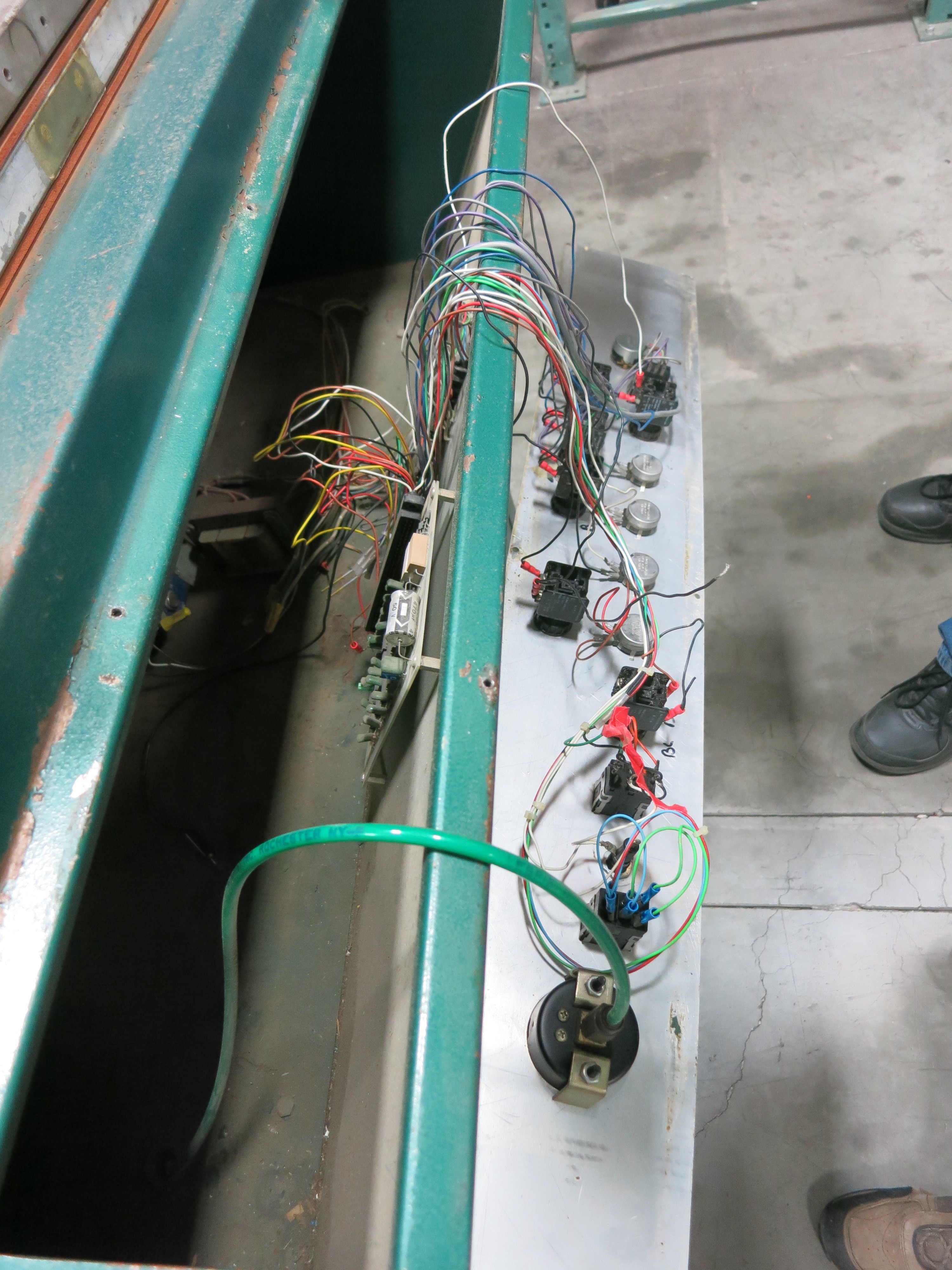

The first session was spent taking everything apart. We want the machine down to its fundamental components and rebuild from there. We decided this after seeing the tangle of new and old air lines, vacuum lines, and wires. There's been lots of work done to this machine over its lifetime of service and we don't care to put time into figuring out why somebody did something years ago.

Here's one of the puzzles: aftermarket Home Depot quality latches. The obvious answer is that somebody had to install them because the adjacent electromagnets no longer work to hold the frame shut. But when we energized the magnet (24V 0.45A) it seemed to hold the frame quite well. Why were the latches installed? We may never know.

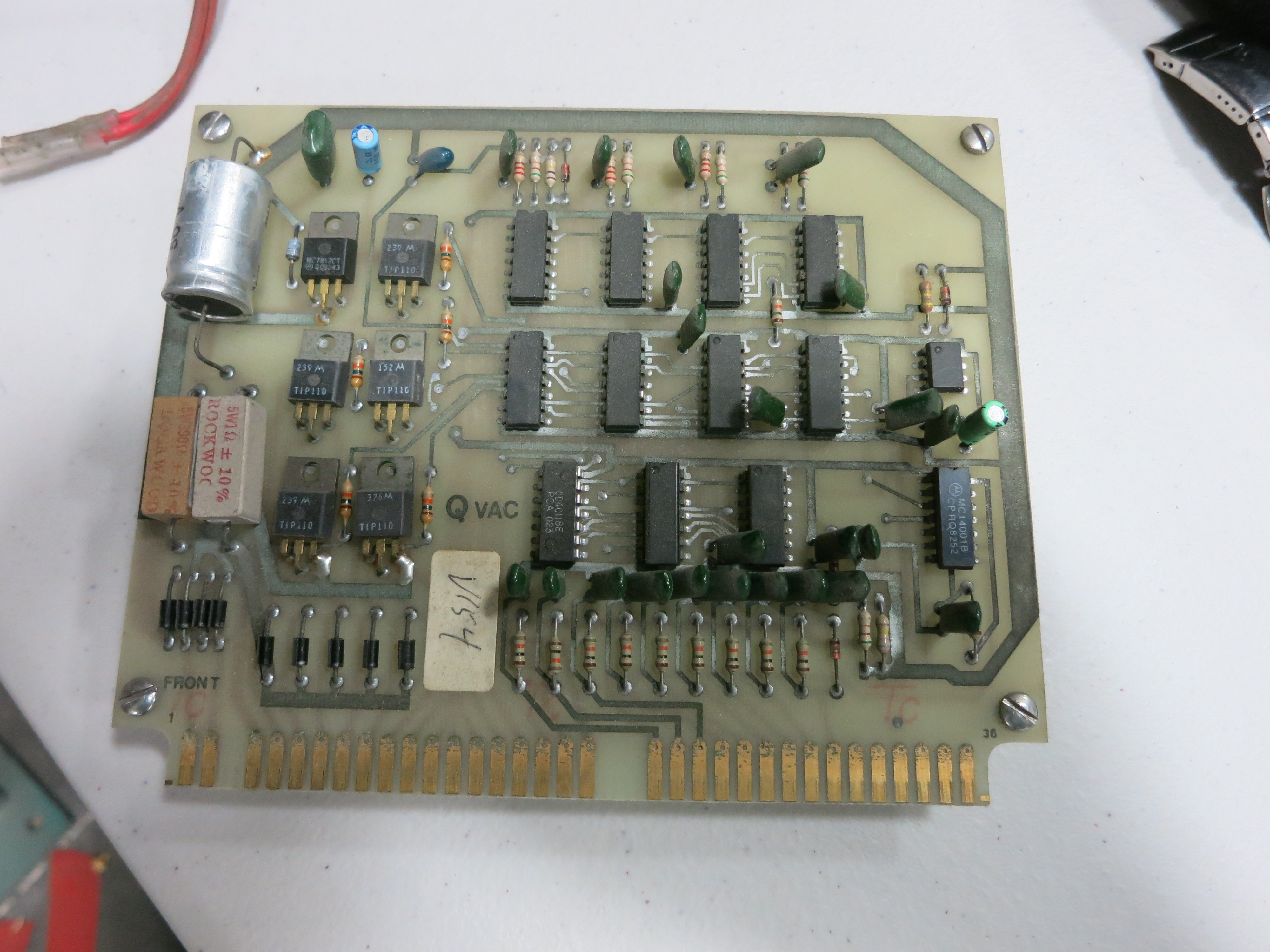

The advertising copy for the current-generation Q-VAC PC Series machines tout its labor-reduction automation capabilities. Judging by controls, this ancestor is also quite proud of its automation. The rebuild crew here, however, is rather less impressed by the ancient circuitry. Since we're interested in low-volume maker projects, and not high-volume commercial production, automation is not a priority. We want to get the machine up and running in a manually-operated fashion. If and when we need automatic cycle we'll tackle that with a more modern brain to orchestrate the process.

Given the age of the machine we didn't hold high hopes that replacement parts would be available. Every time we find something it's a pleasant surprise. For example: when the electromagnets release, a torsion spring will pop the frame open. At the top of the travel, these hydraulic dampers keep the frame from slamming open. The dampers have long since worn out and leaked out all of the fluid. We refilled with oil and found one still worked and one did not. And they both started leaking so it wouldn't be long before they both stopped working again.

The label said "Enidine .5B" and a web search found we can still get new replacements straight from the manufacturer. Or buy surplus from eBay, or a rebuild kit. Awesome.

The machine was pretty gutted by the end of the disassembly work session.

Roger

Roger

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.