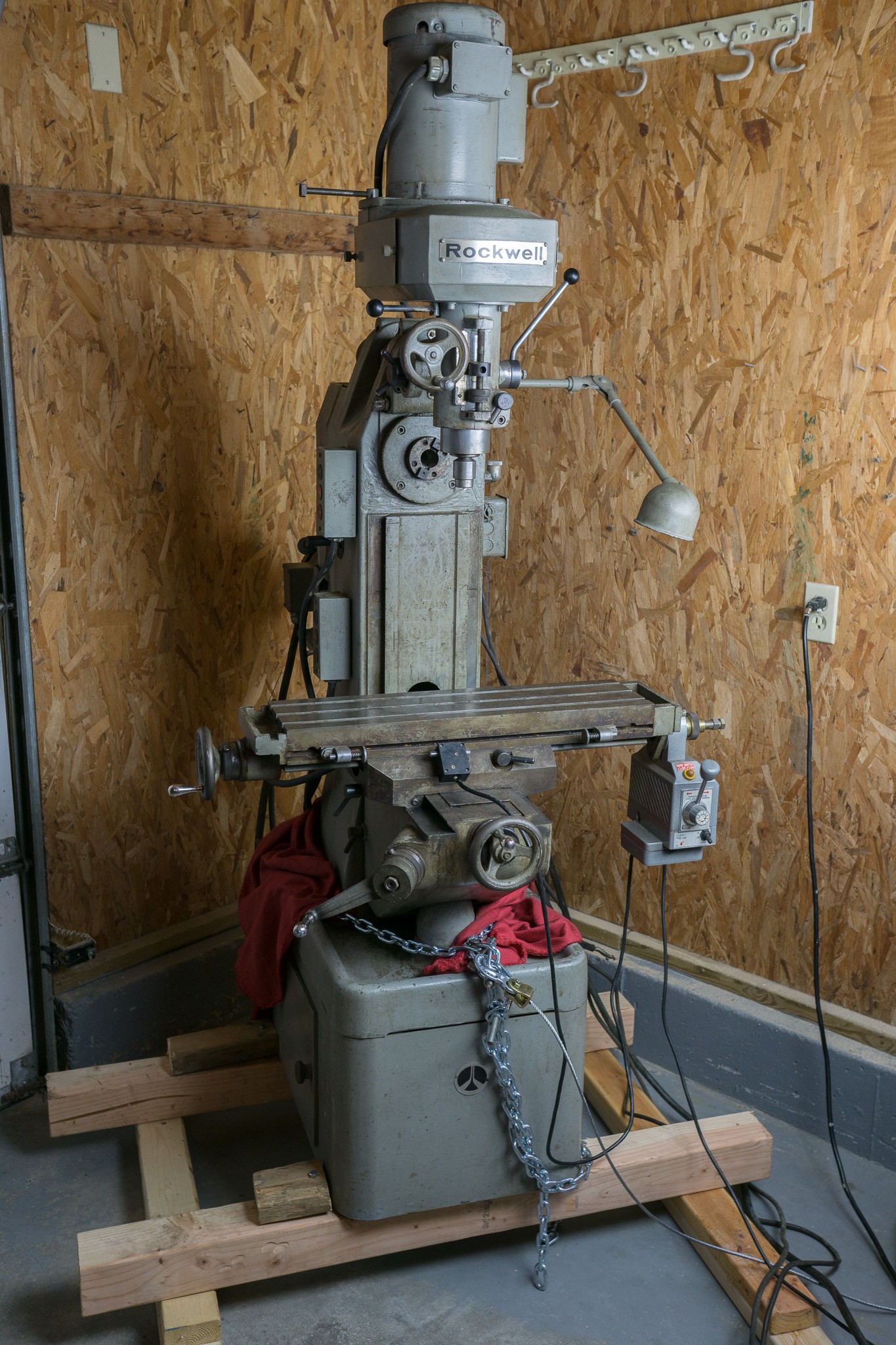

I recently acquired this Rockwell 21-122 Horizontal/Vertical milling machine from my local Craigslist.

It’s in remarkably good shape; most of the moving parts are free, the ways look very clean, the table surface is relatively free from dings and not a whole of obvious rust. The quill doesn’t have full travel though. It can only actuate from 1" to 2.5" … it can’t fully retract inside the spindle.

The bearings also feel a bit rough. Given the overall good health of the machine, I’m thinking it’s just old, dried up grease. These RWs don’t have an oil reservoir system for the spindle, so the bearings are just packed with grease. It looks like this mill was sitting idle for some time so old grease is pretty good bet.

I’ve been tearing the machine apart over the last week or two so that I can inspect the bearings, degrease everything, relubricate, etc. I’m also going to strip most of the paint back to bare metal and repaint. The paint job is in pretty good shape, but there are a few areas that have flecked off and are rusting. So I might as well just do the whole job.

Specs:

- ~1000 lbs

- 6.5"x24" table

- 16.5" vertical travel, 3" quill movement

- Power feed on x-axis, spare power-feed that I can install on the knee

- R8 taper on vertical head, #30 NMTB taper on horizontal

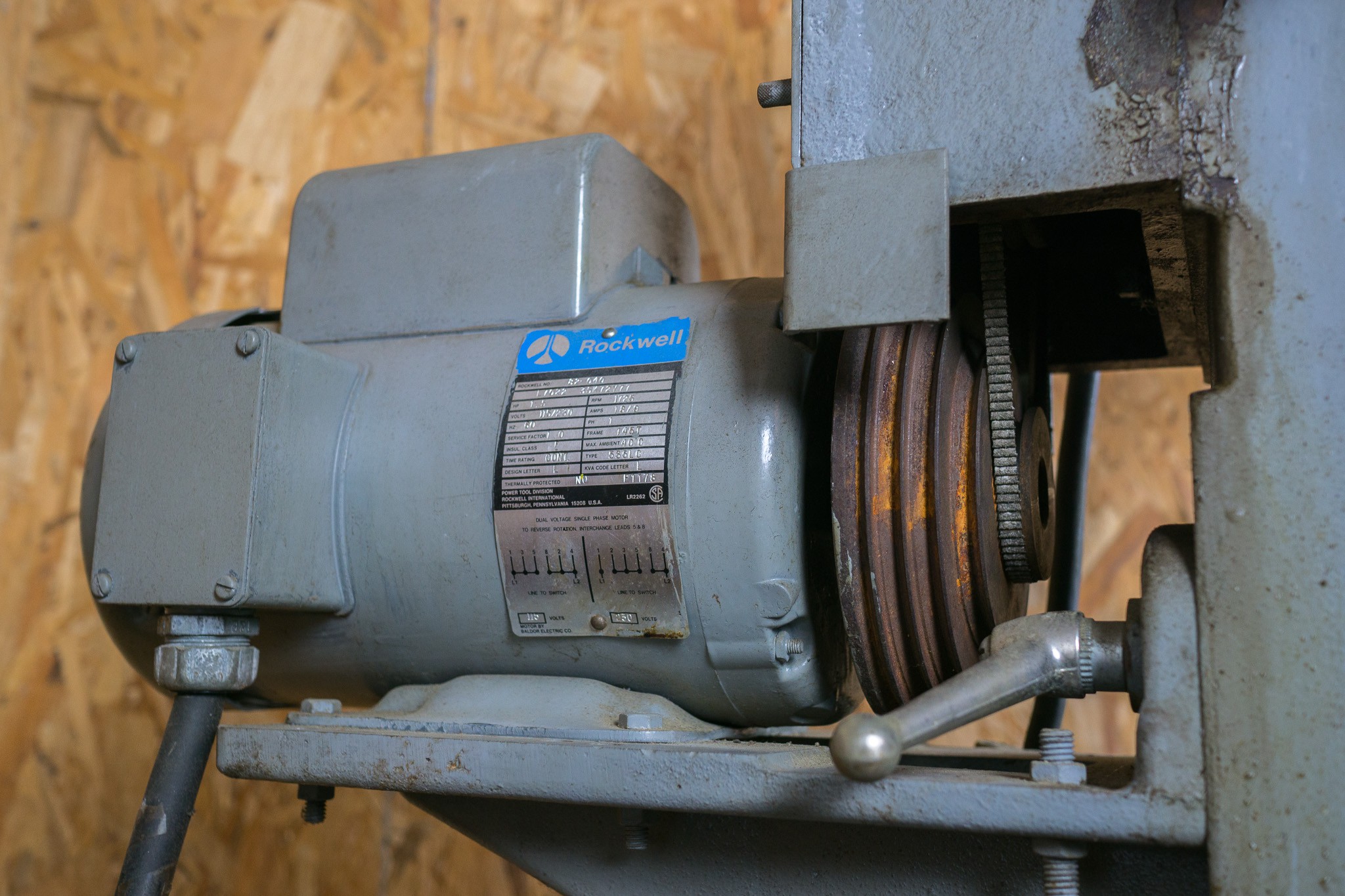

- 110v, 3/4 HP motor on vertical head

- 220v, 1.5 HP motor on horizontal arbor

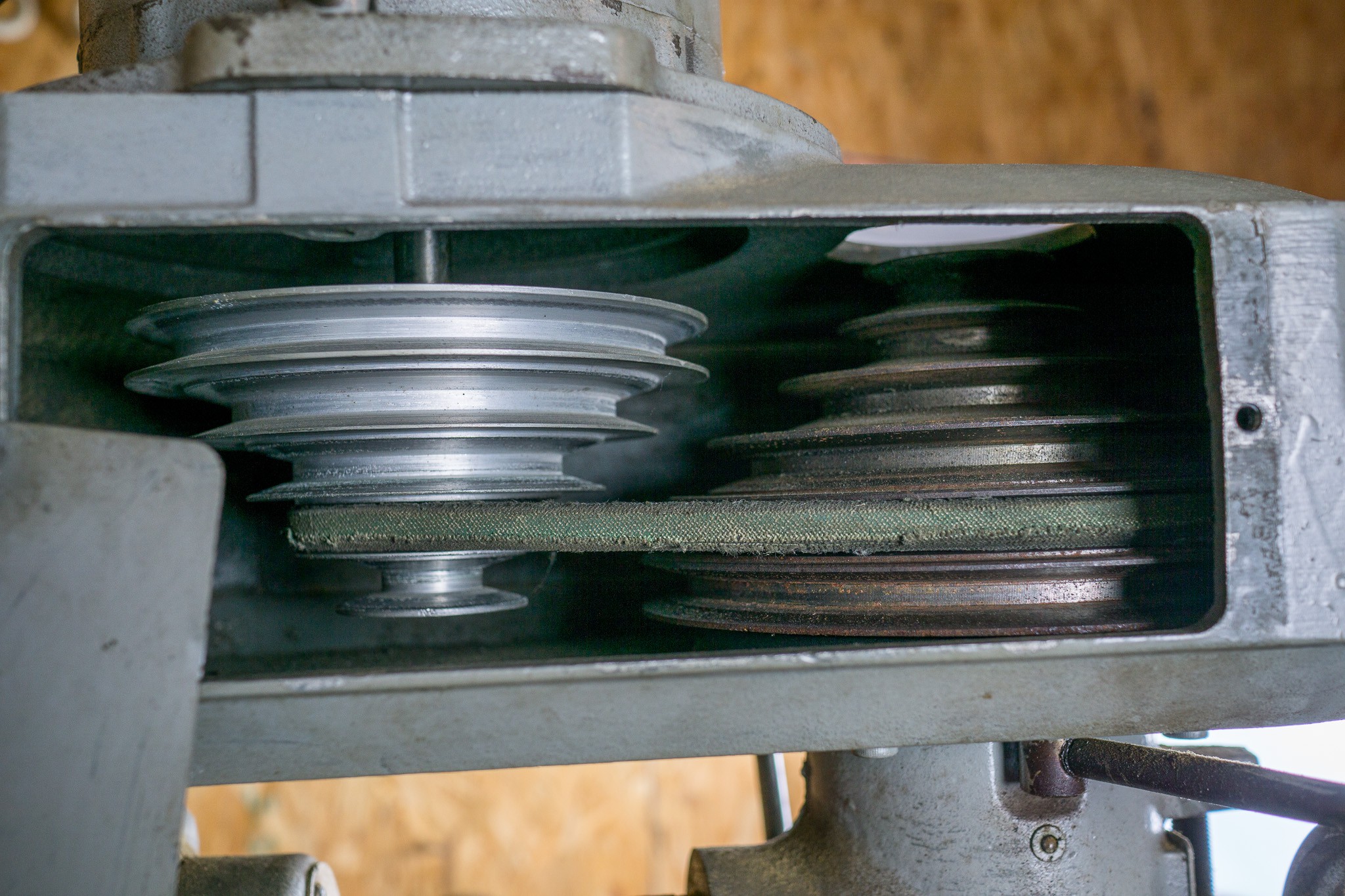

There is no gearbox for the vertical head, just a set of pulleys that you adjust to change the spindle speed. This gives a few rpm options: 370, 700, 1170, 2440, 4420 and 6300 RPM.

I plan on replacing the belt with a nice cog- or link-belt... the existing belt is pretty worn. The horizontal arbor is driven by an interesting mixture of pulleys and gears. There are 5 pulley speeds that you can select similar to the vertical head.

Then there is a "backdrive" mechanism that can be engaged. This is a set of gears configured similar to a lathe, which provides a 6:1 reduction. By engaging this, you can slow down all the pulley configurations. These slower speeds allow slab milling or other heavy cutting operations, or potentially lathing wide-but-short pieces.

The speeds available are: 60, 135, 240, 300 and 385 rpm with the backdrive engaged, and 375, 845, 1500, 1875 and 2400 rpm in direct-drive.

This mill was being sold as part of an estate sale, so I also nabbed a huge amount of tooling. Probably several thousand dollars worth of tooling, all told. Some of it is in rough(er) condition, but most of it is pretty good.

Most importantly, it came with all horizontal accessories (arbor, overarm support) and three vices (6.5", 3" tilting and a 1.5"). There is also the extra power feed as mentioned, as well as a rotary table and tilting tailstock. For the tooling, there's a wide array of end mills, taps, punches, drills files, clamps and a boring head. Oh, and some really nice mitutoyo small bore gauges.

I had to purchase a few essentials (R8 collets, parallels, some indicators) but overall the tooling that came with the mill should have me set for a while.

Over the next few posts I'll be pulling the head, spindle and quill apart, stripping what I can, cleaning grease, re-lubricating and repainting. Stay tuned!

polyfractal

polyfractal

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.