A quick interlude

M.Bindhammer's Hackaday Prize project proposes making hand-held chemical reactors for the synthesis of Aspirin.

Whether making Aspirin locally is cost-effective or not, I like the idea of hand-held chemical reactors that anyone can make. If the "proof of concept" can be made with Aspirin, then his ideas may lead to a wide array of hand-held chemical processing components.

We have a laser cutter at my space, so I offered to make and send him some prototypes. The results are below.

The first one on the left is a vacuum filtration system. You put a section of filter in the horizontal slot at the top, then connect a vacuum pump to the passage leading from the side. (Doesn't photograph well - see his project page for info.)

The second one (middle) looks a lot like a reflux distillation system, which would be totally awesome if that's what it is & it can be made to work. The third one (right) is how the plastic comes from the laser: sticky paper protecting the surface, and without the intervening blocks removed.

These are comprised of 3 acrylic pieces: a clear face and back plate (upper left) with 0.3" ivory acrylic in between. To assemble, you line up the middles on the plates, then dribble a little methylene chloride (MEC) at the interfaces using a syringe. MEC, an acrylic solvent, gets soaked up by capillary action and dissolves some of the acrylic. Then it evaporates, leaving the acrylic pieces welded together.

If I understand his process, acrylic *should* tolerate the temperatures he needs for his synthesis, and should be immune to the reagents. (And if not, it's still a good material for a physical prototype.)

Check out his Hackaday Prize project for more info. His ideas hold a lot of promise.

Power supply development is proceeding apace

I figured out a lot about computer PSU transformers, and now have a good idea of which ones are good to use for this application; meaning, I can now write a build procedure that describes to others what to look for when scrounging for this part. If everything holds as I think it should, anyone who wants to build an ultrasonic supply can use one PSU for power and cannibalize another one for this singular-and-difficult-to-find part.

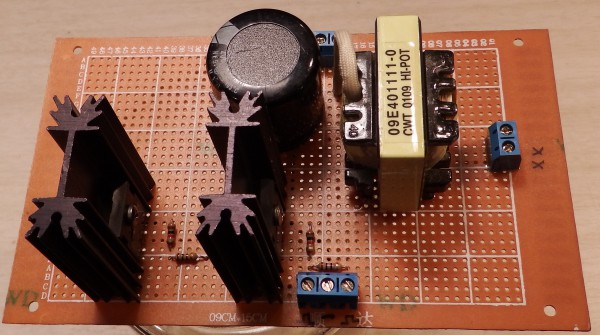

I got my UC3525 SMPS controllers running on a breadboard, and made a new power control board, shown below. Testing starts tomorrow.

Peter Walsh

Peter Walsh

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Awesome! Thank you, Peter

Are you sure? yes | no