Interactive Hand Sensor

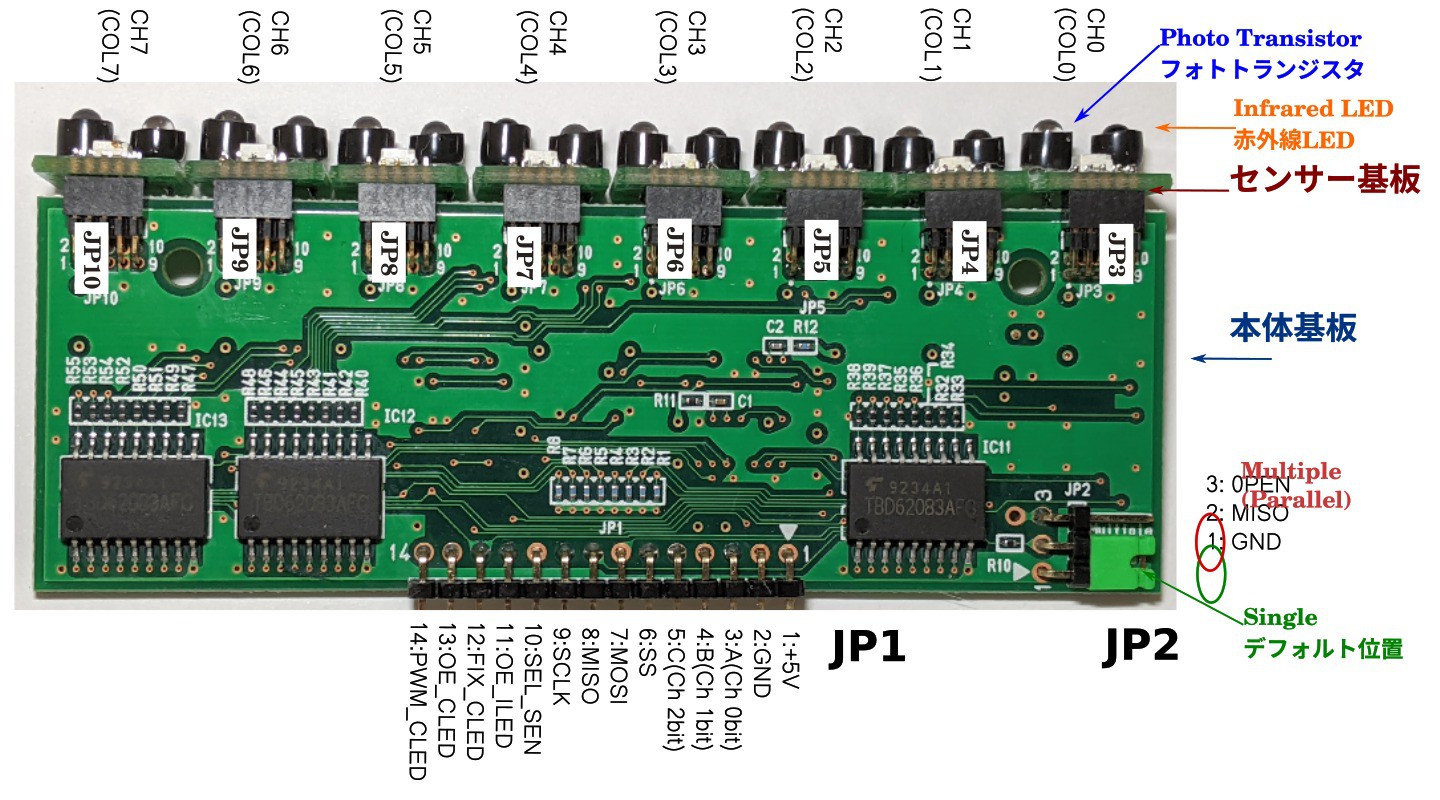

"Interactive Hand Sensor" can be detected with a resolution of 0.4~0.8 inch (1~2 cm).Can be applied to non-contact switches, non-contact touch panels, motion detection, etc.

8 sensors from 0 to 7 channels can be sensed in the shortest 1.2 milliseconds

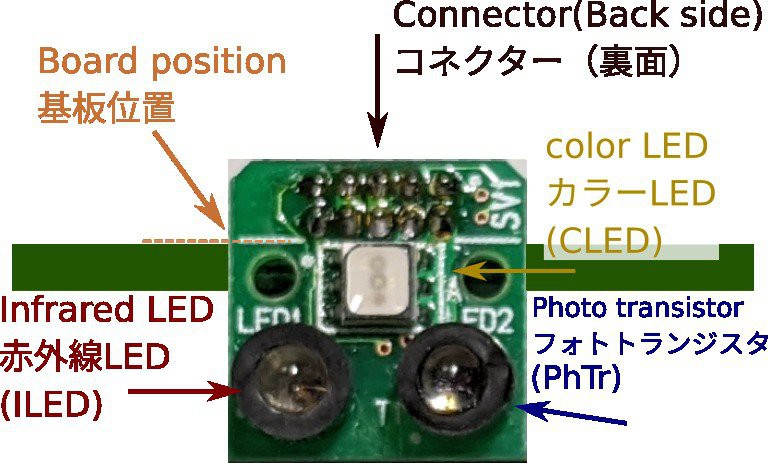

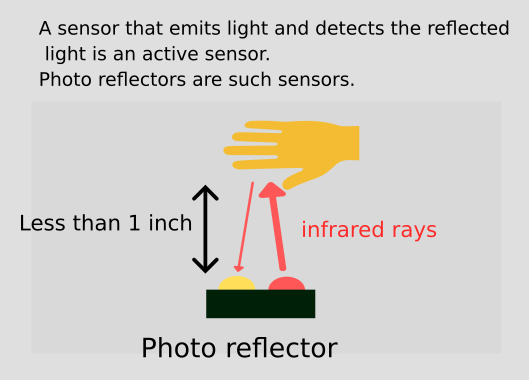

Photo reflector

A photo reflector is a sensor that emits infrared light and detects the reflected light. They are used for line tracing in robots.

How it works

The principle of this sensor is an application of a photo reflector, which I call a "switching photo reflector".

An infrared LED emits infrared light, and a phototransistor converts the light into an electric current, and the resistor converts it into voltage.

When reading the voltage with the AD converter, the infrared LED is lit at the SCLK timing of SPI Interface. It is driven for 10 microseconds without a current limiting resistor and emits strong light at a current of about 1.5A.

The sensor is not accurate in measuring distance. The intensity of the reflected light is not proportional to the distance. I'm throwing away accuracy of distance and taking speed.

The 12-bit AD converter number contains a lot of noise, so it's processed by a micro controller.

V = (A - B) - C

V: distance approximation

A: Reflected light from turning on the infrared LED

B: Reflected light with infrared LED turned off

C: Ambient brightness measured at startup

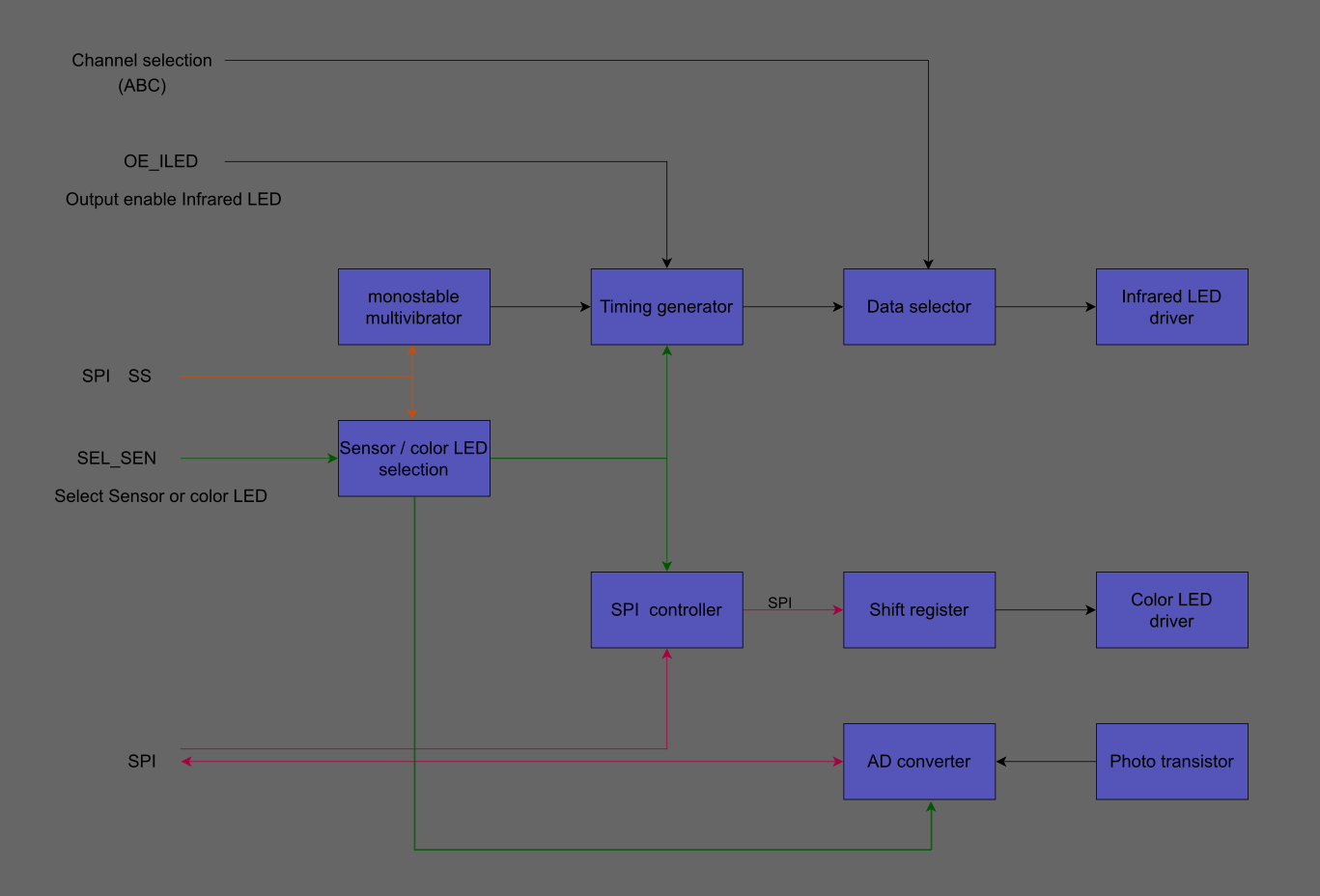

Block diagram

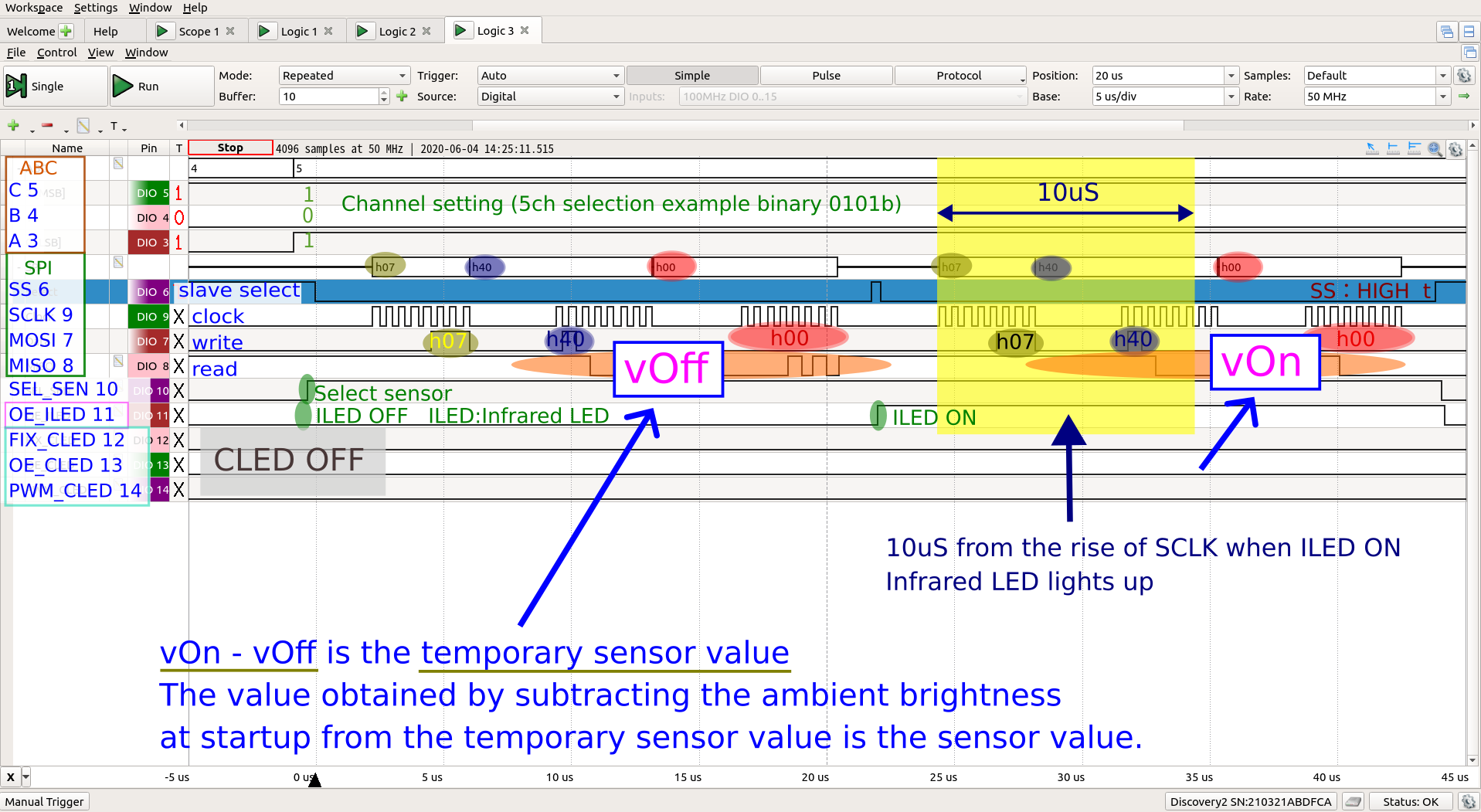

Sensor Operation

Before starting sensing, select the sensor with the SEL_SEN pin and set the channel. The first sensing session reads the ambient light intensity with an AD converter without emitting infrared light.

The second time, infrared light is emitted and detected in the same way, triggered by the SPI interface SS that is generated before reading the AD converter, which generates a 10 microsecond infrared LED drive signal, causing infrared light to be emitted. The AD converter reads the input value of the same number as the channel.

The infrared LED emission ends at the timing after the AD converter detects it. The difference between the second and first values is used to determine the approximate distance to the object.

Color LED Operation

Before starting the color LED operation, select the color LED with the SEL_SEN pin. Next, calculate the (8X3=)24-bit value for the color corresponding to the detected value. This value is written to the shift register via SPI, and when the output is turned on, the color LED glows.

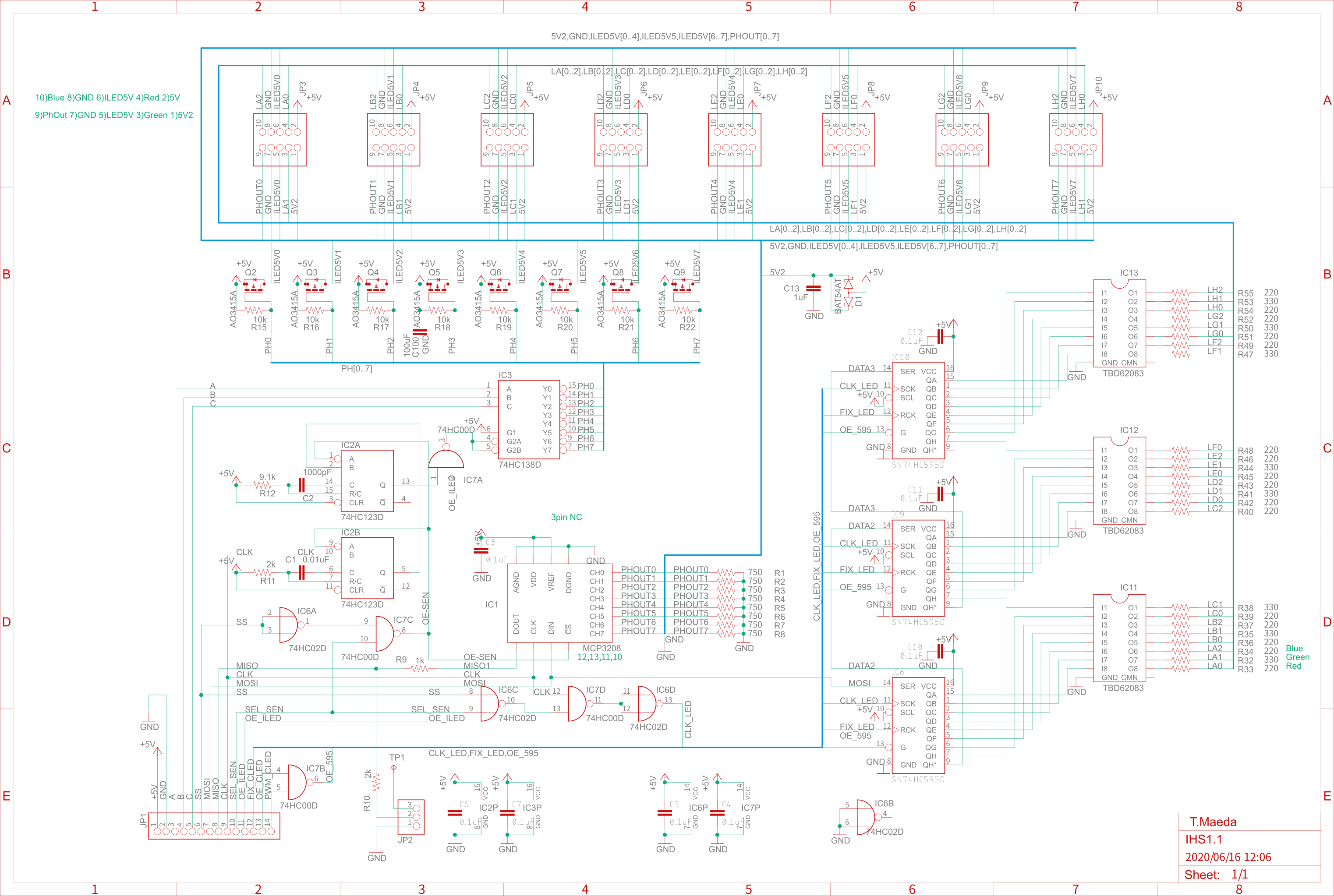

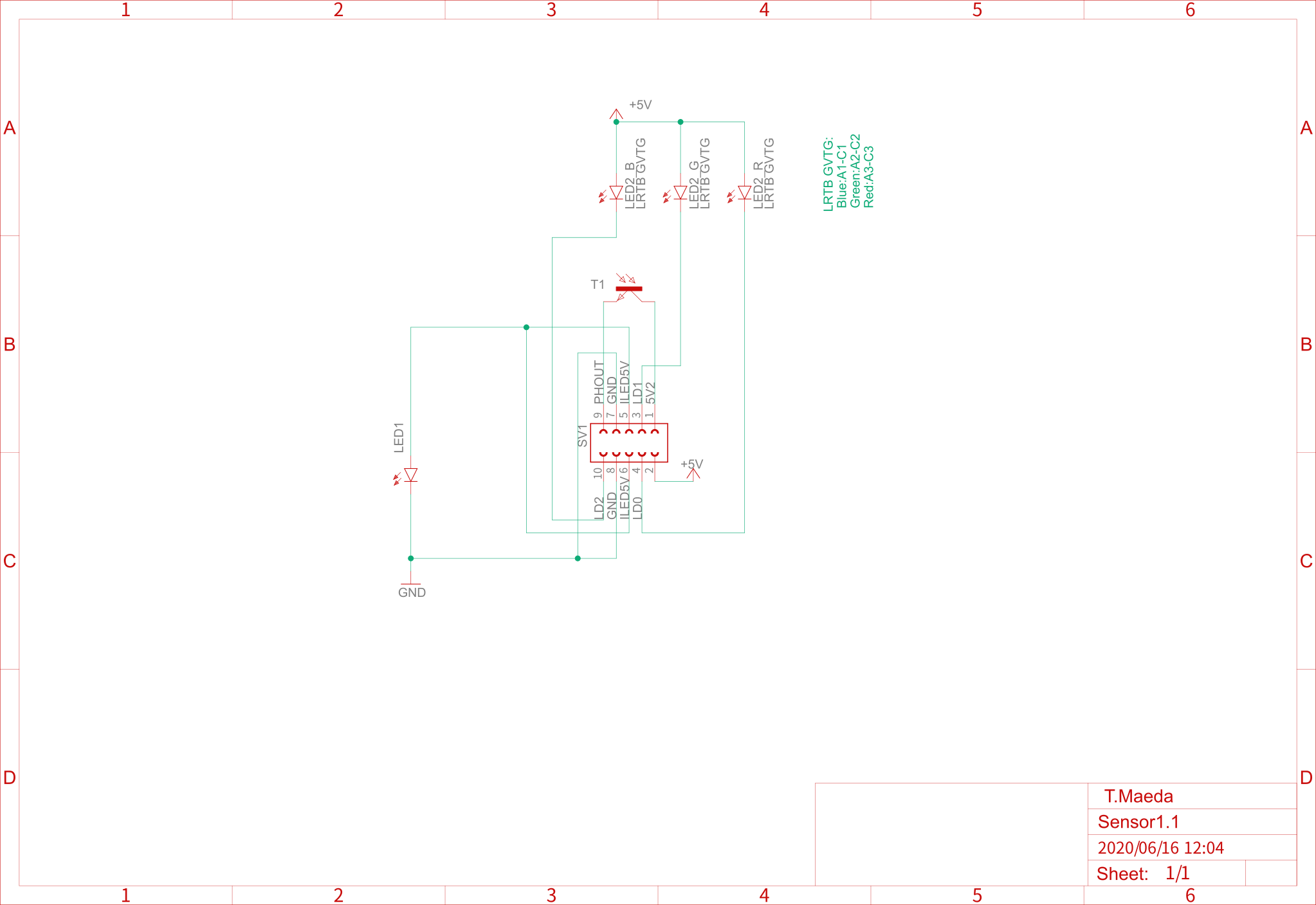

Circuit diagram

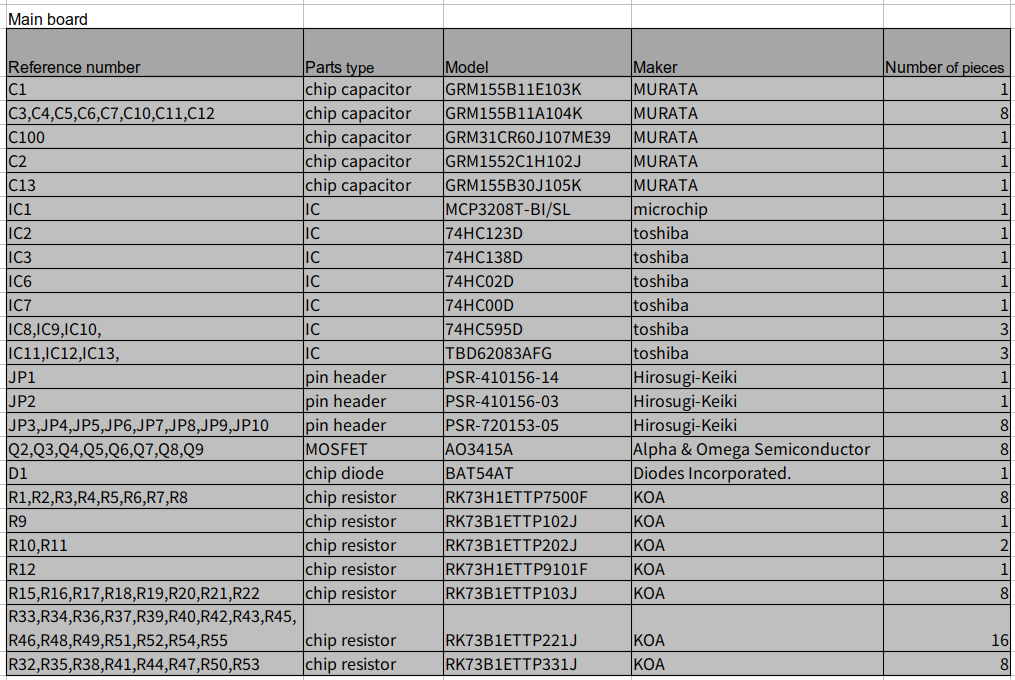

Parts list

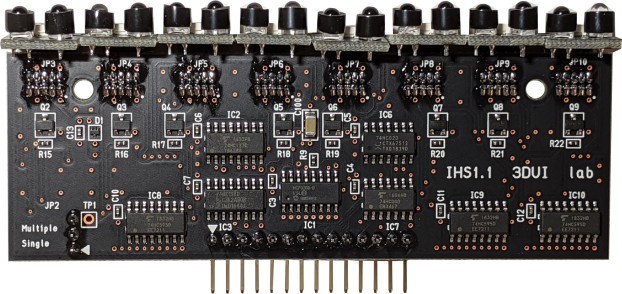

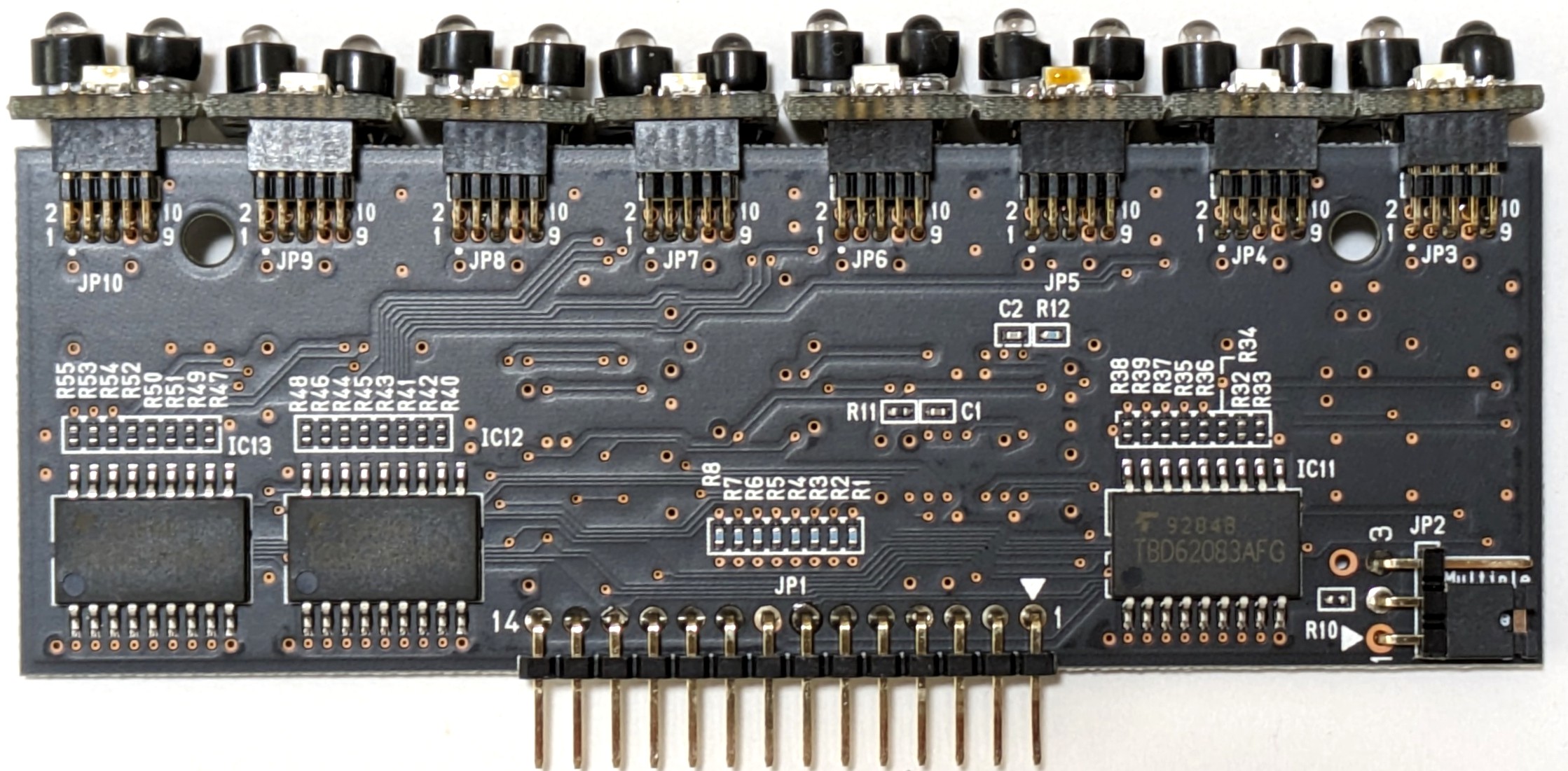

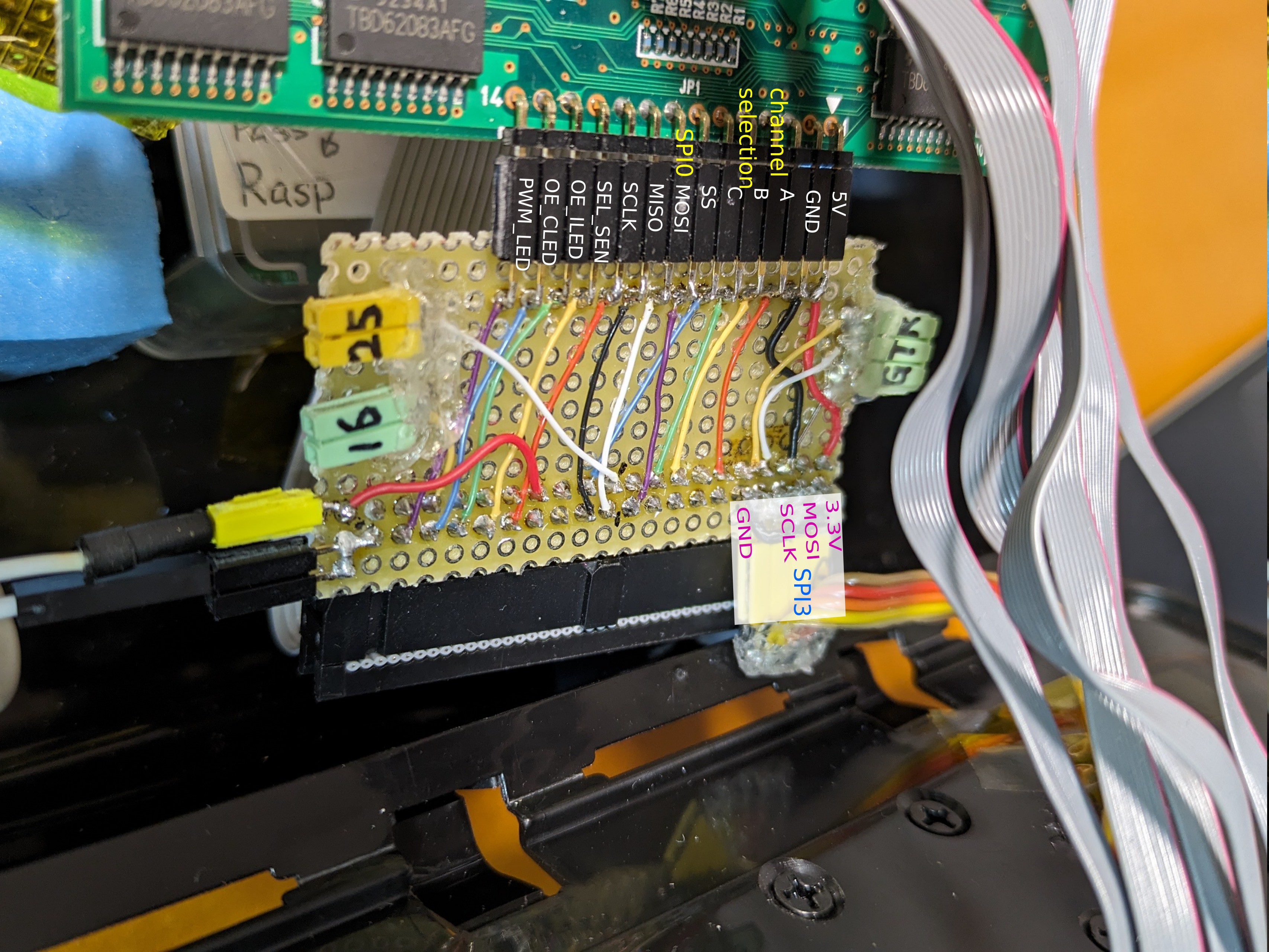

Photo

Logic analyzer

Logic Explanation

The AD converter reads the light intensity twice. Then, the infrared LEDs will emit light only for the second reading. Infrared LEDs draw currents that exceed their absolute ratings, so the on-time should be kept as short as possible. The MOSFETs that switch the LEDs switch ideally as in the simulation with zero delay. The distance value is the difference between his second value and the first value of the AD converter, minus the ambient brightness (calibration value).

Why sensors are now possible

I have worked in semiconductor failure analysis and am familiar with SEM and TEM photos of semiconductor failure areas. Most failures are caused by tiny distortions or cracks in the crystal. A device without crystal distortion or scratches can be said to be less likely to break.

Unlike LSI chips, infrared LEDs may not be subject to miniaturization of semiconductor processes, but as the precision of semiconductors is improving worldwide, I think they are becoming more difficult to break every year.

Recent semiconductors have a gray zone of about 100 microseconds. In the gray zone range, even if the current exceeds the absolute maximum rating, it will not be damaged. The sensor has been tested continuously for more than 2 years and 4 months without any deterioration.

This is on sale in Japan.

Non-contact touch panel

The sensor's infrared light passes through a transparent OLED panel and detects our fingertip.

Since it can be detected from a distance of about 1 inch, I think it will help prevent infections caused by contact. I believe that if a non-contact touch panel using this technology is commercialized and used in ticket vending machines at airports and ports around the world, it will be useful in preventing infectious diseases.

I think non-contact touch panels will be in practical use around 2030, and by then the principle of "Interactive Hand Sensor" will likely be used. This is the basic technology for active optical sensors that do not use lasers.

Since only 1.51-inch transparent OLED modules, which are less than half the size of a hand, are available, non-contact touch panels are prone to false positives. The software assumes that only six sensors can be used, and compares distance data to determine which direction the hand is coming from.

In the actual product, I plan to arrange many sensors in a wide area to detect the direction of hand movement and product selection. Compared to the sensor's resolution of about 0.5 inches, this distance is wide enough to make false detection difficult, but I haven't tested it yet.

Distance detection of non-contact touch panel

There is a slight delay in drawing graphs on the Raspberry Pi, but sensor detection is faster.

In air, it can detect up to a height of about 9 inches, but when it passes through a transparent OLED, it is attenuated and the detection distance becomes less than 2 inches. Glass and acrylic can detect longer distances.

Glass and acrylic are single crystals that allow light to easily pass through them straight through. However, since transparent OLEDs have a complex structure that includes transparent wiring and semiconductors, I think the light is diffused.

Detailed photos

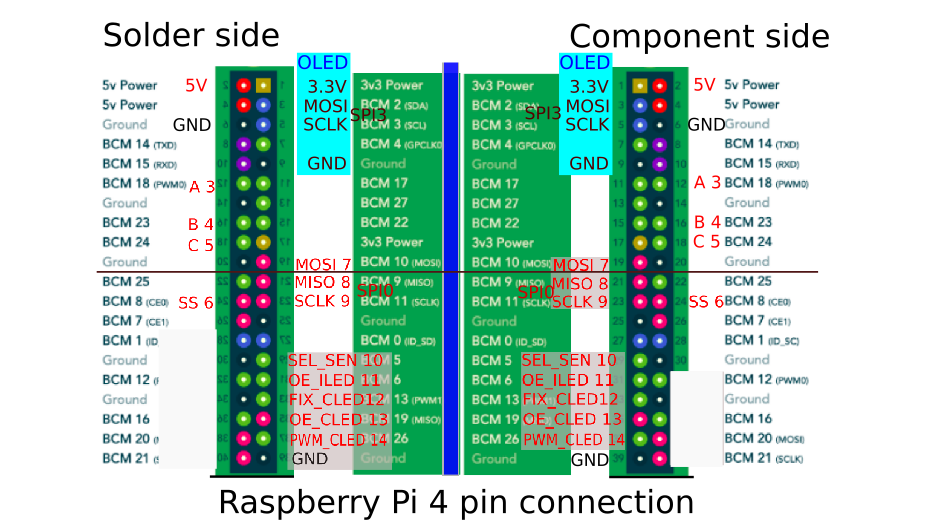

Wiring diagram

Software is Python on Raspberry pi 4, using the luma.core library

https://github.com/rm-hull/luma.core/blob/master/LICENSE.rst

Takahiro

Takahiro