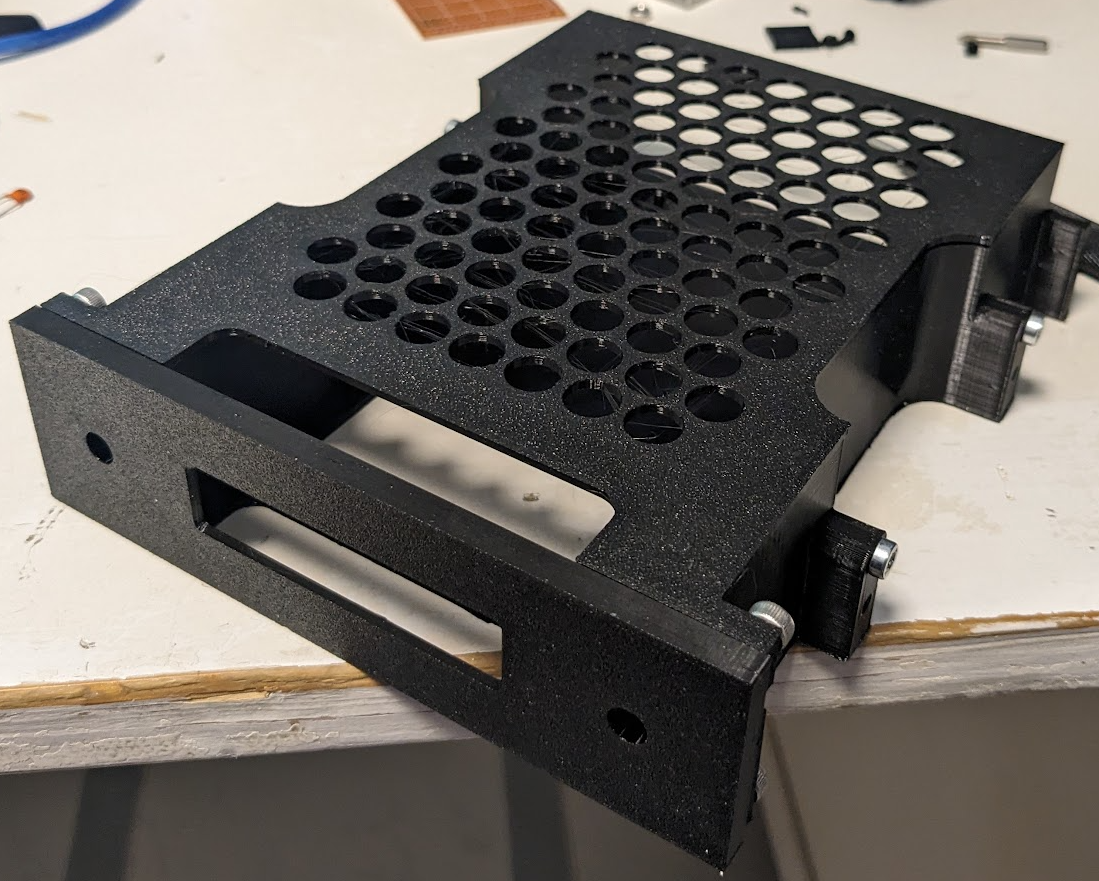

The top plate has a pin that keeps it aligned with the bottom part nicely, and also latches onto the faceplate with screws. The hole design was a nightmare to do in FreeCAD, as hexagonal arrays are not a thing you can do.

If I had to redesign this, instead of securing it to the faceplate I would have made the bottom plate the sole responsable of holding the faceplate, and add a way to attach this with screws instead of friction. It worked, but could have been better. Unfortunately redesigning this would have meant also reprinting the bottom plate, and I was not keen of doing 10 more hours of that.

All in all, the model looks nice (ignore the stringing, I could have heatgunned it but nobody but me is going to see it nromally. The top plate does not flex much (The bottom plate does flex a little because of the big holes, but seems this arrangement is much more stiff), and from afar it looks even something you could buy off the shelves.

On this photo is also the reprinted faceplate. The original one had a noticeable texture due to the Monotonic layering (it basically covers everything with a 45º slanted deposition, then it rotates the thing 90º and goes again for the next layer). I switched it to hilbert curve layering which worked much better. The only texture it shows now is the one from my printer surface, but it looks good on this model.

Abraham Limpo

Abraham Limpo

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.