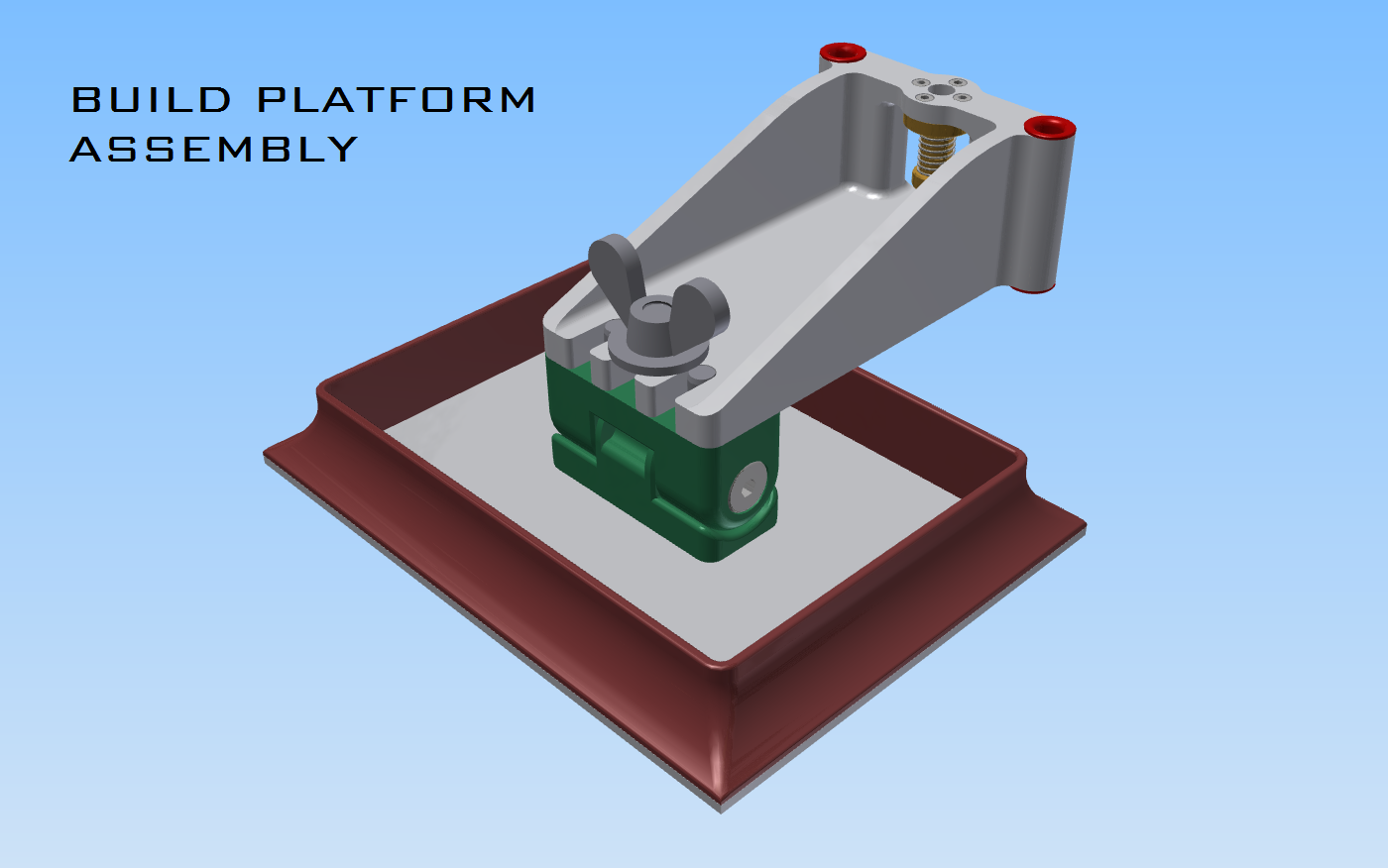

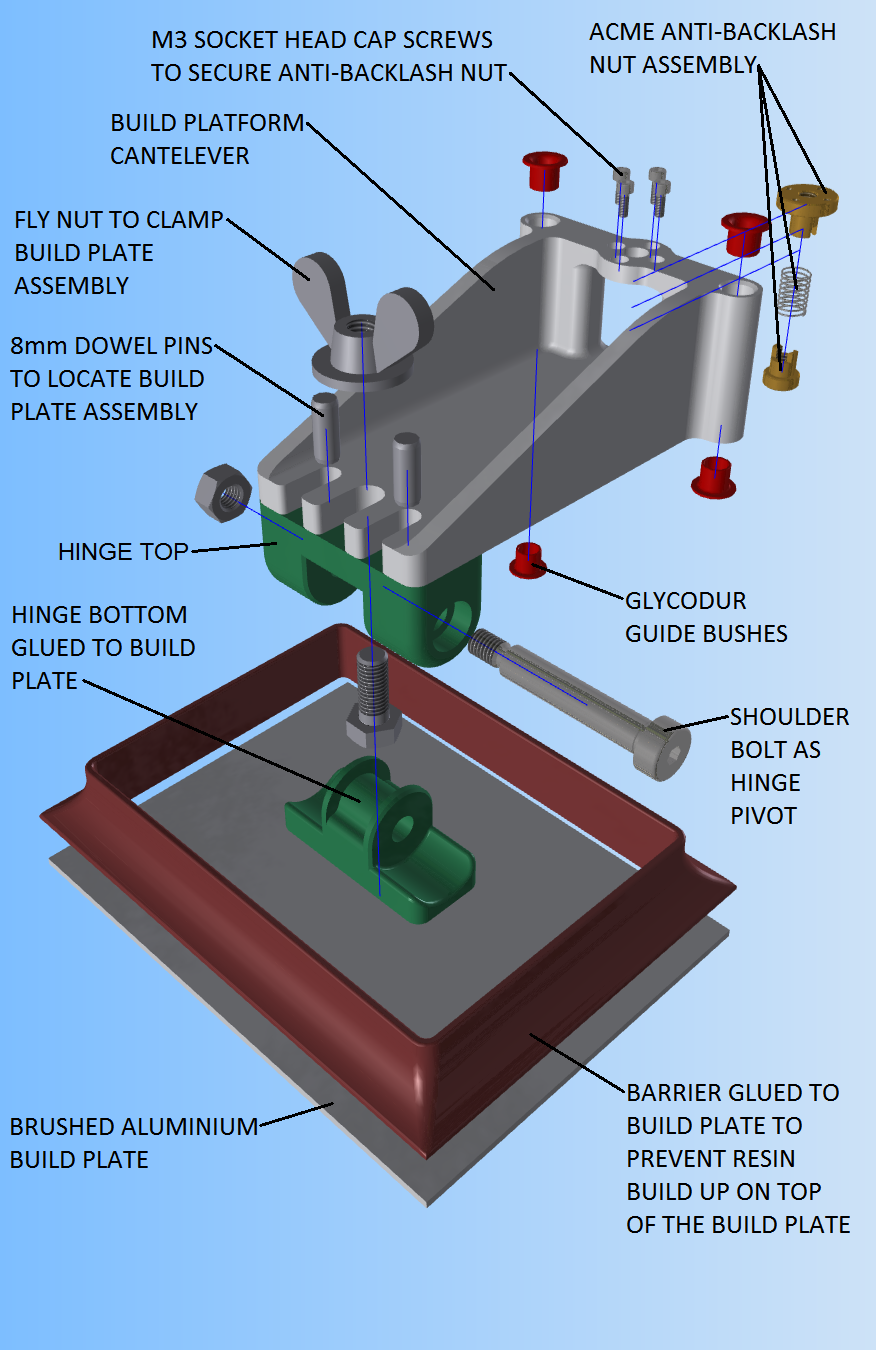

Most of the build platform assembly will be 3D printed by Shapeways or a similar service. This includes the resin barrier, both hinge elements and the cantilever arm. It would be fun to replicate these parts with the machine once the first iteration is built!

As can be seen above, the actual build platform is brushed aluminium plate. This is a light, durable material that the resin can adhere to and be removed from. Pockets underneath the hinge bottom and the resin barrier allow for them to be epoxy glued to the build platform.

The main function of the resin barrier is to prevent resin from pooling on top of the build platform as it raises out of the resin. Its secondary purpose is that of making the build plate more rigid.

The hinge is there to facilitate adjustment so that the plane of the build plate may be parallel with the plane of the LCD display. The pivot is a standard 10mm shoulder bolt.

The build plate, resin barrier and hinge make up the build platform assembly. The build platform assembly slides horizontally to and from the back of the machine so fasten and remove it from the machine. It locates in the cantilever arm via the 8mm dowel pins and then gets fastened by hand tightening the M10 fly nut.

The cantilever is guided up and down the guide shafts via the Glycodur bushes and is raised and lowered when the machine is in operation by the anti-backlash ACME nut.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.