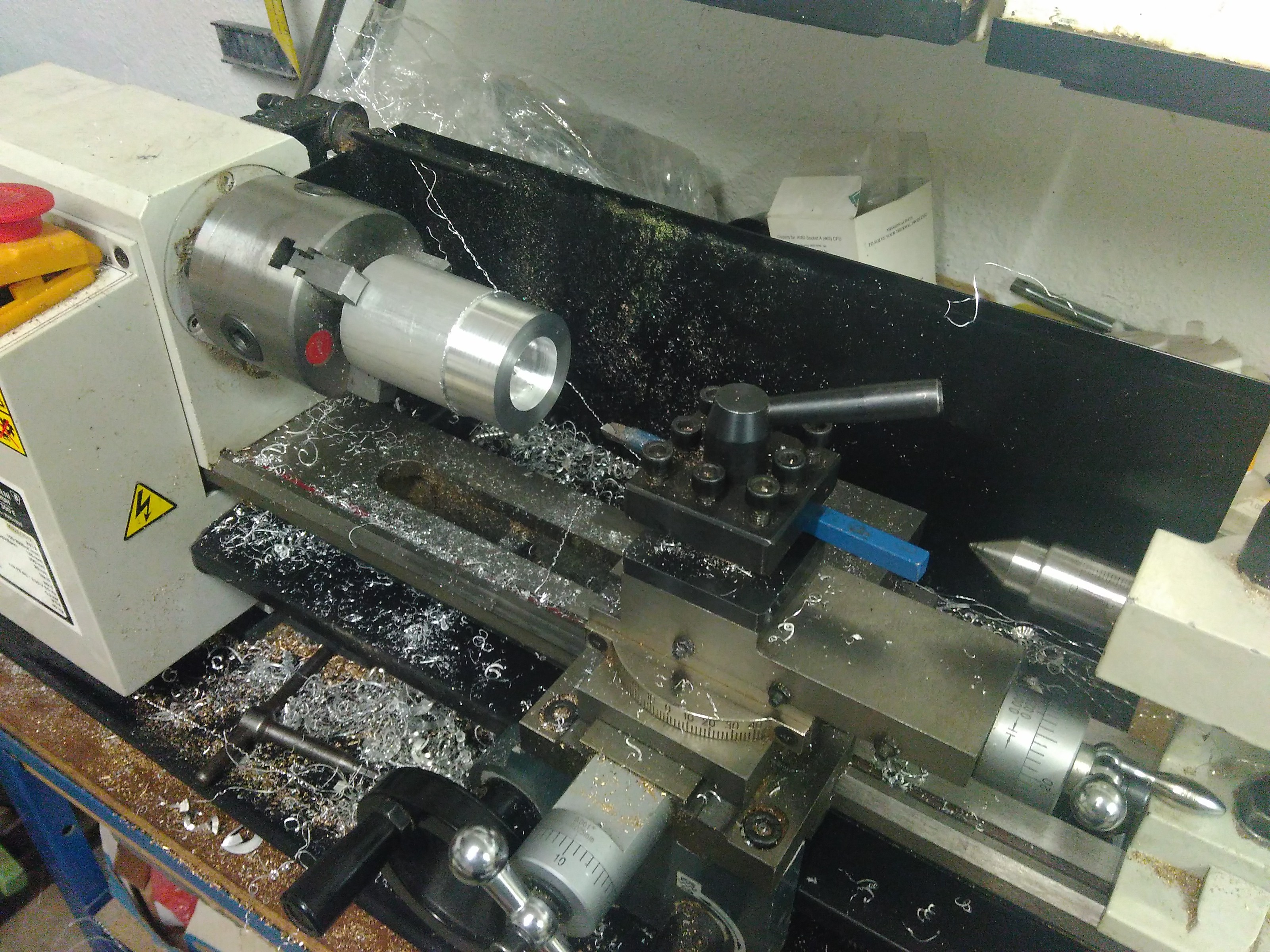

The mechanical work is mostly finished.

After few attempts, I was able to hard anodize the headlamp body at home and it looks quite well for the price! The process is quite simple, 30 seconds in 20% NaOH, washing, 45 minutes in 20% H2SO4 with current density about 2 A / dm^2, washing, 60 minutes in egg paint solution heated to 50°C and finally 1 hour in 90°C water. That's it. The final surface looks amazing and it's scratch resistant.

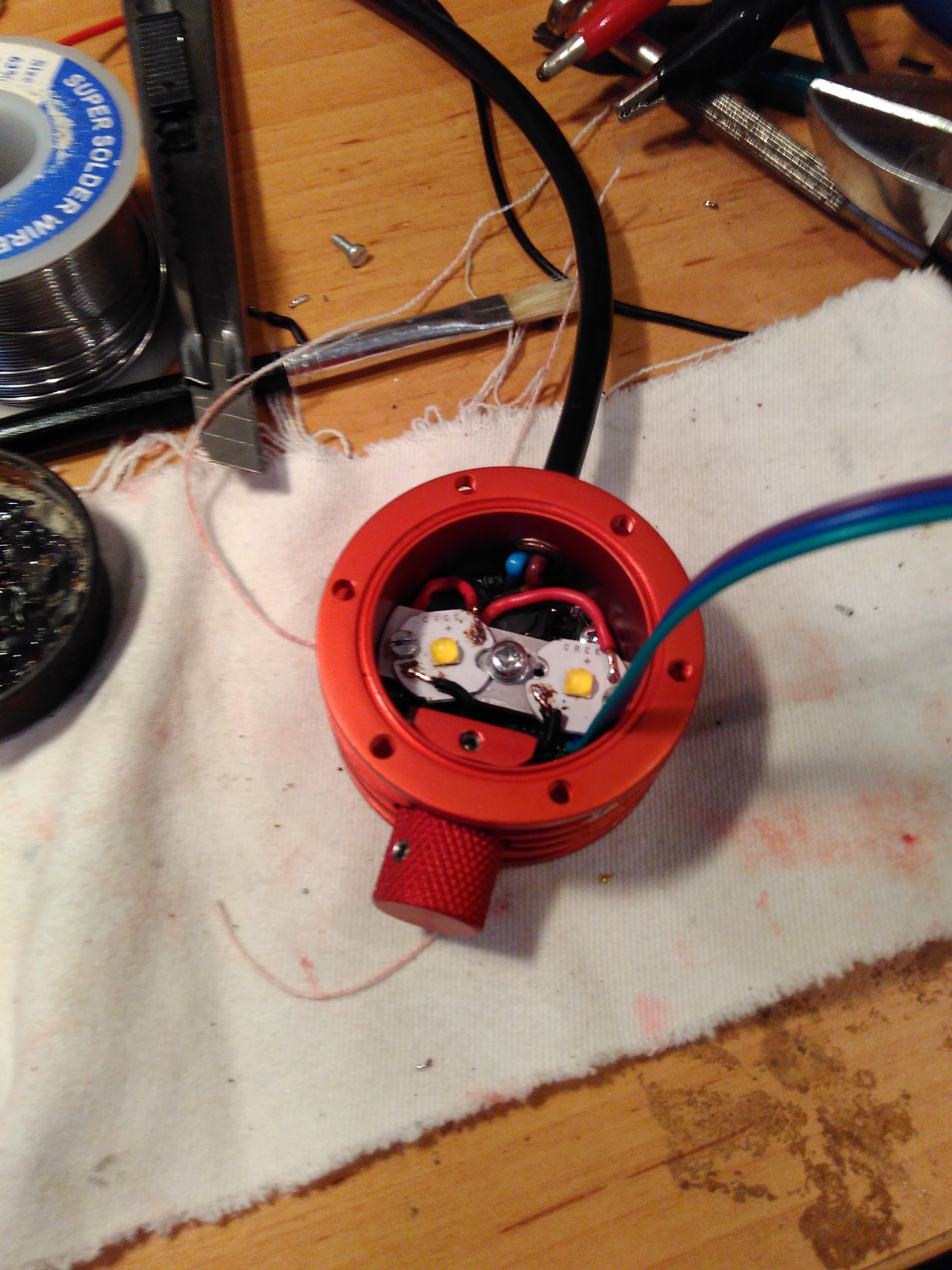

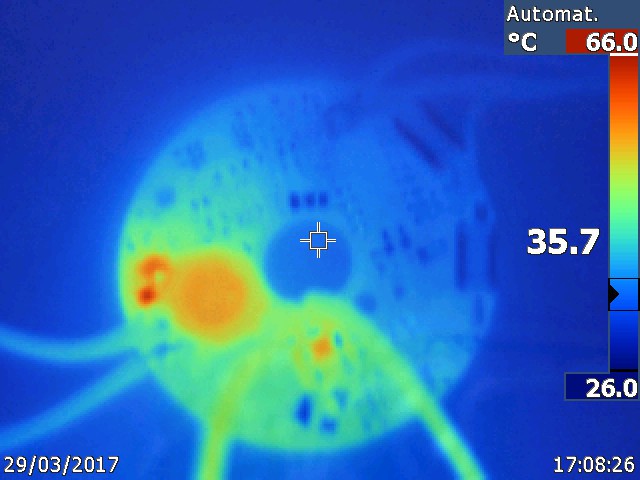

Also few electronic design tests were conducted. Under maximum operating voltage of 4,2 V and 2 A per LED the board behaves as expected. After 1 hour running on highest setting, the highest temperature measured was 66°C. That's for board placed on the table and room temperature of about 25°C. When sealed in the headlamp body, the temperature will rise higher, but I guess it won't go much over 90°C.

Jakub Kaderka

Jakub Kaderka

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.