Since for this project I need a very fine finish on the room facing enclosure piece – the one that goes into the Decora face plate – using a filament printer did not seem to be an option. So, it came down to Formlabs (or some other SLA printer) versus Shapeways.

The Shapeways path is easy but sort of slow and costly. Using the latest .stl file of the part, the price with shipping is $26.75 including delivery to California in 5-9 days

The Formlabs path at my local TechShop that has Form 2 was $ 15.70 for a 37ml print volume (including supports). Since I am lucky enough to live nearby, I can have the part same day at about half the price, assuming the Form 2 is available.

So, what is the quality difference?

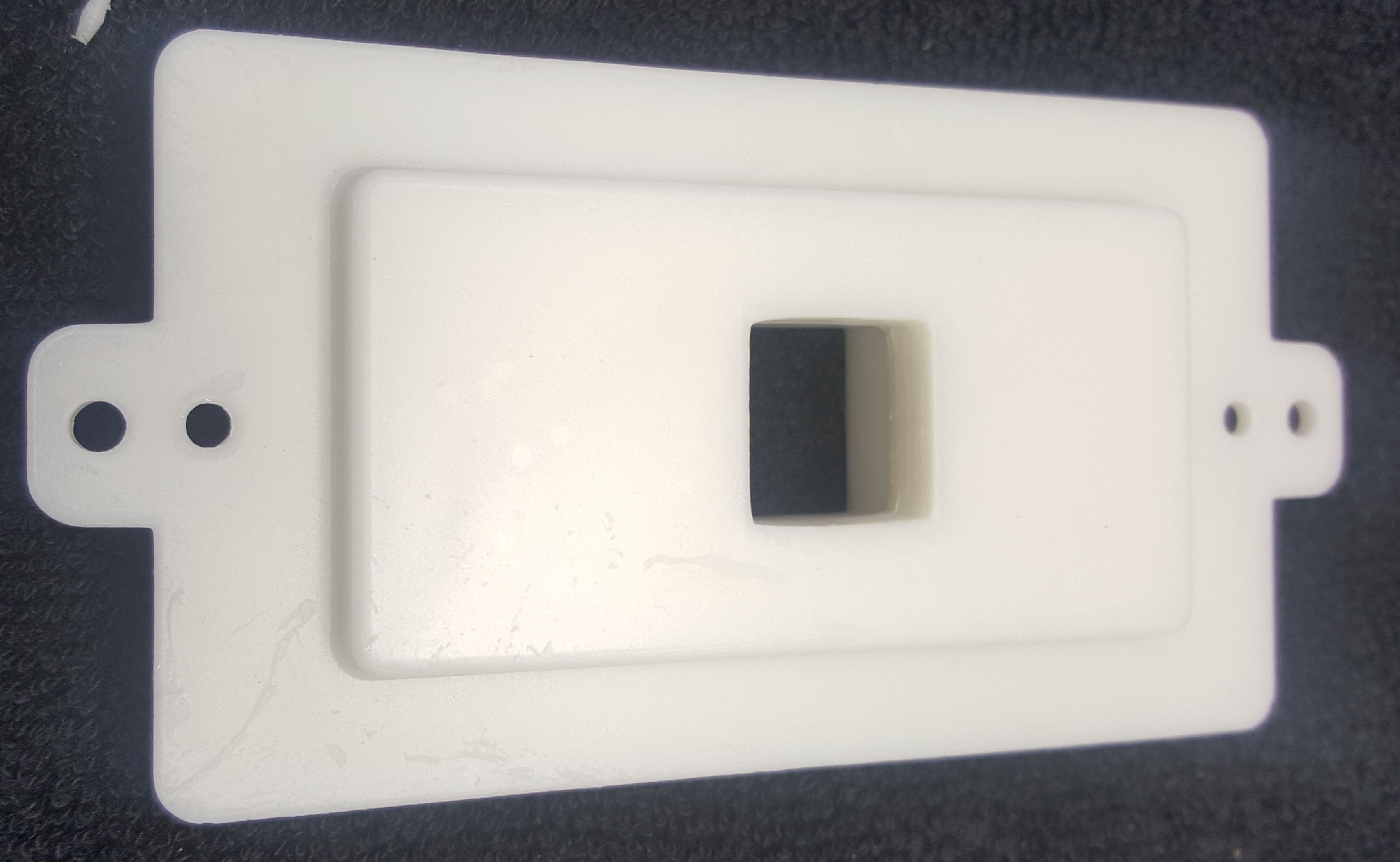

The Shapeways part is very good. I do not know what 3D printer they use but the quality is certainly good enough to look fine inside the Decora switch plate. Compared to the Formlabs, it is a slight touch grainy but looks perfectly fine.

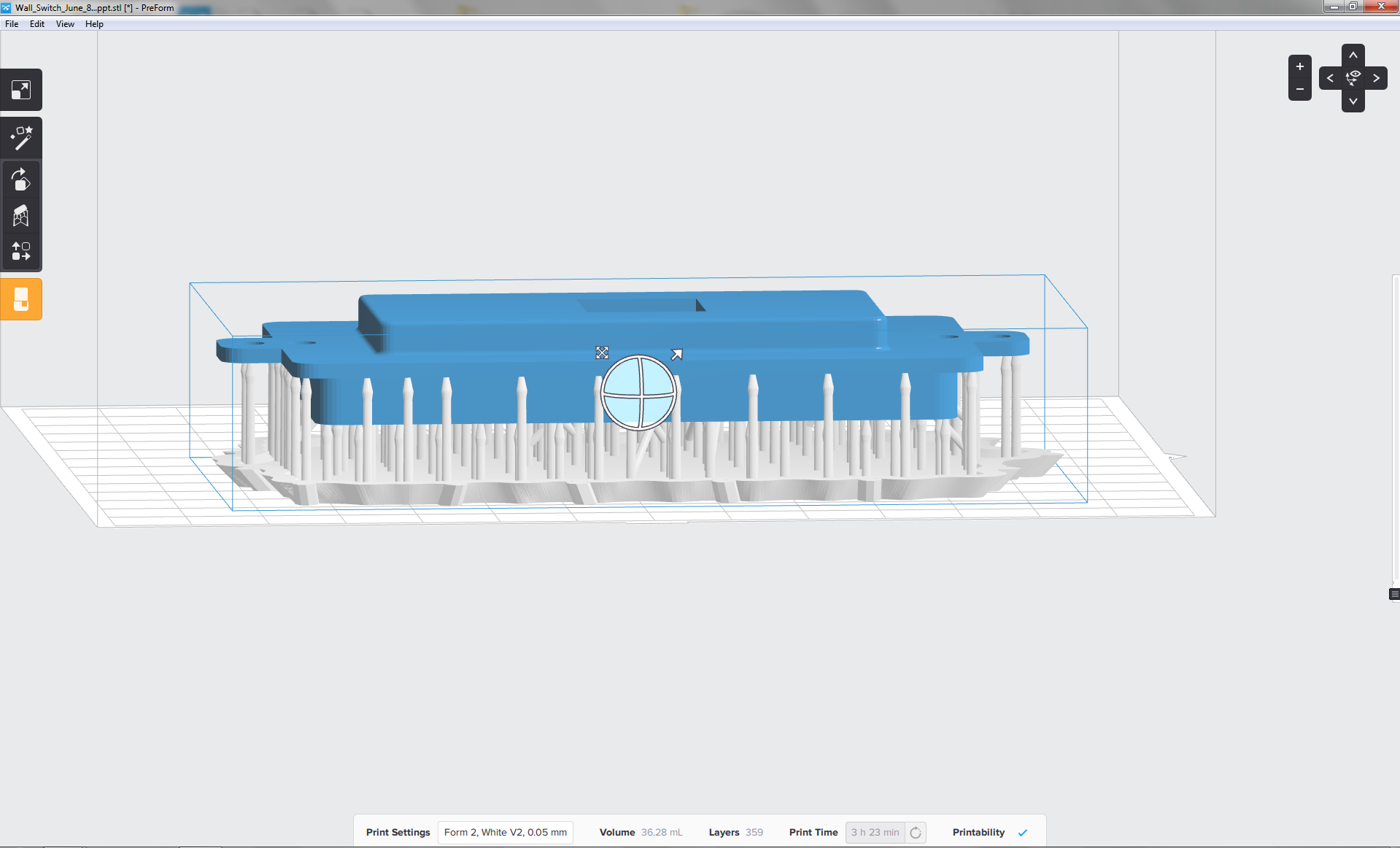

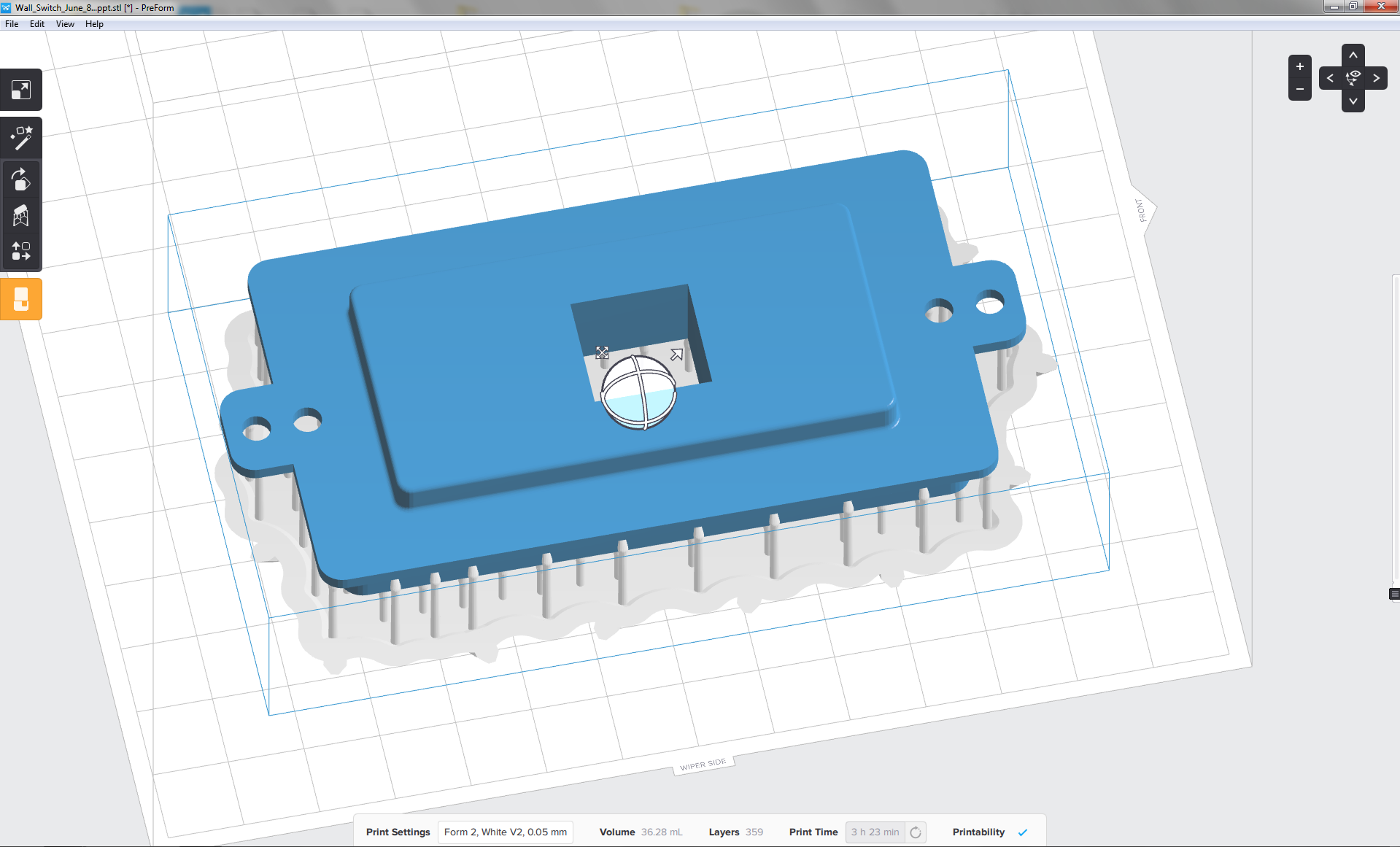

To print the part on the Form 2, the best way to proceed is to have the Form 2 slicer insert supports as seen below:

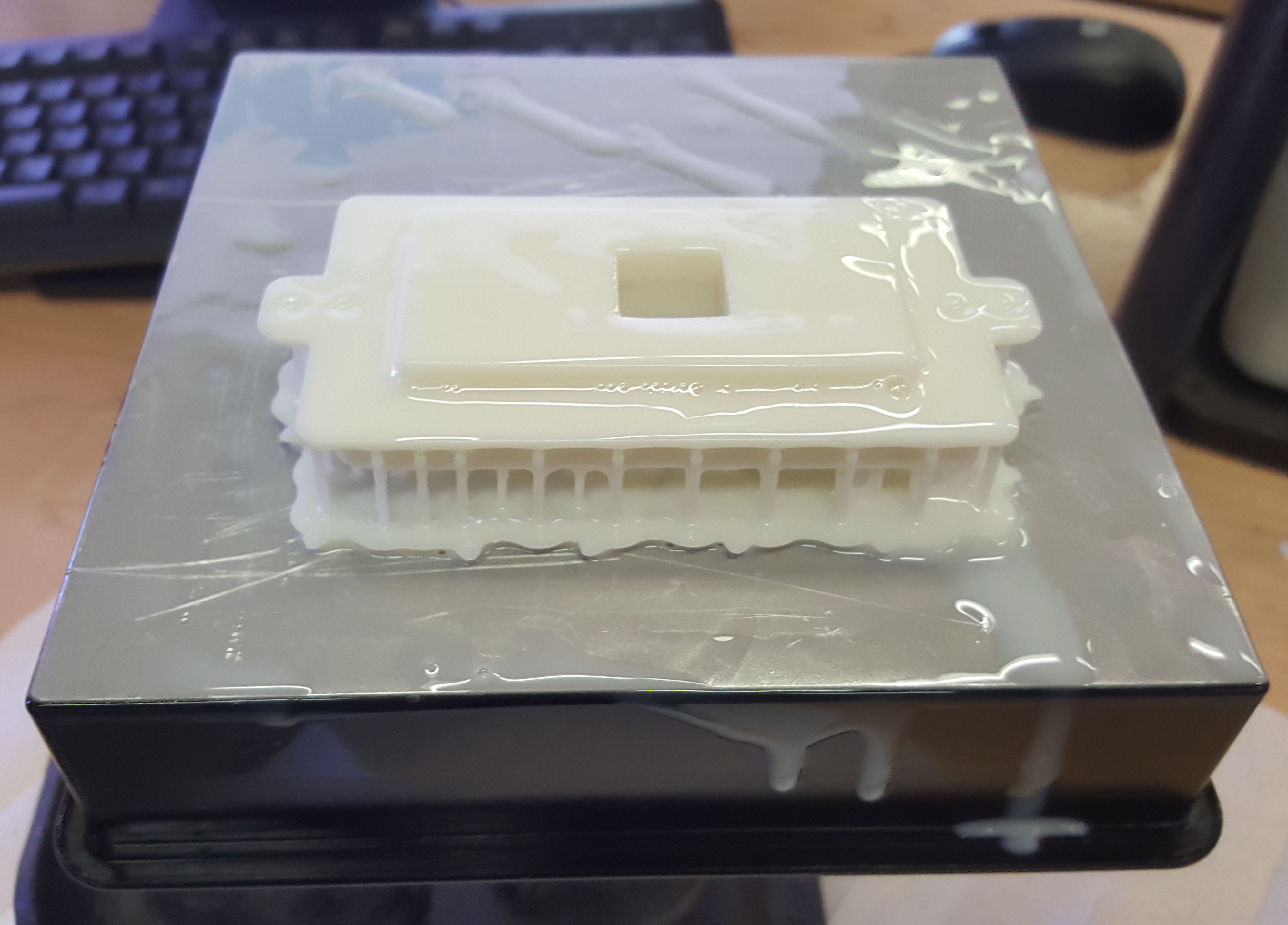

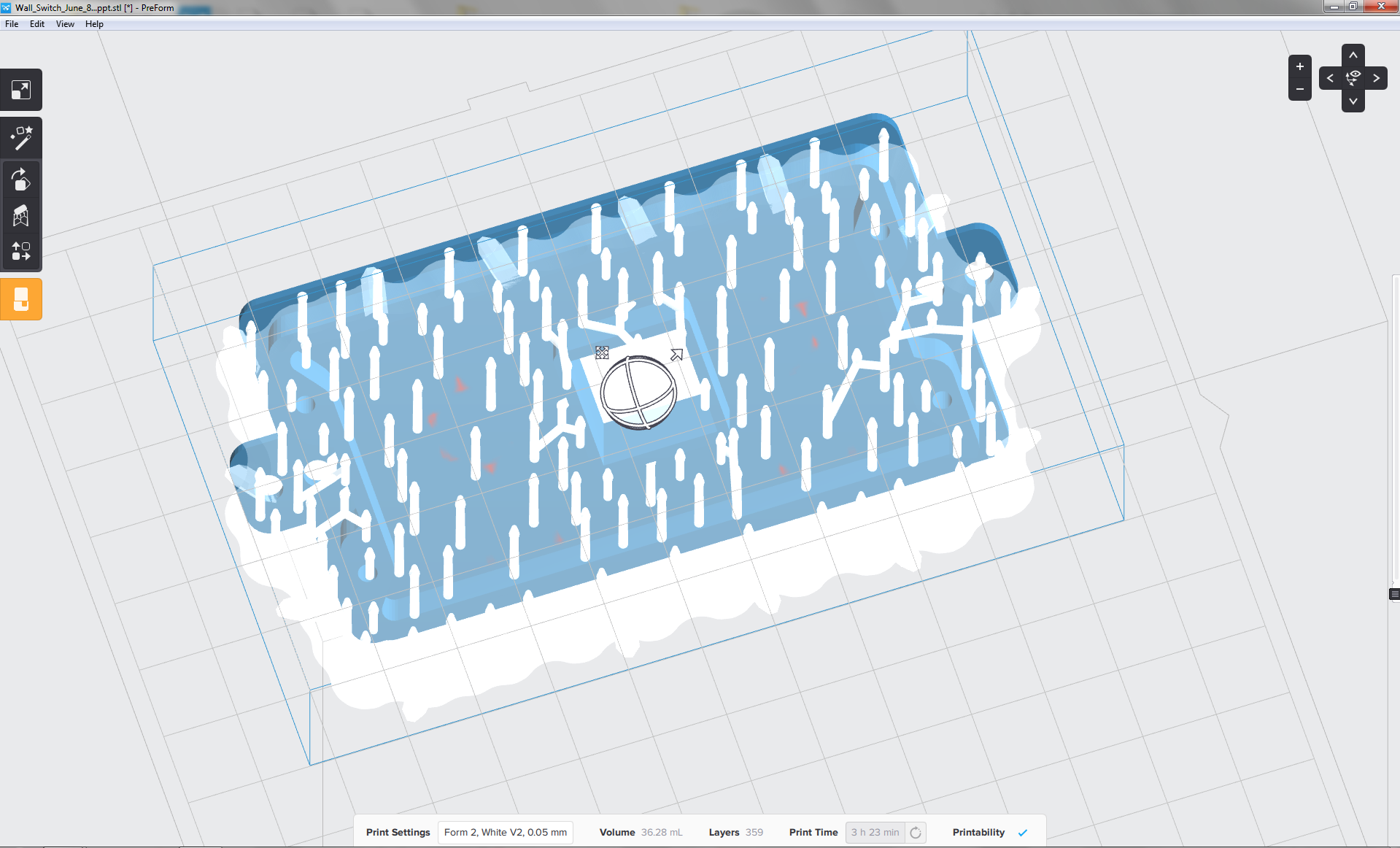

And this is how it comes out of the Form 2:

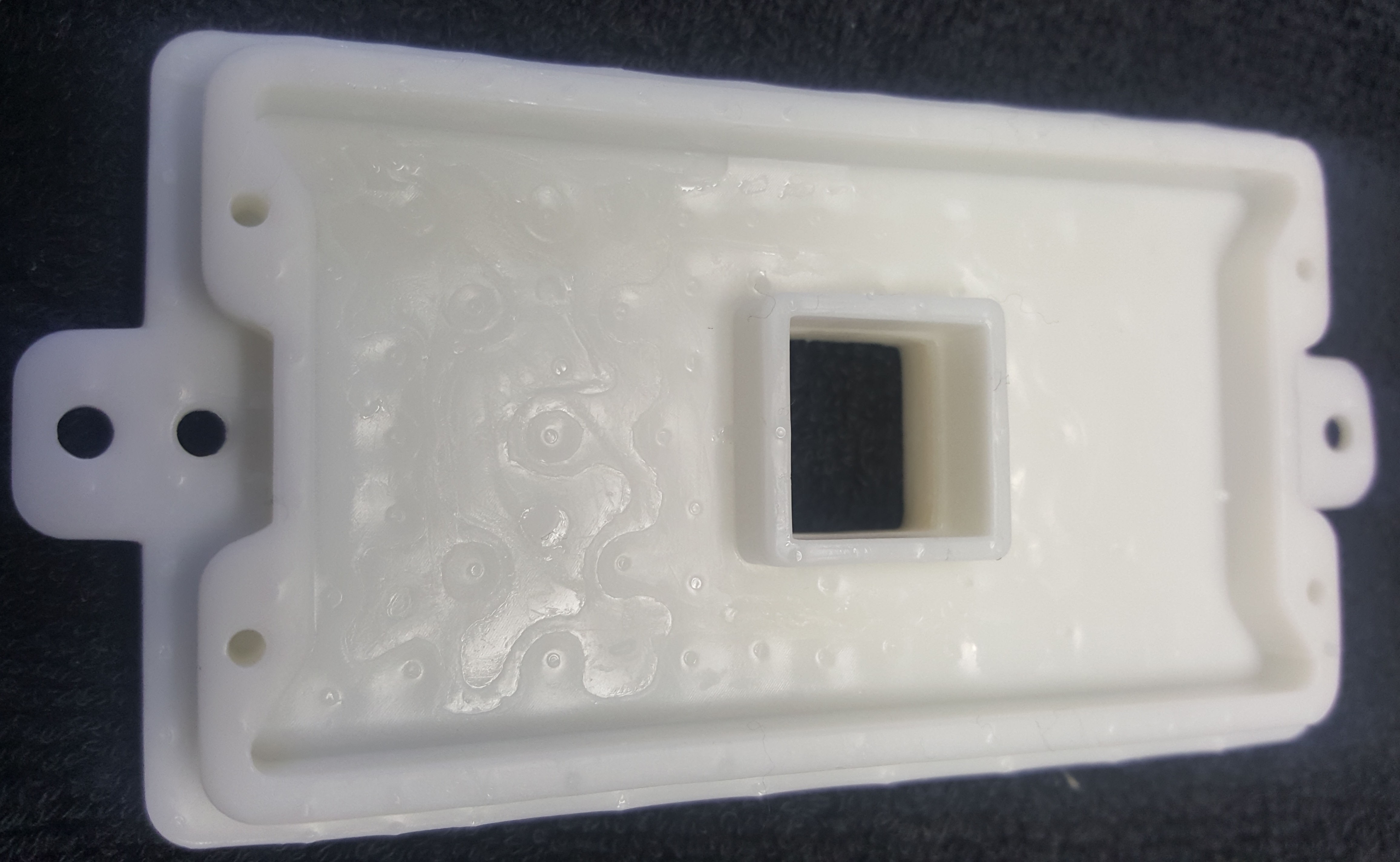

After trimming all the supports away, doing the alcohol bath for a couple hours, and final clean up, the quality of the print surface is outstanding. It looks injection molded.

On the side where print supports held up the part, there is a bit of dimple roughness from the supports. This is OK everywhere but on the surface of the side-walls where the PCB must mate to closely so there are no gaps in the front piece/PCB/back piece sandwich that makes up the assembly.

So, this piece will need a little filing to smooth it out. One other thing – it is slightly off white. The Shapeways part is slightly closer to the white of a Decora switch plate.

Note that if you bought yourself a Formlabs Form 2 (at the delivered and California taxed price of $3900), the cost would be 37ml out of 1L of resin. The cost of 1L of resin is $149. The cost of a build tank is $59, and they are good for 2 liters worth of resin, so half that is $29.50. Then there is California tax and shipping of $34.40. All told that comes to .037 x $210.91, or about $7.80 per part, with no fails. All of this assumes you have the prototyping need to use up the rest of the resin and the 2L build plate capacity. Beyond that, you will need to get even more resin if you want to use the remainder of the resin that is left in the resin tank because below a certain level, it is logically unusable. Say that amount is 50ml, that is 1/20th of a liter so you decide if you should factor that into the cost.

Finally, if you amortize the cost of the purchase of the Formlabs machine, and assume you will have a 2-year life of the machine, and in that 2-year period you will print, say, 500 parts, then the capital adder to the cost of each part can be approximated as $3900/500, or coincidentally another $7.80, for a cost-accounting based total of $15.60. TechShop calculates their costs precisely!

So, what do I recommend if you need a fine part? For me, I do not print hundreds of parts. If that is also you, I recommend printing your parts on a cheap filament printer that you own, or one at a nearby Makerspace, and iteratively refining the design across many trials. Once done, if you have TechShop or Makerspace nearby with a Formlabs printer, go there. If not, and you can afford the lag time, send it to Shapeways. If you print lots of fine parts and need them now, the Formlabs Form 2 can print outstanding parts but they come at high cost of acquisition and resin/resin tank supplies.

One last point – a 3D Hubs print on a Formlabs was in the $30-$70 range.

Joe Menard

Joe Menard

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.