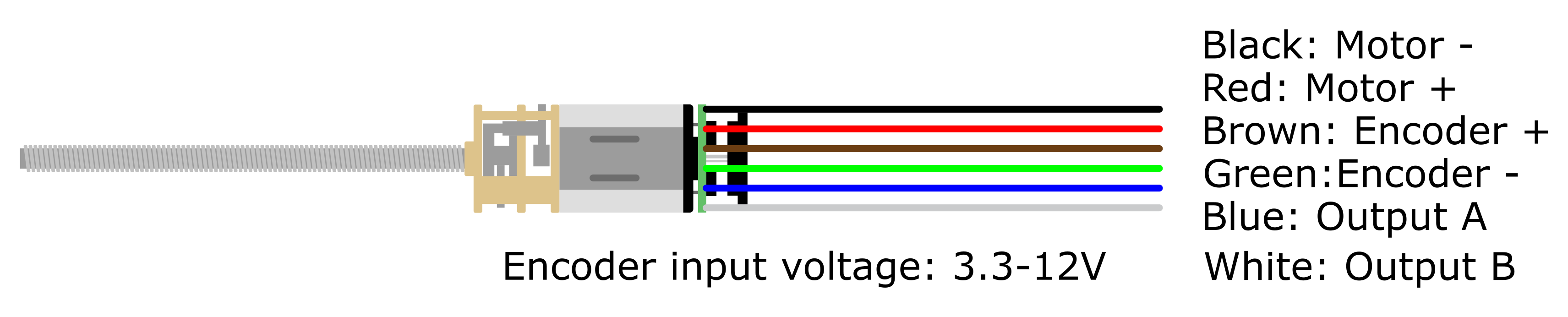

It took me a while to figure out the wiring of the encoder PCB. It is as follows:

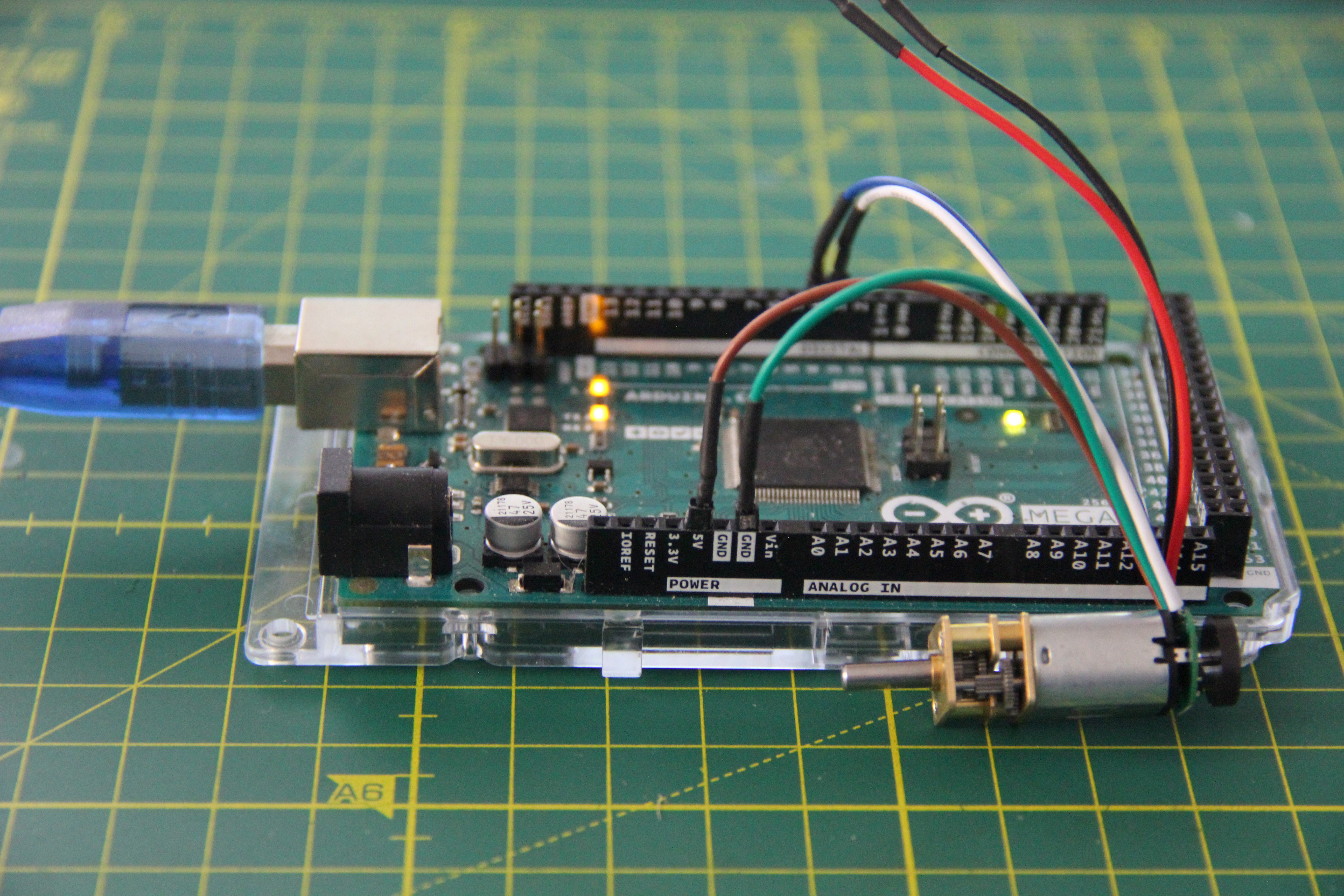

After soldering pin headers to the motor wires, the rotary encoder was tested with an Arduino Mega.

I took the test code from the Arduino project hub.

int counter=0;

String dir="";

unsigned long last_run=0;

void setup() {

Serial.begin(9600);

attachInterrupt(digitalPinToInterrupt(3), shaft_moved, FALLING);

pinMode(4,INPUT);

}

void shaft_moved(){

if (millis()-last_run>5){

if (digitalRead(4)==1){

counter++;

dir="CW";

}

if (digitalRead(4)==0){

counter--;

dir="CCW";}

last_run=millis();

}

}

void loop() {

Serial.print("counter : ");

Serial.print(counter);

Serial.print(" direction : ");

Serial.println(dir);

}

The rotary encoder has a resolution of six counts per revolution of the motor shaft. A motor driver with a break function is certainly required, plus PID control.

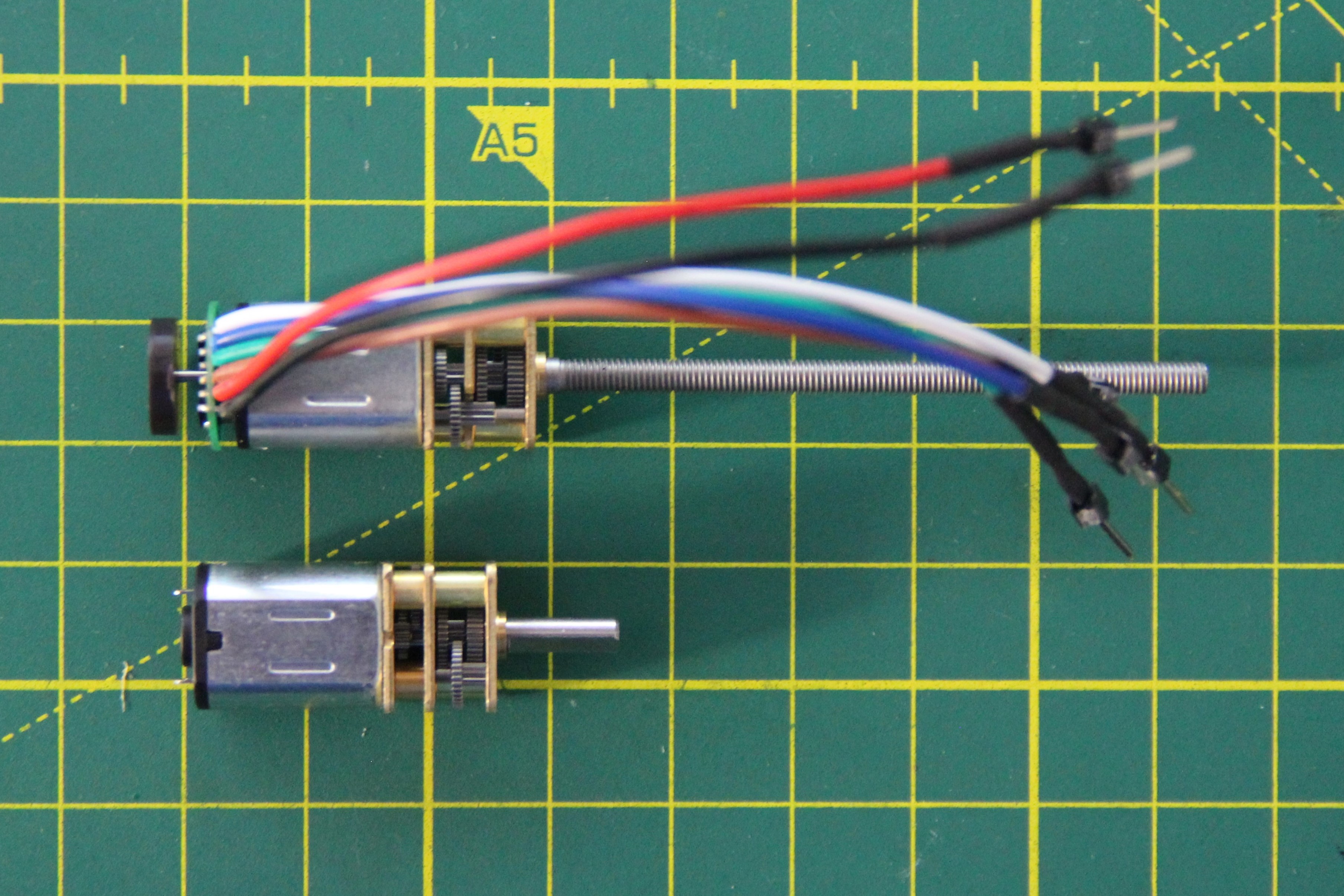

Finally, I changed the motors, which is absolutely no problem. For this, only two screws have to be loosened with a small Phillips screwdriver.

M. Bindhammer

M. Bindhammer

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.