Toby's Automatic MCH PD Reflow Hotplate

(tindie, git-imuslab, hackster.io, CH554 SDCC)

_q6p7kiQ4lw.png?auto=compress%2Cformat&w=830&h=466.875&fit=min&dpr=1.5)

A USB-PD powered metal ceramic heater (MCH) based reflow hotplate.

Key Features:

- USB-PD

- MCH

- Fully automatic (and any changes requires reprogramming the IC)

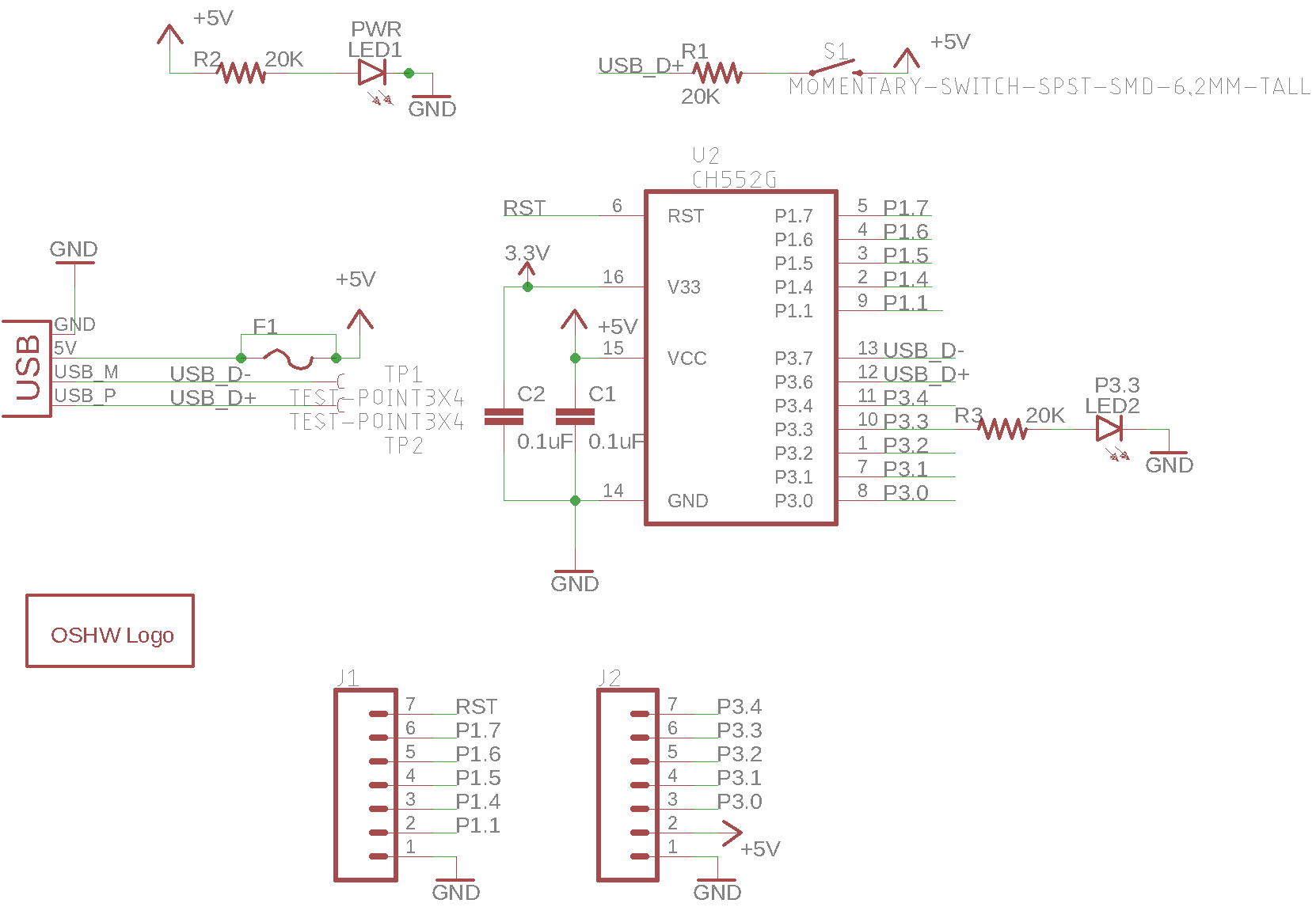

System Info

| Controller | CH552G (Arduino Programmable) |

| Power Input | USB PD 20V 3A (60W / 65W PD power supply recommended |

| Interface | 1 button Press and hold to start |

| Profile Change | reprogram over USB |

| Cooling | no |

Hotplate

| Hotplate Type | MCH (Metal Ceramic Heater) |

| Hotplate Size | 40mm * 40mm (± 1mm) |

| Hotplate Power Consumption | 30..50W |

Temperature Sensor

| Temperature Sensor | 100k 1% Thermistor (example, datasheet) |

| Temperature Sensor (Controller) | ADC on-board MCU (8bit) |

Components

- CH552G

- 8bit MCU (16pin)

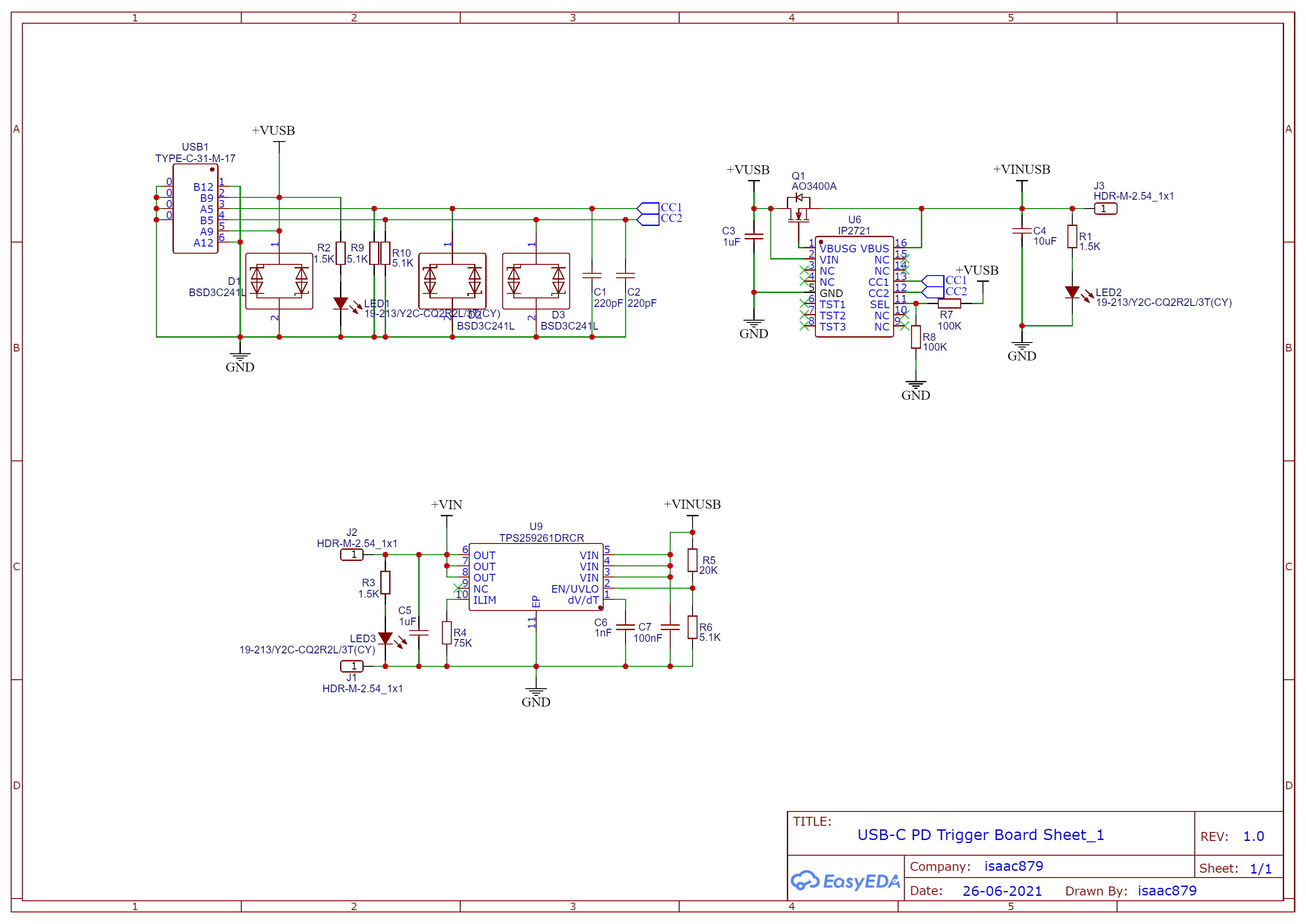

- IP2721

- USB-C/PD physical layer IC (datasheet)

- TPS259261

- 12V eFuse protection switch

- AO3400A

- n-channel MOSFET 30V 5.7A 1.4W

Connectors

- 4p (2x2) 100mil "PROG1"

- 2p 100mil "SENSOR"

- 2p screw terminal 5.00mm

- 3p 100mil

ICs Not Shown

Unlisted part

- 2-wire 100k 1% Thermistor

- with 1k at 240° and a 100k NTC at 25° (utils.ino) --> Beta ~4000

![IP2721 schematic IP2721 schematic]()

Toby's Automatic MCH PD Reflow Hotplate IP2721 schematic

Solder-Reflow-Plate by AfterEarth

A 12V barrel jack powered PCB hotplate.

Key Features:

- PCB heater

- OLED display

System Info

| Controller | ATmega4809 (Arduino) |

| Power Input | 12V 5A Barrel jack |

| Interface | 2 pushbuttons and OLED |

| Profile Change | pushbuttons (select Zone temperatures) |

| Cooling | no. Temperature is displayed during cooling |

Hotplate

| Hotplate Type | PCB trace resistors |

| Hotplate Size | 70mm * 50mm (± 1mm) |

| Hotplate Power Consumption | ~30W |

Temperature Sensor

| Temperature Sensor | LMT85LP (datasheet) |

| Temperature Sensor (Controller) | ADC on-board MCU (10bit) |

Note: the temperature range of the LMT85LP is limited to 150°C.

Devin

Devin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.