The requirements for this project are fairly unique. It needs to be a very small motor with precise motion at low speeds while still maintaining decent torque in not that high of cost or weight. More specifically:

- Size: To scale with, say, a LEGO character and fit horizontally on a hot wheels track. <10mm in height and < 30mm in width including wheels.

- Torque: Needs to lift 4-5 LEGO characters at 3g each, some 3D printed cars (5g?), a battery (6-8g for 10x30 LIC), and the motor itself.

- Speed: 100cm / sec max speed, but ideally even faster if someone wants to emulate a "Hot Wheels" speed.

- Cost: Ideally under $5 for the powertrain, direct from the factory in quantity

Sounds impossible, right?! Turns out there are a number of options still, let's go through them!

Continuous servo-style motor

I've seen cheap brushed DC motors with gearboxes and encoders that are small and cheap. Here is an FS90 from Adafruit (https://www.adafruit.com/product/2442): A similar style was pursued by the Anki Drive team for their sort of similar toy car project (more like slot car racing), with brushed motors, a bevel gear and magnetic sensors. Here's a picture from the excellent teardown by Lee Teschler: https://www.microcontrollertips.com/teardown-inside-anki-overdrive-racecar-set/

A similar style was pursued by the Anki Drive team for their sort of similar toy car project (more like slot car racing), with brushed motors, a bevel gear and magnetic sensors. Here's a picture from the excellent teardown by Lee Teschler: https://www.microcontrollertips.com/teardown-inside-anki-overdrive-racecar-set/

Some positives include low cost and less power draw. The brushes on the motors should be able to last long enough for a toy too.

However, there are some downsides!

- There's a tendency for cheap plastic gearboxes to be "squeaky", like this video, even when new. I want to avoid that!

- I'm not confident I can get high torque at low speeds while still getting high speeds. All while getting precise motion too (requires good PID tuning)! One way to put it is I don't know what the "dynamic range" of a brushed motor is. Thoughts?

Stepper Motors

By outsourcing the "switching" brush mechanism to a microcontroller, brushless motors increase the resolution of the steps they are able to make at the turning level, no gearbox or feedback needed!

These types of motors are all over the place, but importantly still made cheaply ($1) in small electronic devices like DVD drives and cameras with zoom lenses.

I had the opportunity on a vacation trip to Shenzhen to visit a few factories, and was able to go to a motor factory that made stepper motors among other things. They bothered to film me looking at things and asking questions, did a tea ceremony, and took me out to eat afterwards and made a video! It was flattering for just a guy with an idea, but maybe that was the point too!

Aaanyways, among lots of other learnings I took away some key points:

- The yield for 8mm diameter and below stepper motors is not great, so the prices start increasing a lot. Better to go with 10mm stepper motors and higher.

- While some steps in the factory are automatic, others are manual. They were tinning the motor pins into a solder bowl by hand! It varies from factory to factory, which interestingly makes some more flexible / lower MOQ than others.

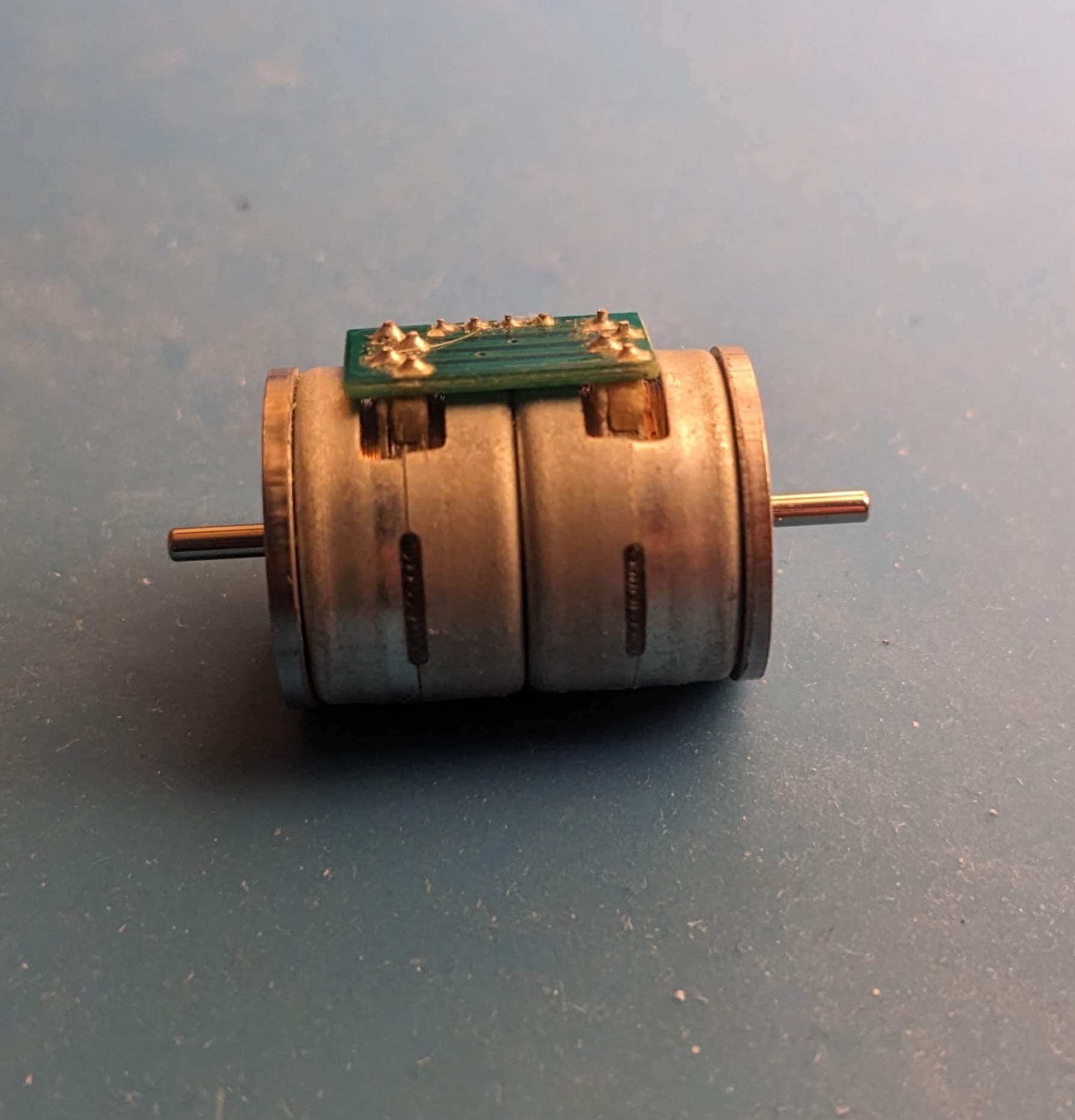

- They gave me a great idea to use a dual stepper motor design with a common shaft. Since I am riding on a Hot Wheels-style track, I don't think I need independent motor speeds and I get double the torque and a mechanical design more robust to dropping. He even gave me one to take home!

- I got the datasheets for a 10mm variant of one of these motors (not double sided).

- Torque: Up to 20 gf.cm of torque per motor at standstill (while gulping down 200mA of current). Assuming a wheel size around 13mm and a weight of 5g each, the total torque requirement above is ~31 g/cm of torque, including two motors. 31 < 40 with a good margin, so we're good!

- Speed: 2400 rpm, which with a 13mm wheel gives a top speed of 163 cm / sec. Not bad!

- Cost: One motor is 6rmb, so probably 15 rmb for two together = $2. Great!

- The owner emphasized the importance of good bonding (UV cure resin of some kind) between the motor and the PCB and to not rely on the solder connections. He was willing to accept some prototype PCBs sent to him and have someone solder and glue the motors properly.

Brushless DC Motors

While intuitively they look the same as stepper motors, they have conflicting design constraints around speed and torque, documented well here: https://electronics.stackexchange.com/questions/79498/difference-between-brushless-motor-and-stepper-motor

Practically I haven't found small off-the-shelf brushless motors that are also cheap, small, and made in quantity, so I haven't pursued this option that much.

Nolan Hergert

Nolan Hergert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Thanks! Looking forward to trying out the options. I updated the post with some more information, but trying out a stepper motor is pretty enticing at the moment. I have to prove out the other parts of the project first though. We'll see!

Are you sure? yes | no

Probably good to look at what others doe

https://hackaday.com/tag/tiny-robots/

Are you sure? yes | no

Did you look at dynamical range? Xc330 for example.

Or k-power (cheaper )

Are you sure? yes | no

Hi zoxoxu, thanks for asking! It looks like those servos start at around $10 and are pretty bulky, relative to my option of a double-sided 10mm stepper which is under $5 and is about 10mmx20mm. I'm pursuing a stepper for now, but might switch back in the future if it turns out to not be effective.

Are you sure? yes | no

One thing that I love about the dynamixel range is their control board, daisy chain, quality protocol, precision and robust PID.

If you ever go back to DC motor, normal tiny RC servo for exemple, you can take the control board from the dynamixel and replace the one from the RC servo, it's a little Frankenstein but will give you the accuracy and will reduce a lot the noise because the pid doesn't oscillate when it reach position due to a better quality sensor without so much electrical noise.

Also saw someone making a tiny robot arm with RC servo and custom control board recently on here.

Don't underestimate the importance of the control system, size, resolution,...

And try to characterise what you need, torque/speed, even if it's an estimation. You will quickly rule out a lote of option.

Are you sure? yes | no