Seems that two moths is really big challenge for such a complex project like this :D

As my thesis supervisor suggested, I did implemented pressure sensor for check if component was picked up or not. For this purposes I ordered MPXM2202AS from Farnell. This sensor has differential output with only 40mV full scale. So the differential amplifier was needed.

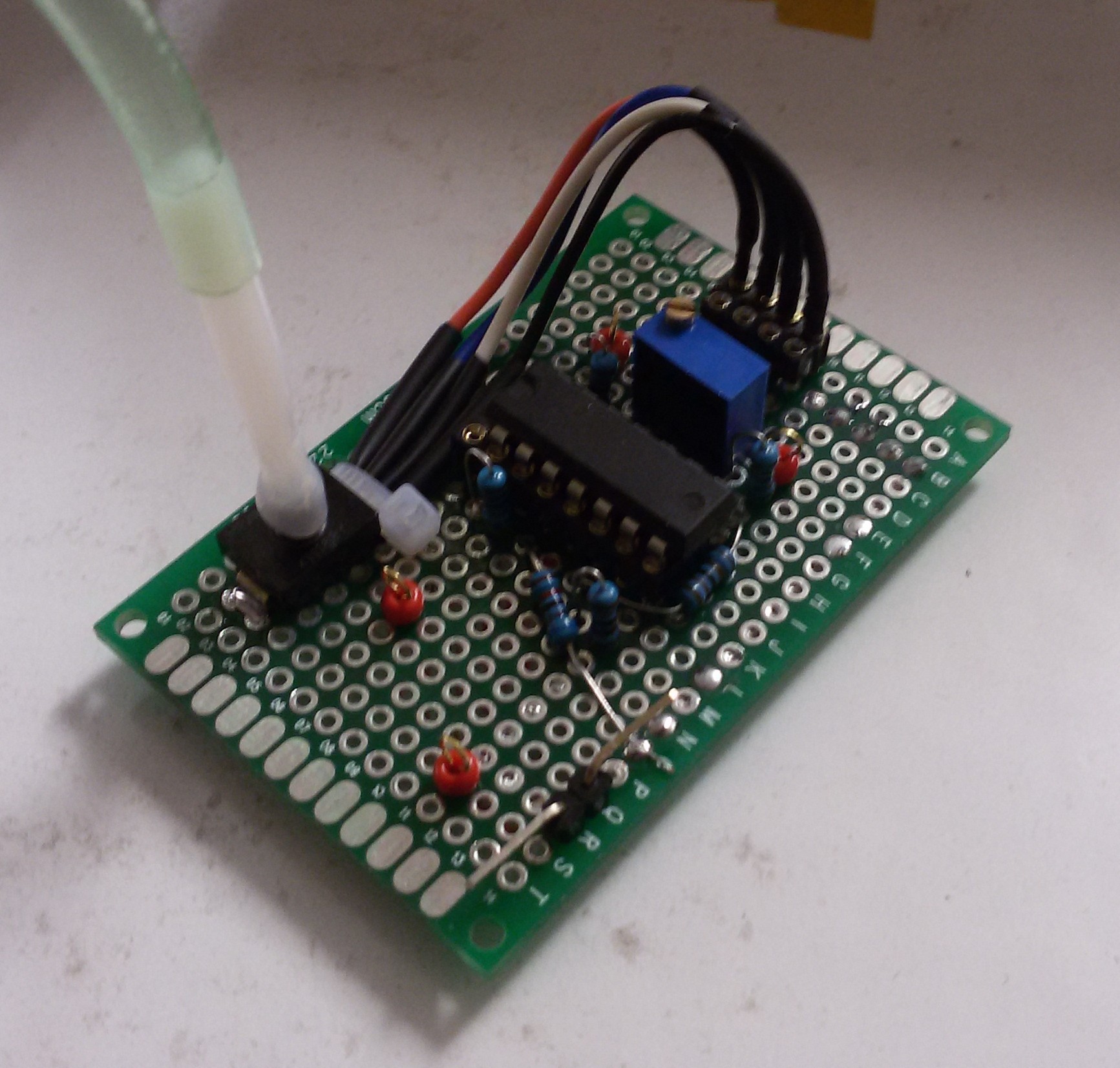

Here is the prototype

Output is set to 3V at atmospheric pressure and goes down to 2V when pump is directly connected. This should give me enough range to detect presence of components.

Output is set to 3V at atmospheric pressure and goes down to 2V when pump is directly connected. This should give me enough range to detect presence of components.

Feeders

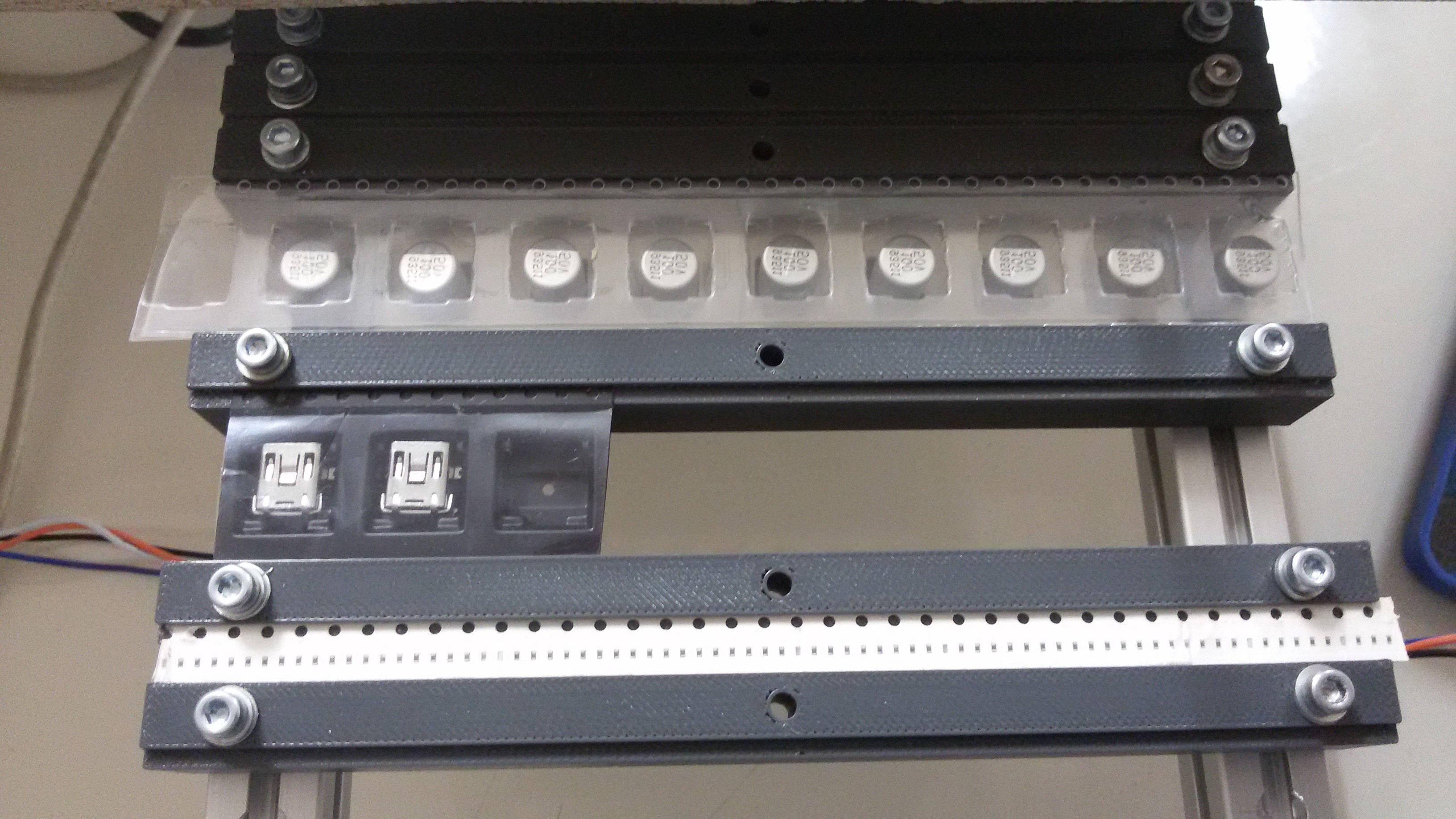

Most of the components which i normally use came in cutted tapes. After few minutes in OpenSCAD and two iterations I came with following solution.

For the rest of the components there will be "single component" type of feeder implemented.

Make a good feeder is crucial, so I expect a lot of redesigns.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.