What we are looking at here is;

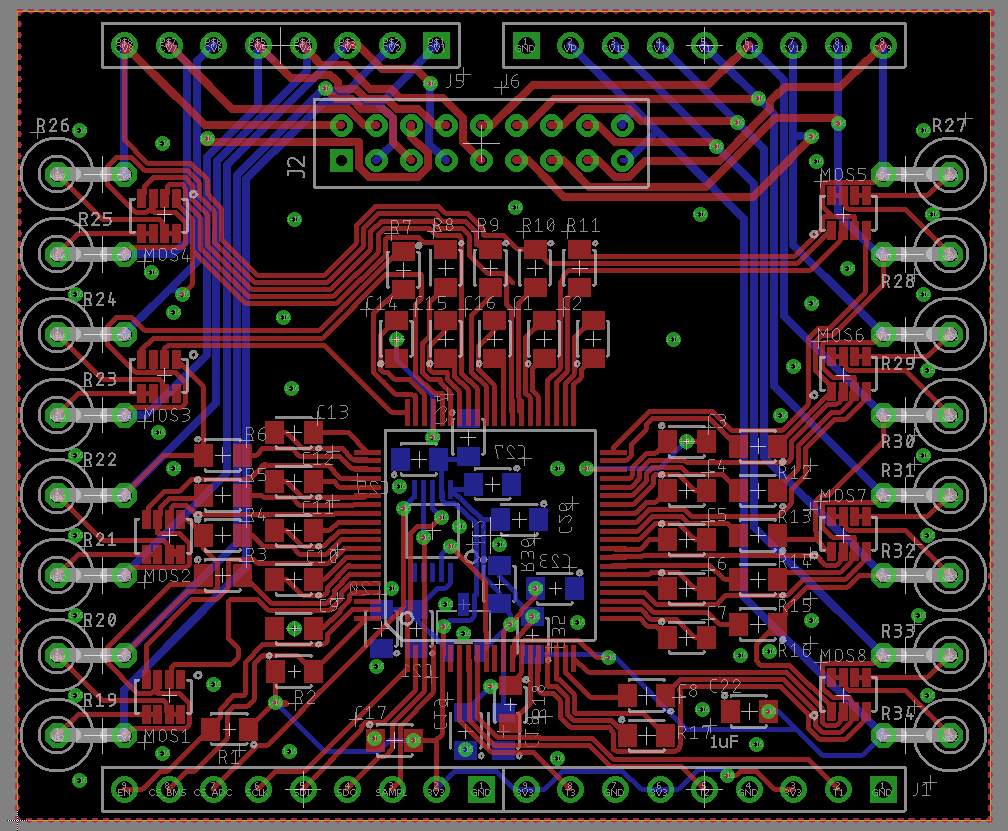

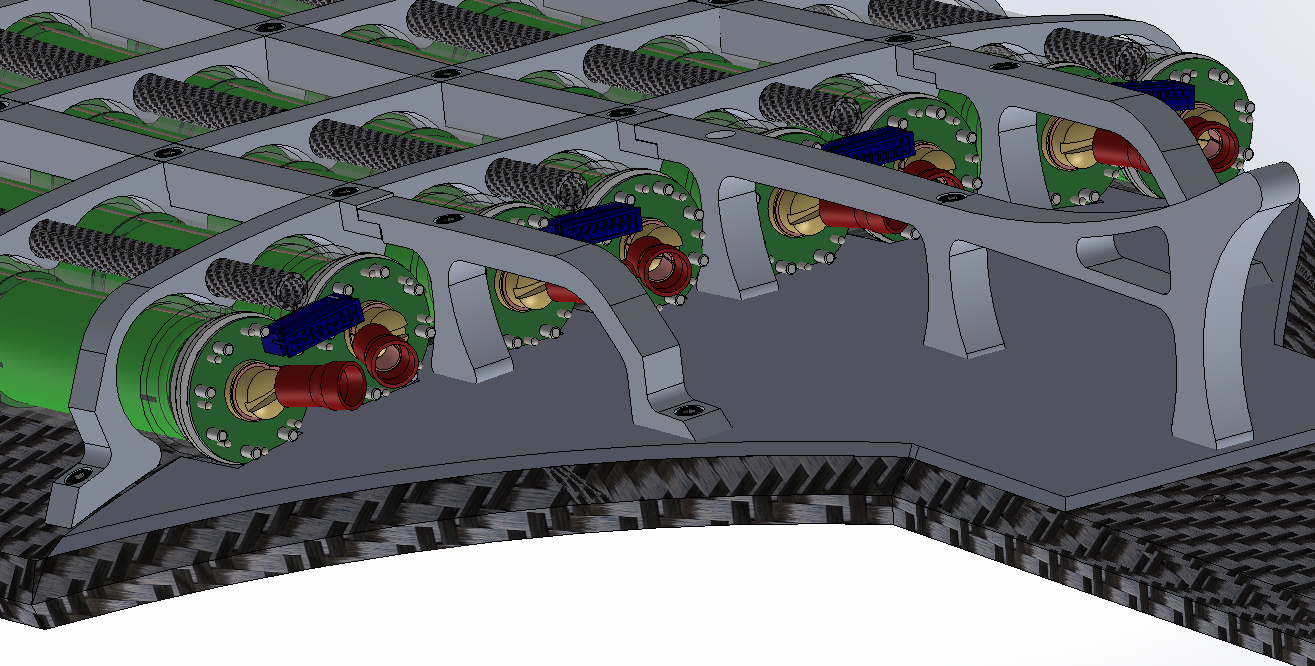

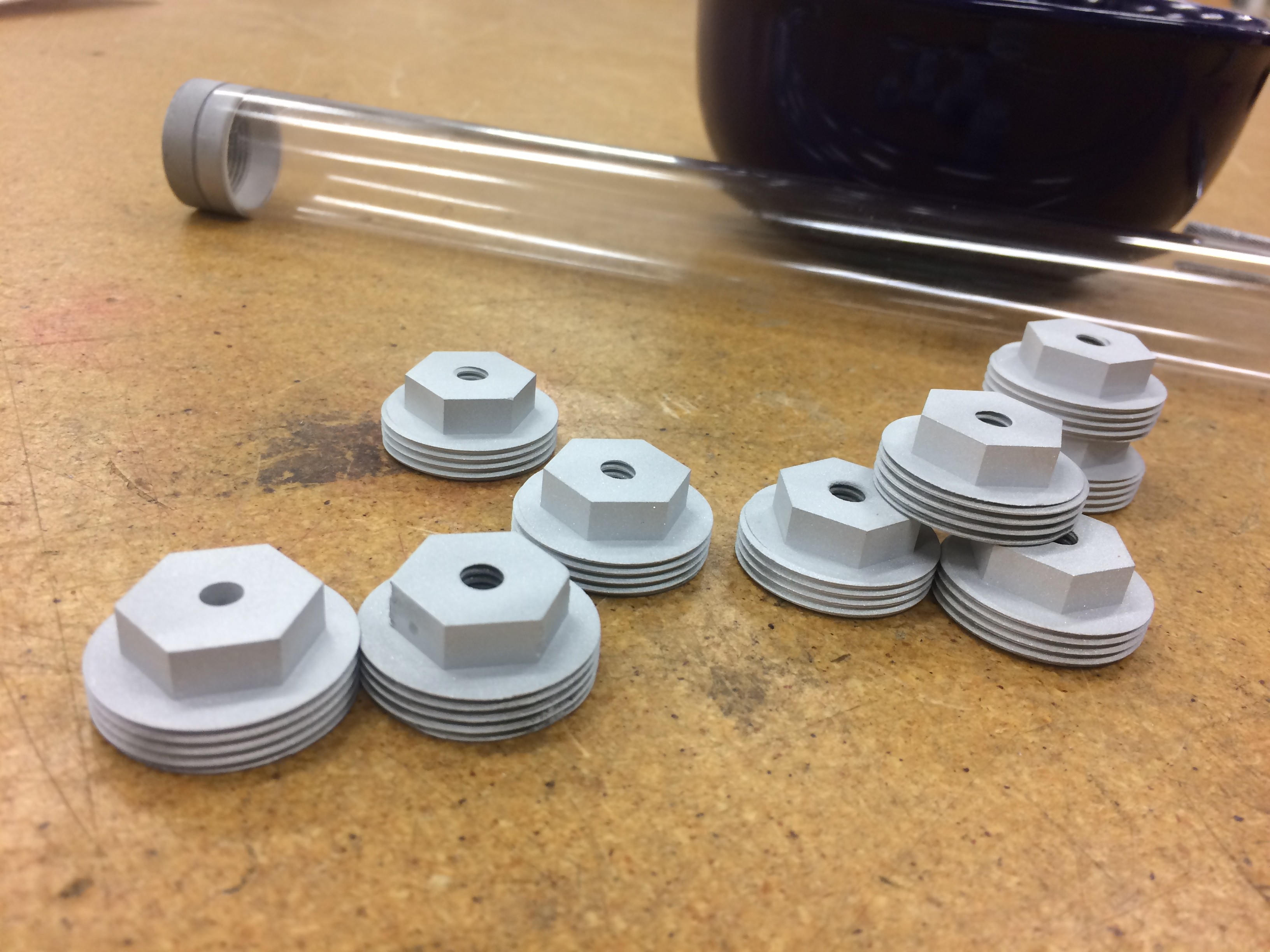

12 Hp 4 Wheel Drive - 4 x 6374 2250W BLDC motors

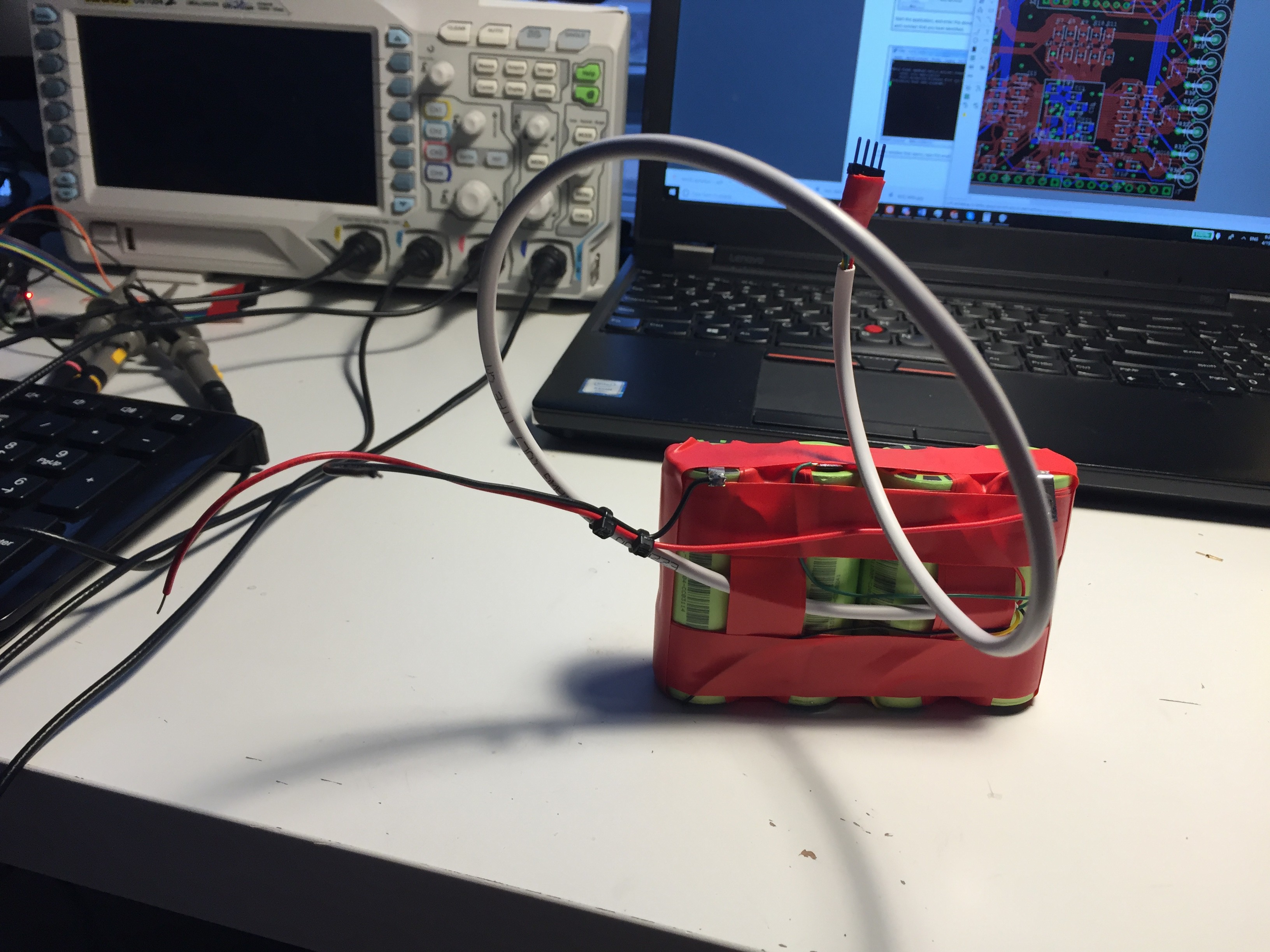

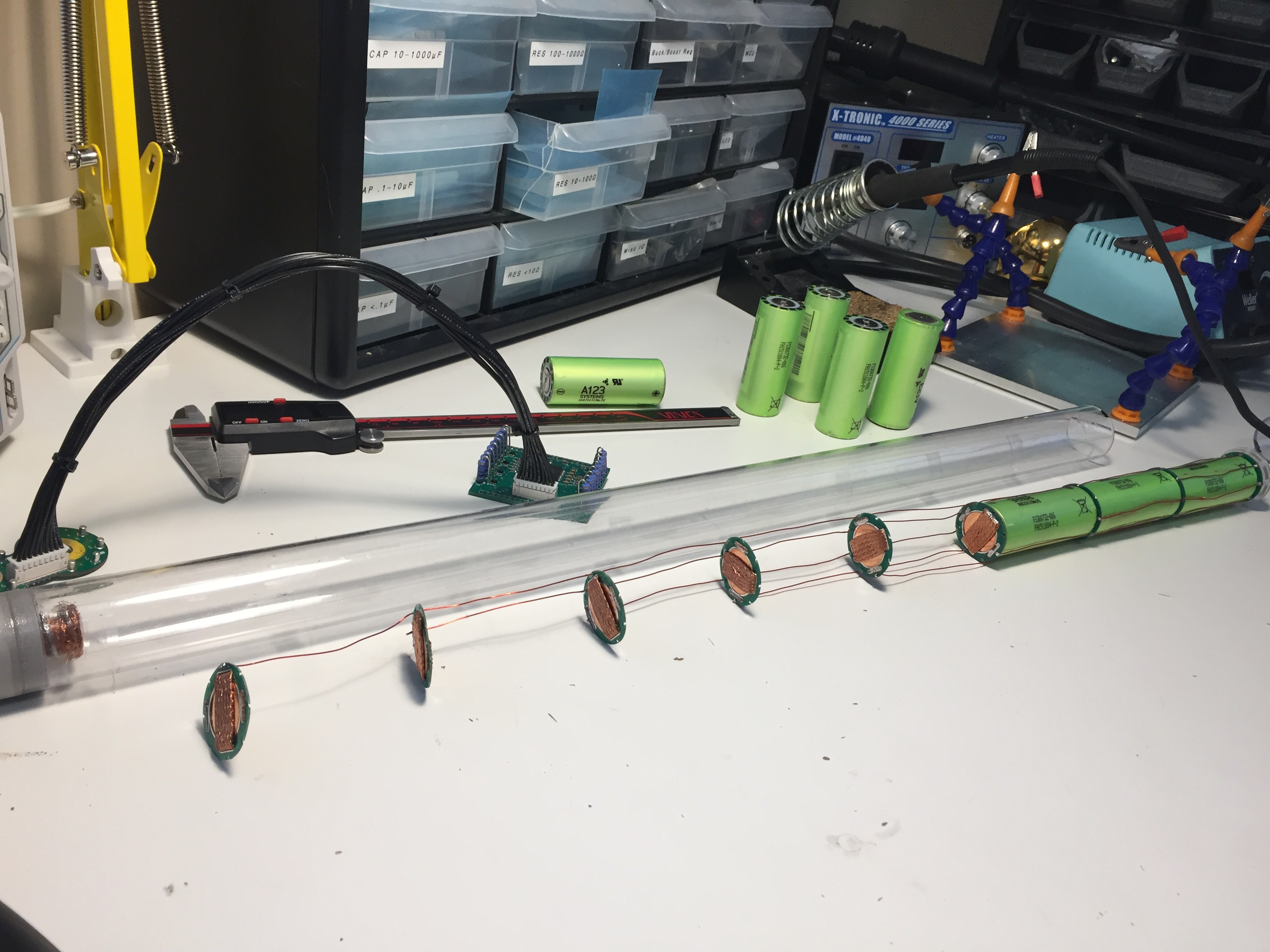

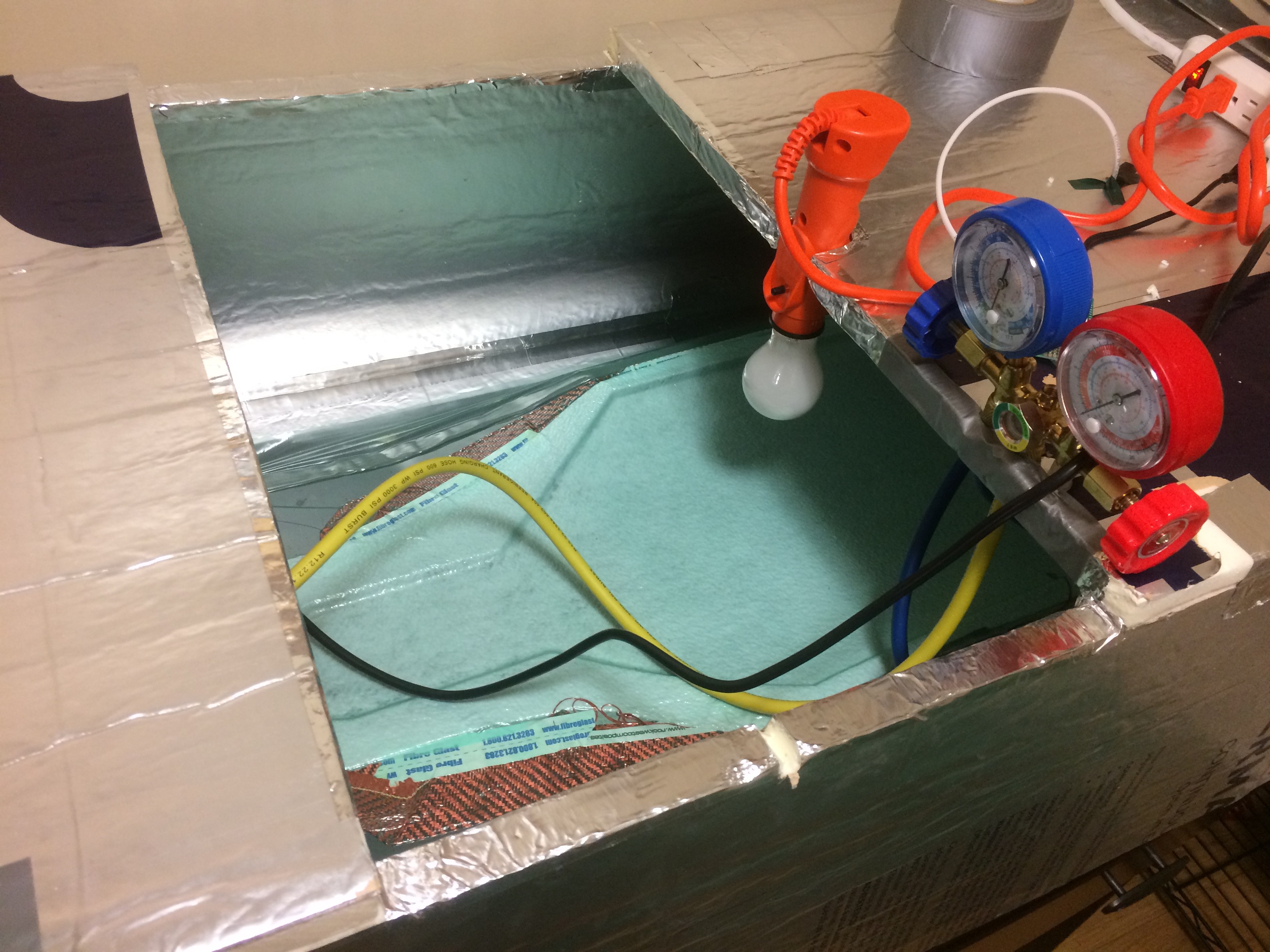

.5kWh battery pack - 64 x ANR26650M1-B LiFeP04 2.4Ah 10C - 12min charge time batteries

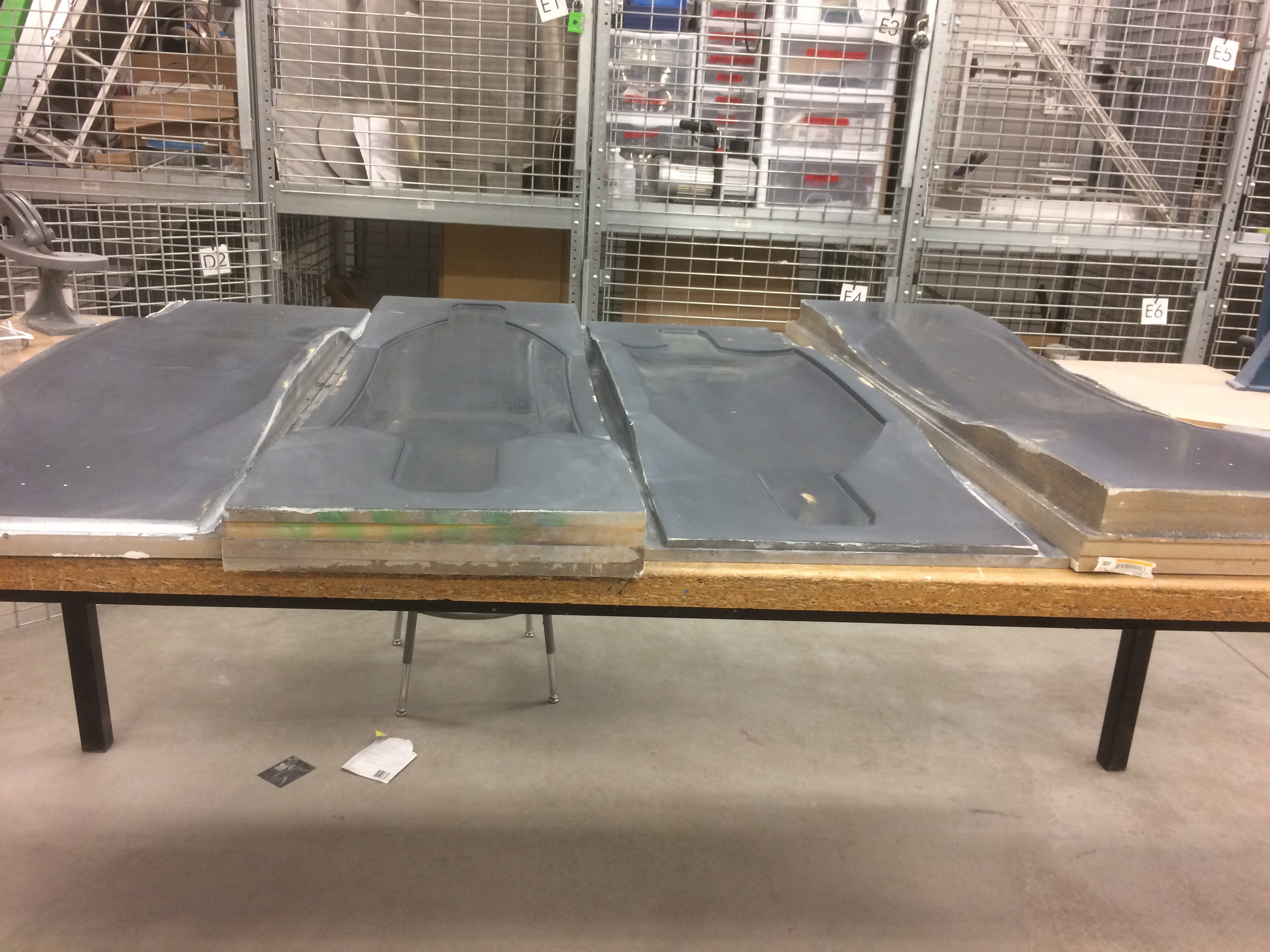

48in x 13 in deck

60 volt system

60mph+ Top speed

40mile+ range

1.5kW charger - 20min charge time.

RGBW headlights - 1000+ Lumens

RGB LED underlighting

Carbon fiber deck - 500Kg+ load limit

Splash proof

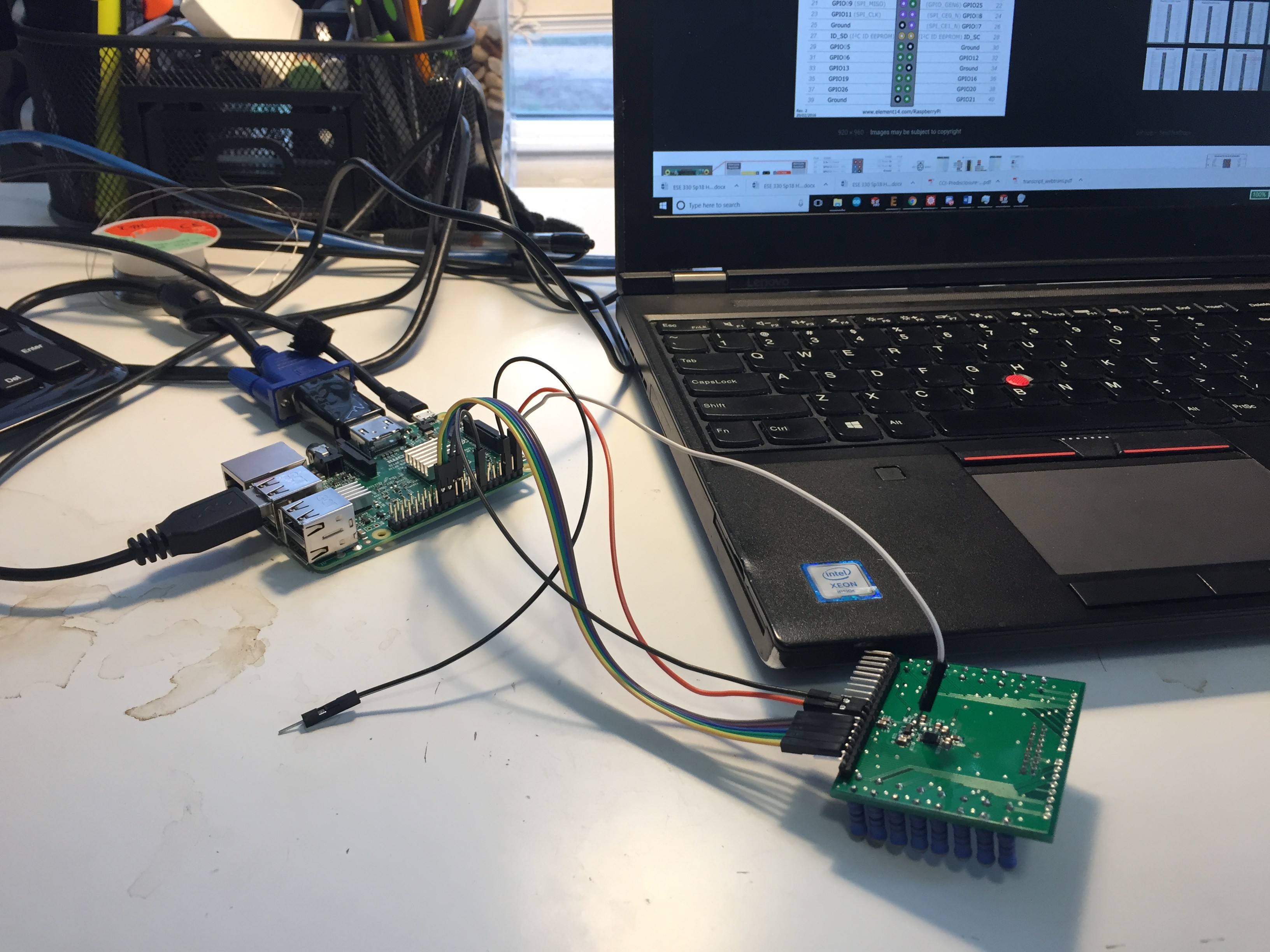

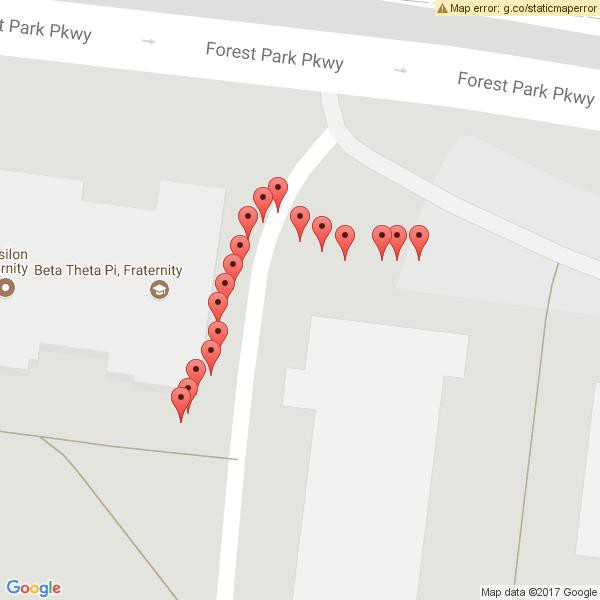

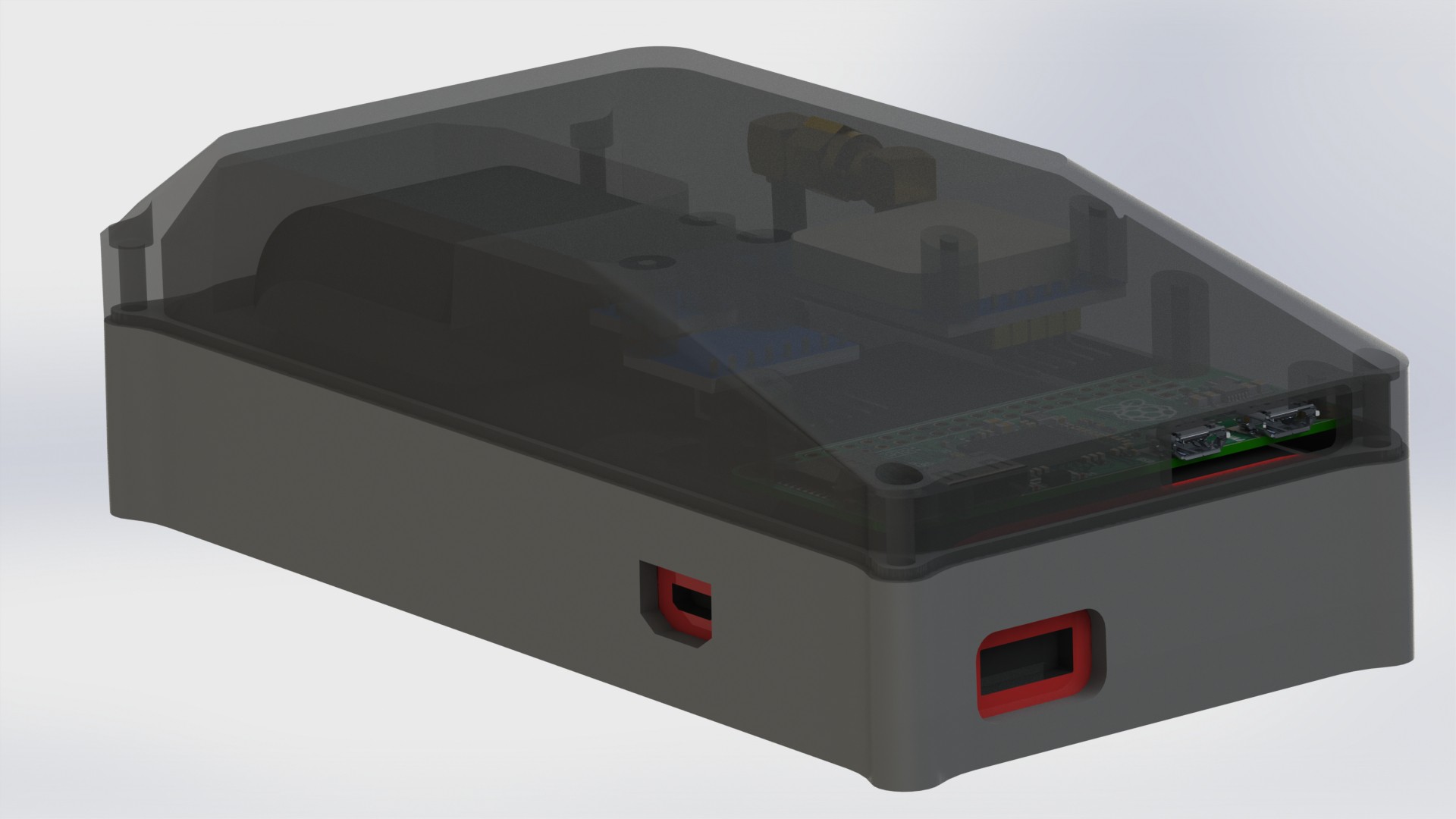

Onboard linux box managing GPS, phone-app connection.

All the files are hosted on the project Git page. This is an open source project.

Danny Andreev

Danny Andreev

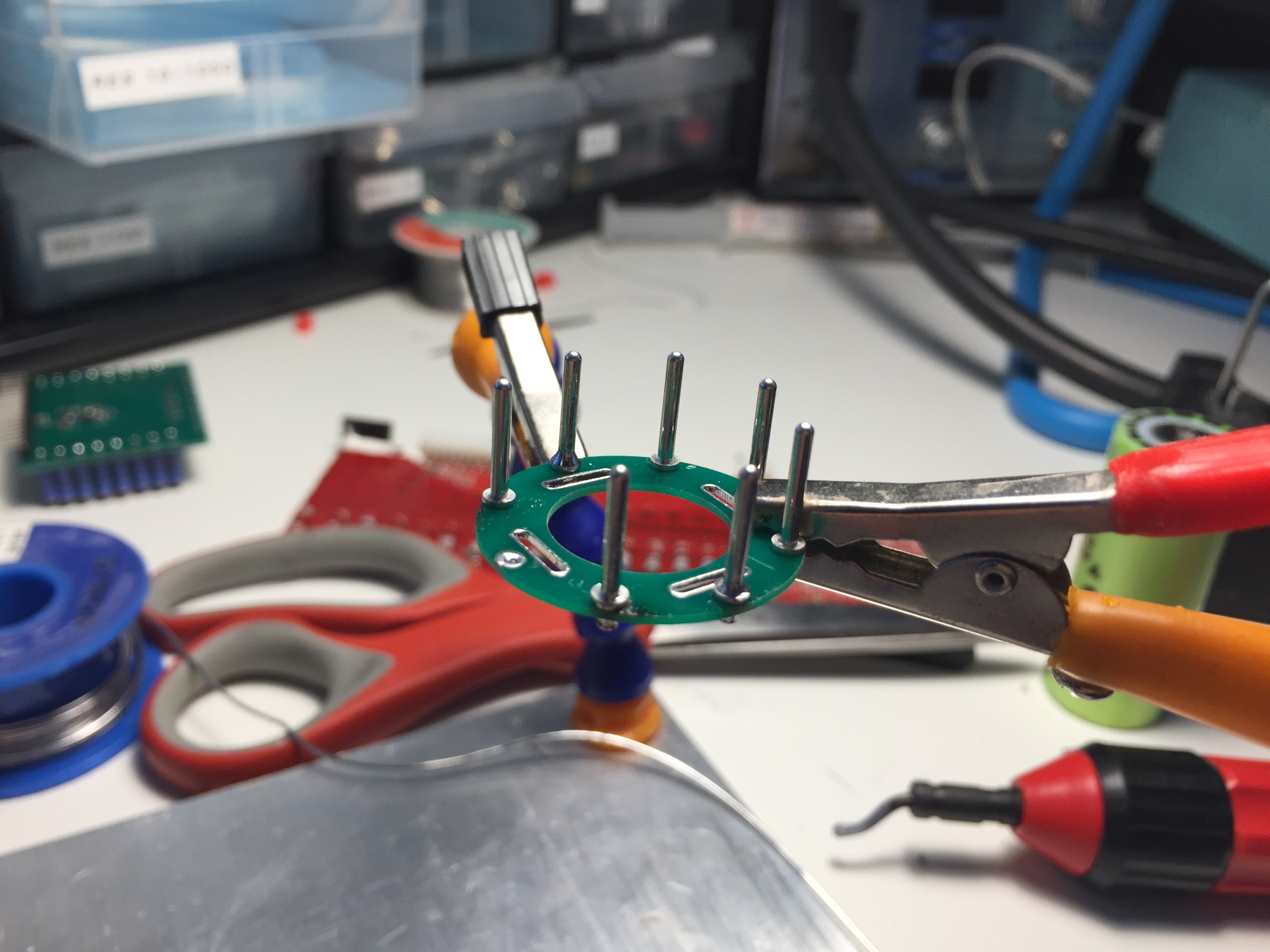

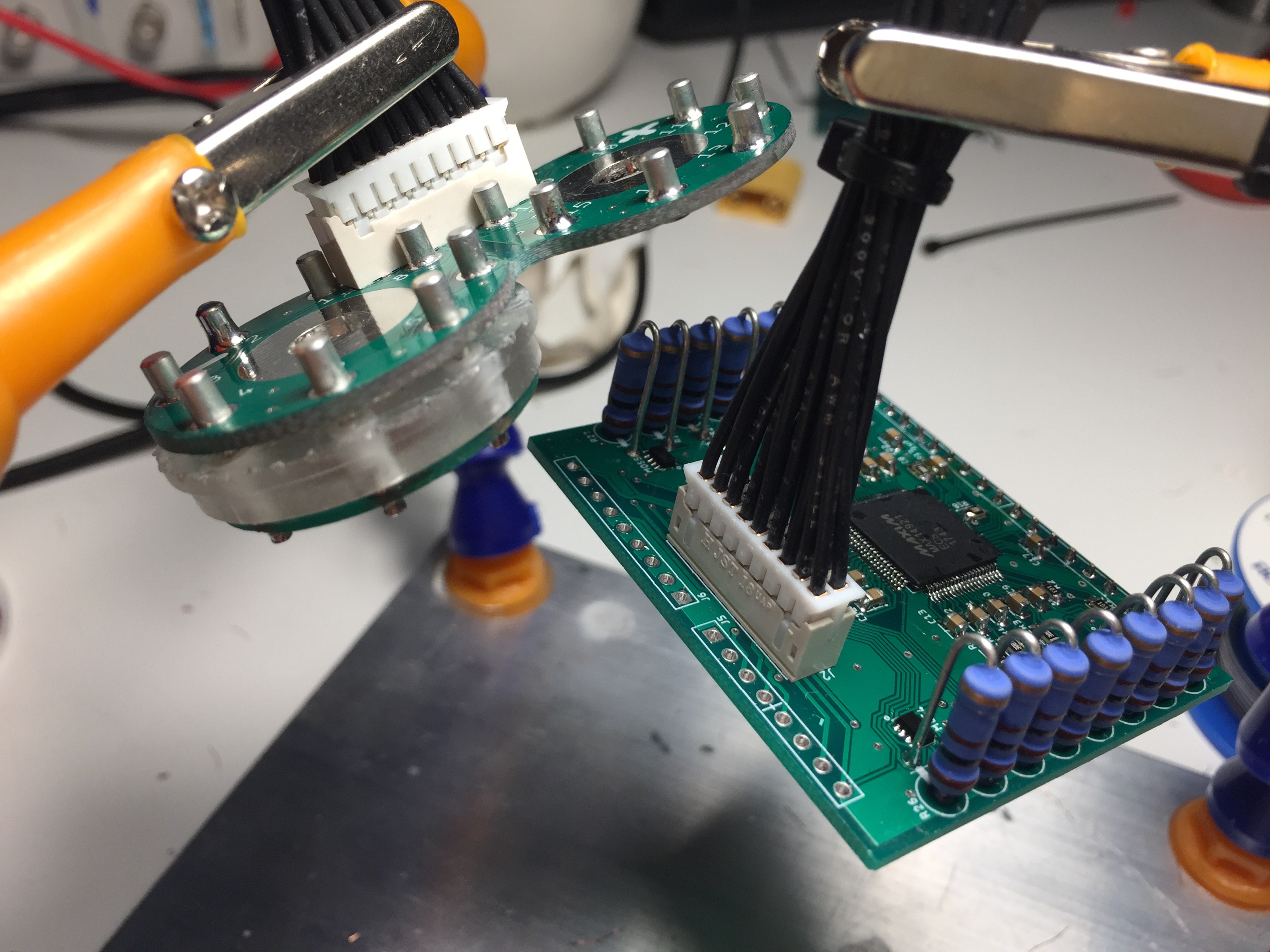

Finished debugging the SPI, time to start pumping out code...

Finished debugging the SPI, time to start pumping out code...

forrest.thelucas

forrest.thelucas

Joseph Demers

Joseph Demers

Matthew James Bellafaire

Matthew James Bellafaire

Mike Szczys

Mike Szczys

what kind of engineer are you ?

mechanical or electrical ?