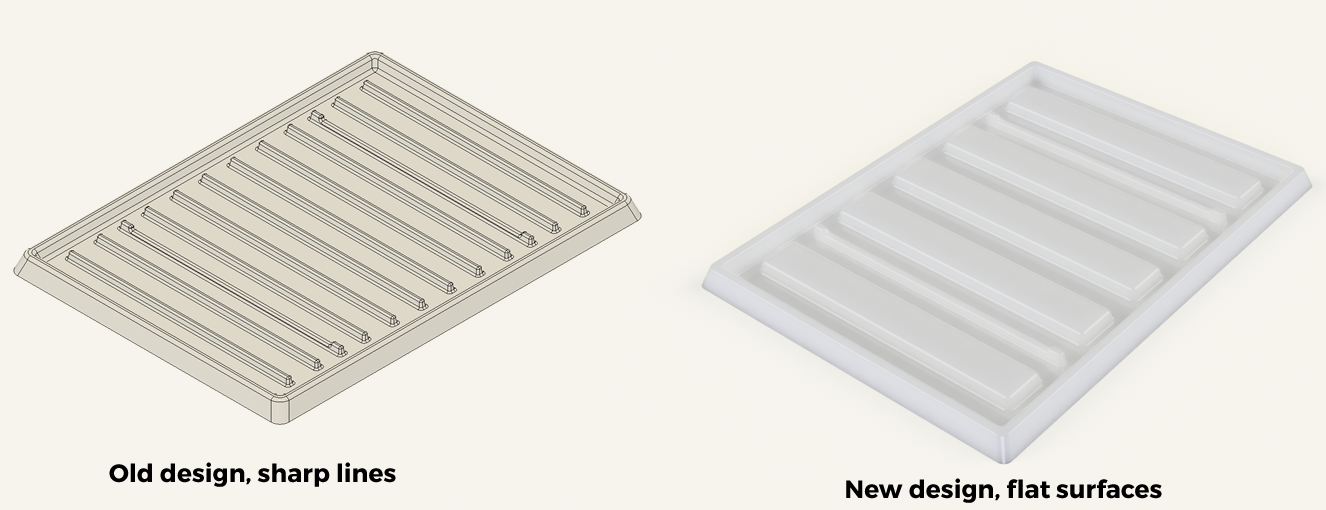

On Thursday I printed the first models of the soap dish plastic tray, and the 3D printing revealed that the top ribs were too sharp. They would "shave" a wet soap bar and create a lot of buildup and waste.

I redesigned it that very same evening, and on Friday I happily printed the new model, right?

Not.

I sent my print job and got down to business without checking in on the printer. What could go wrong? 20 minutes later the printer arms were moving like Toy Story's Baby Head Spider and molten, tangled PLA was all around the printer's nozzle. I did not realize it at the time but feeding a Rostock printer with GCode for a Bukito really messes things up. Do not try this at home kids.

Trey (https://hackaday.io/Tpweber17) and Metal (https://hackaday.io/Metal) helped me fix this mess and in no time I was printing again. Yes I double checked before leaving the printer alone. I will update more on this next week, as a few adjustments still need to be made.

The Dejlig products are made in plastic and wood, so the next step was getting familiarized with the CNC. Next week we'll work on it and I will show some of the progress.

gs

Giovanni

Giovanni

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.