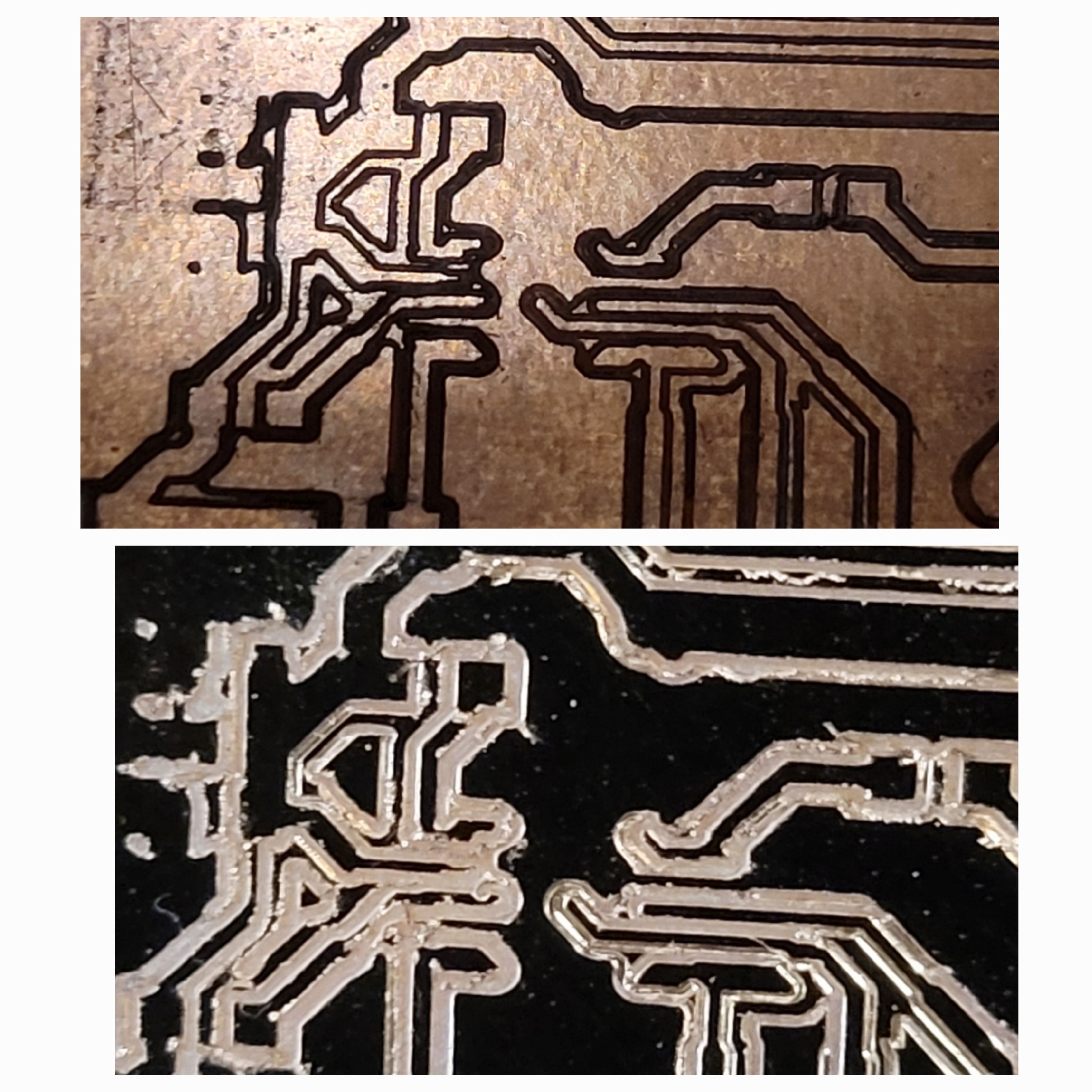

We already saw how to create 1mm pitch (distance between IC's terminals) once we want to get down to finer details it gets much harder. If the bit too high it will just scratch the surface. If bit to low it will make deep trace. Breaking fine details or even break the bit itself.

I already have CNC so something should be done with it. It does really good jobs until it comes to the final details.

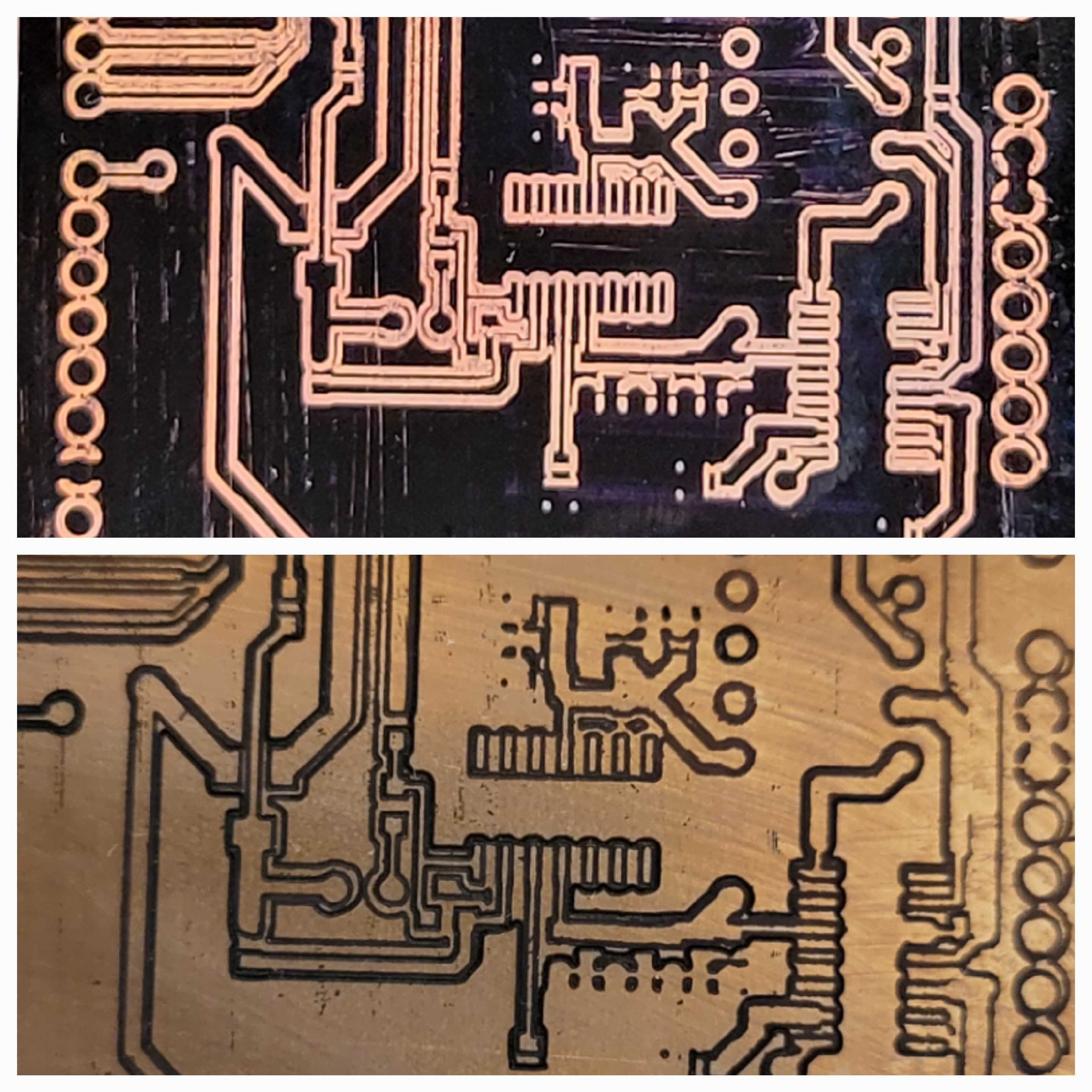

Then I got an idea what if we lift the bit a bit. And use chemical etching instead of milling. The result was really good relatively to just milling. But it still was not enough.

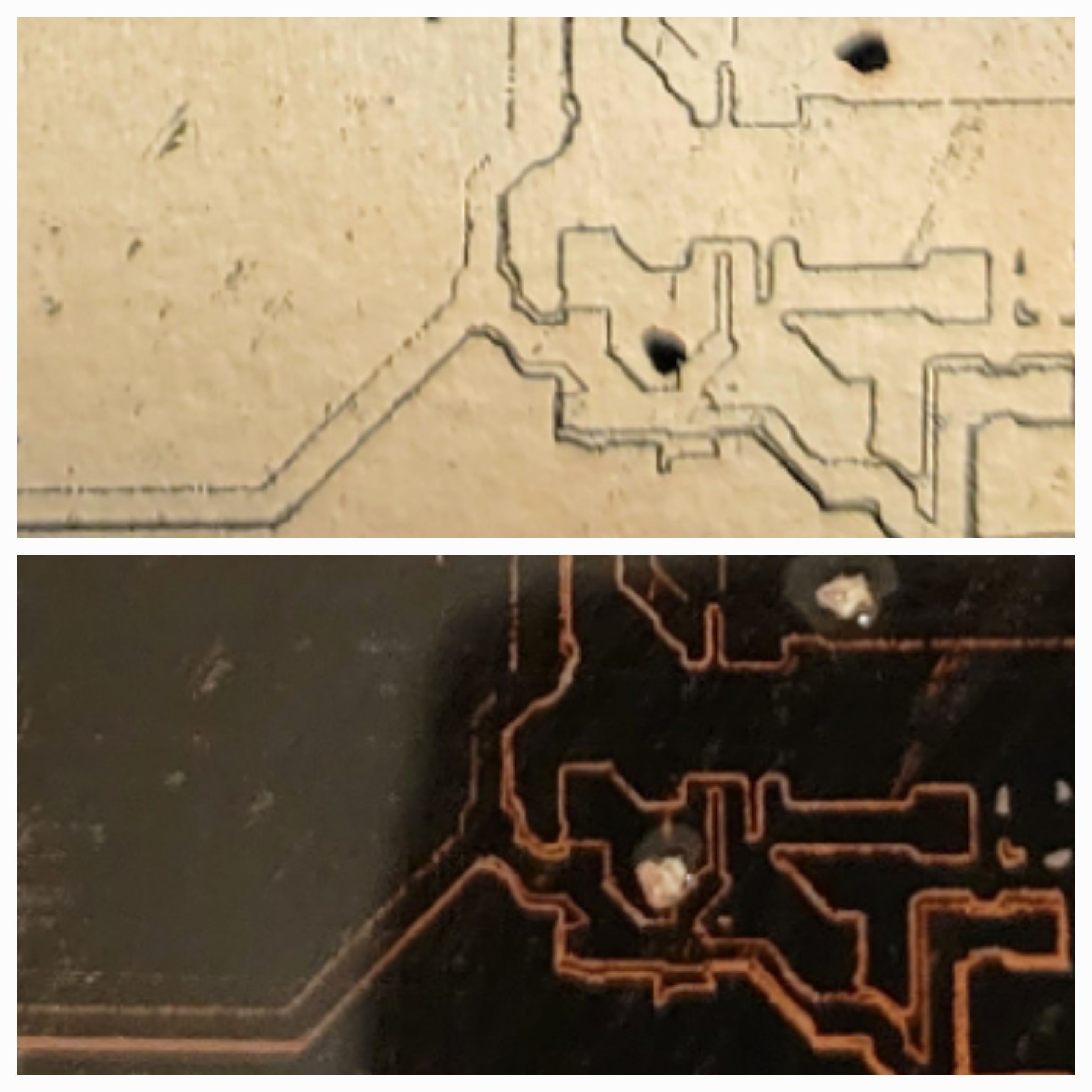

So I've just turned off CNC's motor and let the bit scratch painted surface.

The result was much better than I have ever seen.

Once I started to make full board the scratch method was not that good some places left not scratched as result wires has not been created.

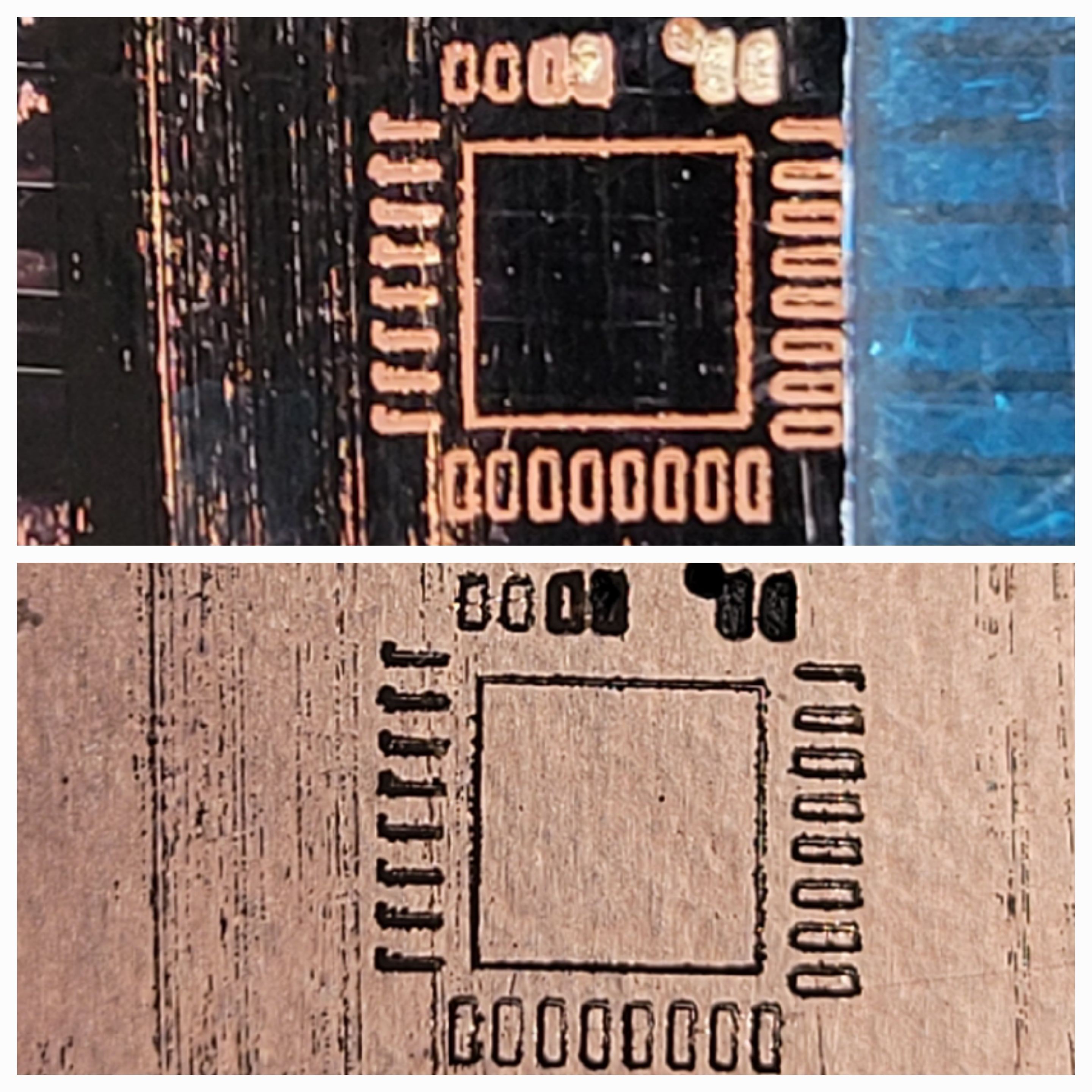

So, I went to the previous method but now instead of removing all the coper, I made just a gentle scratch of the surface. Then put it to Ferric Chloride for 10 minutes and Walla!! PCB for 0.5mm pitch ICs.

The method to create those board is simple:

* Make a height map of the copper board with distance of 5mm

* Paint the board with black non erasable marker

* Find a bit that makes tiniest scratch (of 0.1mm)

* Bring bit up and then start lowering the bit until surface scratched. This is done by lowering the bit by steps of 0.01mm and check if it started scratching.

* Reset current height as zero.

* Check 'use height' button (forgot it more than once)

* Press send button

After finish with CNC machine

* Lower the board to Ferric Chloride deluted solution of 1:4 FC to water.

*Leave it for 10 minutes

* Wash with water and clean with acetone to remove black coating

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hello dekitree64, thank you for sharing your video. It's much better than mine 😉 Although this method is great there are yet many problems with it. Scratching may break the PCB board, at least it happened with my CNC (mine is cheap 130$ Chinese 3018, not even pro version). You probably right it's the best way to do PCB boards. By the way great idea with the pegs. I got a feeling that something better can be made.

Are you sure? yes | no

Here is a good video about using a cheap tungsten scribe for scratching. More durable than V bits. https://www.youtube.com/watch?v=VN0X4jVp4XI

Are you sure? yes | no