Intro

So why the radio silence? Well I have been building an getting a small supply chain in order! So after the initial Hackaday post with the hackester.io several people had reached out about how to obtain a ready made version of Nyan Keys! I could not be more thankful that people had taken interest in project of mine when all former projects end up in boxes. With that said, the challenge of turning a single prototype into many began and the challenges were numerous.

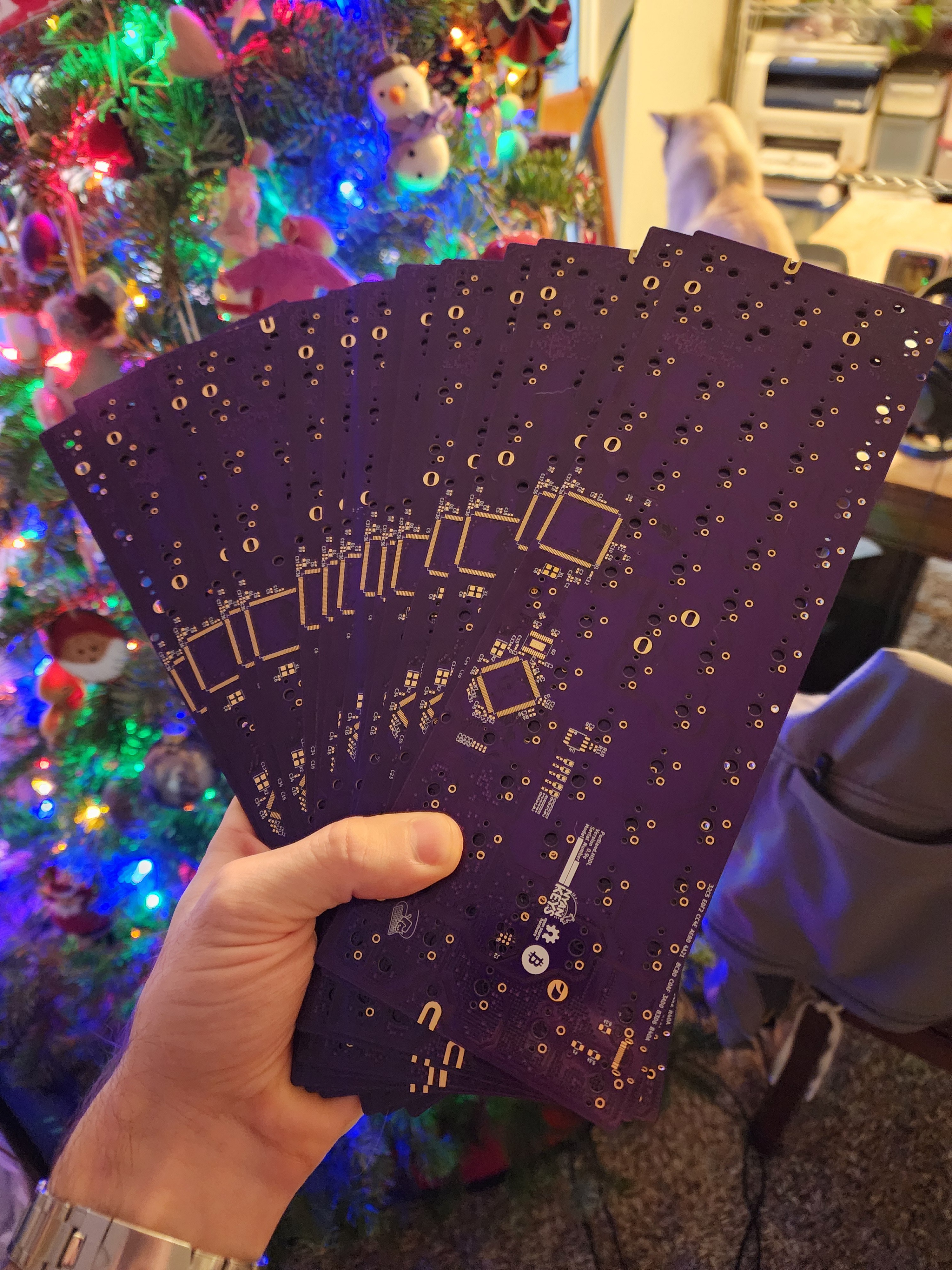

Lets start off with step 1. First I went to OSH Park and requested 10 Nyan Keys .9e boards through their medium run service which totaled to $409. Spendy but to me worth the cost for a product/project I love so much and have no interest in corner cutting. For the first time ever I also decided to get a solder stencil to hopefully save time. This step turns out to be the most important step in board production. Out of all the things you can take away from this piece it would be to get stencils of you are attempting any kind of volume.

Also thanks OSH Park for sending 14 boards.

2 weeks later!

Some glamor shots of the boards :D

Some glamor shots of the boards :D

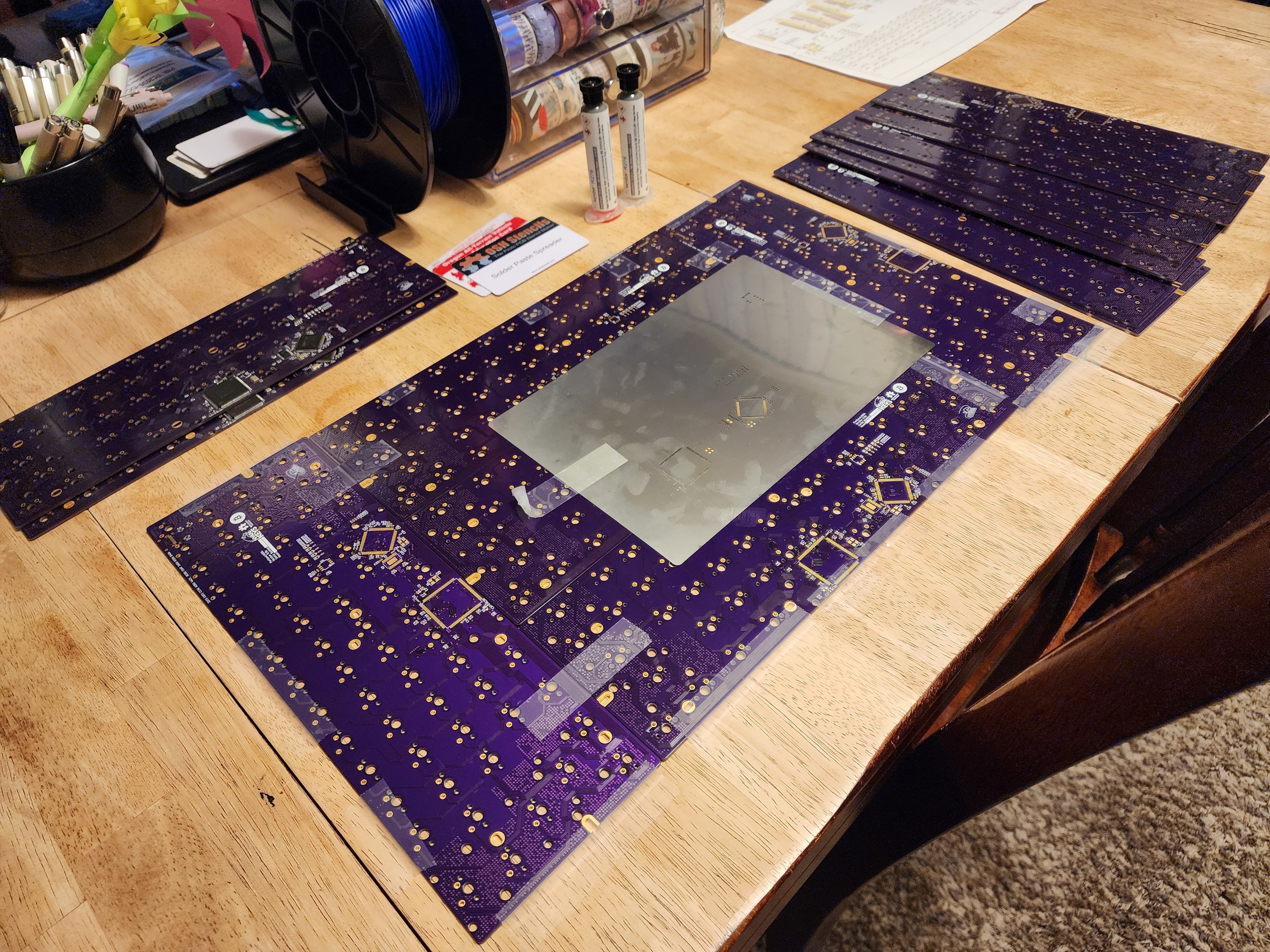

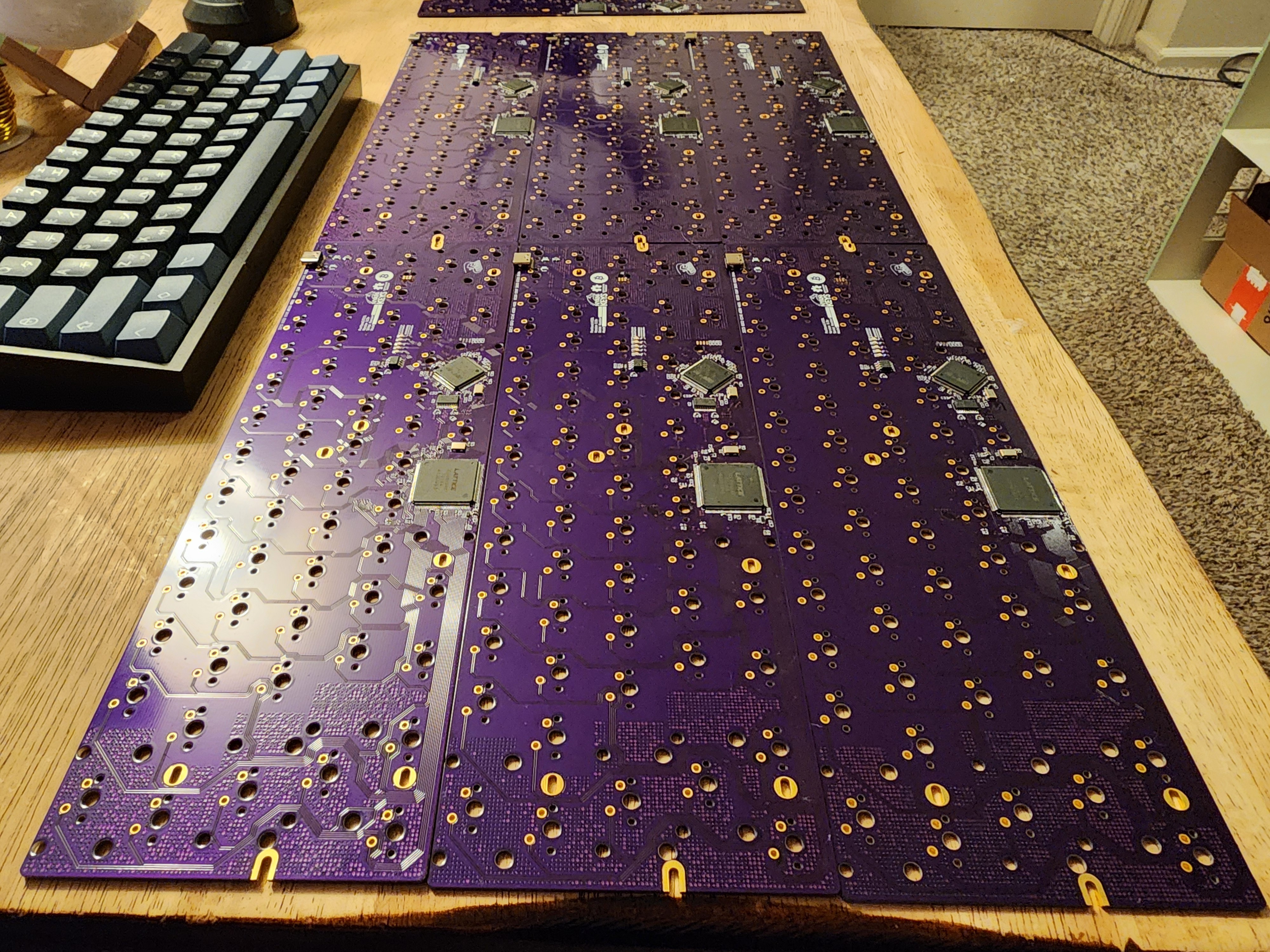

The day is now Saturday, I decided today was the day to build as many boards as possible. A jig was made with 4 PCBs and some scotch tape

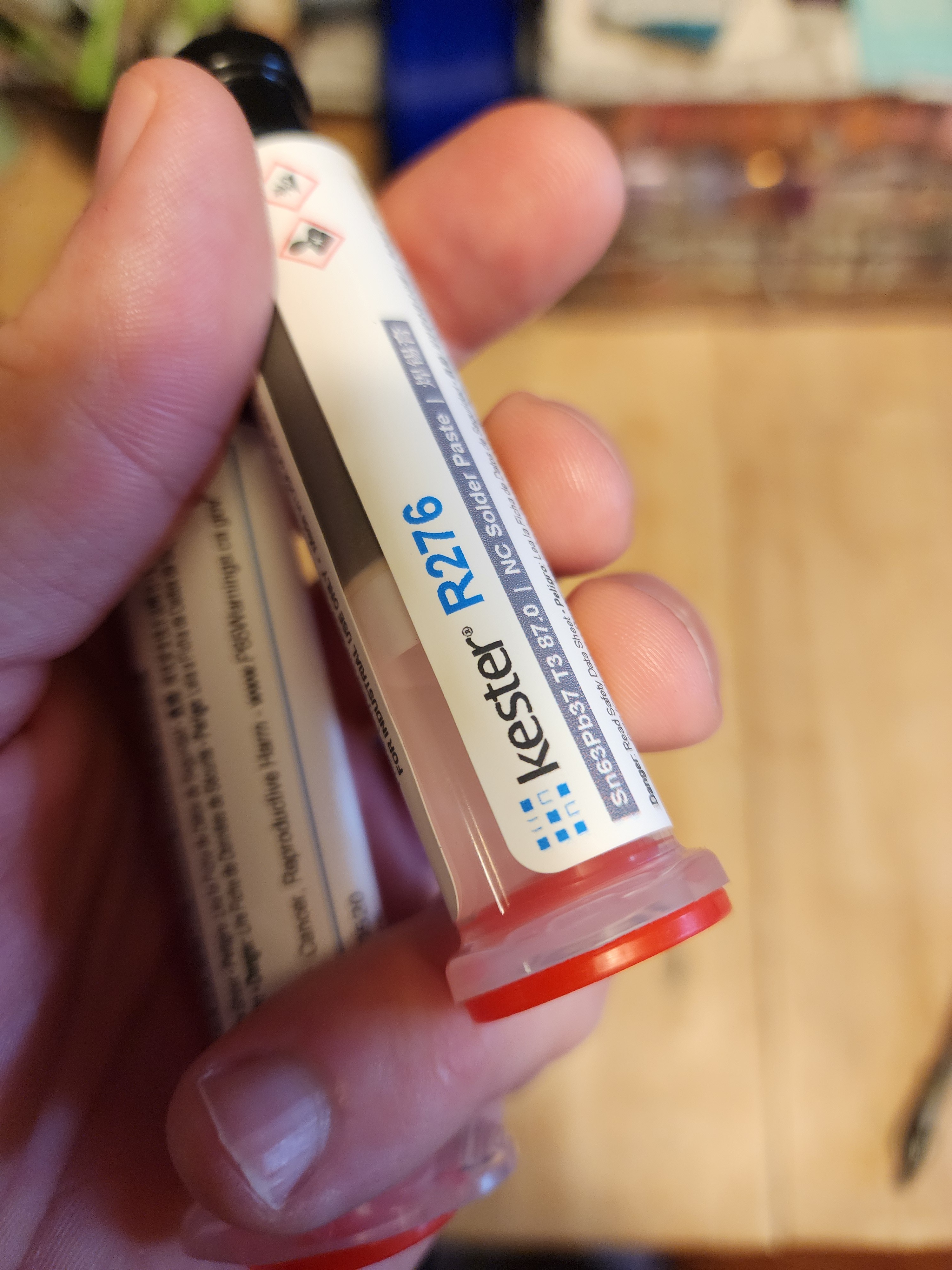

For anyone who is curious this was the paste I ended up using. I decided on going Pb because of the overall ease to work with combined with no long term risk of tin whiskers

So next thing I use a plastic gift card as a spreader and ... well let the results speak for themselves....

So next thing I use a plastic gift card as a spreader and ... well let the results speak for themselves....

So the next optimization was to not be picking things from the reels so I used these tiny SMD boxes so I could pick the parts out quickly with tweezers.

So the next part is just using air and such to reflow these parts after I have placed them by hand onto the PCB.

And boom!

In conclusion get a solder stencil and good paste of you want to try to do any volume production. The time per board went from 8 hours to just over 1 in my case. I hope you all learned something and enjoyed the read.

Portland.HODL

Portland.HODL

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.