Since the hand welded method was time consuming and inaccurate I needed something better. I ordered a cheap Neje Master '7W' laser engraver from China and started some experiments.

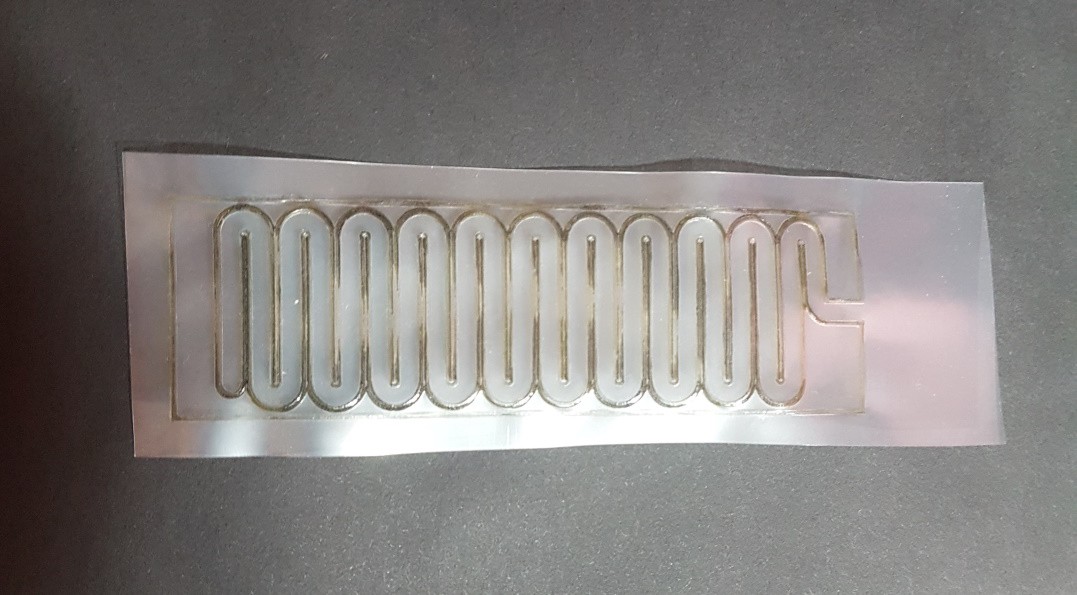

Originally I planned to cut the paper and then seal the actuators with the standard way with an iron. However a quick test showed me that welding the plastic together was more than possible, and so I've been refining that process since.

So far I've found that it's best for the plastic to be placed on top of black card, and then sandwiched between 2 planes of glass. The glass I used were borosilicate 3d printer beds. A weight can be added to help hold the glass flat. The sous-vide pouch I was using for the glass wasn't sealed perfectly flat around the edges and had some small undulations to them. This lead to extra space between the glass sheets. I decided to cut all but a corner of the pouch weld off. This held the plastic sides together but without the undulation.

Of course the Neje software didn't like the modern dxf formats that Fusion 360 output. So I used Librecad to convert the modern dxf files to 2007 versions.

So far I've found that the laser settings (450nm 2500mW optical power) that are best suited for welding are 60% power 1ms dwell time. The lines in the dxf file are best placed 0.075mm apart, although this is based on the rastering settings rather than extensive tests.

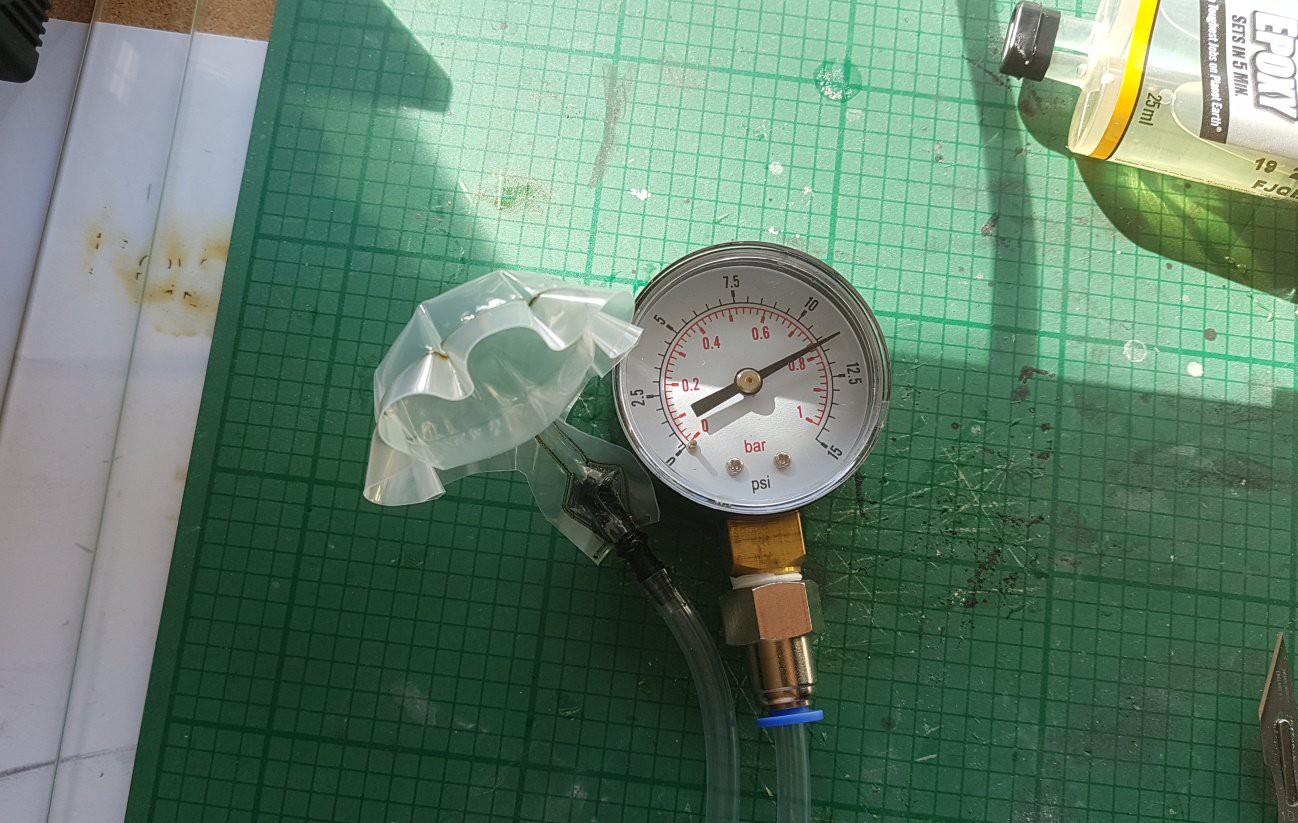

I made a new 3d printed connector. I decided that it was best to use epoxy to seal the connector in. Whilst I doubt the bond between the epoxy and the polyethylene plastic is strong, I designed it so the epoxy forms a plug and the geometry of the weld line prevents the plug from popping out. So far this has worked up to 12psi and I've had no failures so far.

The next step will involve various muscle geometries, including sandwiching layers together so that they can provide greater than 25% contraction ratios.

Anthromod

Anthromod

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.