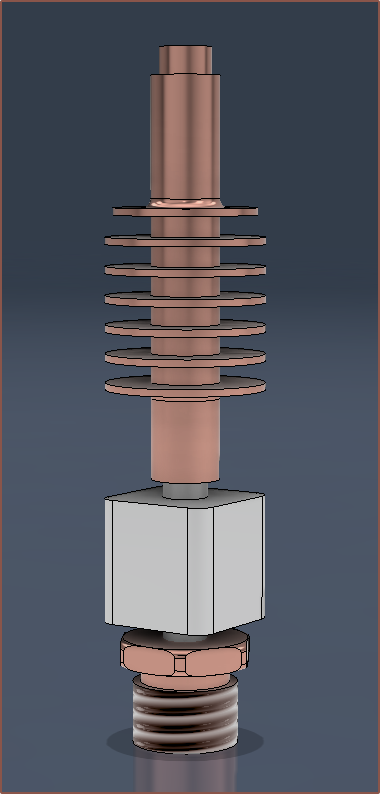

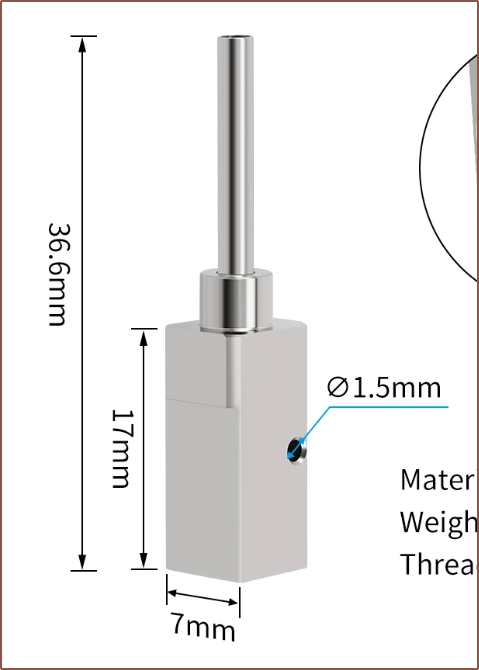

I envision a merge between the small heatsinks and the Bambu Lab heatblocks (see below) as a way to be able to turn on and off different inputs. Something like 10 watts should be enough.

This comes after I spent some time yesterday putting the heatsinks in fresh-out-of-the-kettle water to be able to get the PETG out of them:

I believe that the temperature doesn't need to be too precise, and that it might even be sufficient to simply connect the heater to a thermal fuse to have both quicker heatup times and a bang-bang temperature control. An example could be a 200C thermal fuse that resets after it cools to 170C.

Even this might not be needed, as if I recall correctly, ceramic heaters naturally have a temperature limit due to increasing resistance at higher temperatures. In that way, it may be possible to design a heater that quickly reaches equilibrium at 200 - 210C, which is the maximum temperature Deckingham needed for the majority of his material tests.

In this way, only 9 wires would be needed to implement this, there would be no moving parts, and the potential for unused channels being clogged would be minimised.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.