Hey kid… yeah you… wanna see some hot pics of the stamping mold for the clips?

** opens trenchcoat **

So, you’ve probably noticed that sticking things into the Jumperless’s breadboard contacts isn’t quite as easy or smooth as regular breadboards. Here’s why:

I was being to cautious with my original design, I was worried those would catch on the underside of the plastic breadboard or hit the walls and not open enough for larger wires. Turns out, that created the issue of leaving too much of a gap for things to get around the clip or catch on the edge.

So I’m having the spring clip molds updated with a small adjustment:

I’m just extending the arms by 0.25mm to hopefully act as a better guide for the wires as you stick them in.

Now they should cover the entire opening to the breadboard and make it much harder to get a wire around it and possibly damage the clip.

I know this doesn’t help people who already have them, and these probably won’t make it into the next batch being made, so you’ll probably start seeing these Q1 2024. I’ll set up some sort of trade-in program for people who are bothered by it and want the new revision. Or you can just ask me for a set of the new ones when they’re available and I’ll send them to you for free and you can solder in the new ones yourself.

Anyway, just to take full advantage of my Fusion 360 student license’s free cloud rendering credits, here are a bunch of renders of the new clip revision.

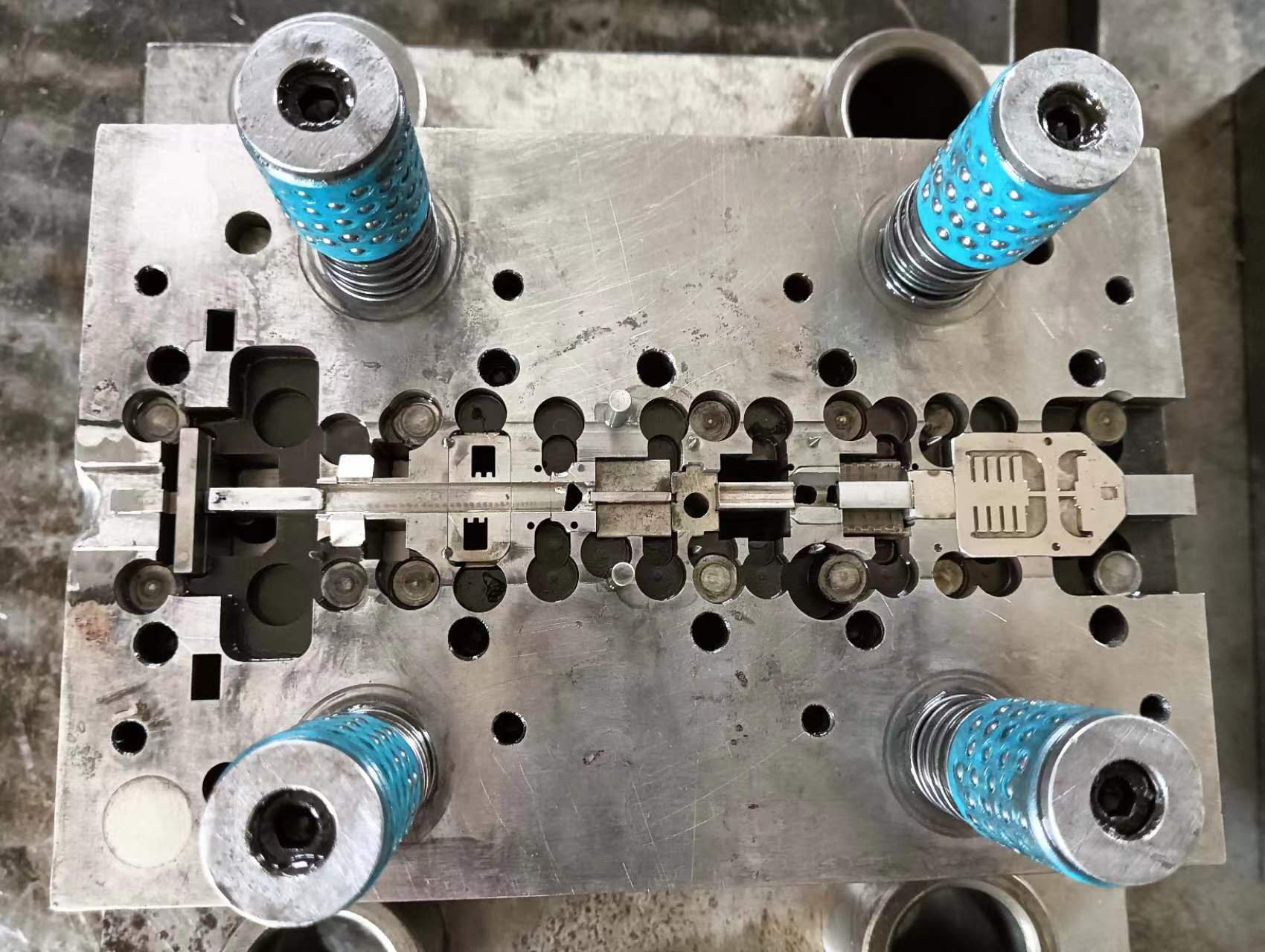

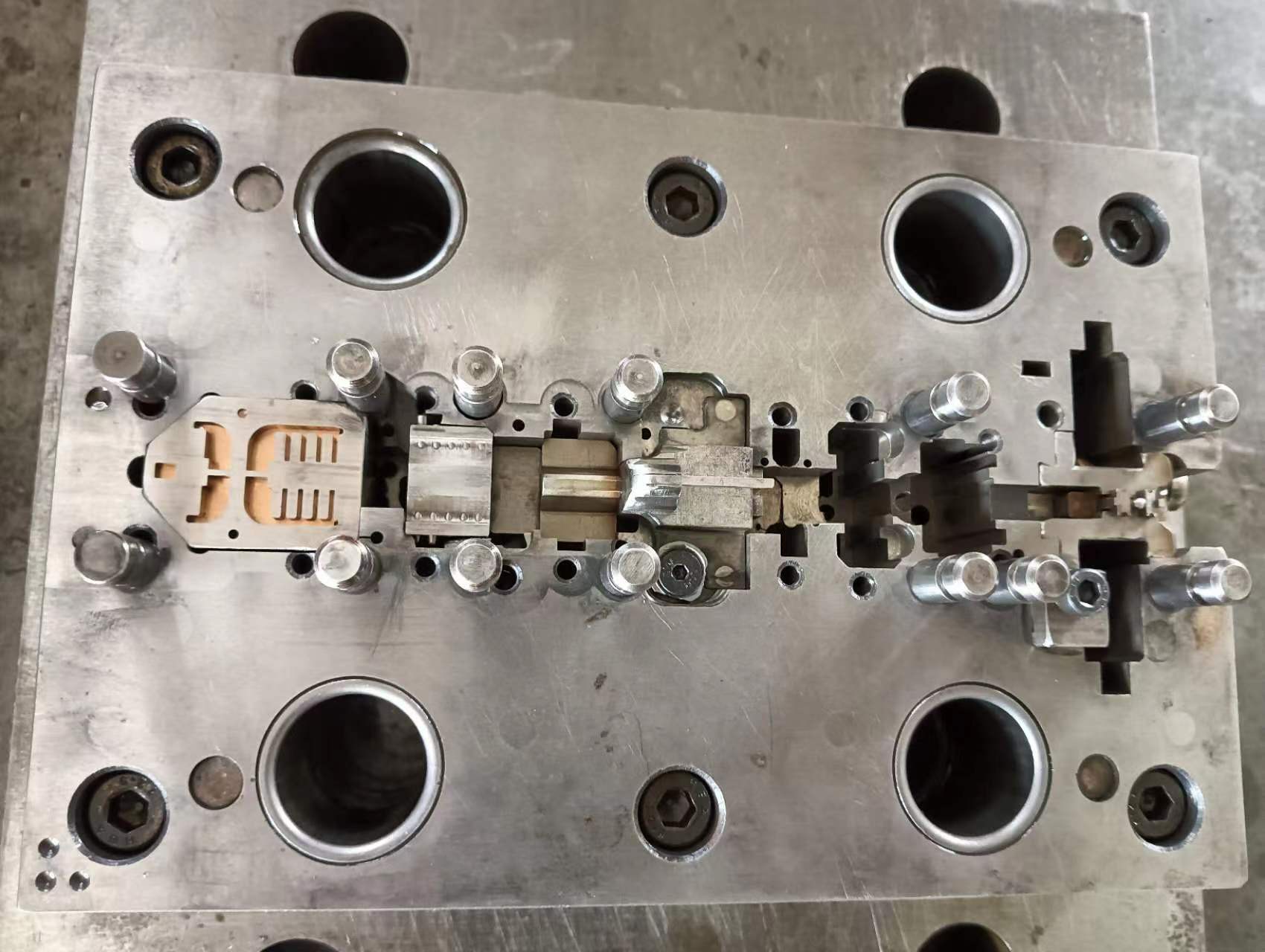

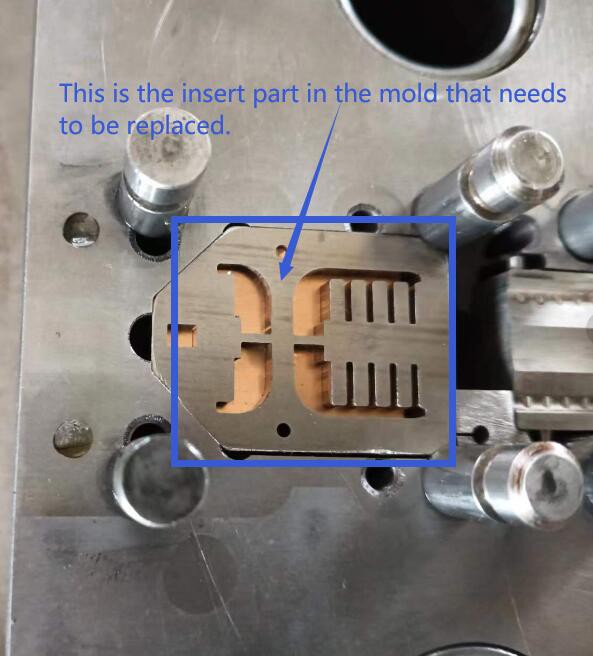

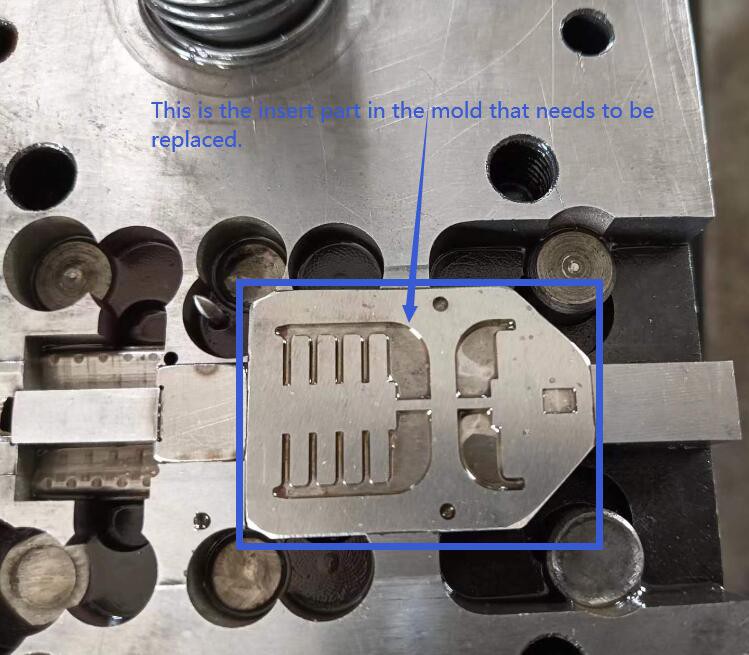

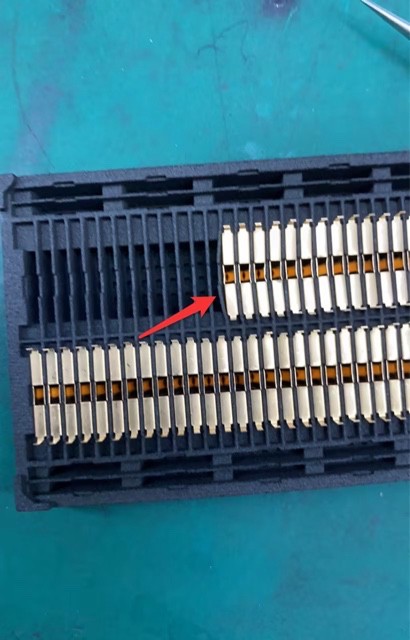

The reason that making changes to something like this is such a huge deal, is that they’ve made a big custom fourslide mold for this to do all the stamping and bending (here’s a SmarterEveryDay video about this exact process, just pretend everyone working there is Chinese.) So any adjustments to the part require them to CNC out parts of the mold and add extra metal bits on the mating surfaces. It’s an expensive process, this little edit will probably cost me ~$1,500-2,500 (or if I was doing this in the US, ~$60,000.) But it bothers me that it isn’t as perfect as it could be so I think it’s worth it.

For reference, here’s what I sent to the tooling engineers at Shenzhen Fulimei BBNew DrawingRevisedClipsUpdated.pdf (393.8 KB)

And the new drawing in case they decide to just make an entirely new mold bbSimpleWider Drawing v1.pdf (350.4 KB)

And the STL for good measure bbSimpleWiderOpen v2.stl (342.6 KB)

Let me know how much or little these clips are bothering you. If enough of you really hate it, I could hold up production on this new batch, have them dump the 40,000 clips they’ve made into the nearest wildlife sanctuary, and have them remake them all with this update.

UPDATE:

There's also a good news update about all this. So, I ordered 40,000 clips for this current batch of Jumperlesses, and it turns out the spring clip manufacturer made 32,000 of them with positive tolerance, meaning they measured from the inside instead of the outside to account for the thickness of the metal, so they're too wide to fit in the boards.

Elecrow (the people assembling them) told them so and they immediately agreed to remake all 32,000 clips for free. I paid them half price anyway for the remake because they're a pretty small company and I didn't want them to lose money on my project; I want them to stay around because they've been great to work with. But, what that means is, the new clip update will be pushed out way sooner than I had expected.

They had 8,000 extras from the last run, so there will be 100 boards made with the old clips, and the remaining 400 will be made with the updated design. It's funny when someone comes to you with what they think is terrible news and you respond with "Holy shit that's awesome!"

So yeah, there will be 100 boards with the old clips ready before Christmas, and then 400 more sometime in January with the new revision.

I also ordered 10,000 extra clips so when they're ready I can swap out the clips on the boards you currently have if you like.

Kevin Santo Cappuccio

Kevin Santo Cappuccio

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Good job on "attention to detail" in every aspect of your product! Keep it up

Are you sure? yes | no