Well, there went 8 months with no progress, sorry! Heading in a slightly new direction...read on.

I picked up some 4x4" aluminum bar stock from ALRECO with the intent of making a whole new head assembly to work with the Juki nozzle and longish quick change adapter from Betz Technik. Then I spent some time learning Fusion 360, then I got busy with...uhh, actual paying full time work. Gotta make hay while the sun shines.

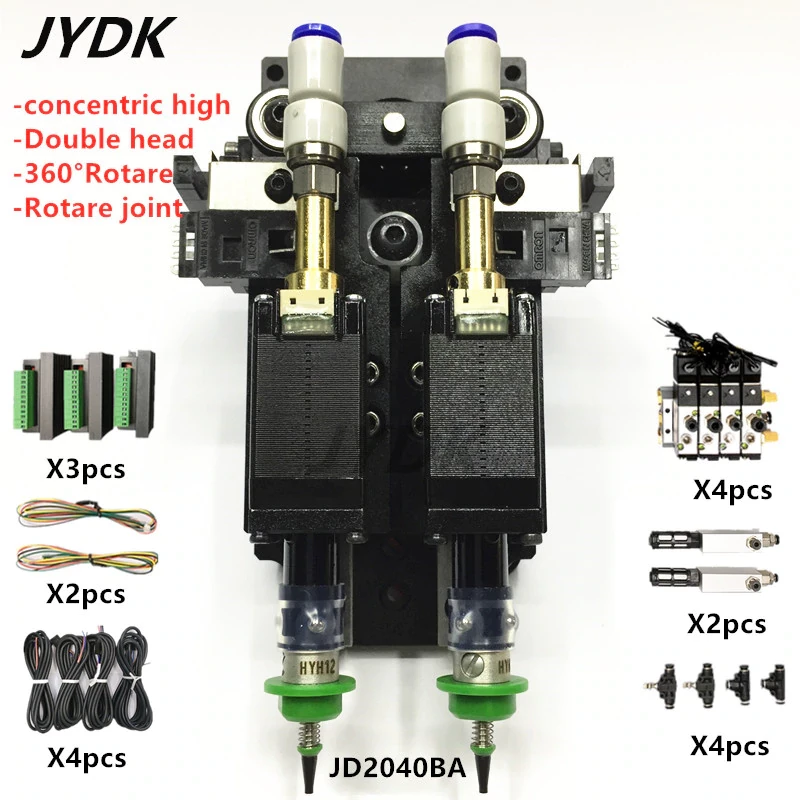

However, I just recently had a potential consulting client who desperately needed some SMT assembly work done, but couldn't say "yes" since the machine is disassembled. Re-inspired by the utility of having a working placer, I looked into buying a new head assembly with Juki nozzle support. I decided instead to buy a dual head assembly from AliExpress. I expect there will be some minor machining required to make it work, but nowhere near as ambitious as making the whole thing out of raw stock. The new head assembly will arrive around the end of September.

So now the to-do list looks like this:

- The nozzle adapters included with the new dual head don't appear to support quick change, so I have ordered a pair of spring-loaded Fuji quick change adapters from Betz Technik. That leaves the first one as a spare.

- Mount the new dual head assembly to the existing head block, replacing the original head and drag finger, and adapting the head block as needed to achieve the correct height for the quick-change adapters.

- Top camera - design and 3d print mount, and design or adapt an illuminator.

- Bottom camera - design and 3d print mount to work with existing illuminator.

- Juki nozzle quick change holder

- Visual pickup area or tray, for using top camera to pick from cut tape and loose parts.

dar.ryl

dar.ryl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.