The garage in my house was pre-wired with two connections for the wall mounted garage door opener controls. The primary location was by the man door into the house; the secondary location was next to the garage door. The second location provides a convenient way to close the door instead of the awkward run and jump to get under the door but over the safety-beam sensor.

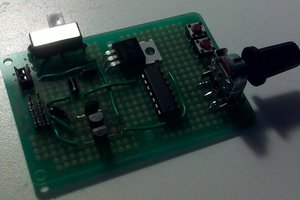

The garage door manufacturer only included one wall mount control panel with my package. The control panel has a back light LED, a vacation lock-out switch, a button to control the door operation, and a button to control the lights integrated into the opener. A quick review of the opener PCB shows the door control button shorts the two control wires, while the light control button connects the two control wires through a resistor.

A quick little project was fabricated to implement the door control and light control functions for the secondary wall control. Two different push buttons were used for a distinct tactile feel between the two functions. A very low quality clear storage box was selected for the enclosure. This box was the right size for the project but the lids did not fit very well. Wrapping the base of the box with electrical tape provided the extra material for the lid to fit securely.

I was going to print out a sticker to put on the lid to mark the button functions and hide the inside of the enclosure. A sticker in the garage environment might not hold up all that great. As the lid was clear, printing a paper insert to sit inside the lid was next solution considered. While this would have worked the final solution was conceived. Draw the button functional icons on the inside of the lid with a sharpie and then spray paint the inside white.

The spray paint caused the pen markings to crackle a bit, adding some character to the legends. Maybe the ink wasn't fully dry. Otherwise this proved to be a long lasting, good looking enclosure. With the lid installed, the spray paint is protected from scratches. The sharpie marks are likewise protected from wiping off or smudging by the lid. No need for extra step to apply clear coat. Overall, a very professional finish for a quick and dirty project.

mulcmu

mulcmu

Audrius

Audrius

Joe De Filippis

Joe De Filippis

Rhys

Rhys