I did the mental calculations and thought that it would take at least 5 hours to clean up the Coaxial8or R0, since solid plastic is difficult to remove, and then it would take another 2 or so hours to put everything back together again, as well as 1 hour for resolving anything that I didn't account for.

That's 8 hours. I've seen Stuff Made Here scan jigsaw puzzles, and suspect it won't be the first and only time I'd find myself in this situation now that I need to find a new gasket material.

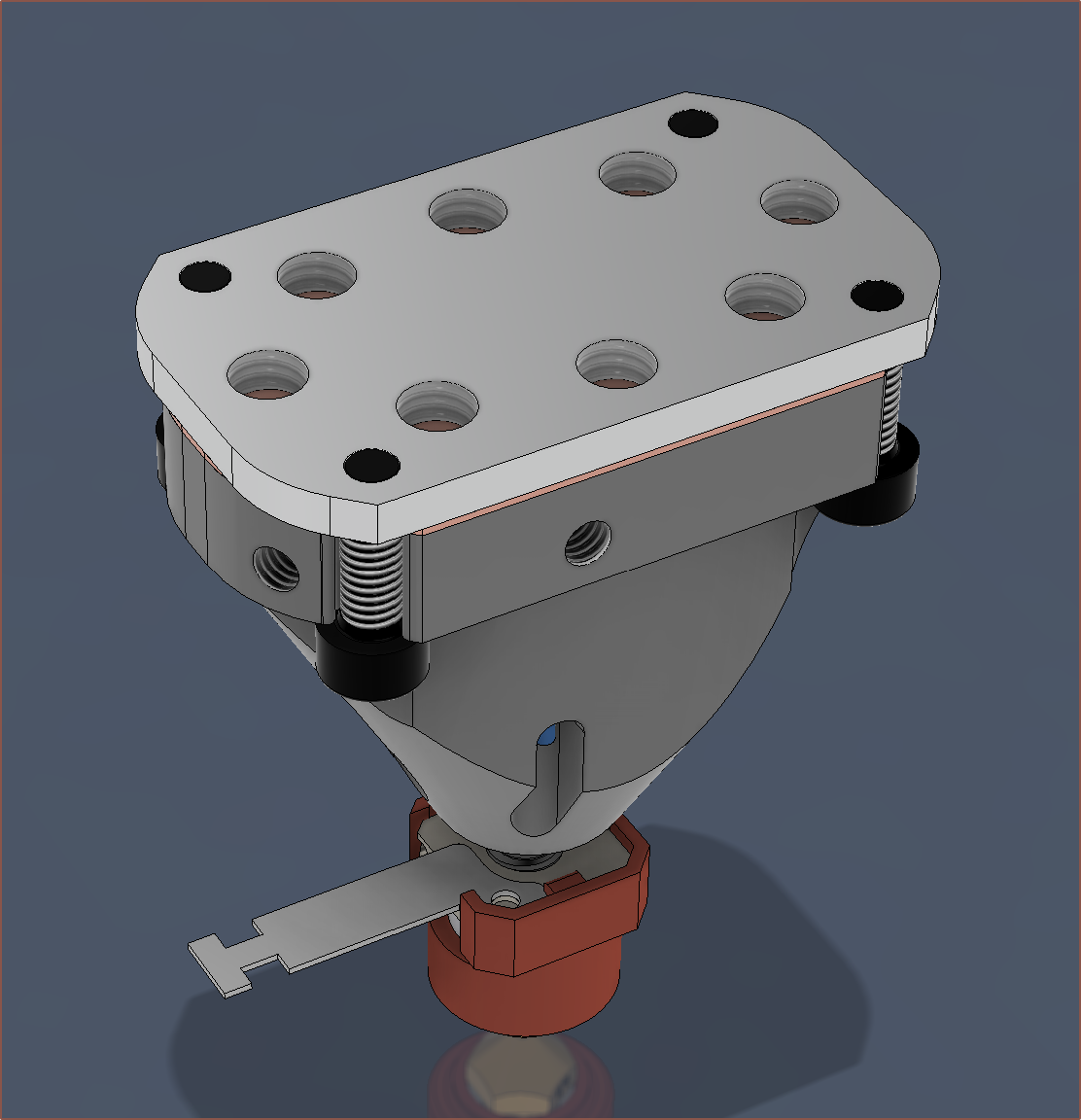

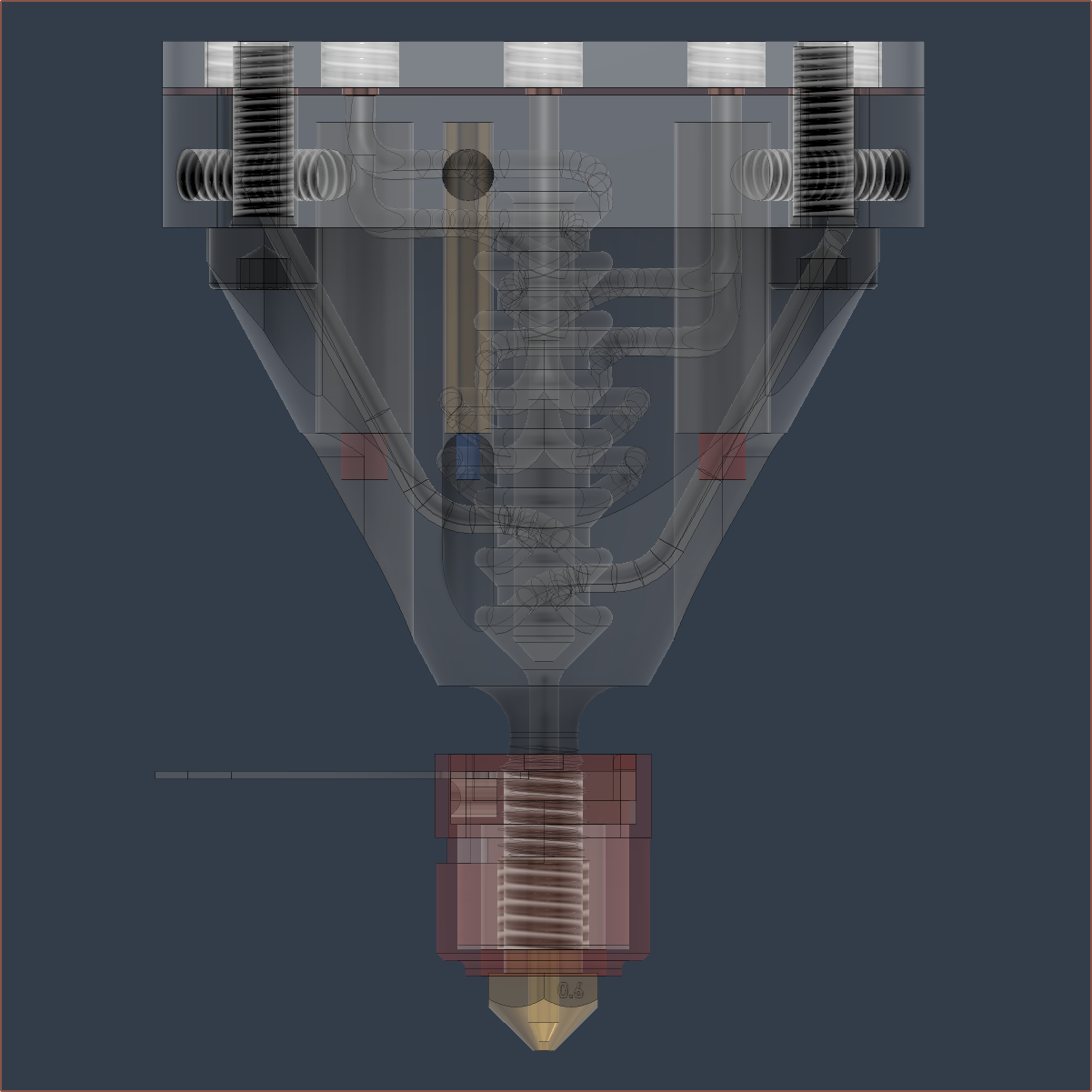

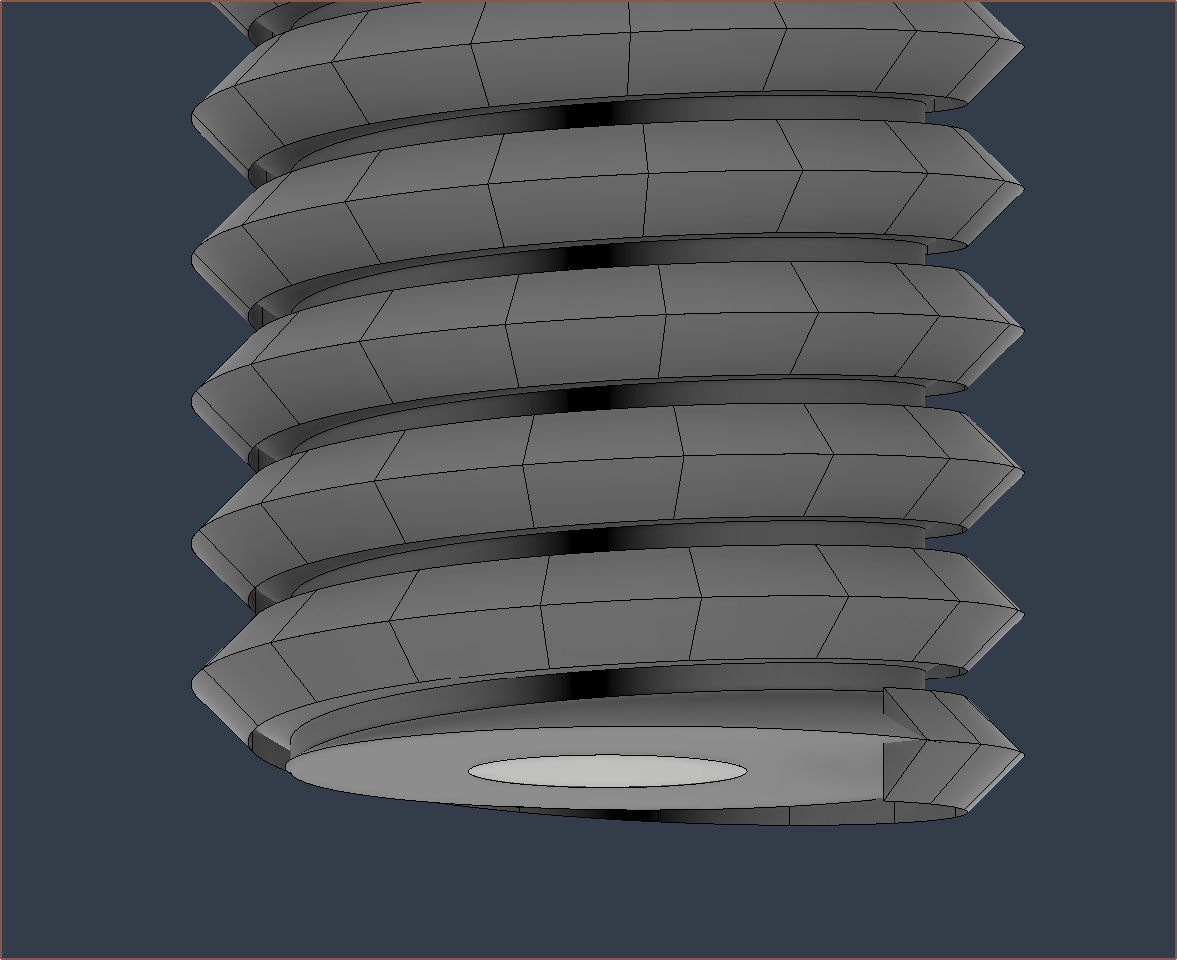

I have instead spent 4 hours updating the design of Coaxial8or R1 to hopefully increase flow rate and prevent any future leaks from melting onto the surface of the heating elements.

Cartridge protection

I think I now understand what I've heard in the past about "safe failure modes", in that in the event that the system fails, at least it fails nicely. Putting the cartridges on the underside means that I could have the heatblock heated when cleaning off plastic. The only concern with this solution is that it's possible for one of the heater cartridges to fall out onto the print if not sufficiently secured.

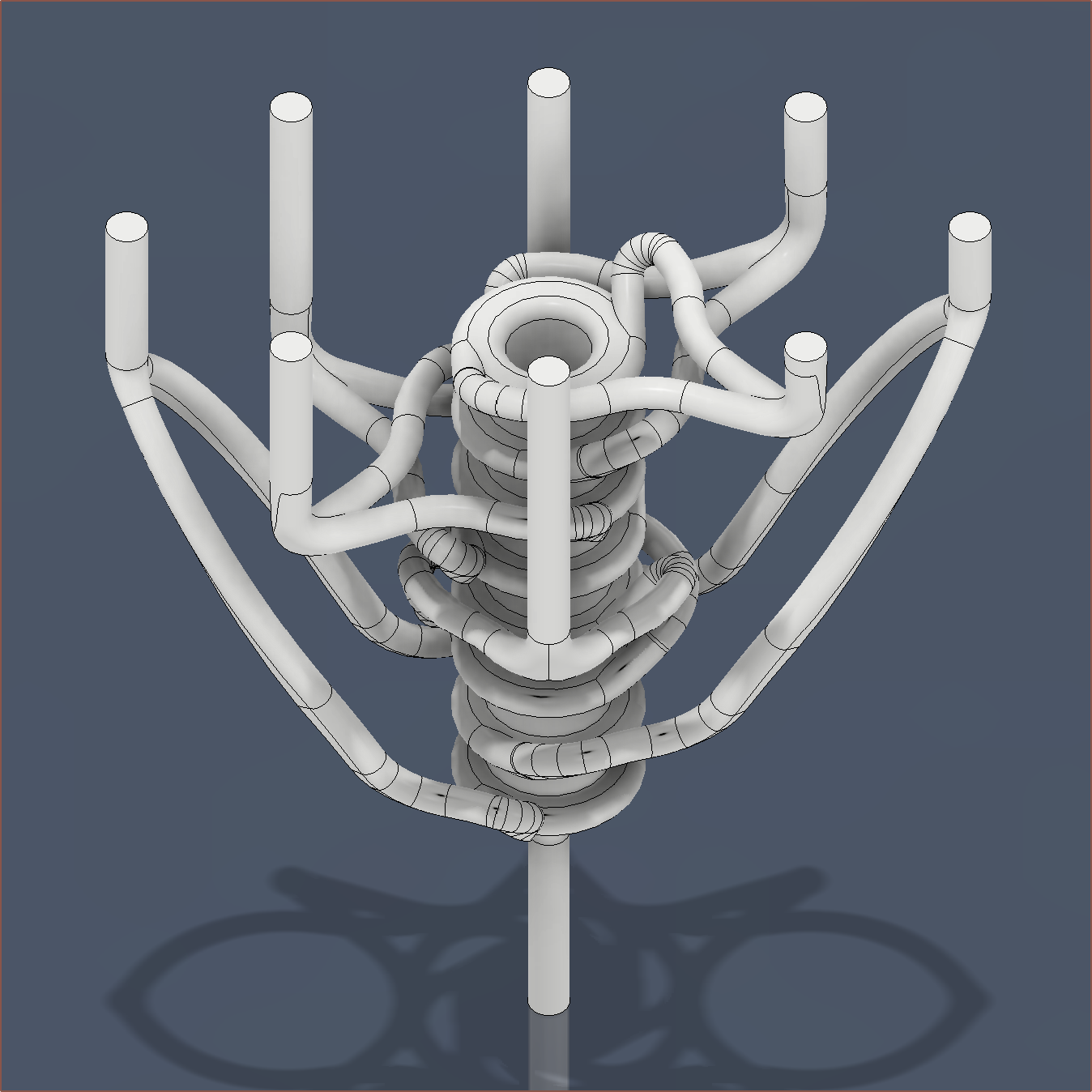

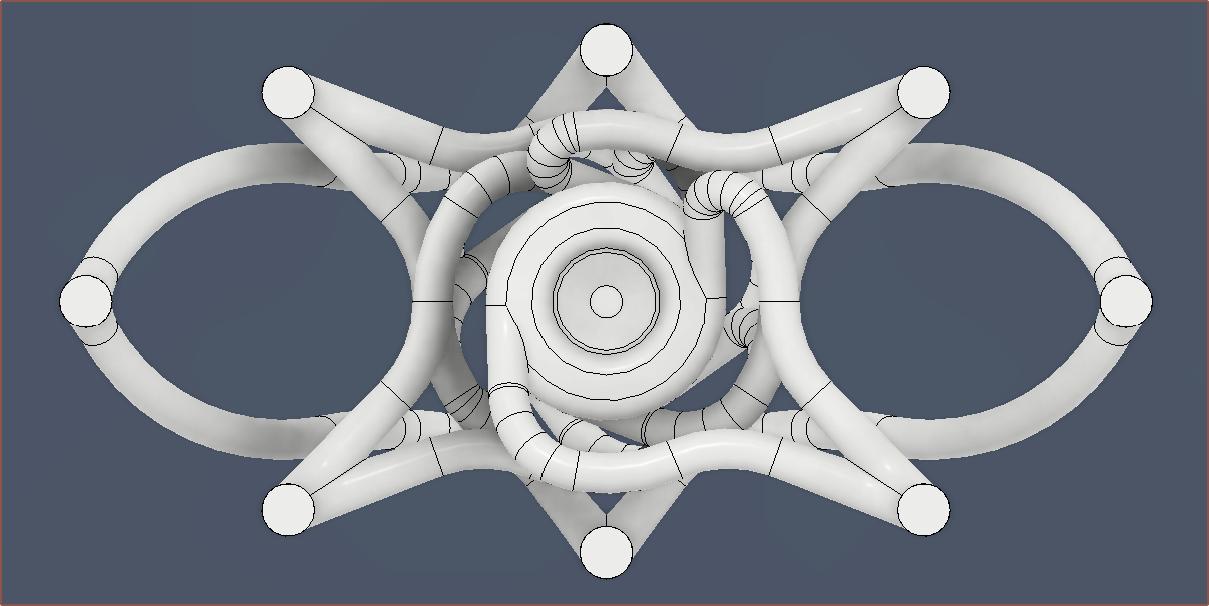

New pathways

As you may be able to see, I've now replaced the T-like intersection between the major and minor channels for more of a Y-like intersection:

Since the thermistor is no longer in the centre, I've also reduced the diameter of the internal column to 4mm. I still feel like it's important to give the molten material something solid to build upon, especially when the main coaxial-ising section is 30mm long. I tried to reduce it but I wasn't able to. At least with this diameter reduction, the cross sectional area drops from about 20mm3 to 14mm3, which should notably reduce the amount of internal material.

Other things

Bounding box is now 49 x 29 x 49mm XYZ and the heatblock is 23,200 mm3.

I also tried to make the M6 thread more printable but Fusion generated so many faces and froze when I tried to offset them.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.