In order to enhance the communication of my concept i decided to use the waiting time for the anodised parts for some drawings which should help to explain the concept behind the Blackbox.

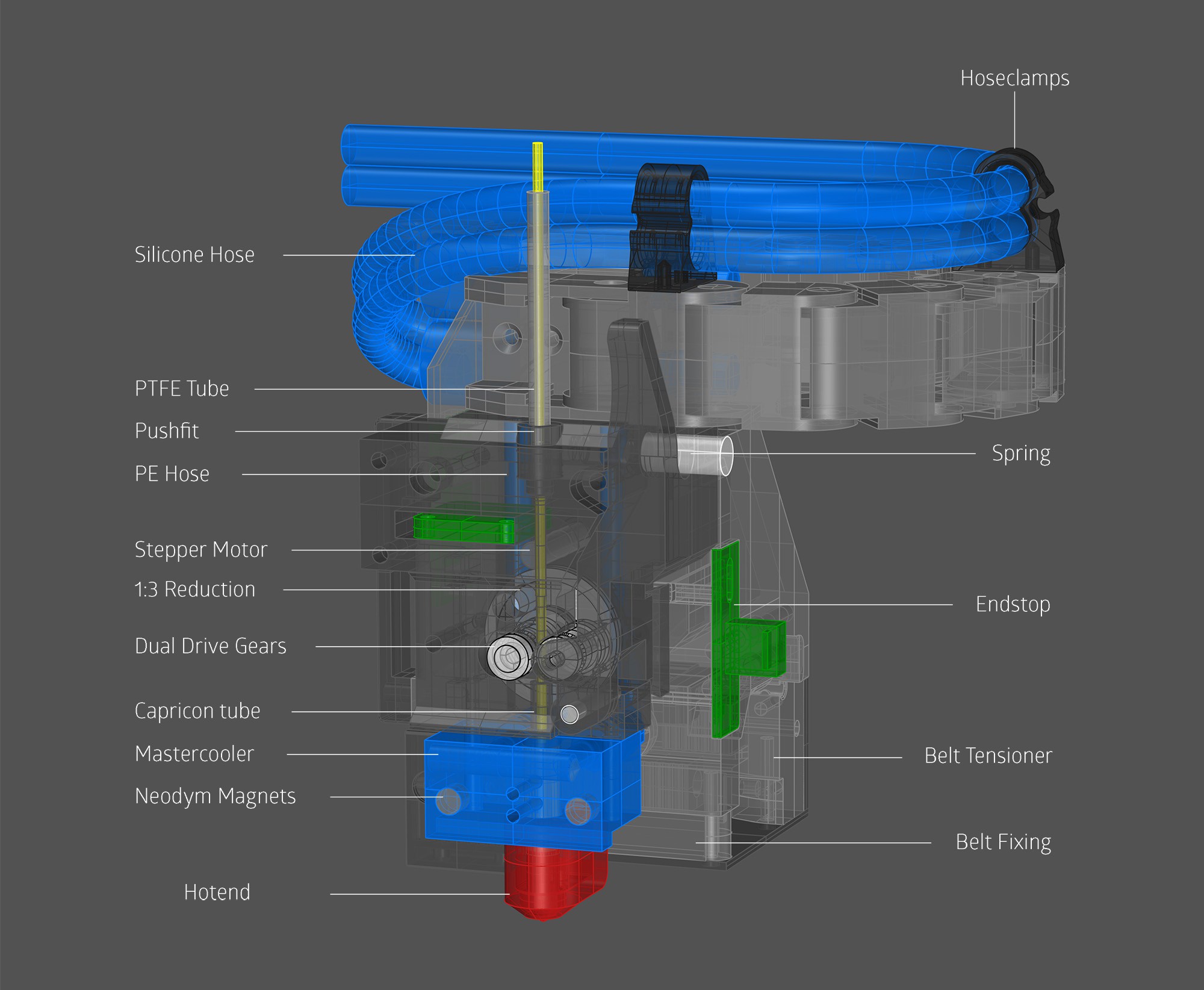

X-Axis, direct drive extruder and toolchanger.

Toolchange process, the X-Axis has a watercooler as well as the toolbank. So no matter where the tool is hooked to it gets cooled by it.

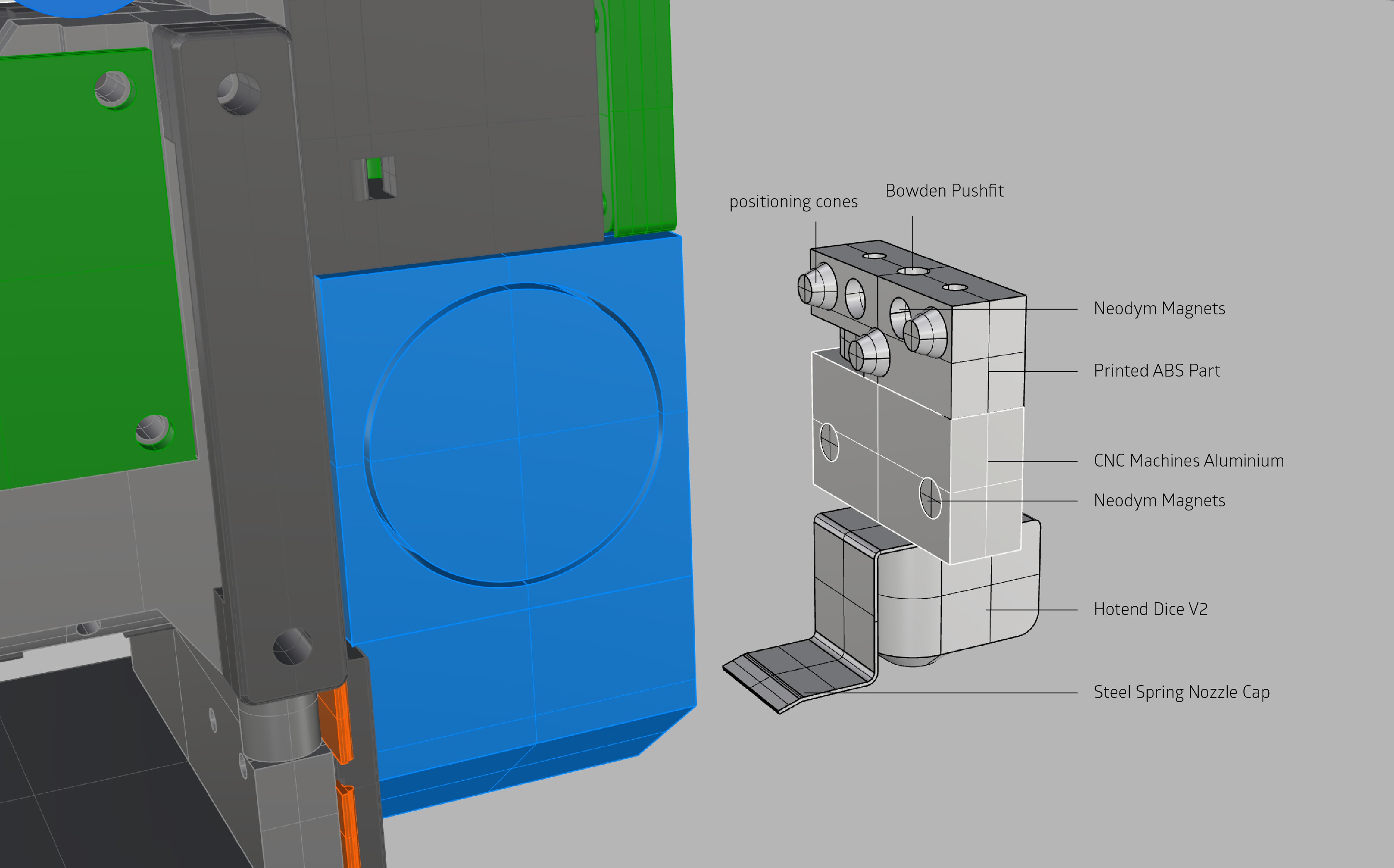

A single tool close to the X-Axis. The CNC machined alumium parts touch the Mastercooler and are constantly pulled by neodym magnets. The tools can be very compact and lightweight that way. Lightweight tools are making the coupling process much easier.

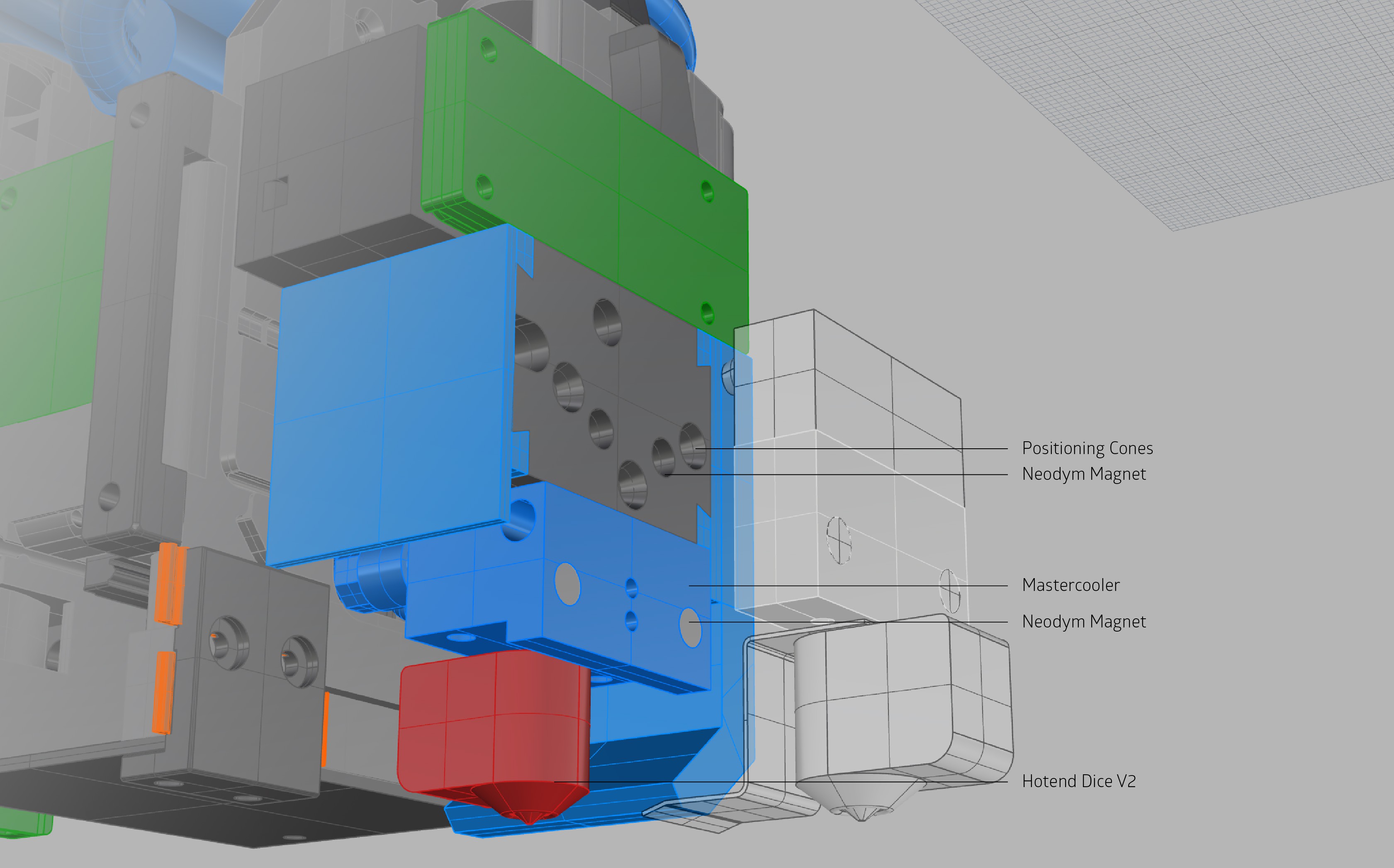

The X-Axis side of the toolchanger. You can see the blue Mastercooler which features two neodym magnets. Dividing the tools and the coupling into two Parts (Aluminium parts for cooling and printed parts for coupling) makes this solution way more accessible.

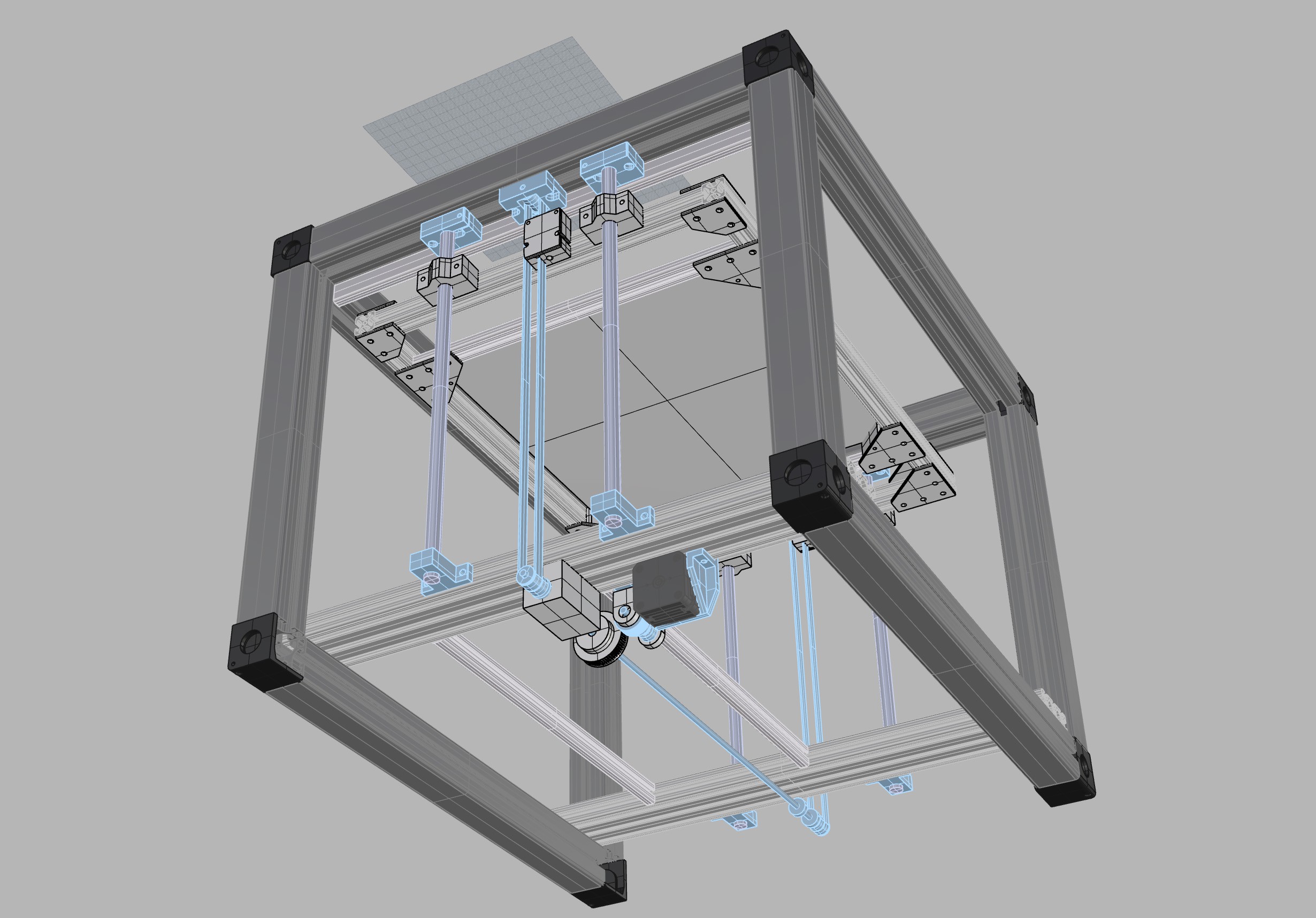

Here you see the belted Z-Axis. The reduction happens next to the stepper motor which transmit the force to a 5mm rotation axis.

Marc Schömann

Marc Schömann

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.