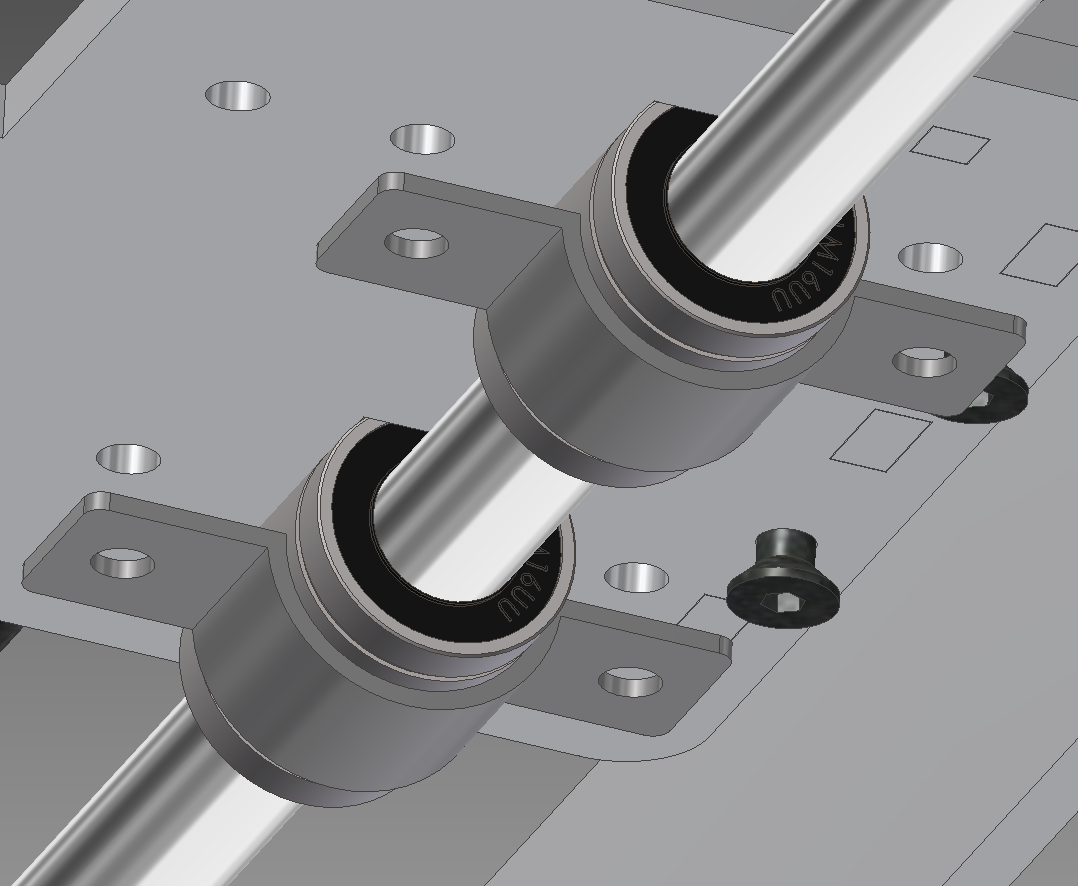

As I mentioned currently my plan was to hold the linear bearings in place with the pipe fasteners and a 37x20 mm cutout in the board. I am not happy with that anymore, though.

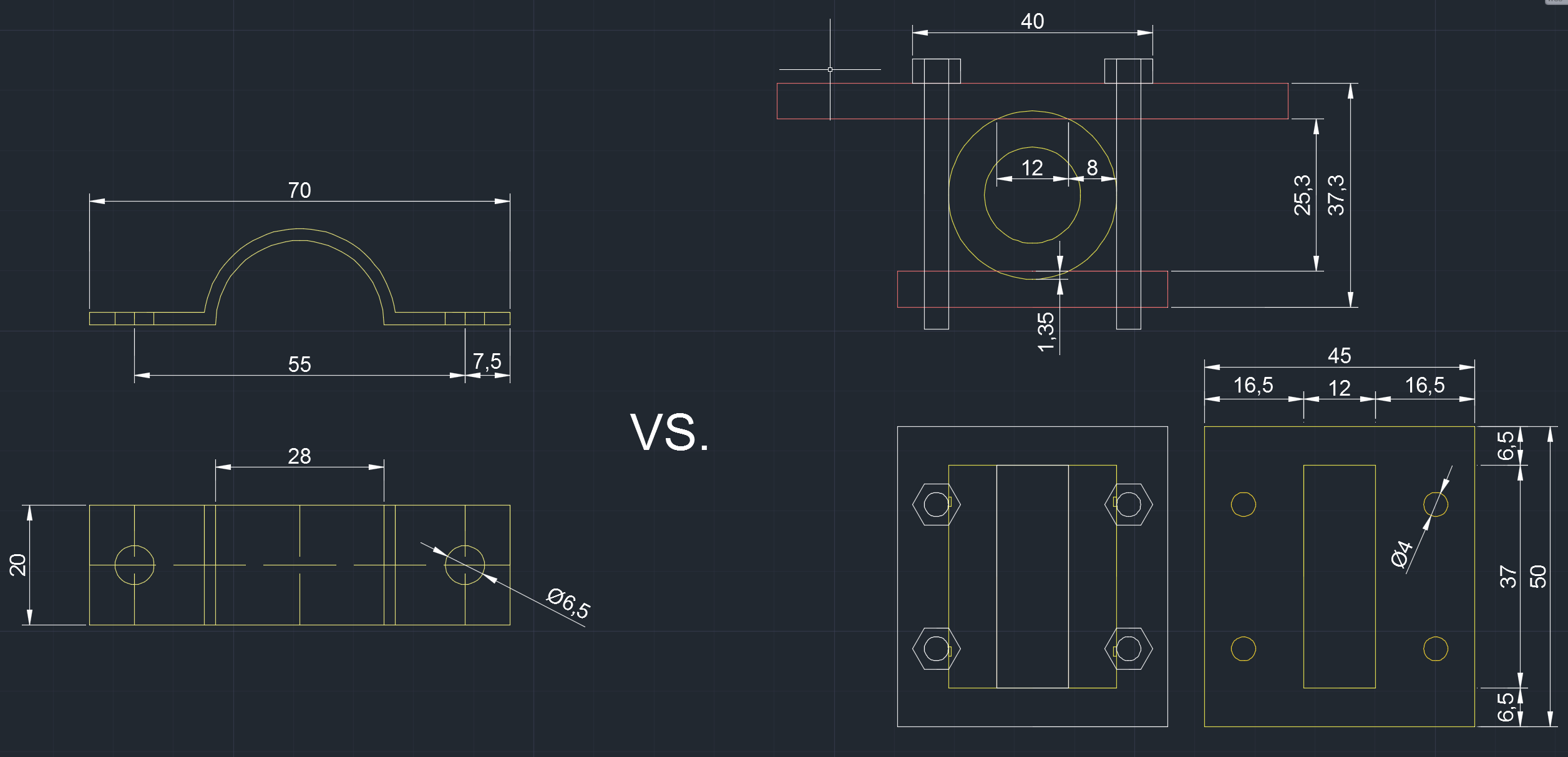

It is pretty wide (70mm) for a start and uses M6 bolts. Out of these two being a bit too wide is the main issue as it costs me about 50 mm of potential work area in z and y axis. So I have a new idea to use instead smaller acrylic plates to hold the linear bearings in a smaller cutout (M4 bolts). Something like this

I have some reservations if 6mm acrylic is mechanically durable enough for that as I have not worked with acrylic before, but the price per bracket should, in theory, end up even slightly lower than using the pipe fasteners (that cost about 1 EUR a piece in the local hardware stores in the needed size). The draft is with zero tolerances - final part will need some wiggle room. Another note is that I'm not particularly happy about these cutouts either - the contact surface with the linear bearing would be rather small and needed tolerances far too tight for it to work in real life I suspect. Plus I'm trying to not over engineer stuff - at the cost of extra component - I could just add a extra bottom bracket as well.

Note how, if I use 6mm thick plate the bottom plate would touch the linear rod with zero clearance. Using some other material thickness, on the other hand, might drive up the costs a bit more and add complexity to the machine I'm not that keen on.

I will, probably, end up using the two different thickness plates approach as it seems, after some thinking over it, it seems more reliable than getting a 20x37 mm hole in the plate doing the moving with uber-tight tolerances so that all the linear bearings would be perfectly aligned. I will probably have to visit the shop I looked up which sells acrylic and see what the prices are - perhaps it is not that bad and I can get few sheets of 4mm acrylic as well without doing too bad things for the budget.

Then it would be time to do some numbers and figure out if it would be after all more economical to get the linear bearings with mounting blocks vs jury rigging something together myself.

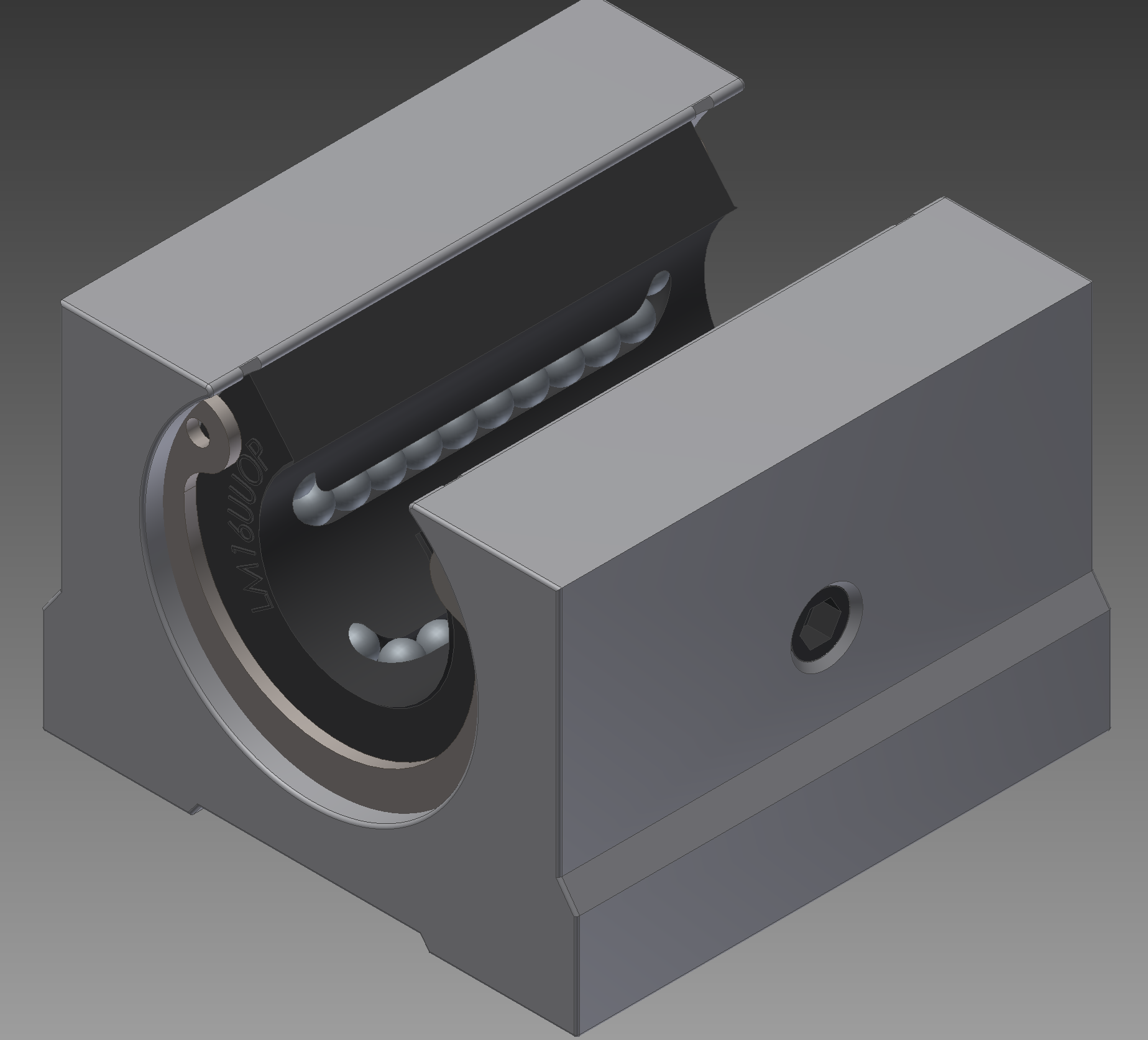

Edit: After sleeping over it I have decided to do some more digging in ebay/aliexpress to dig up more options for linear bearings with a block. Even with the extra shipping charges associated with heavier packet it should turn out to be much more reliable than re-inventing the wheel myself. Preliminary digging around with my morning cofee indicates that a semi open 16mm block could come out about 3 EUR extra per linear bearing. Sure, that is about 10% of my intended budget but at the end of the day with everything considered doing my own mounting option in acrylic might not come out substantially cheaper and definitely would not come out much cheaper if I would have to do it in metal. Pity there is no 12mm calibrated rods available around here. Linear bearings for these would be more economical. The rod sizes available around here are 8 mm, 10 mm, 14mm, 16mm, 25 mm and upwards for the calibrated ones.

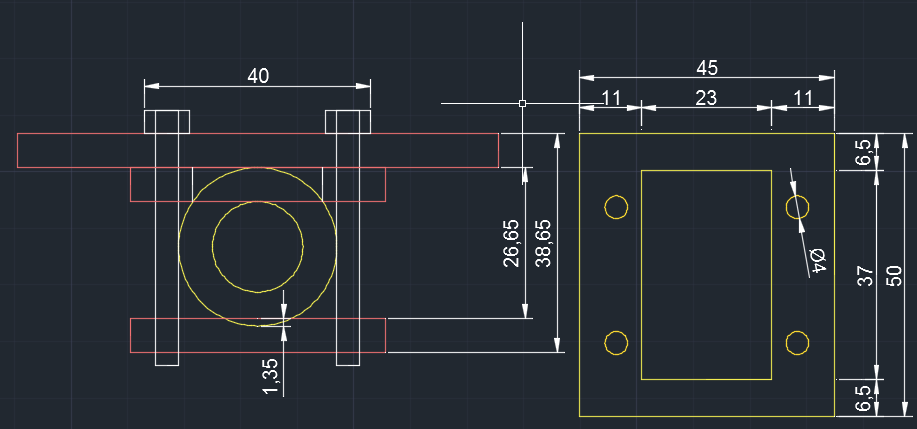

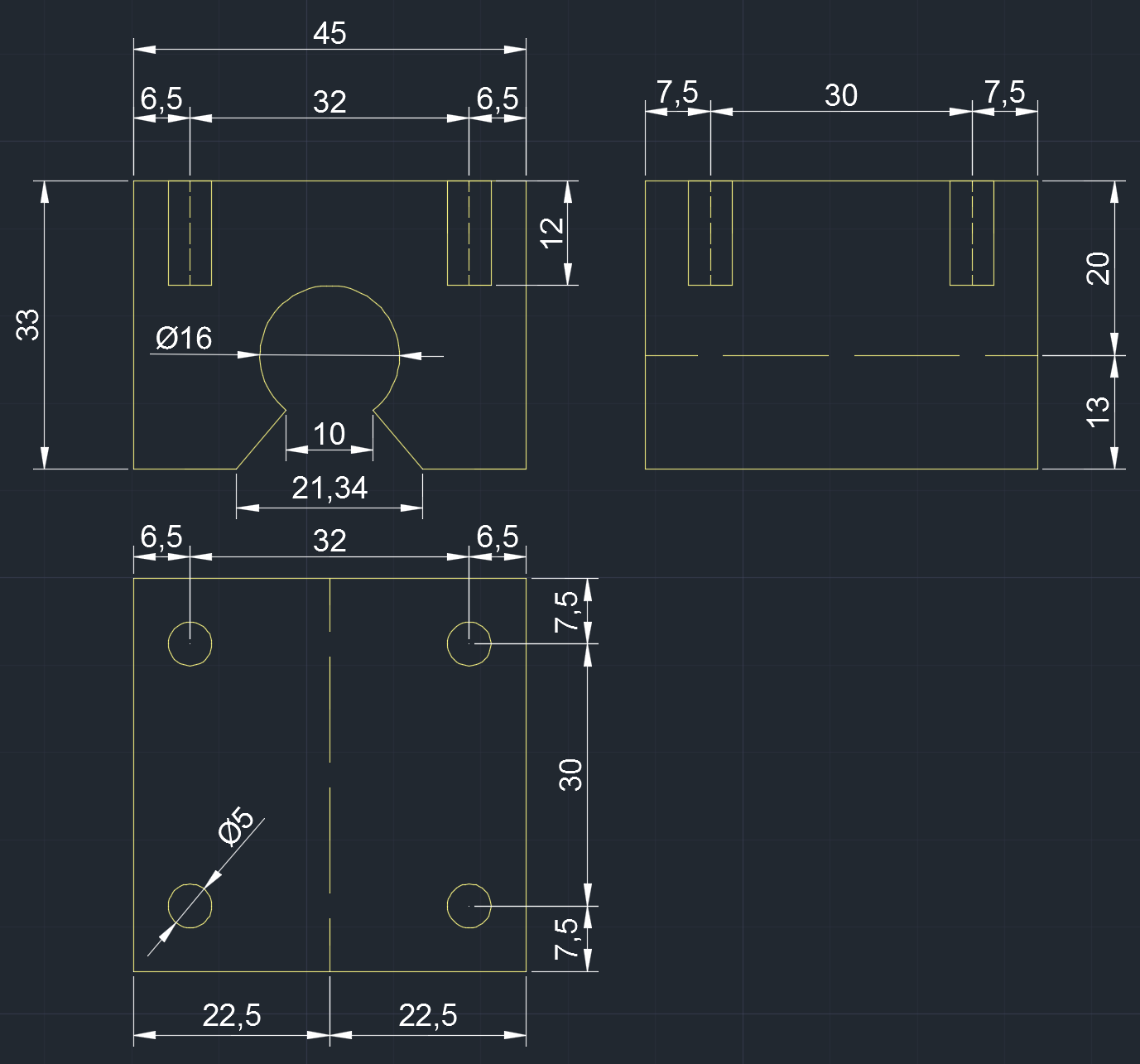

I think I will use SBR16UU linear bearings. These are the "open" kind with a cutout for a rail supported rod but that is not the reason I'm opting for these - main reason is that they are 5 mm smaller in height than closed ones (33 mm vs 38.5 mm in height) and smaller width wise (45 mm vs 50 mm). The fact that they are open ofc means that they are probably mechanically not as durable if force is applied in a "wrong way" but then again I'm not expecting particularly violent forces considering the relatively small dimensions of my intended machine. If crap starts getting in them through opening on the side I can just apply some duct tape over it to cover it up.

Opting for "real" linear bearings with mounting block was ofc not gentle to my budget. It went from approx 190 EUR up to 230 EUR before frame assembly. That leaves only about 70 EUR budget for getting the frame done and for any unforeseen obstacles. But we will see, the budget is more of a guideline than a hard limit atm (within a reason) - it is, afterall a bang for buck machine, so as long as extra expenditure yields substantial benefit it must be considered. What I spend in extra budget I win in the construction being simpler. I ... think...

As an added bonus someone had already done it and uploaded to GrabCAD https://grabcad.com/library/sbr16uu-16mm-open-linear-bearing-1

Did also a new draft in CAD based on the numbers on the spec sheet. I suspect the height of that block I grabbed from GrabCAD is off by about 4 mm or I have missed something. Anyway - in my thinking process for the new revision (Which for me happens in AutoCAD) I'm planning to use following draft

Kert

Kert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.