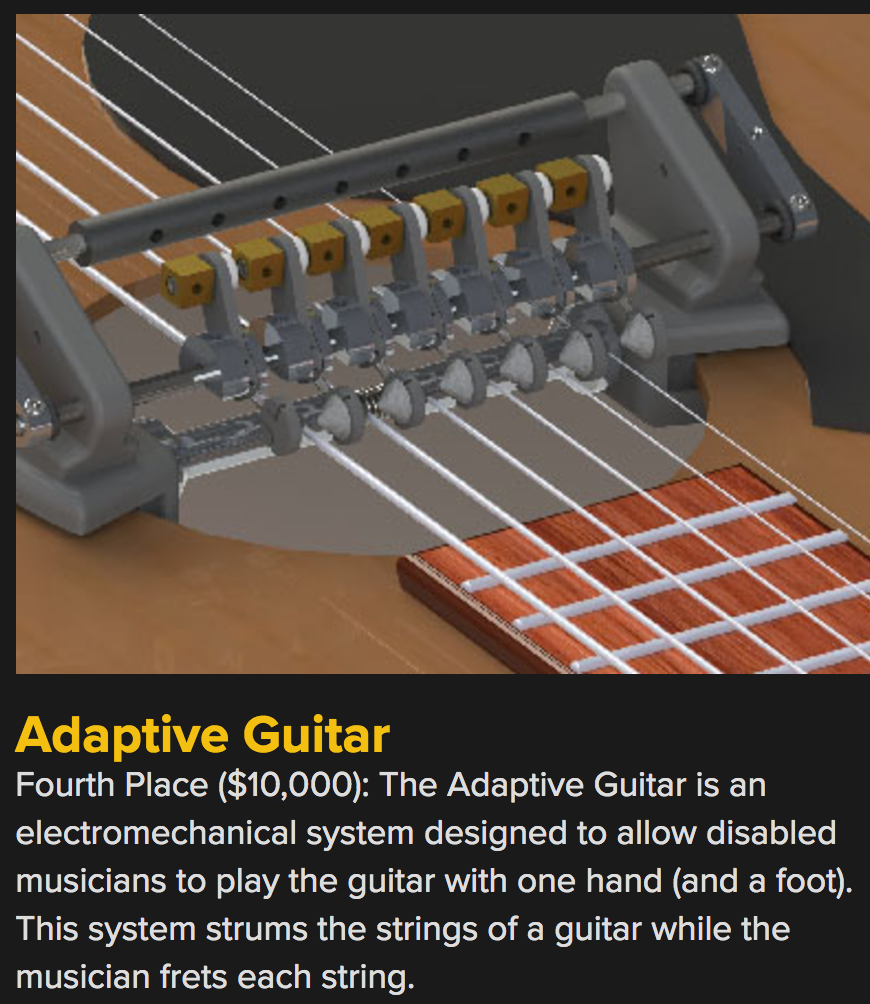

WOW! I can't believe it - 4th Place! Thank you all so much - it really means a lot to me and the Weinstein family that you enjoyed our project so much, and the prize money will go a long way towards pushing this forward to help more people.

THANK YOU!

-Joe

As a musician and engineer, I know what a huge role music plays in my life, and I can't imagine my life without the ability to play and make music. For some people like the girl I'm helping, being a musician is more than just a recreational activity - it's part of life. For a lot of people, it's depressing enough to need help holding a spoon or doing laundry; but to also have to give up the things that just made you happy can be so much worse.

This project is about so much more than playing the guitar.

The overall concept is simple: An electromechanical device that allows a musician to control the strumming of the guitar with their foot, while using their [good] hand to perform the fretting.

The system has three parts:

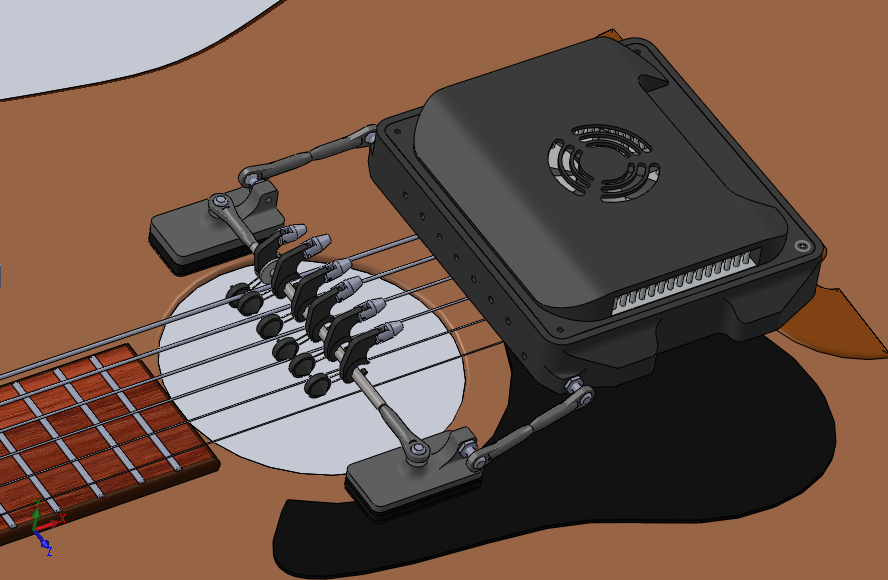

1) The Pick Bridge, which mounts to magnetic bases over the sound hole of the guitar, and supports custom-designed "rocking picks" just over the strings. The picks rotate back and forth between the strings, and have a small rubber pick cone protruding from the side. Each forwards or backwards motion makes the rubber pick cone strum the corresponding string. The picks are driven by part #2, the Actuator Module. The picture below shows the Pick Bridge and Actuator Module in position on the guitar.

Here's a not-quite-complete original render:

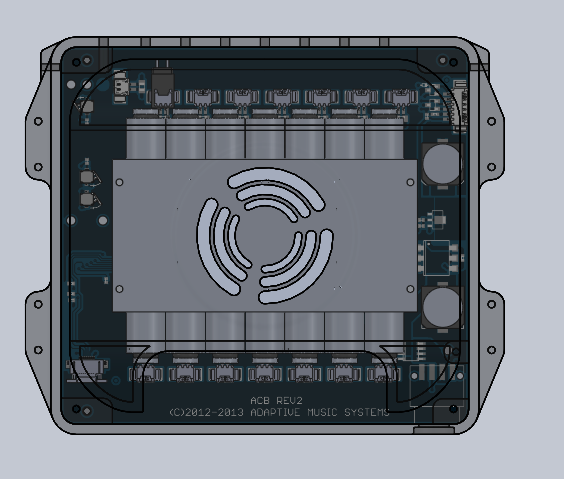

2) The Actuator Module is the system component that does all the heavy lifting. It's a box that sits behind, and is mechanically linked to, the Pick Bridge. The Actuator Module contains the custom-designed 3-position linear solenoid actuators, heat sink, and actuator control & drive circuitry. It sits lightly on the face of the guitar with four spring-damped rubber feet, and is held on to the guitar by fabric straps that velcro to the sides of the guitar. The picture below shows the current internal design of the Actuator Module. If you're wondering why there are 7 actuators instead of 6, I don't explain that yet, so you'll have to let it be for now...

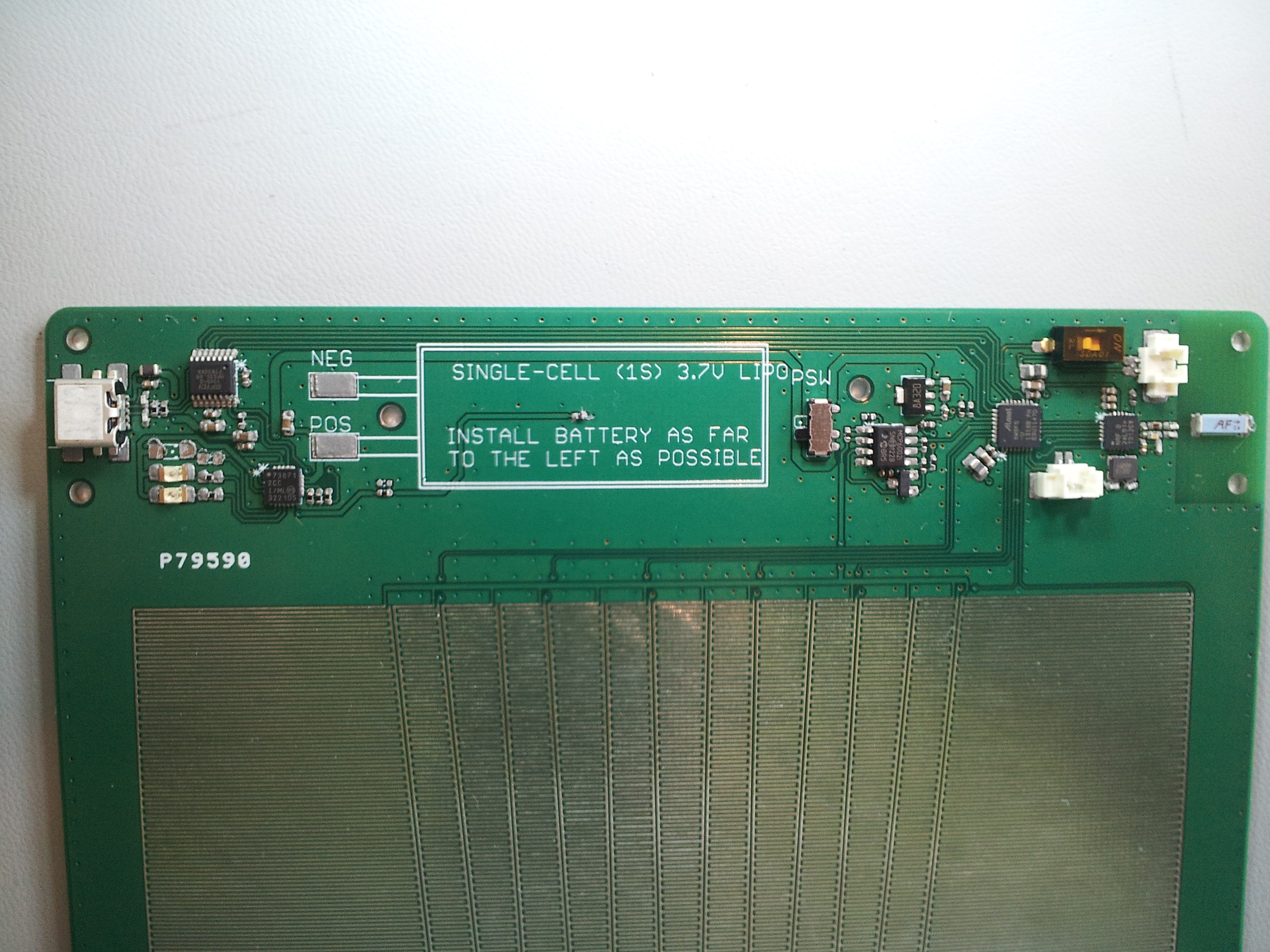

3) The system is controlled by a Foot Controller. The Foot Controller is made up of six (6) independent, pressure-sensitive sensors. As the user presses/releases a sensor (or slides their foot over), the controller wirelessly sends the command to the Actuator Module to strum the corresponding string. I'll get a better picture up soon.

Here's the Gen2 foot controller in action. It's wired, and it doesn't actuate anything in this video, but you can clearly see the sensor pad is working:

*********

The hardware is also ready for integration of a dynamics mechanism I've designed, but I don't mention that yet, as it's completely untested. But the system highlights are:

* The whole system can be stored, set up, and used with only one hand.

* The picks are replaceable, and are designed to snap off/onto the pick support axle when they get worn and need replacing.

* The mounting system only requires four points of non-damaging adhesives; no holes, no physical modification to the guitar.

* The pick spacing is easily adjustable, so it fits on just about any guitar.

***********

There are no 3rd party licensing requirements or restrictions associated with this project. All of the designs are original designs. Every line of code is written by me. Even the wireless protocol between the foot controller and control PCB is of my own design.

I do have a patent granted - however, I would absolutely not care if you want to build one of your own! I want to help people, first and foremost, but I plan to go into manufacturing and need to protect my investment so that I can afford to do more of these projects.

Joe

Joe