I'm happy to announce my short was selected as the winner in the Supercon film festival! This is an incredible conclusion to a mad rush project.

A summary of project timeline:

- Previous weekend: "What am I going to do with the badge?"

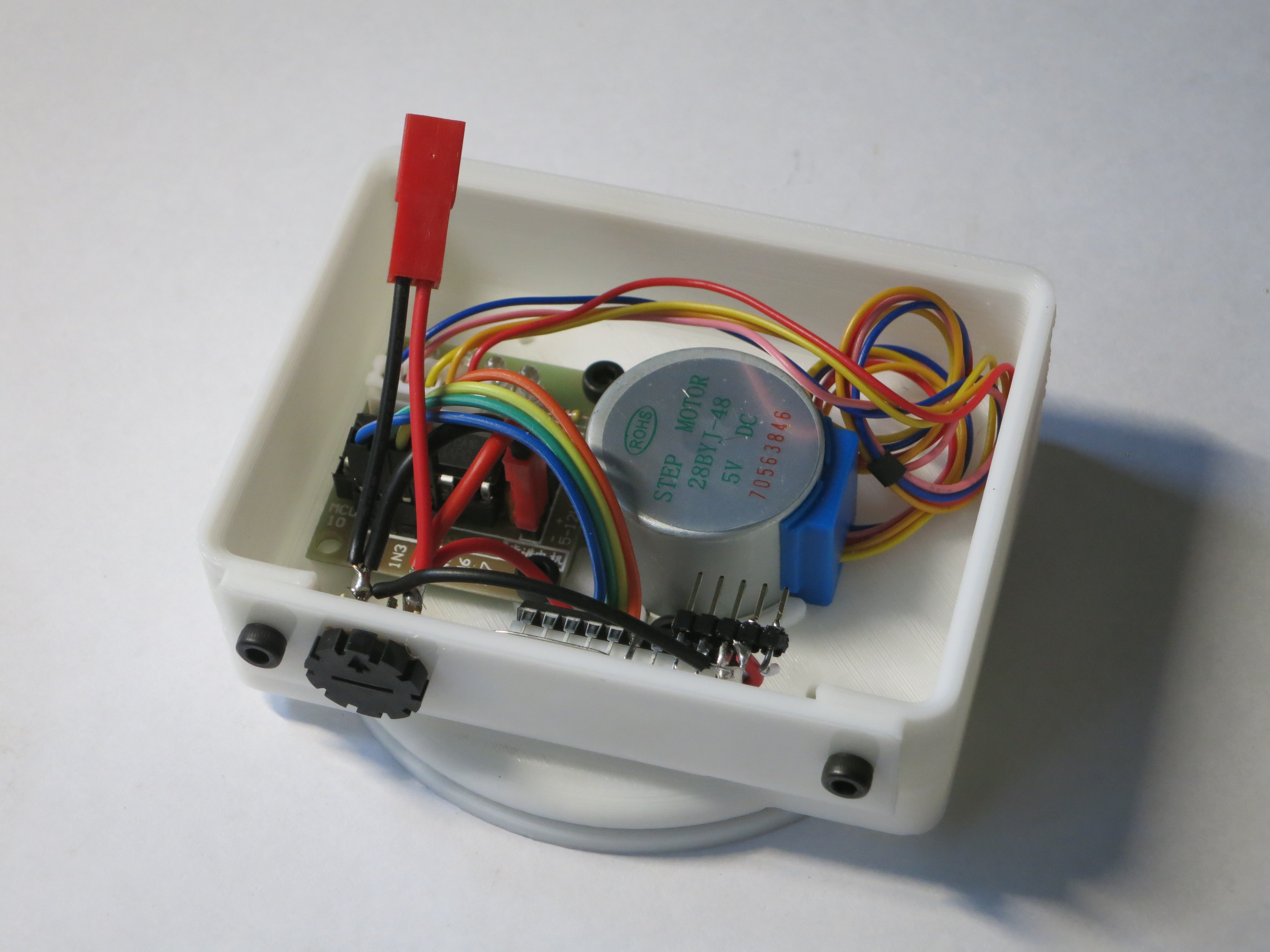

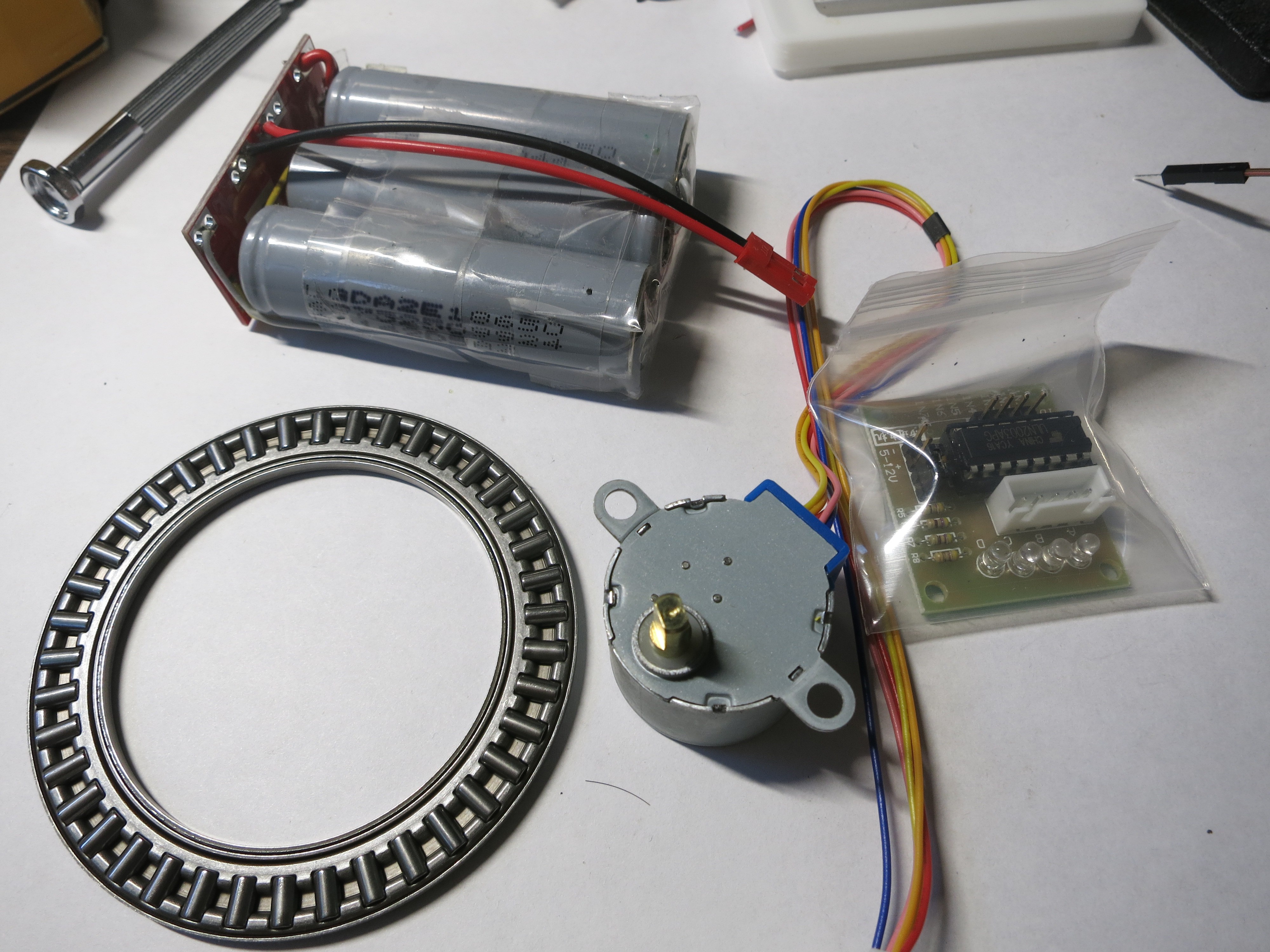

- Wednesday: "I'm going to do panning time-lapse videos." Commence 3D printing to build the motorized panning base.

- Thursday: Panning base is good enough to proceed.

- Friday: pick up the badge, dig into code: "How am I going to take time-lapse with this thing?"

- Saturday morning: Standard camera app hacked to take time-lapse video.

- Saturday afternoon: Record footage around Supercon.

- Saturday night: Select the best clips and write a crude playback app to show them in sequence.

- Sunday morning: Record playback app for uploading to YouTube.

Roger

Roger

ric866

ric866

Mike Rigsby

Mike Rigsby

Gradivis

Gradivis

setCREATE

setCREATE

Hurry!