Heatblock ordered

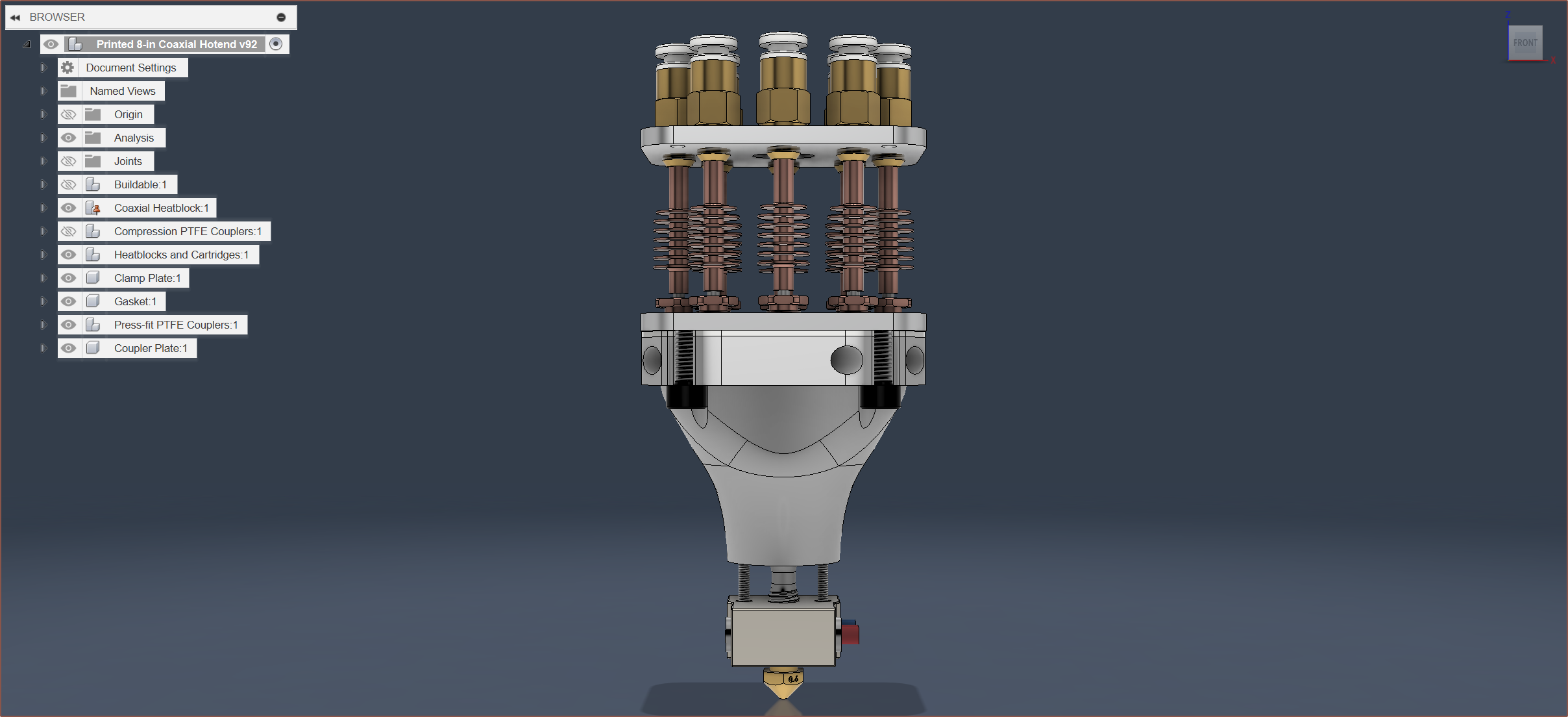

Hours of modelling, thoughts, issue mitigation strategies and error checking has finally got this project to the state when I could finally send my 2nd attempt to PCBWay to manufacture.

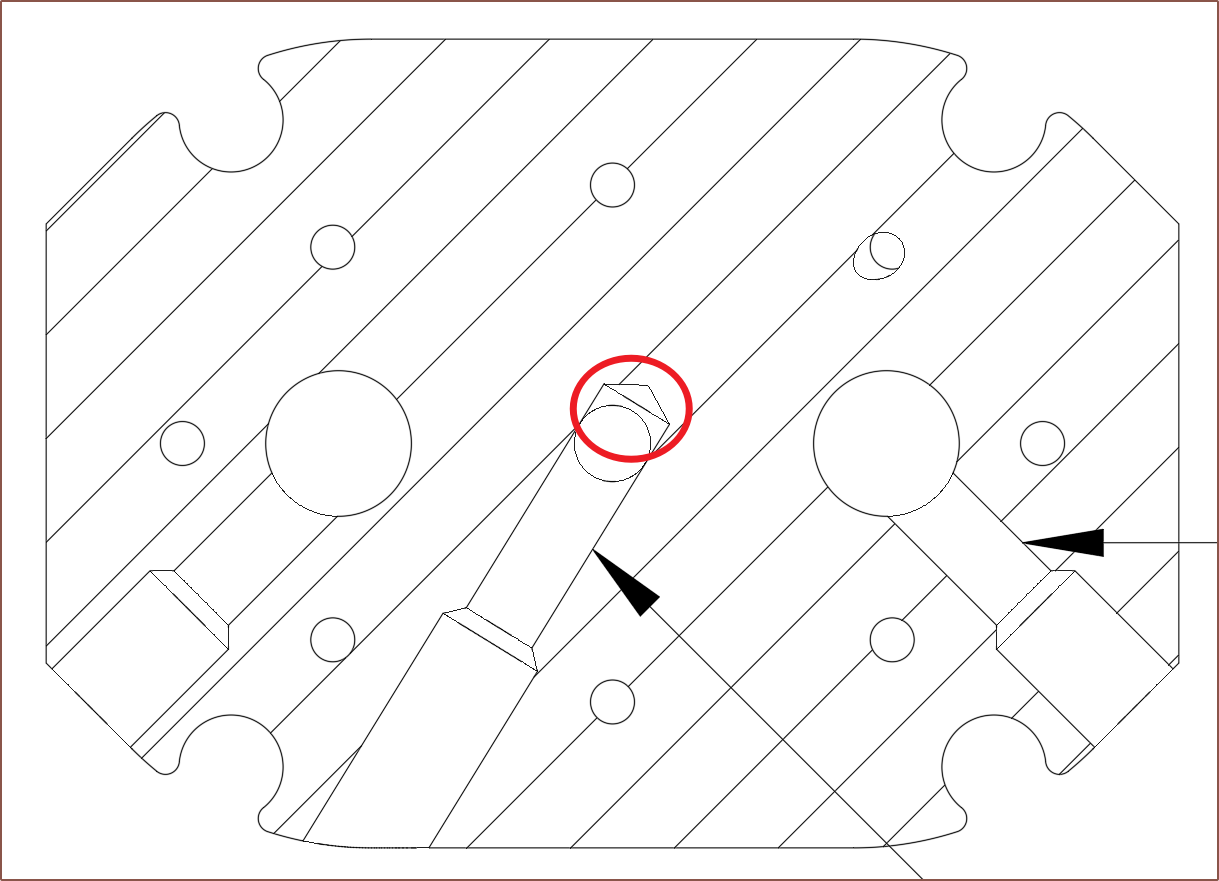

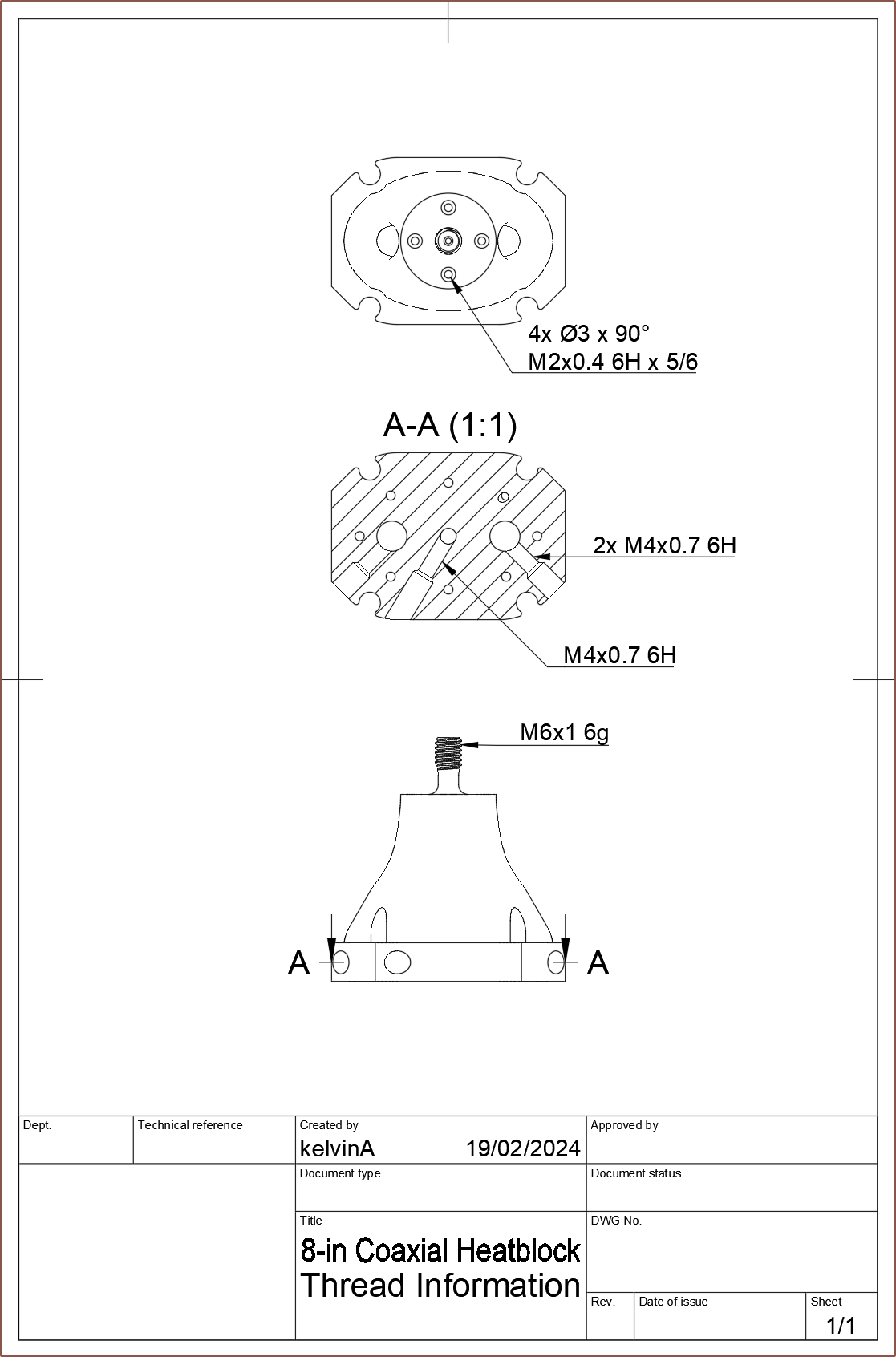

So I woke up this morning and decided to make a Thread Information Drawing. Whilst doing that, I decided that the extra depth of the thermistor grub screw hole (circled in red in the image below) didn't really need to be there. Me In The Past added it in so that there was enough clearance. Now I'm thinking that "If it's needed, the technicians could drill the extra material away. If it's not, now there's less contact area that the thermistor could've had" and so removed it. It was also in an effort to prevent supports in hard-to-reach locations.

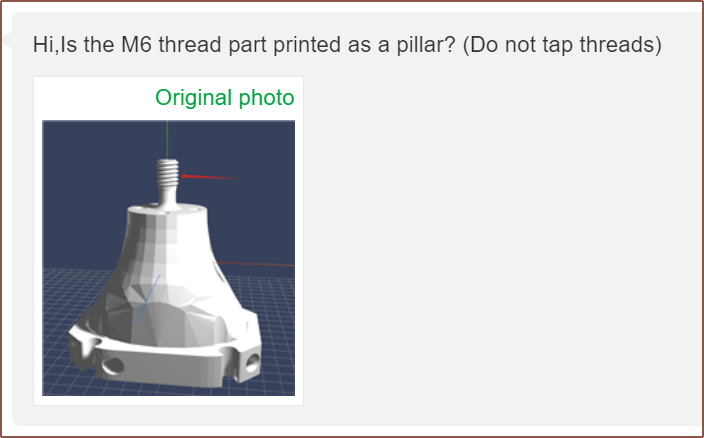

I also uploaded this thread information just so that the engineers were aware of them, even though I'm not asking PCBWay to actually tap them. "Maybe they might adjust the holes to the ideal size for AM" is what I thought.

In practice, it seems to have caused a bit of confusion over at PCBWay, since I checked "No threads" but also gave thread information, and when I said that "I just need the M6 that is in the CAD file" (trying to mean "Don't turn the modelled threads into a cylinder."), they thought that I wanted that single M6 threaded:

I cleared up that misunderstanding, but after paying for the order with the expected $64/part ($83.66 with shipping + card fee), the misunderstanding I was trying to avoid surfaced anyway:

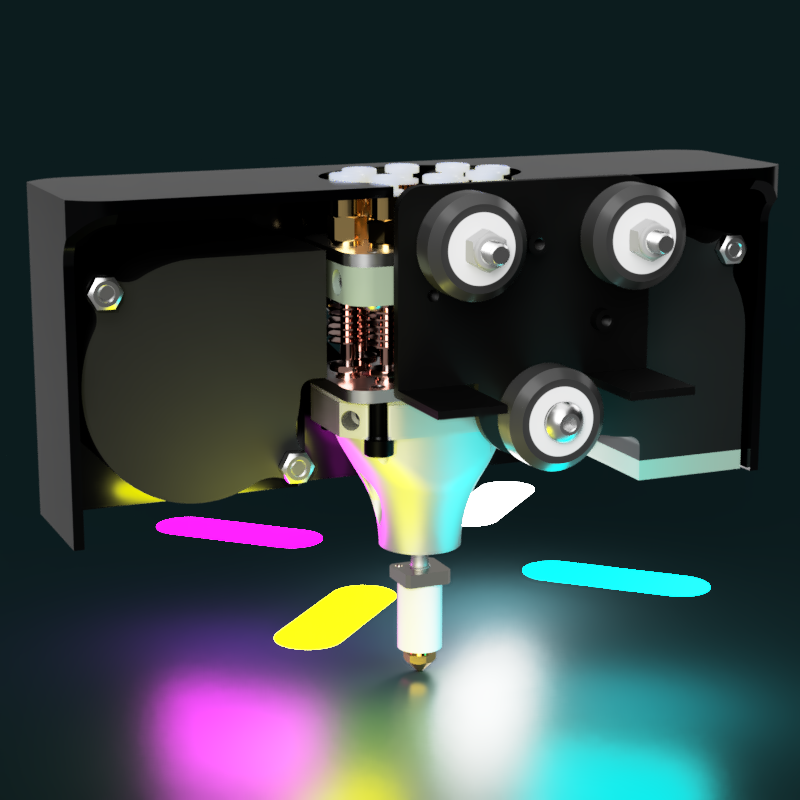

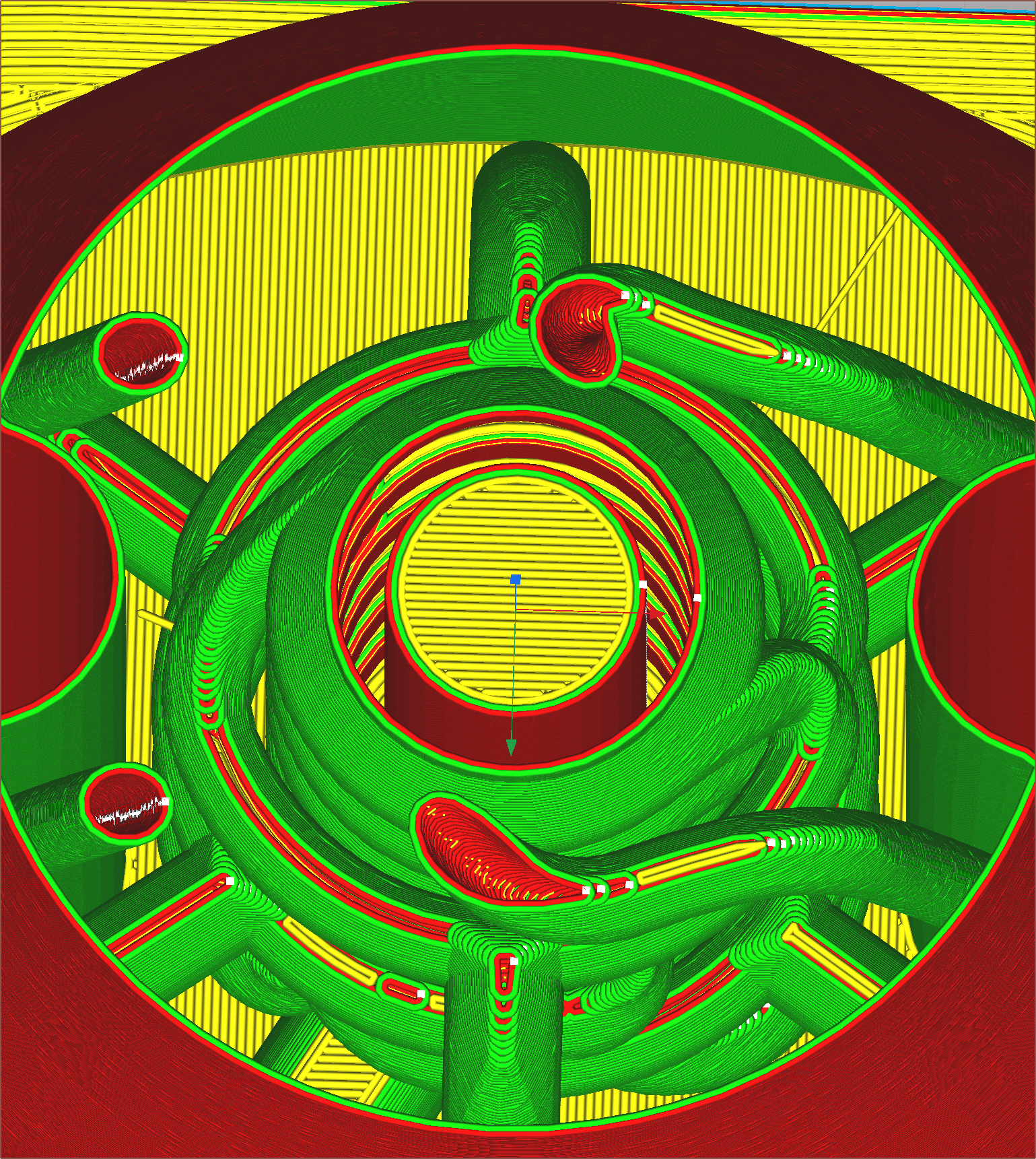

So, like with the first attempt, I'm expecting that I'm going to need to be checking in daily just to make sure that this design gets through. I do wonder how long it took for engineers to create those super complex heat exchanger prints that the industry likes to demo as an AM metal application:

It did feel a little rushed when I actually bought the thing, which I'd describe as a similar feeling to wondering if the door was locked when leaving one's location of residence. I had to keep reminding myself that I spent at least an hour yesterday and at least another hour today combing through to find any last minute bugs / mistakes in the CAD.

It did feel a little rushed when I actually bought the thing, which I'd describe as a similar feeling to wondering if the door was locked when leaving one's location of residence. I had to keep reminding myself that I spent at least an hour yesterday and at least another hour today combing through to find any last minute bugs / mistakes in the CAD.

Gasket

I'm going to see if I can use the laser cutter my uni just happens to have to manufacture the gaskets. I'm also going to use 1mm PTFE instead of 0.5mm silicone as it should be stiffer and have a higher working temperature. Also, I could get some for £2 locally instead of £3 from AliExpress.

Additionally, while the recommendation for gaskets is "as thin as you can", thicker is used to mitigate issues due to the imperfections of the real world. Basically, there are more potential issues from going too thin than too thick. Even with that said, 1mm is still a rather thin gasket, but thicker than a business card so should be less floppy and easier to assemble into the hotend.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.