So my soldering dilemma...

I was hoping that the solder on the board from the HASL process together with the solder balls on the CSP and some good flux will be enough. I did this a few times successfully with 1mm pitch BGAs and leaded solder. However now this is 0.8mm Pb-Free. The more I read about it the worried I become.

Alternatively I could order something as a StencilQuick permanent polyimide stencil (75 bucks for a 10pc pack if I understand it right), this would even help placement, however the 125USD shipping fee makes me a bit reluctant.

I could ask for a small steel stencil where the PCBs beeing produces for like 40-50EUR but then I need to fix them properly in place, deal with lifting and after that somehow place the chip into proper position because I don't have equipment for that.

All the articles I found were either about rework, so dealing with cleaned pads, or about mass production onto empty pads. I have no clue how this will turn out for my case. Maybe I'll just try the first one (54USD for a single ZYNQ) and if that fails order some stencils, but that would risk that I can work on this in my winter holiday.

I'm thinking on creating a test firmware that toggles all IOs at least from the PL (FPGA part in the ZYNQ), this way before populating the series resistor array I could even check if inputs are connected properly. I could run this test before soldering the rest of the expensive components.

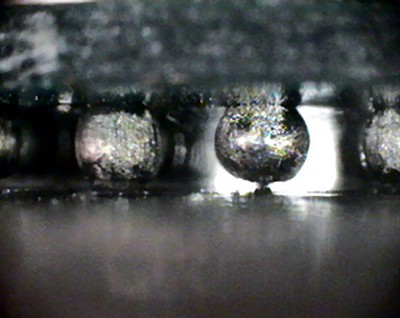

I'm afraid of opens like this:

Marsupilami

Marsupilami

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.