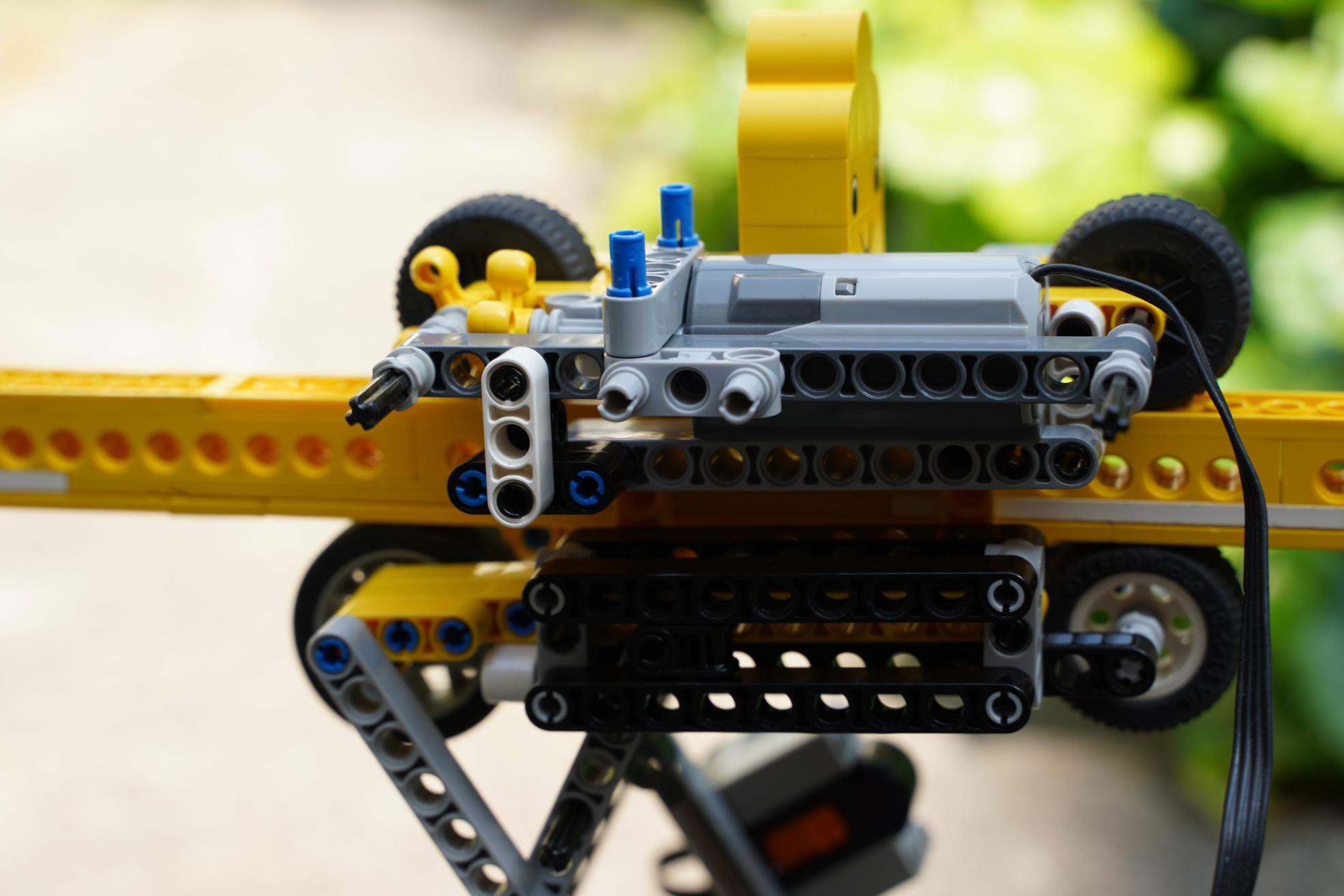

The car (unfinished) : on the right we can see the system to get the wheels to turn simultaneously and on the left is the part connected to the motor.

The scissor lift (unfinished) :

We still need to do a railing system so the lift and the car don't fall off the bridge and we need to make the lift motorized. For now we were able to make the wheel on top of the lift motorized so it can slide with the car to get to the other side of the bridge.

Here is a video showing how the system at the top works :

And here are some videos showing the car :

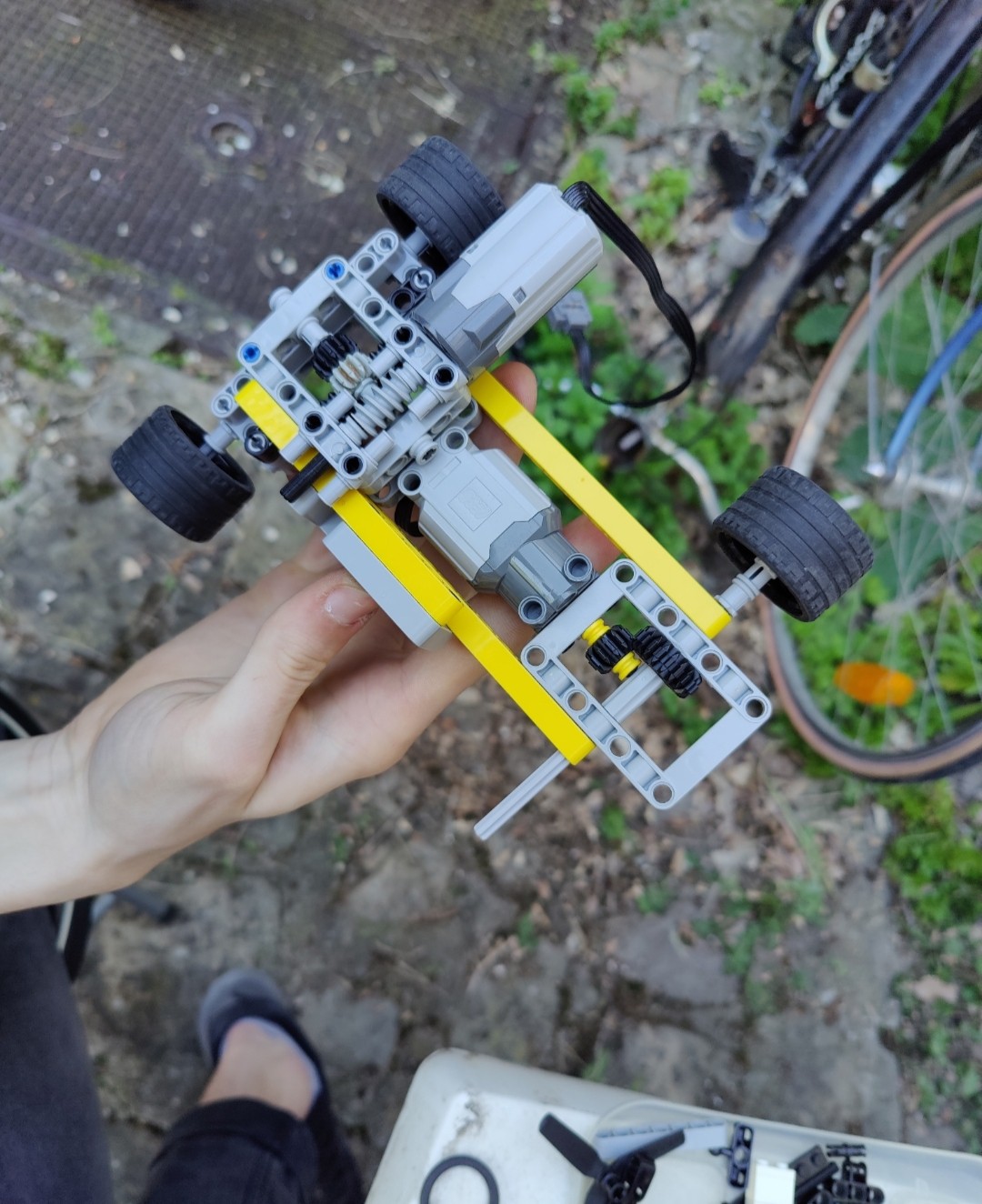

And after many hours of hardwork we were finally able tu pull off a working Lego Prototype !

There were many things we improved over the last couple of hours put into this work :

- First, the bridge : we tried to make it sturdier but not too heavy otherwise the car wouldn'tbe able to slide it to the other side of the gap due to losing it's center of mass.

- Second, the scissor lift : it was really tricky to set it up because some of the parts that we used to make it would get entangled with the upper body of the car as well as the cables used to connect the battery to the motor. Thus, we decided to solve this problem at the end of our project, when we would have finished all the other parts of the prototype, so that it would be easier and clearer to adapt this part. For the lifting part, we decided tu use a jack that would either push the scissoring parts up or pull them down like shown in the video right below.

- Third, the lower body of the vehicle : The lower body of the vehicle is composed of the car. A lot of adjustment was made for the car in order to sustain the bridge without getting bent under the weight of the bridge and we tried a lot of things in order to connect the car to the scissor lift.

- Last but not least, the upper body of the vehicle which is composed of the sliding mechanism : We decided to completely revamp the sliding mecanism. It is still working the same way as before, but we added more wheels so it would slide smoothly and we centered the motor used to make those wheels turn. Plus, we added a sort of little gap on both sides of the mecanism so the lift could be connected there.

We are really proud of what we were able to do, and this project made us realise how ambitious it was. We realised how much more time we would have needed in order to create from nothing a working prototype. In the end, we have learned so much from this journey, adapting and finding solutions to difficulties, figuring out things, not just alone, but as a group which is so much more refreshing because each one of us has a different perspective to bring to the others so, even if we were not able to pull off a prototype not made in Legos, we are happy with it. A wise man once said "It's not about the destination, it's about the journey".