Well not much has stayed the same since my last update.

There came a point where I decided that I wanted to attempt to produce a full color filament printer, and this project went from 'scrap pile, hey it works' to completely insane machineshop time suck.

I scrapped the old ATX PC mobo and replaced it with a Beaglebone Black. I simply didn't have enough I/O on the PC to take it any further. Nothing in the Arduino world had the horsepower I needed for this, but the Beaglebone gave me everything I needed and more:

- A Debian Linux box running on an 1ghz ARM processor

- 512mb ram.

- 4gb onboard flash. SD card slot, which is bootable

- Hardware floating point acceleration

- Hardware 3D acceleration (with some work)

- Ethernet, I2C, SPI, USB master and slave ports, rechargeable battery management, HDMI with audio, 6 channels of ADC

- and most importantly... 2 programmable hardware real-time processors running at 200Mhz, tied to 68 software configurable I/O pins.

It's an engineer's wet dream. I really don't understand why everyone isn't using this thing.

The Beaglebone has turned out to be nearly perfect for this project. It can easily handle driving the 8 steppers, 6 channels of pwm, compute the extrusion required in realtime, and still run at less than 30% proc. However... it is relatively delicate electrically compared to an Arduino. I have fried 2 of them through carelessness and borrowing it for various other short-term projects.

Switched to a junkyard HP server power supply giving me 75amps@12v to play with. Added some fuses. :)

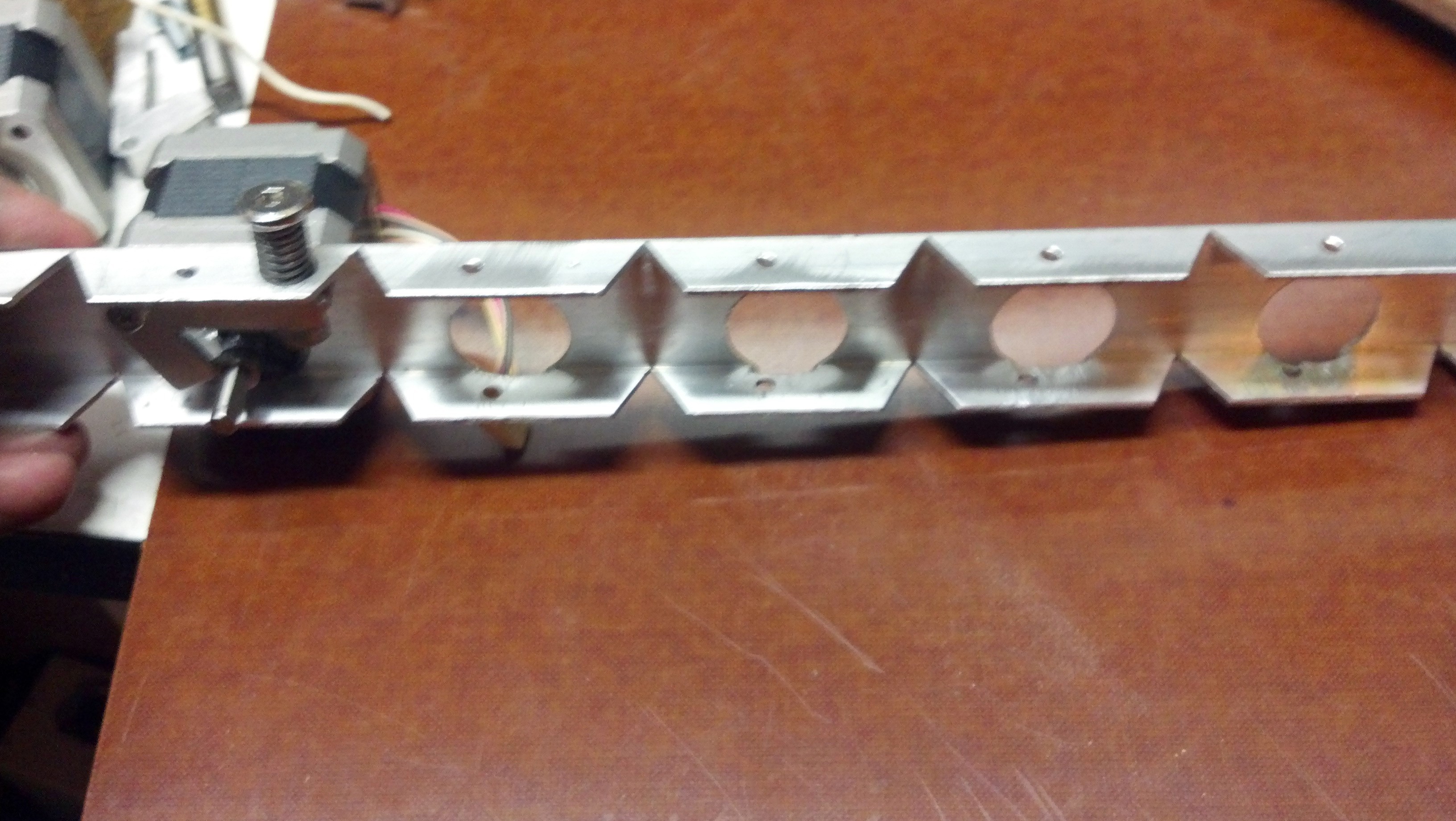

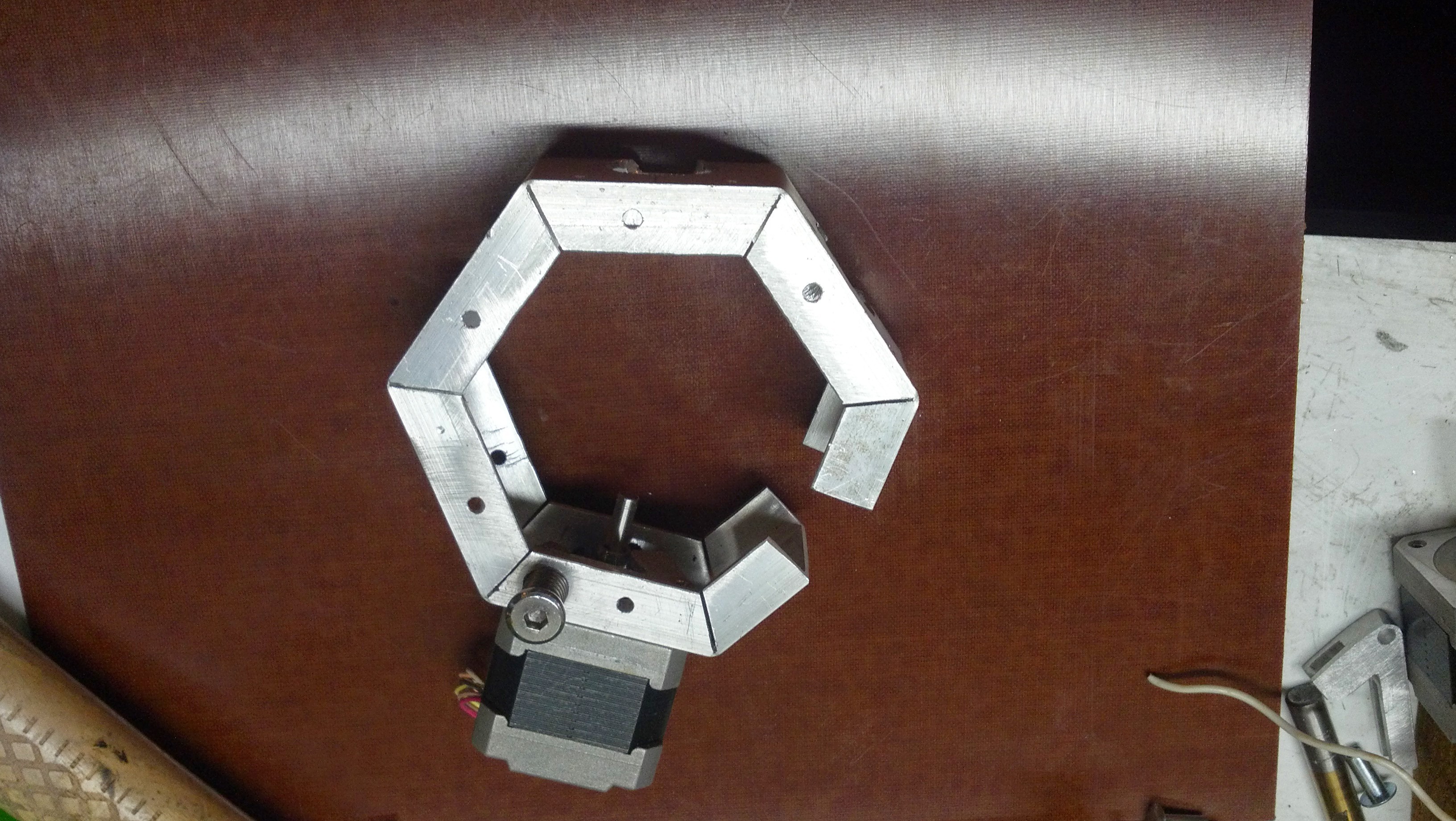

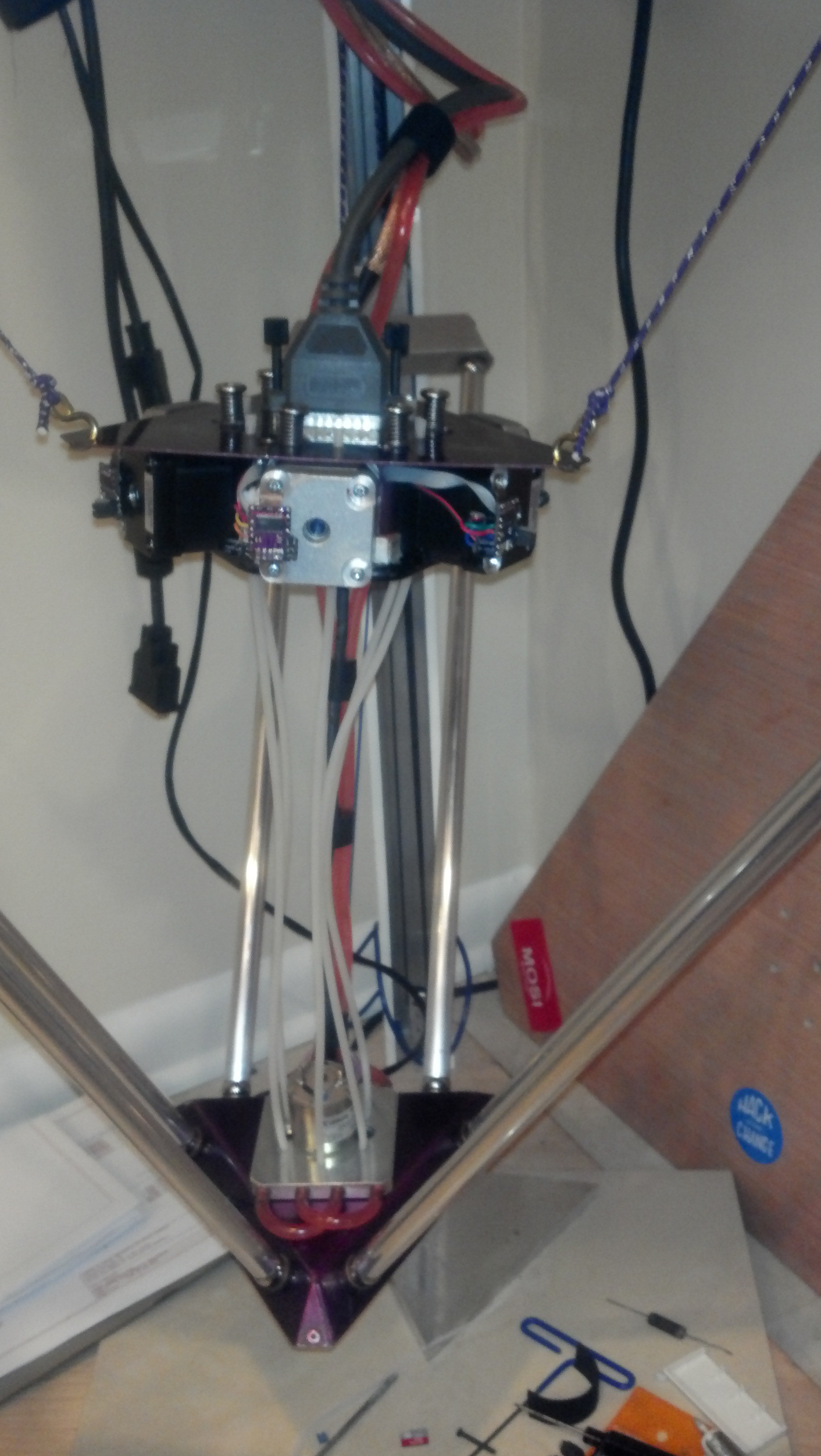

Added 4 more extruder motors for a total of 5. This gave me the choice of either having 20 feet of bowden tubes, or mounting the mass of 5 steppers to my hot-end. Neither was acceptable, so designed a floating carriage. Machined it flat, and bent it to shape.

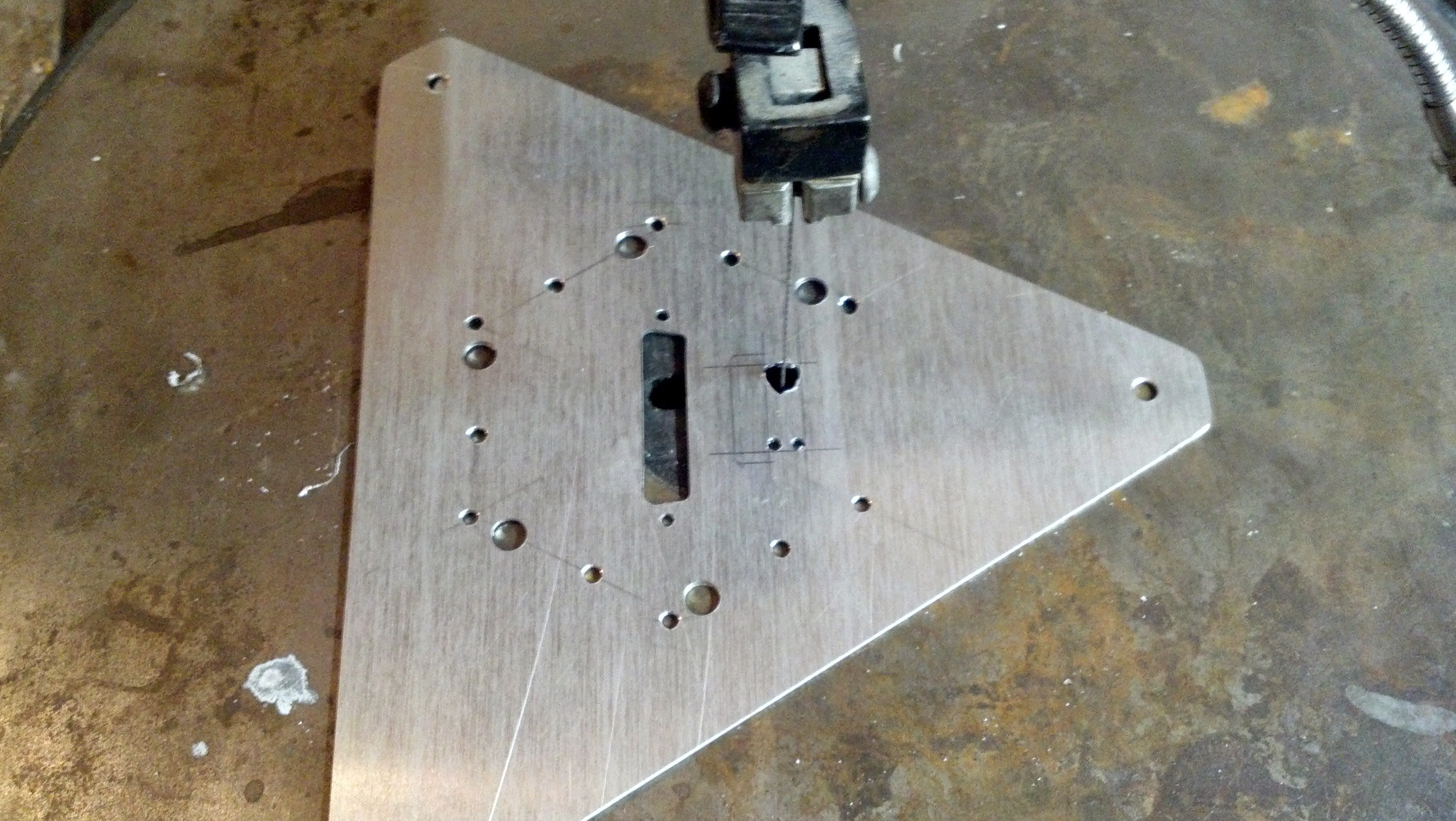

'Machined' the top plate.

'Machined' the top plate.

RIveted. Annodized.

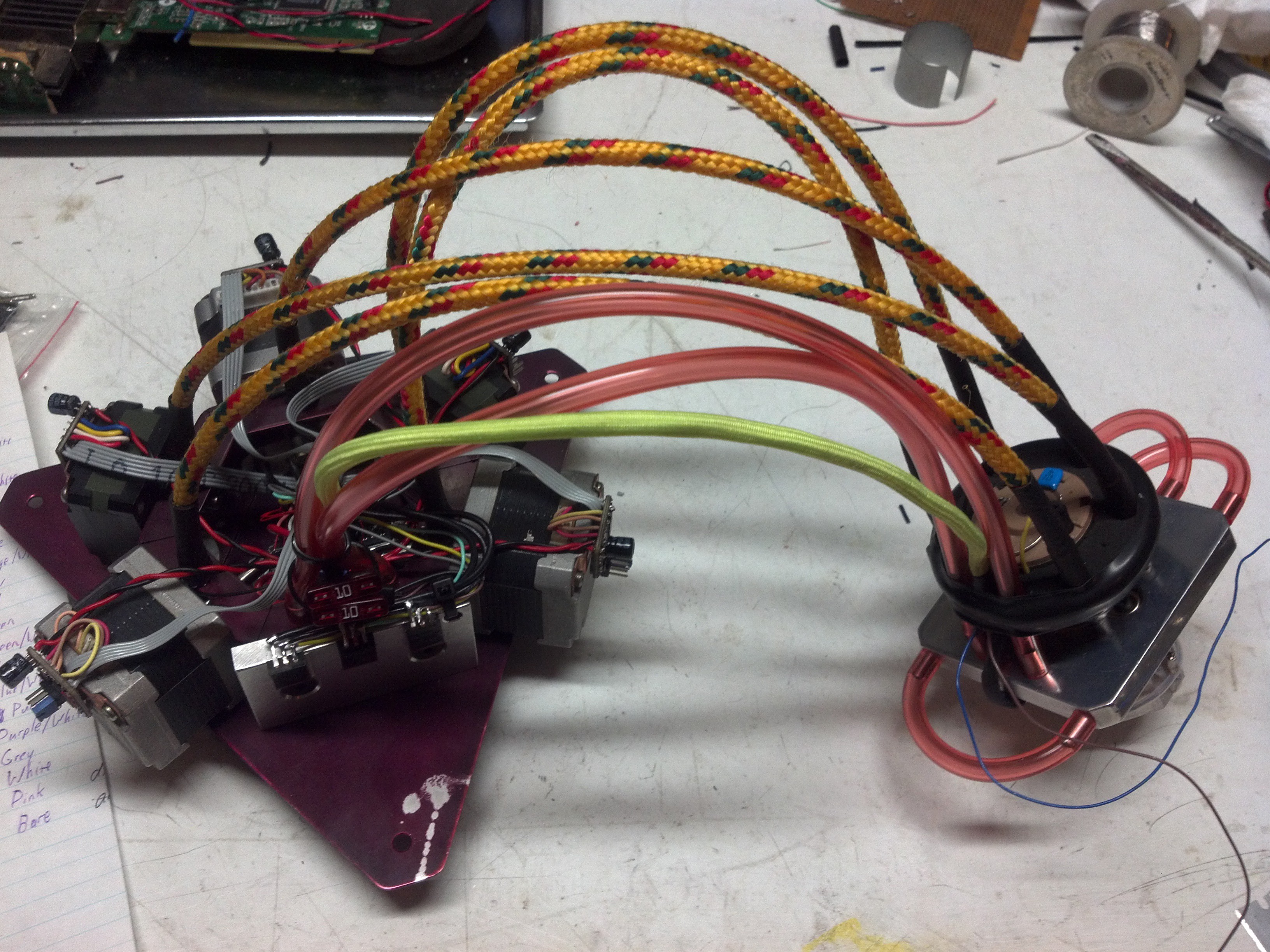

Rather than run ~30 decent gauge wires to the floating carriage, I switched to using DRV8825's and mounted them to the steppers. The backplane of the DRV8825 was soldered to a bit of copper, and then mounted with the existing stepper bolts. The power mosfets were also mounted to the carriage.

Now I can just provide power, and route the signals to/from it via a PC parallel cable (with no wires to spare).

Putting that many steppers in close proximity didn't work so well. PLA would soften at the temperatures generated in the floating carriage and that added up to a bad day. So... added liquid cooling for the steppers. Note the new black tube beneath the steppers. I was already doing liquid cooling for the cold-end and mosfets at this point.

Wrote the software to support it. There was much borrowing from some of the forward thinking guys at the Machinekit project and a small amount of original code. Basically I added a scaling factor to each extruder and the mixer speed, added some g-codes (actually M codes) to match, and wrapped it in a cool UI.

To simplify things, I started with a 'Velocity Extrusion' branch so 'there is no E'. The amount of filament to extrude is calculated from the instantaneous velocity of the print head on the fly.

There is a custom branch of Slic3r which outputs the correct flavor g-code.

Result... Active mixing works!

Here is a pile of pink made from white/red and then a demo of how fast I could change between them.

But...

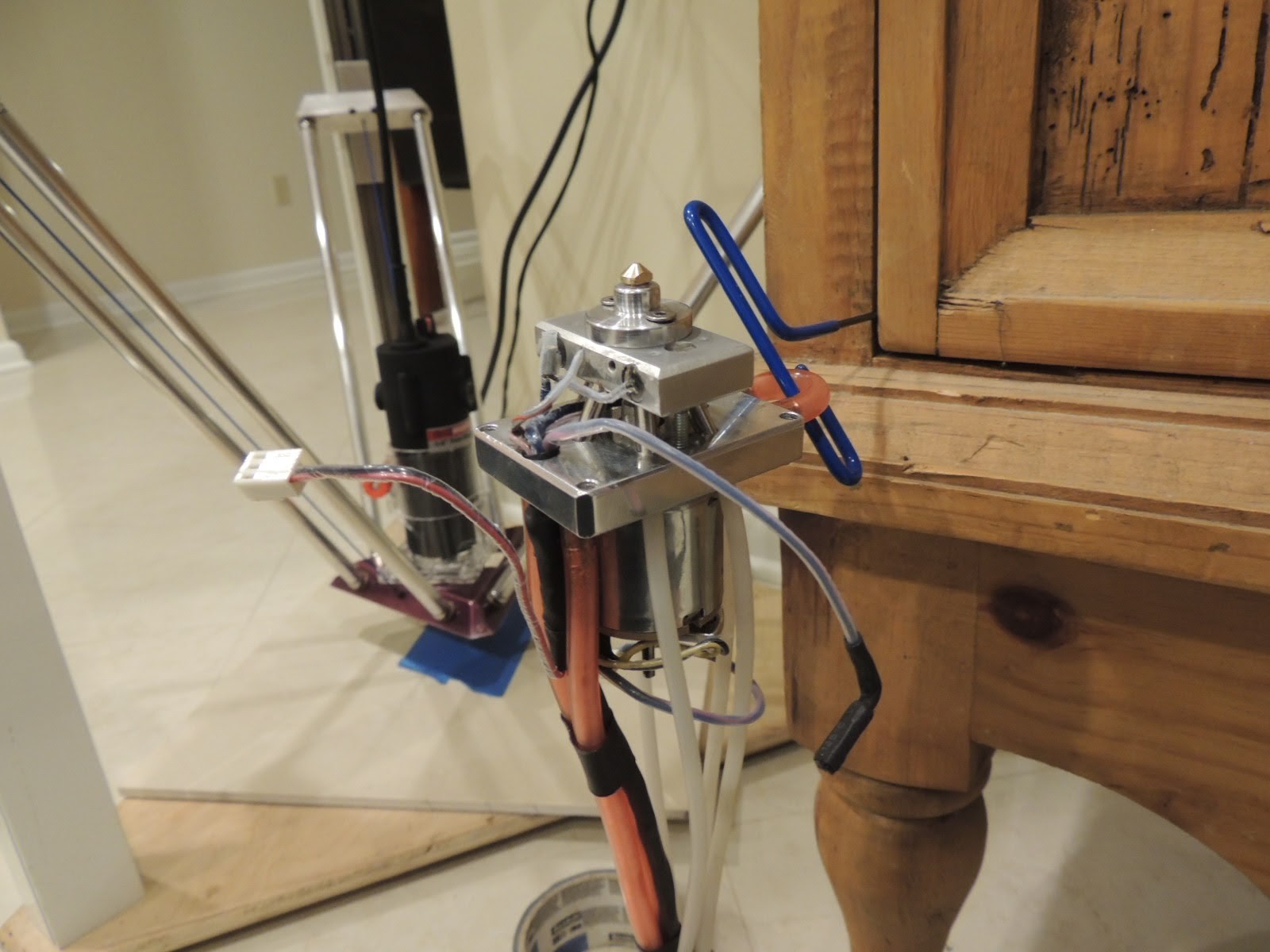

All versions of the active mixing hot-end thus far have eventually started leaking and eaten themselves. The longest running one thus far lasted about a week with light use. I've now gone through 7 revisions of this hot-end:

Versions 1-5 all had some fatal flaw and never worked well enough to actually print anything.

Version 6 printed and stayed sealed for a good long while (a week!), but it eventually leaked around the mixer shaft and ate itself. It had other issues too as it had a lot of thermal mass and suffered from a long melt area. It was modified many times until I machined away too much to continue with it.

Version 7 was born. It was 1/4 the thermal mass, smaller, easier to machine, but it also implemented a new spring loaded idea for mixer sealing which turned out to be terrible. It ate itself in 5 minutes.

Version 7.1-ish was born. I re-machined Version 7 to use the same type of seal as Version 6 and have added the ability to adjust the seal tension after assembly.

Here is the (nearly) latest revision of the hot-end. You can see a router experiment in it's place on the delta in the background.

Then.. life happened and I had to take the last few months off.

I finally was able to spend a few hours on this in the last week, but on final assembly I damaged my mixer seal before I ever got to try my new hybrid. :(

I now have some glass filled PTFE to play with though, so I'm going to see how that works when I get the time to re-make it.

Daren Schwenke

Daren Schwenke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.