Hello all,

thank you for your interest in this project. I am sorry I 've failed to update you to say that I have put this on hold for a while now as I've started (and finished this time!) with new projects.

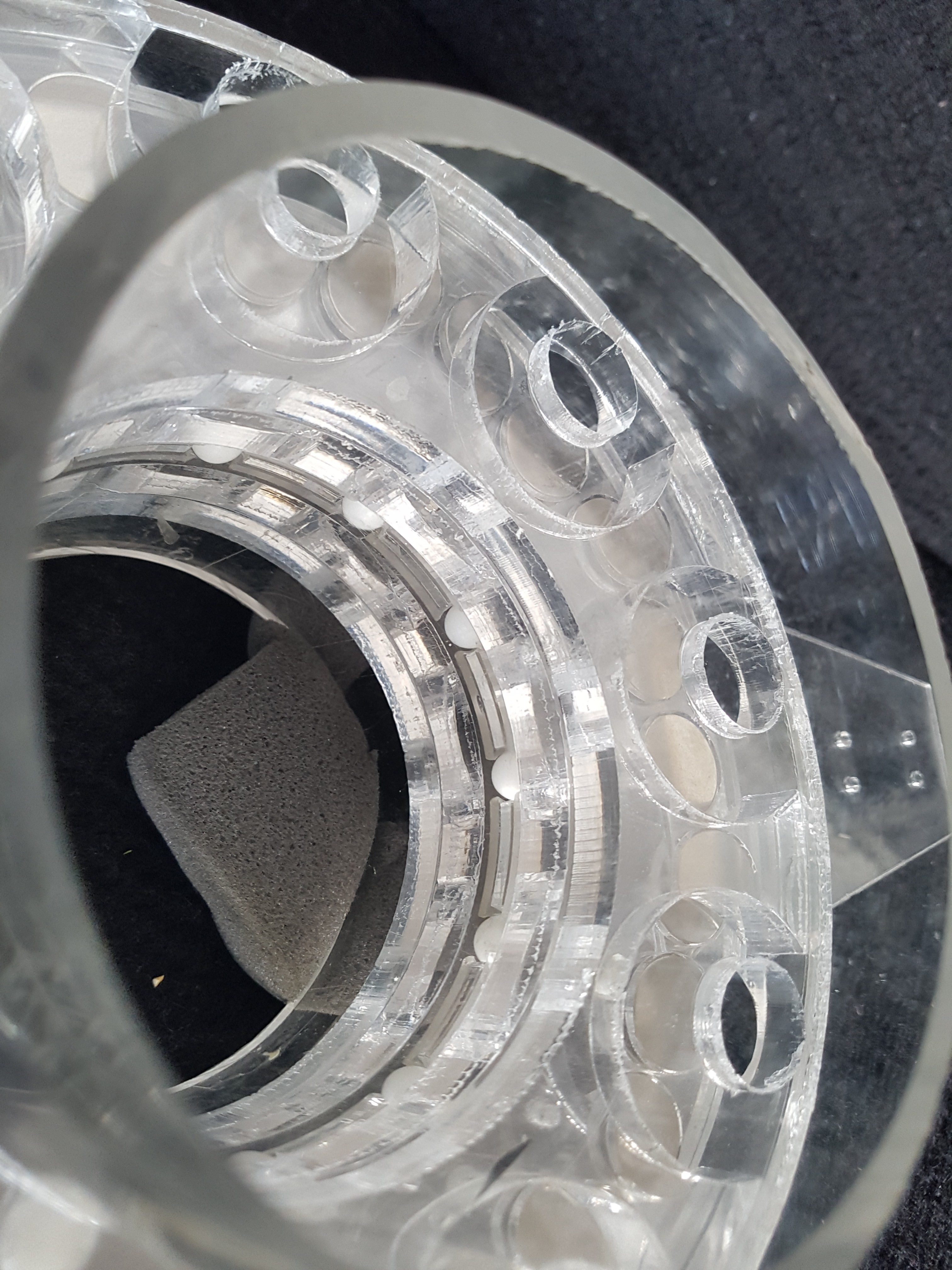

My quick update is that the custom bearing design is not adequate or comparable to what a commercial bearing could give, and also there is wobble on the rotor, unless ball bearings are added on the sides. With the current design these side facing bearings (four teflon balls on the rotor facing the stator coils) are producing too much friction if the made tight enough to stop the wobble.

I believe the ball bearing part of the design needs to be re-evaluated from the beginning, most likely consider off the self bearing solutions (Open to suggestions).

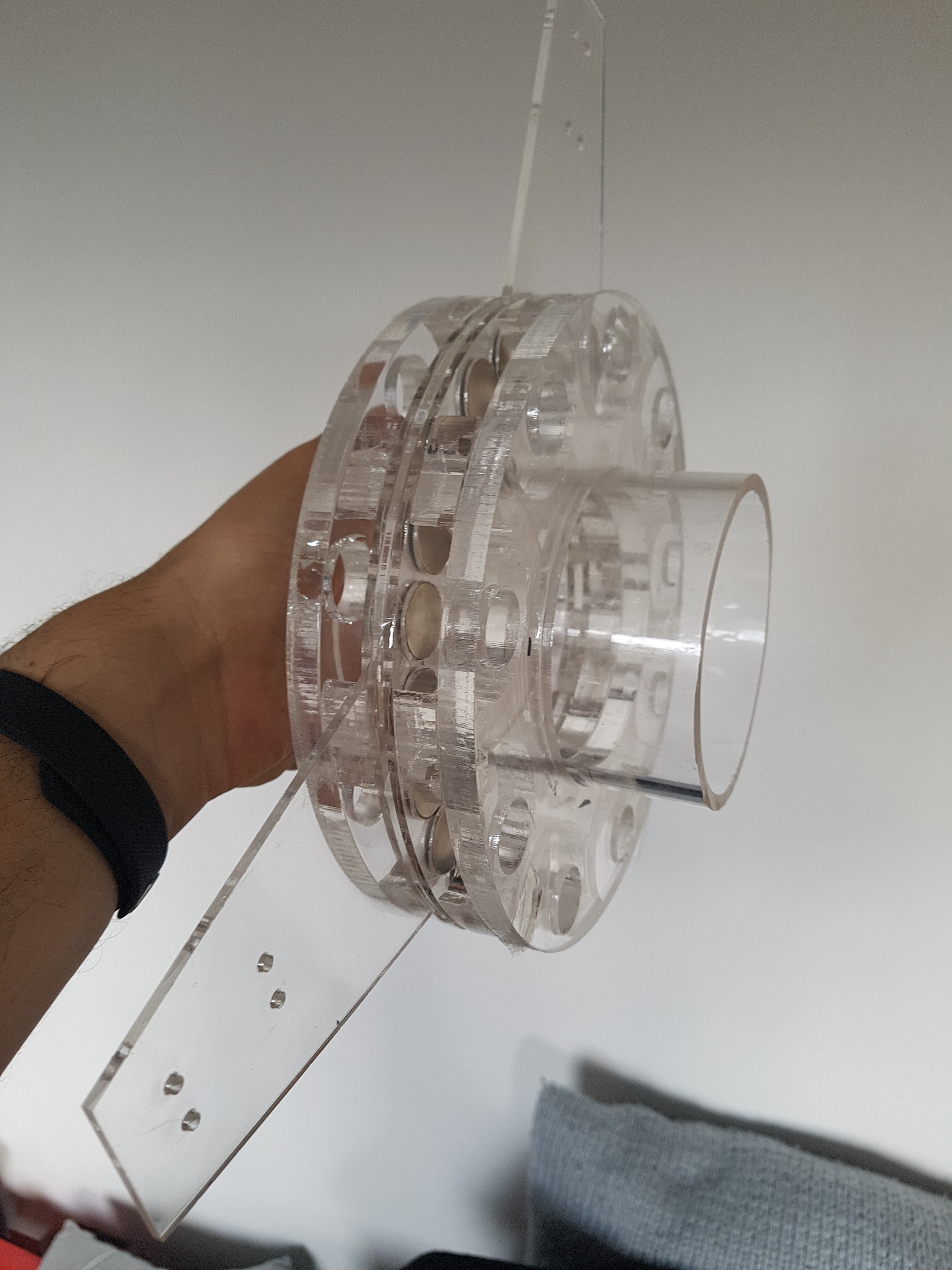

I attach a few more pictures of the a prototype (acrylic) assembly,

Kostas Lagogiannis

Kostas Lagogiannis

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.