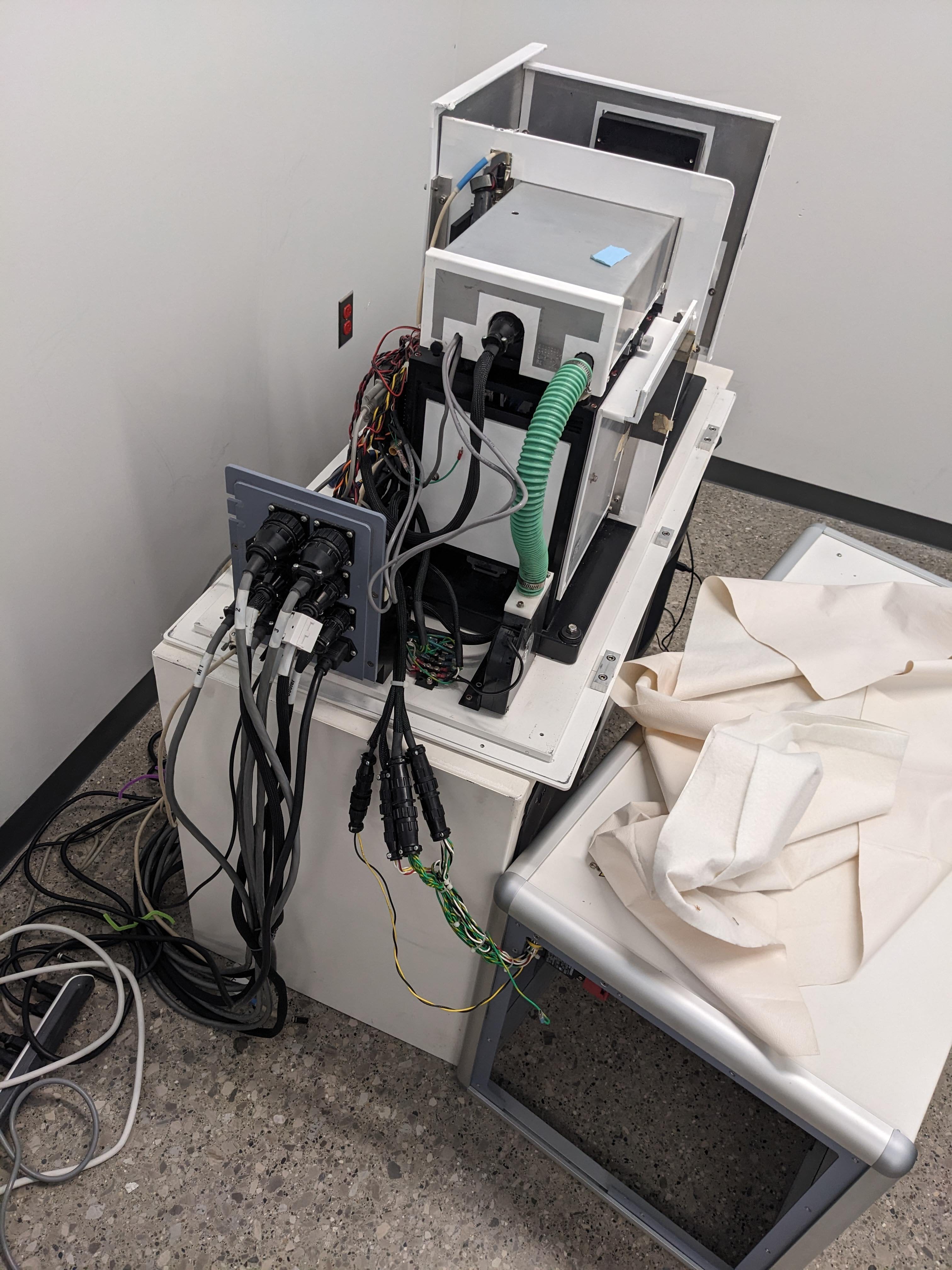

Don't worry, I'm not planning on running the x-rays like this. The cover had to come off because it was probe-y probe-y time again, as we try to fix the shutter (seriously? Again?) which I blew up by accident a few days ago. Actually just the driver board, thankfully.

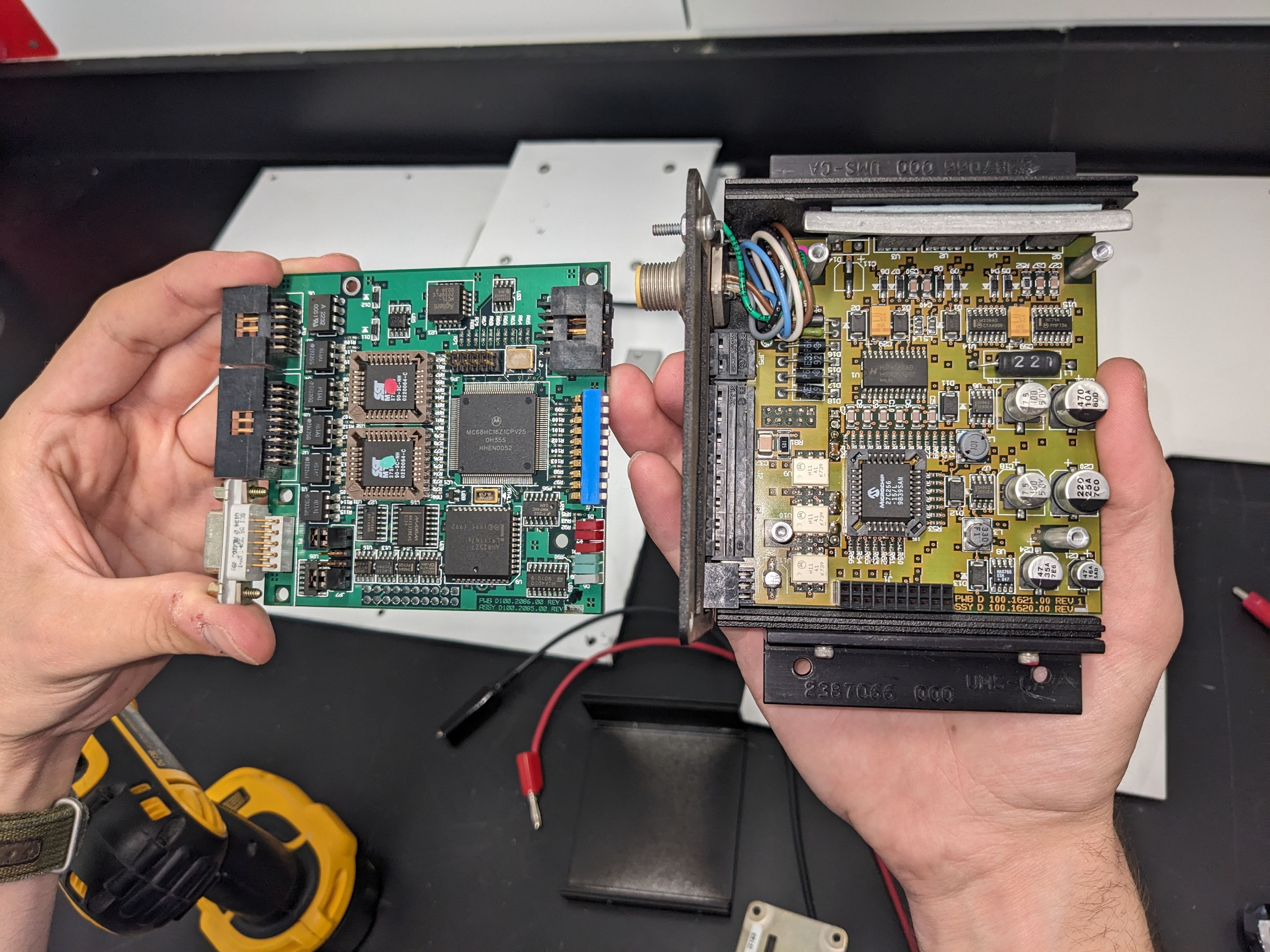

I've spent the last couple of days haaaaaaaaaaaaaating the shutter server, again, with a passion that burns within all of my soul. Basically, since I destroyed the replacement driver board, I wanted to at least try again to get the original to work. And why not? It's perfectly tuned for the motor already... you just CAN'T CONNECT TO IT !@$@$@$%@%@$#%#%!

There's the box that controls the motor, which it turns out even has an encoder. Which would mean it could be used for such very useful and safe things such as moving the tungsten shutter to cover the source when you want it to. We know the motor can be held in position and stably, thanks to some knowledge gleaned while trying to connect to the shutter server, but if we get into that we'll be here all day. Sigh.

I don't think we had much of a warranty anyway. Daniel knew about all the stuff that was inside here, but unfortunately even he didn't spot the magic analog make it go whirr and how fast button.

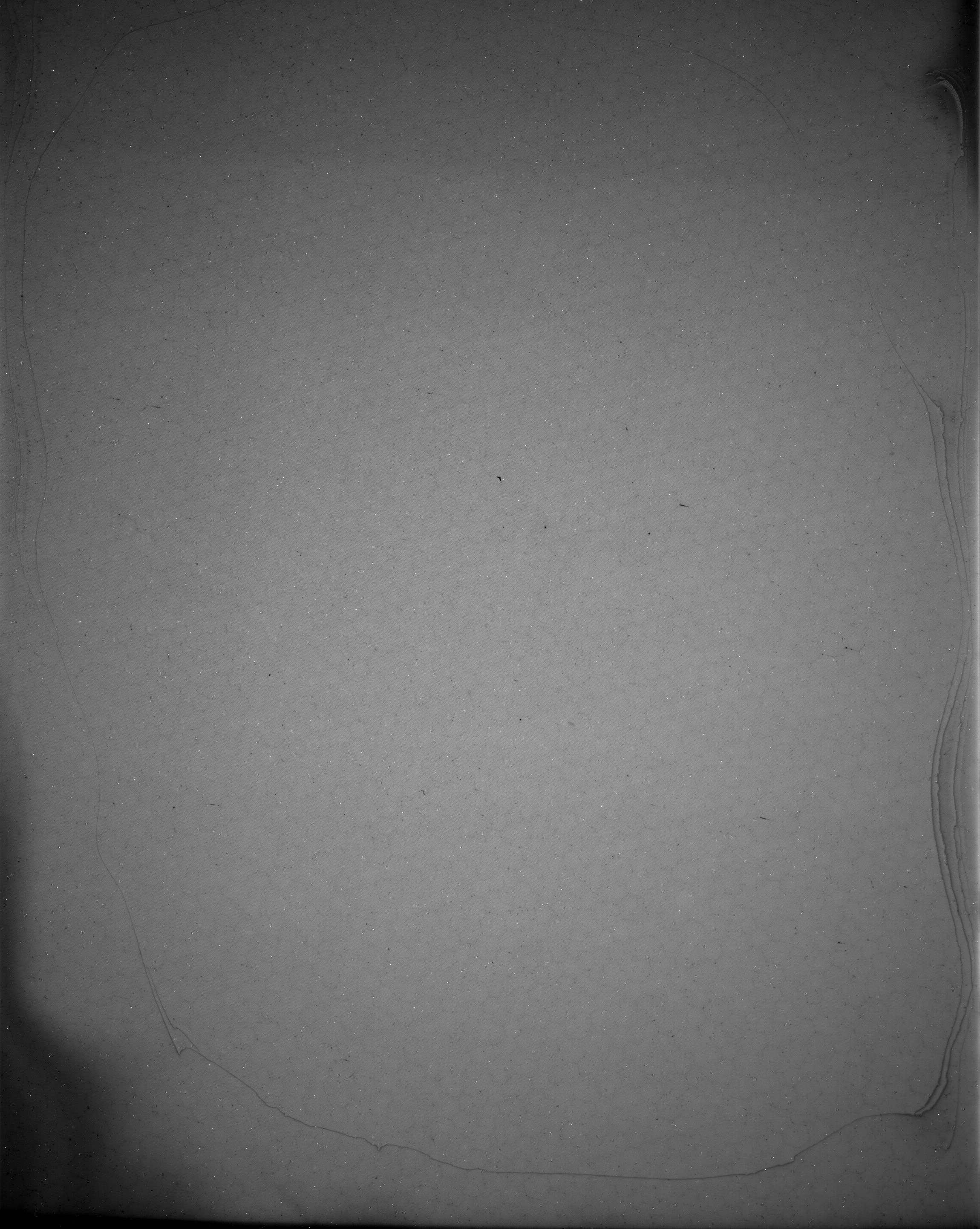

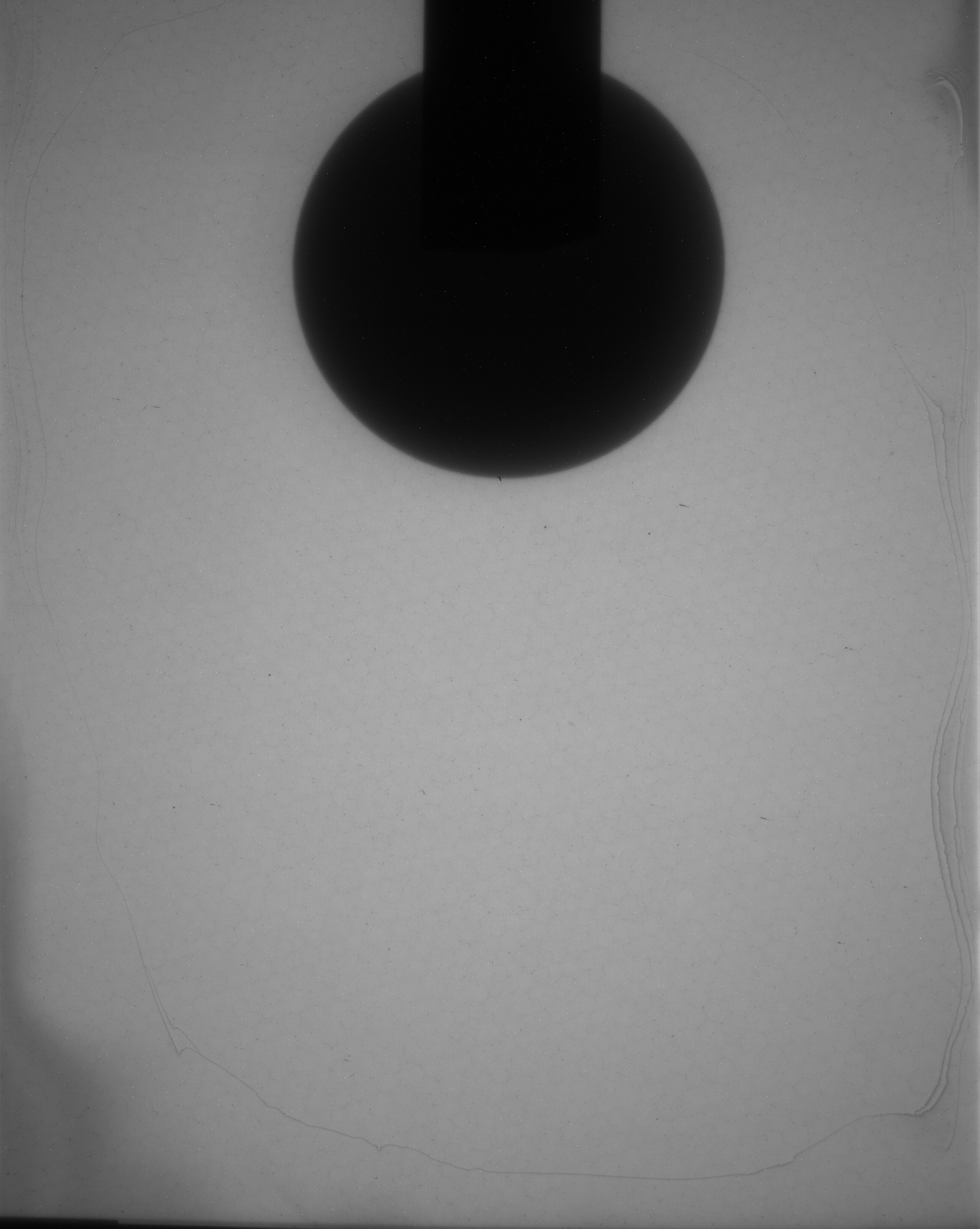

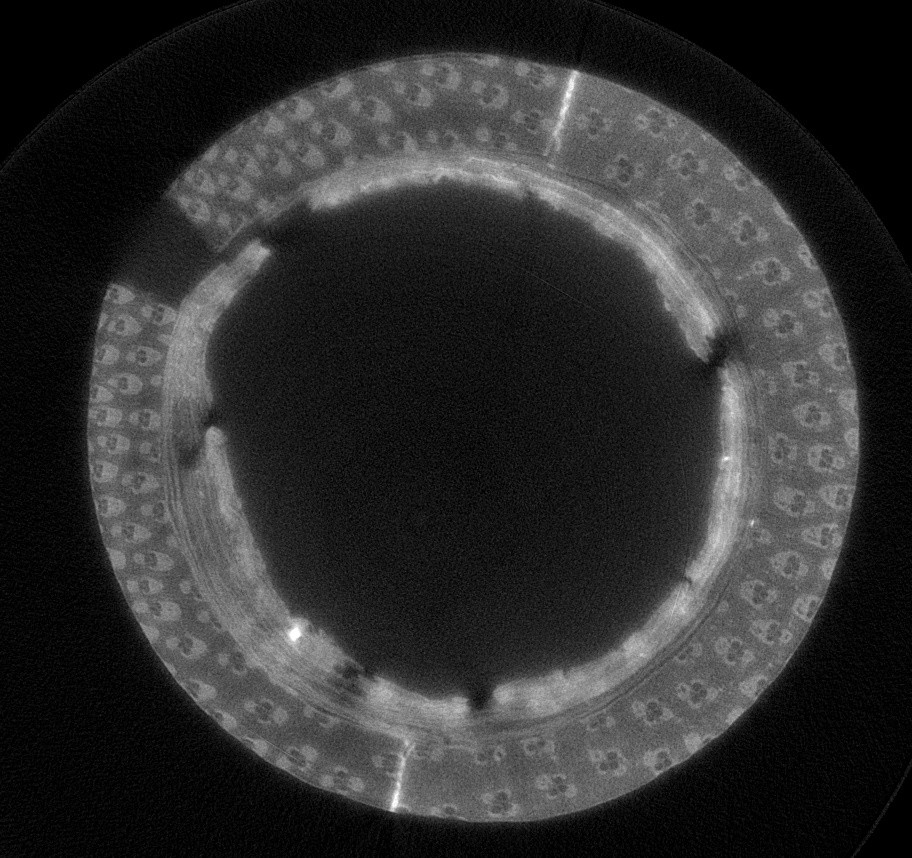

Before the current state of machine malaise, I did some reading and experimenting with calibration, recon settings, and scan acquisition. I think the coolest .exe power I got is applying offset images. You can see in this (FULL RESOLUTION 1X1 binning!!) image, squee, that the detector over the years has sustained a bit of damage:

This is still kind of an awesome image IMO. It's 1x1 binning, and the detail of the detector backing, or fiber optics, is actually pretty cool. To take a 1x1 bin image needs a long exposure time, but our shutter couldn't be ramped down that slow. So instead we just average 10 times, which results in the same SNR as a full exposure image pretty much.

This is still kind of an awesome image IMO. It's 1x1 binning, and the detail of the detector backing, or fiber optics, is actually pretty cool. To take a 1x1 bin image needs a long exposure time, but our shutter couldn't be ramped down that slow. So instead we just average 10 times, which results in the same SNR as a full exposure image pretty much. But yeah, that pattern! And the peeling, yikes! the color is all different! It's practically dirty! What's that gonna do the scans of this round thing?

Not much, if you just apply the blank picture of the detector as an offset image.

Like a cheat code for image processing. There's a lot of chasing the last little bit of quality like by taking multiple references, spaced out through the scan, but 99 percent of the benefit is from just doing it at all. Even JPEG knows how much cleaner this image is; it's only 30 percent of the size of the uncorrected one.

There's more, for sure! The machine had already started proving useful to an applied research task. I'm not sure if I mentioned this yet or not, but this project was born partially out of the Vesuvius Challenge, a very cool and suspiciously side-quest-y goal to read some ancient scrolls that fell into a volcano using x-rays. I've been doing experiments with carbonization to simulate scrolls, with the intent of scanning them. This is now a reality.

Cross section of carbonized papyrus, inside bamboo tube!

So here's to the future --- we're there, nearly, with just the occasional setback! To ancient scrolls! To image offsets! To a working shutter, eventually.

Ahron Wayne

Ahron Wayne

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The shutter is thick! I could estimate volume and look up density, but still have no sense of what a big chunk of tungsten feels like in the hand.

I wonder how well this works with mineral targets. A quick search didn't entirely shut down the possibility. I recently received a smaller-than-fist "rock" which appears to be a dense tangle of mineralized worm tunnels filled with compacted sand. I've been able to pick/shake out some of the sand and it appears that many of the tunnels are open, smooth-walled and continuous. And very twisty. It seems to be a tangle of rigid tubes rather than a rock with holes in it. Would be neat to see inside.

Are you sure? yes | no

It's 80 percent tungsten, 20 percent copper to aid in sintering. But yeah, kind of a niche little component.

The manual says 30 mm, but I can probably scan it if it's less than 50 mm wide. If that matches the description, you can try to send it to me --- no guarantee since my source only goes up to 90kv. But worth a shot!

Are you sure? yes | no