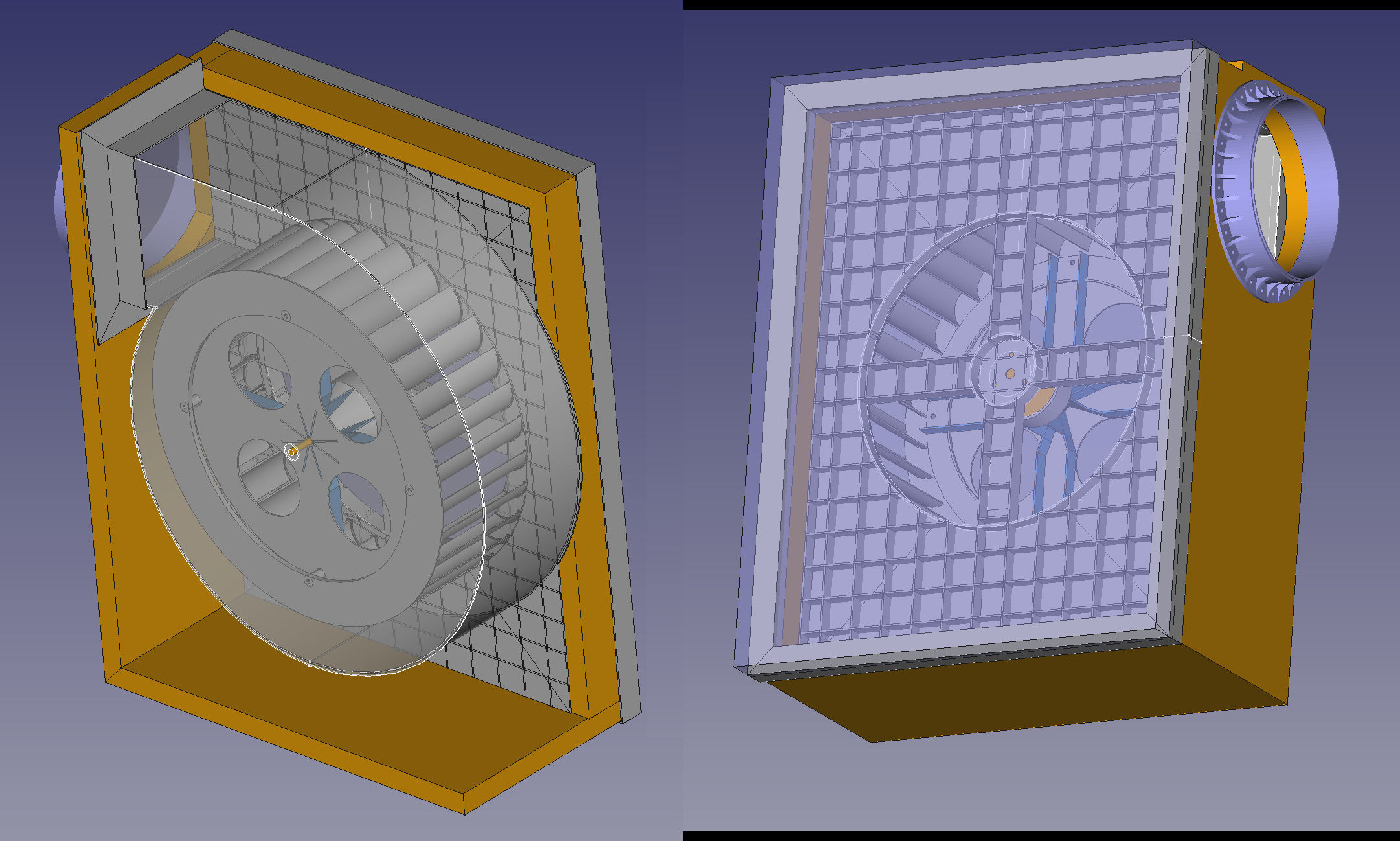

The enclosure has to do many things. It has to attach to the F-35 nozzle. It has to hold the filter. It has to hold the motor.

The great challenge is the largest panel being dictated by the size of the filter, a 340x265mm area.

Then, the inlet needs to attach to the filter. It almost needs very thick wood panels to create enough of a bezel for the filter to tape on & for the inlet to bolt on.

That led to a something where the filter simply tapes on to the front of the blower. There's supposed to be a PLA border for the tape to grab onto, but it's structurally supported by a big piece of wood. It might be easier to paint the wood & tape directly onto the paint.

Around the filter, the inlet is supposed to bolt on. A large orthogrid was the easiest way to mount the motor to the wood. The orthogrid is manely a hole so it's not as expensive as it looks.

That was the general idea. Manufacturing it with required subdivisions is tricky. The great challenge with this is the shroud has to be removable, air tight, & silent. It most certainly needs a clamshell behind the orthogrid.

Making the required clamshell for the shroud will most certainly require scripting the model. All this is long enough in the future to go ahead & document the current state of the blower.

The mane thing that could be a problem is the lack of sharp leading edges. It doesn't move much air for the amount of power going in. There are dreams of making custom gcode to sharpen the leading edges or maybe reducing the line width.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.