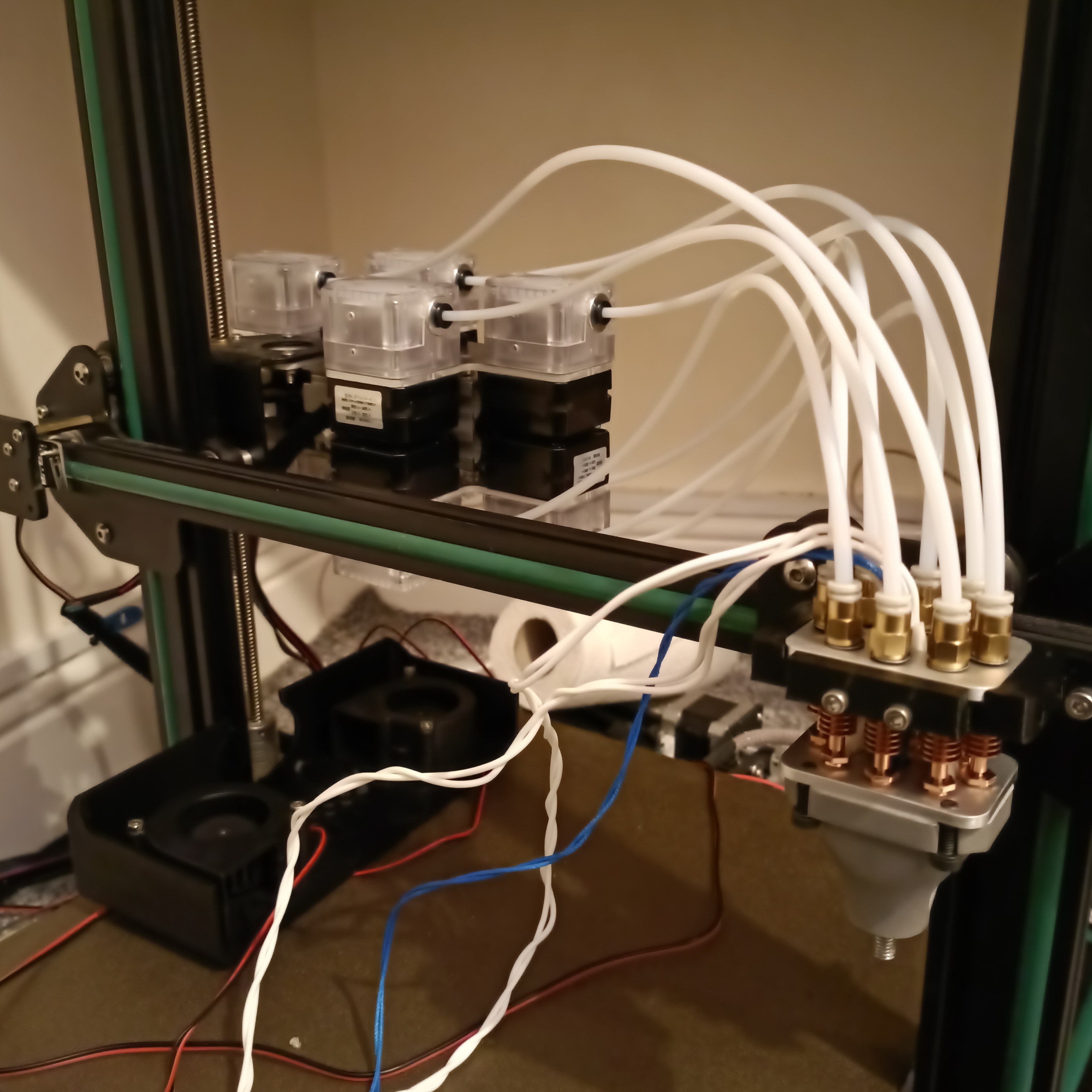

Extruders

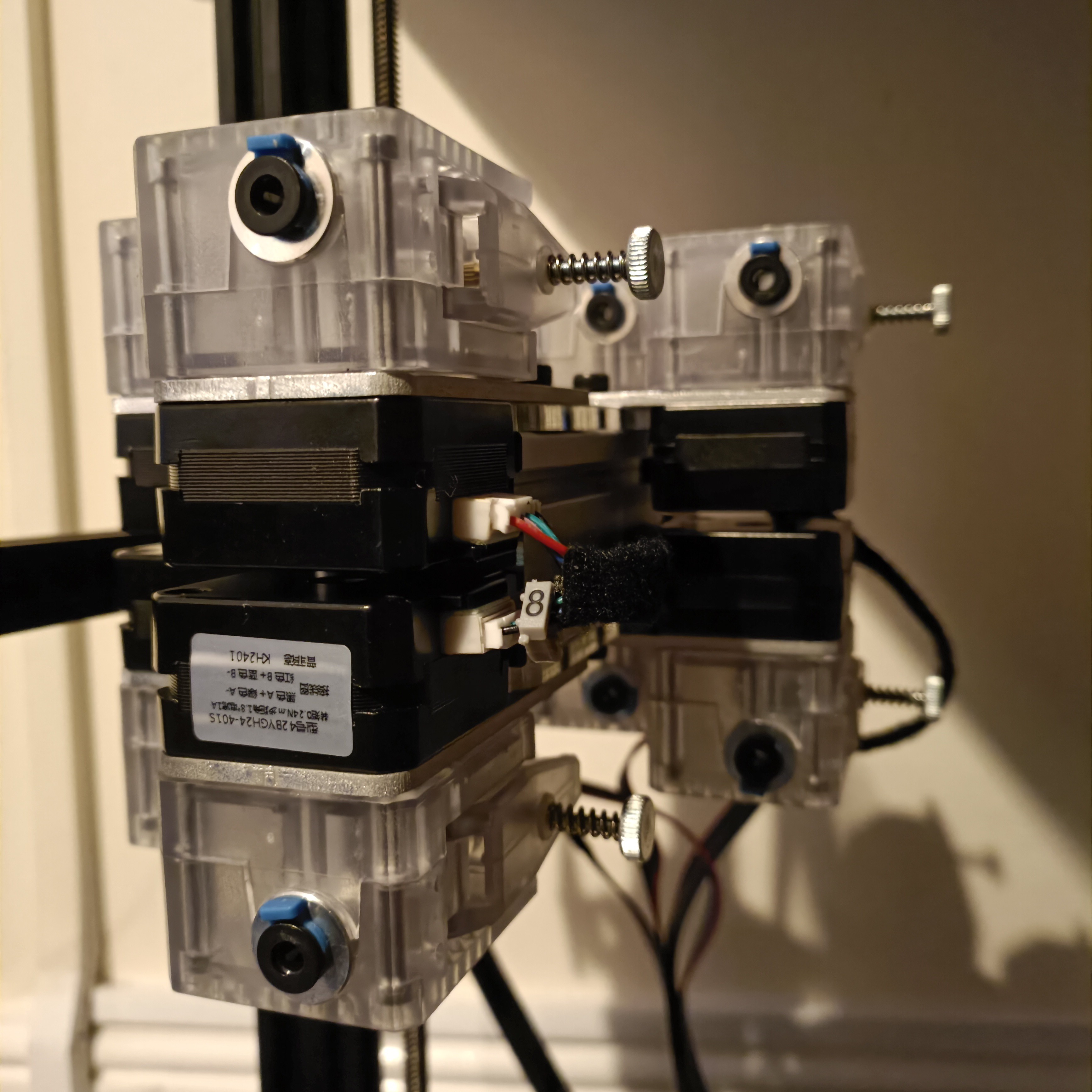

So I should mention some thing if anyone is planning to use a 3mm mounting plate and 35mm bolts with these DDE extruders:

- The holes that they go into are 5.5mm for the bolt cap, and unlike the ones that come with the extruder which is 5mm, the bolts I got in the mail are 5.35mm meaning that the tolerancese are tight and thus need more effort to screw in. The benefit is that they're unlikely to unscrew due to vibrations.

- I needed to use M3 washers (that my university happened to have) to have enough clearance between the end of the bolts and the thread depth of the motors. The washers are 0.48mm.

Other than that, they seem rather nice:

- They're translucent so I can see things like mounting bolt depth, if the motor gear is turning, how deep the bowden tube is...

- There's a small cutout to be able to pull the bowden coupler as far forward as possible. It move slightly inwards when pushing the bowden tube in.

- Perhaps it's the thinner motors having less unpowered torque, but I find that the metal gear is both easier and more comfortable to spin than the plastic gear.

- It's much easier feeding filament in compared to the black ones I had.

- It seems that the perfect height for the motor gears is such that the bottom of the gear coincides with the bottom of the D shaft section of the motor.

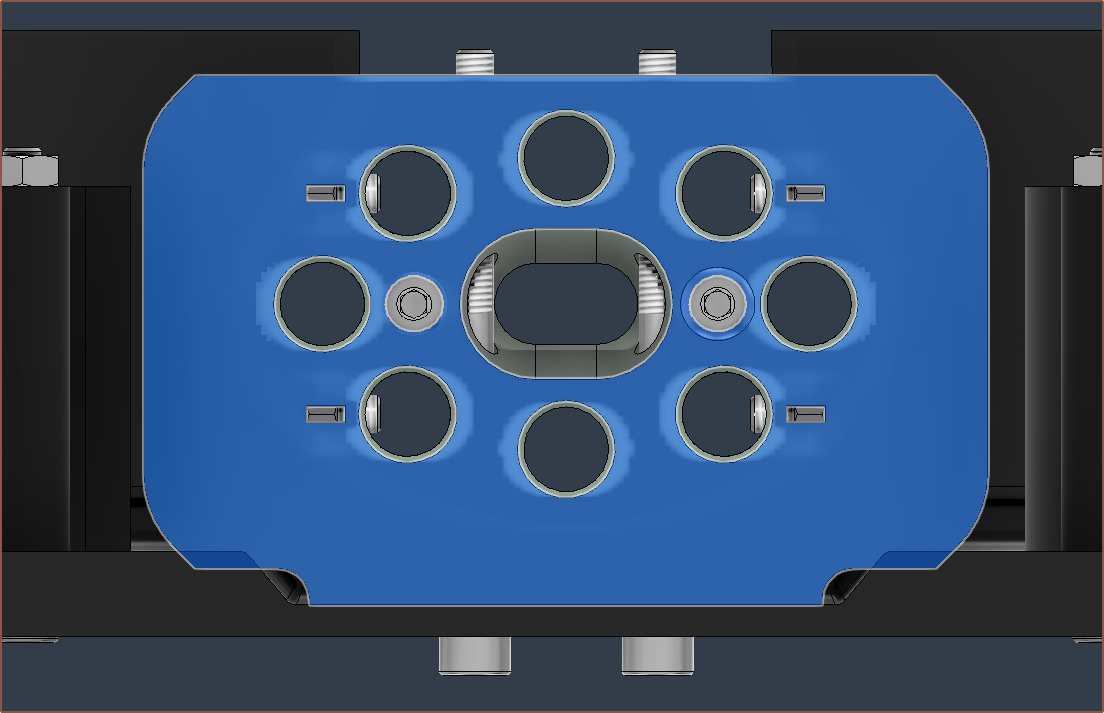

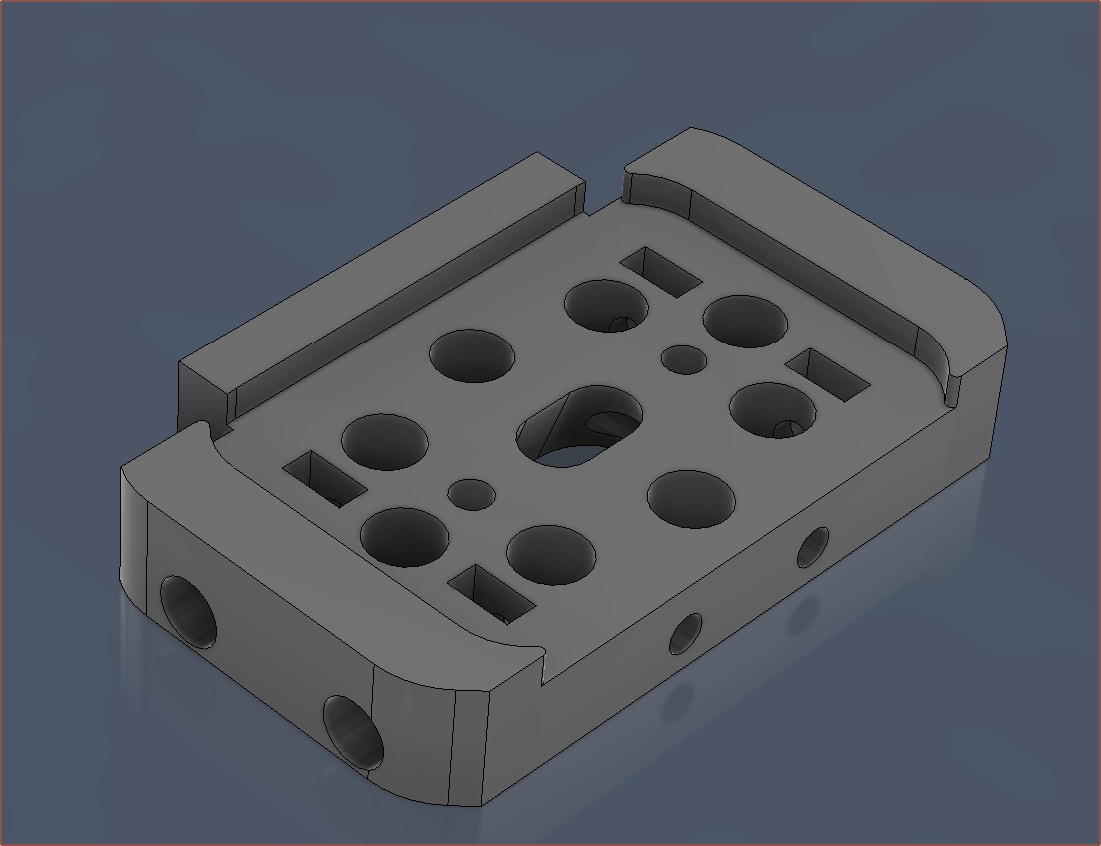

Holder

So I had the hypothesis that it was the holes in the hotend holder that was preventing me from just aligning the heatsinks by feel, and so I made a through hole of the clearance holes used to allow the M6 threads to stick out from the other side of the coupler plate. The good news is that it worked and the grub solution seemed to work nicely (I only needed to softly tighten them for the assembly to stay fixed in place. The bad news is that I did all this in "Isolate" mode and didn't check for intersections:

It worked, but it was not ideal, so I did a respin with the extras cut out.

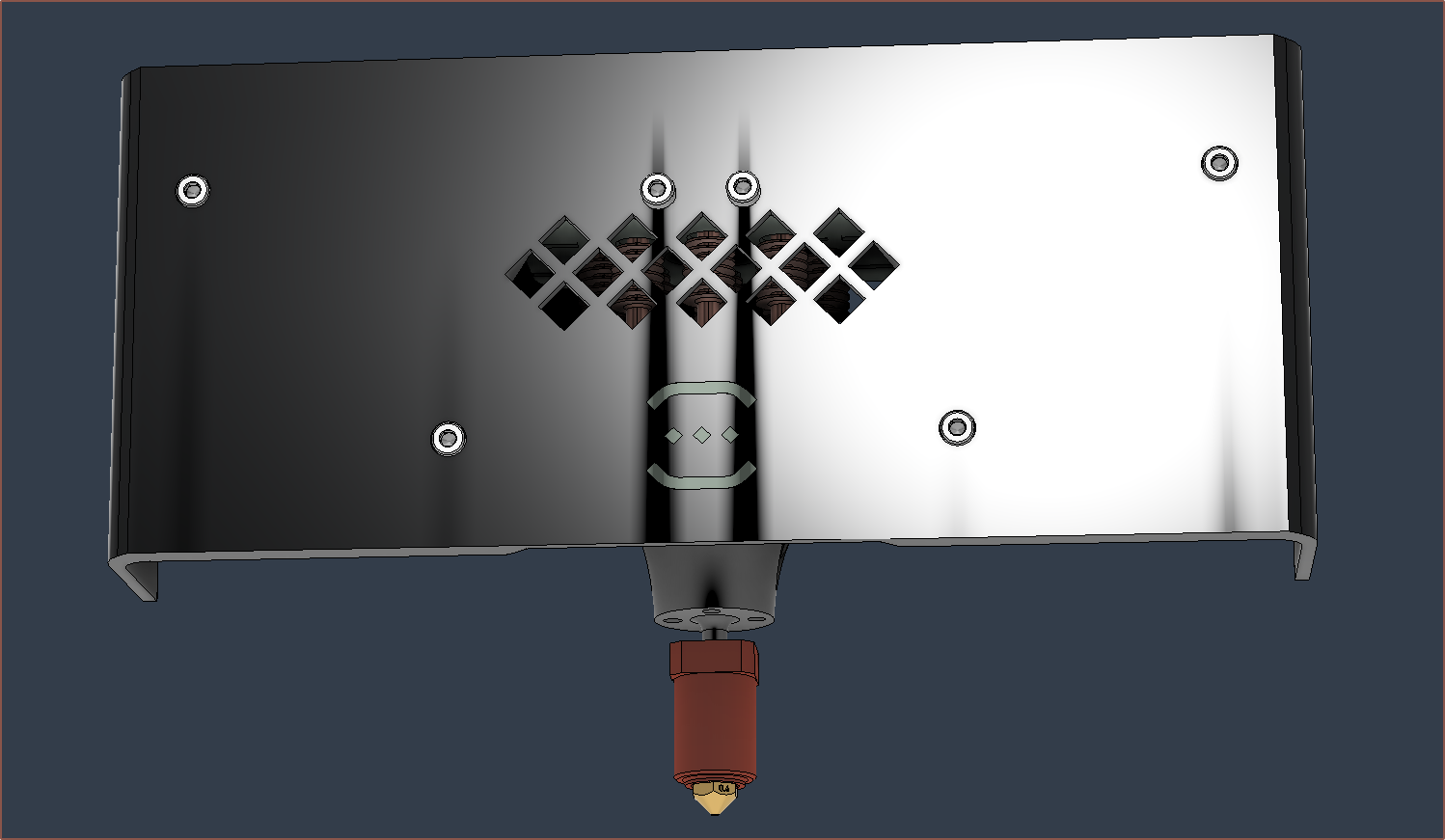

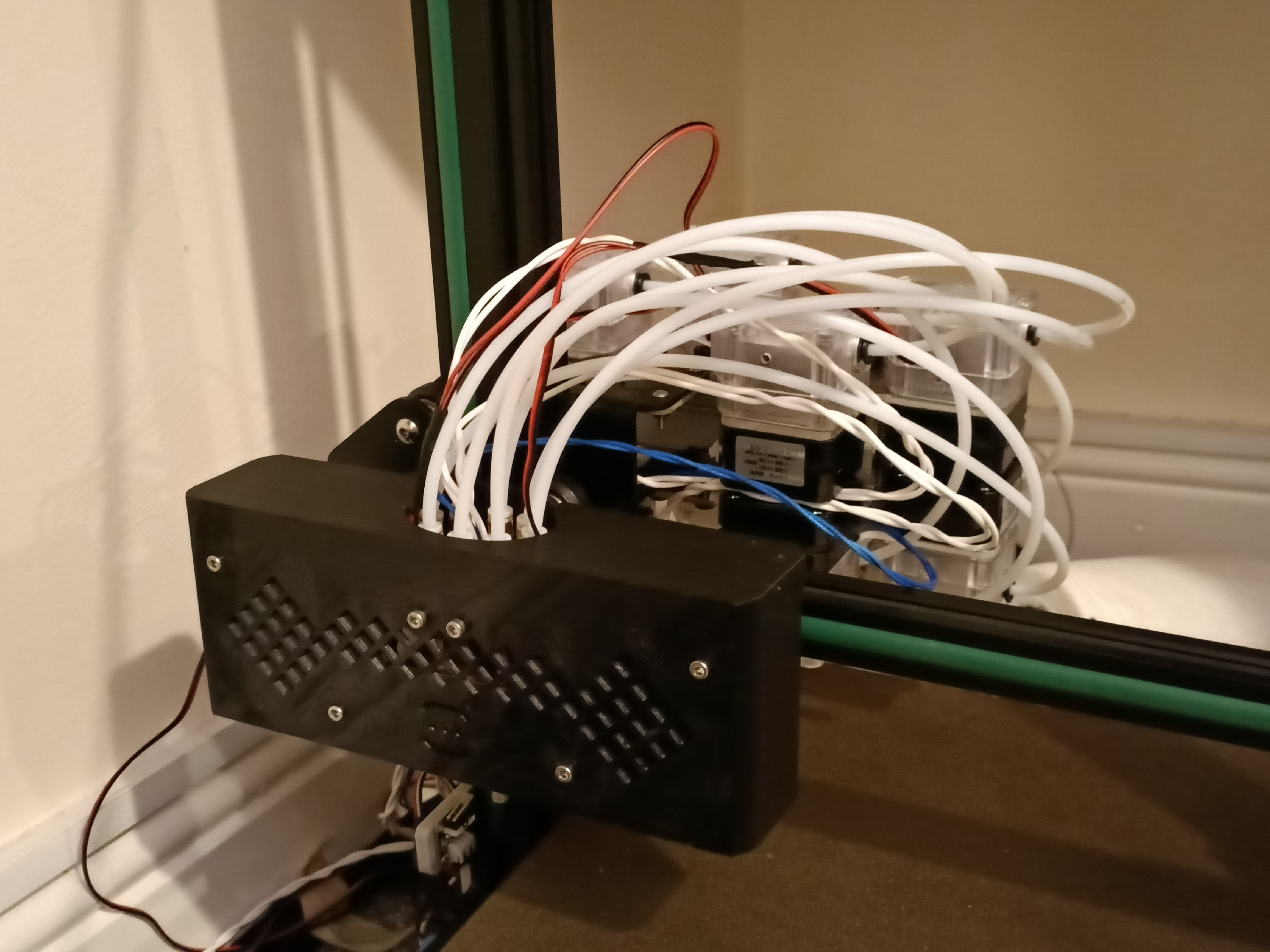

This quick cut was after I made the changes for when I reprint the cover. One of the changes is that I've flipped over the fans because I found out that one of them has a broken clip that is supposed to act as a wire strain relief. There should be enough of an air gap for it to work, and it means that I can reduce the size of the grill:

I also took this time to (somewhat slowly) helix-ify the 70W heater cartridge wires.

Bowden tubes

For E0 to E7, I've gotten { 50, 50, 46, 50, 36, 40, 36, 36 } in centimetres for the lengths of the bowdens.

I then put black filament through (so that I could easily see it through the PTFE) and pushed untill I couldn't see it anymore and then pulled back until I could. Then I'd look at how much I pulled out and if it was about the length between the heatblock and the coupler, I assumed that it went all the way in. For those that didn't, I unplugged the PTFE tube, thread some filament in (approx 40mm) and then thread that into the coupler before putting the PTFE back on. That seems to ensure that the PTFE is properly aligned as it solved the issue every time so far.

Lastly, I installed the cover:

I wasn't expecting the end result to look so messy.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.