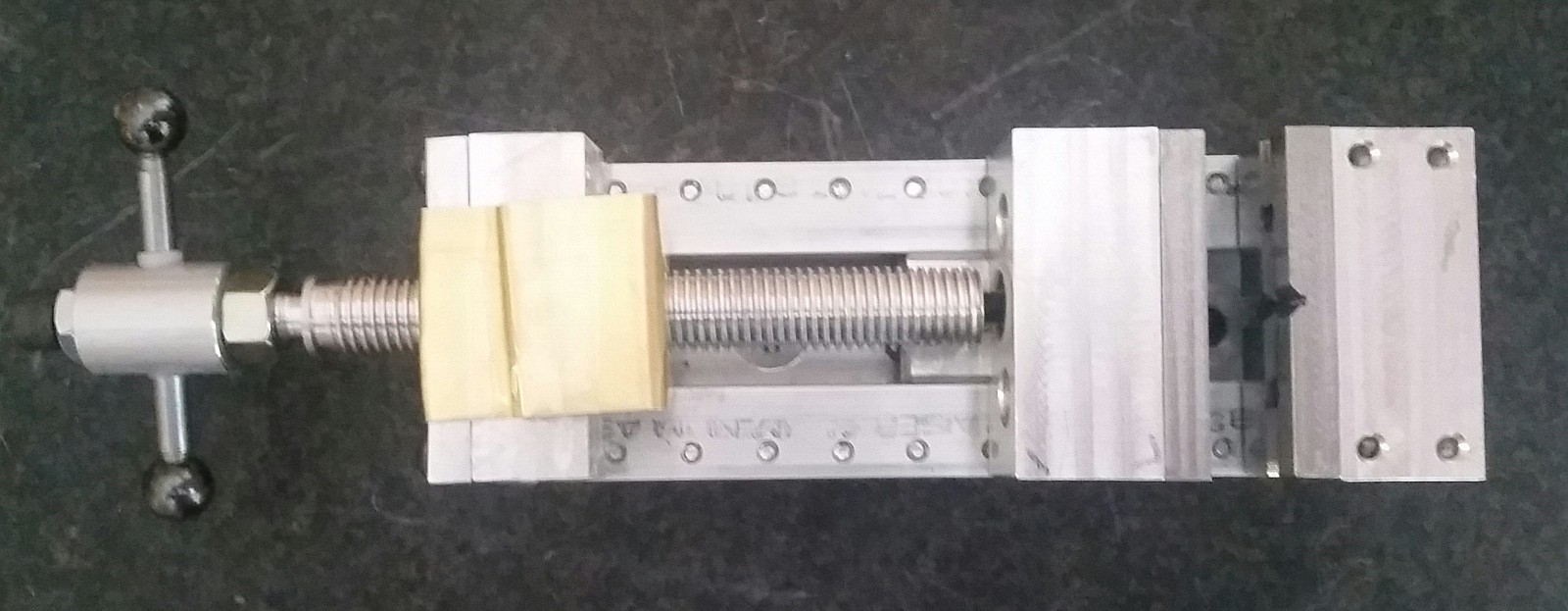

(update 2017-5-23) Here's prototype 2, (maybe 2.5) with the clean jack screw installed. The nut retention leaves a lot to be desired, it was hacked from piece of brass early morning in a hotel room. (yes, I cleaned up the little sharp nibblings.) Works pretty good! I can crank this as tight as I can without damaging the nut.

Something that may be useful to others... the little balls on the end of the crank are actually 0.625" diameter 1018 steel balls from mcmaster. They are case hardened, so I have to temper them down, turning them a blueish black in the process, to be able to drill and thread them. Attempting to drill hardened bearings w/o any annealing was a high density learning experience a few weeks ago. The blueish black (yeah the same sort of thing for "gunmetal blue finish" is coming from ferrite.. an iron oxide that forms at particular temperatures. (another project to be posted shortly uses this)

There's also a threaded ball used for a balljoint that links the jackscrew to the slider. I used 5/16-24TPI thread because it's nice and I have a good tap for it. All this stuff was made on the Smithy.

-------------

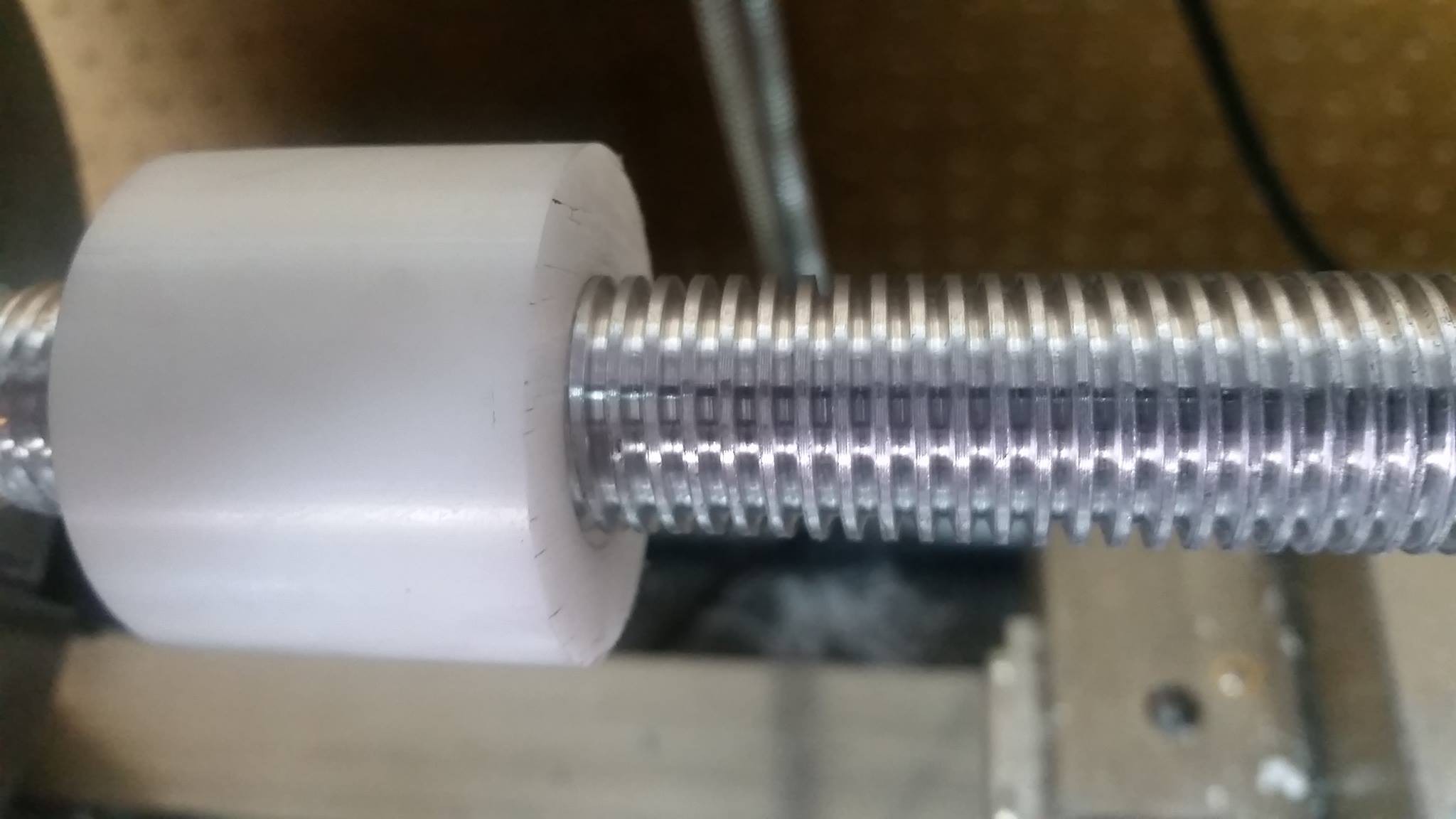

Aluminum jack screw and Delrin nut. 0.75 x 12 TPI. (I kinda copied my lathe's lead screw dimensions. There's also an awesome ACME thread calculator on http://www.engineersedge.com/hardware/acme-threads-calculator.htm that I used.

I wonder if the ACME thread would've got so popular without Wiley Coyote. Took a long time compared to what a 60deg thread would have taken me. But I think it'll be a much better system in the plastic than a 60 deg thread.

Everything I can prototype on the manual machine at home should be easy and cheap to make on a CNC mill and turning center. The aluminum will eventually be anodized.

Some day I want to get hold of a more torquey lathe. The lathe (and mill) I'm using is a Smithy "Granite" which I put a Chinese DRO on.

alex

alex

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.