Nevertheless I decited to start wirst parts for testing the mold. Plan was to just laminate 2-3 layers of glasstwill (this time very light one, about 105gr/m². lightest twill I could get), stuff it into a plastic bag and suck out the air with a vacuum pump to get the fabric squeezed into the mold.

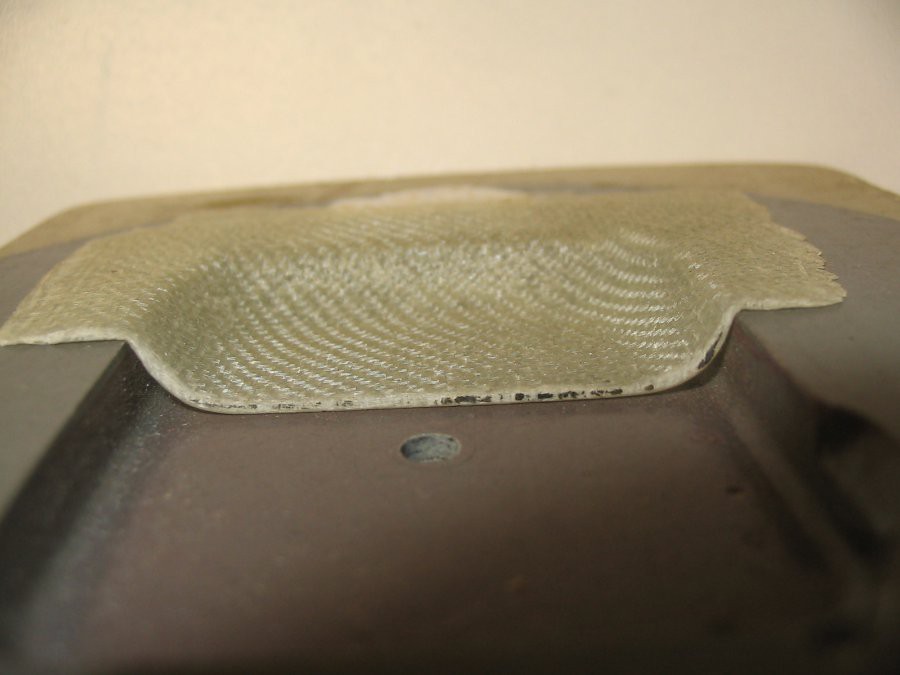

Well, while that works in bigger shapes, the outcome of my fisrt try was this:

I cutted it in half to get a better idea of what happend. As you see by using only the vacuum it won't work.

After that I did some additional runs in teh same way, but this time I started with only little negative pressure (using a little vavle wich regulates the airflow by open the vacuumback controlled to the environment). In that setup I was able to push the fabric tino the corner t0gether with the vacuumbag. During the pricess I regulated the presure until the fabric was pushed into the corner a lot better.

I ended up with a much better outcome, but was never able to get all corners perfectly. In addition to that the mounting holes for the screws were never filled withe enough fiber. I tried to just repoduce the straps and drill the hols afterwards, but non of those methodes ended up in a durable strap with mounting hole:

So 2 things weren't working:

1) a mold with only one half and the use of vacuum

2) mounting starps which have no, no oriented or cutted fibers (by drilling the holes later)

mclien

mclien

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.