This latest pull request introduces a few modules (and 3D-printable files) designed to solve power-related issues. One of the main concerns I've had over the past several months was how readily-available power supplies & batteries might fit into the specification. One of the goals of the specification is to encourage adopters to use parts they already have in their shop. Power tool batteries, for instance.

Presently, most connectors noted in the spec at http://retrospec.cc have pins which can accommodate up to 20VDC. Most power tool batteries have a nominal voltage of around 18VDC, but can exceed 20VDC at full charge. For these types of batteries to be used, the average max power rating for connector pins needed to be higher. How high, though? An RC-industry 6S LiPo battery can exceed 25V at max-rated charge. Most golf cart batteries (and newer fancy RV batteries) have a 24VDC nominal voltage. In the end, I decided to go with 30VDC max voltage on most pins in the new proposal. Many inexpensive DC-DC buck voltage regulators are rated to work with voltages up to 30VDC. These regulators can easily fit into most modules, run efficient & run cool. This higher voltage allowance permits more power-hungry modules on the same relatively thin wires.

The new pull request (http://retrospec.cc/new) includes STL files for the two leading power tool manufacturers & reference information. Files for other leading power tool manufacturers will become available within the coming months. Support for LiPo batteries of varying form factors will follow. For lower-power projects, the good ol' 9V Battery module will certainly suffice.

The larger batteries presented a new opportunity for a standardized modular footprint. After messing around with a few different approaches I settled on the idea that one should be able to just print (or CNC/laser) thin plates... or full enclosures. The hole pattern accommodates up to 2X DA connectors, up to 2X DB connectors, up to 2X DC connectors & up to 4x DE connectors. These connectors, when mounted, should ideally be arranged in a palindromic fashion for greater ease of use.

All power-supplying modules using this footprint should have all female connectors. Each pin on a typical D-Sub connector can accommodate about 5A. As such, resistor-style fuses (or auto-resetting fuses) should be between each power pin and the actual power source. The connectors should ideally have all contacts properly connected so a small module plugged in on one side of the footprint can talk to a small module on the other side. If you're in a rush... just wire up the power contacts. You can always come back later & upgrade.

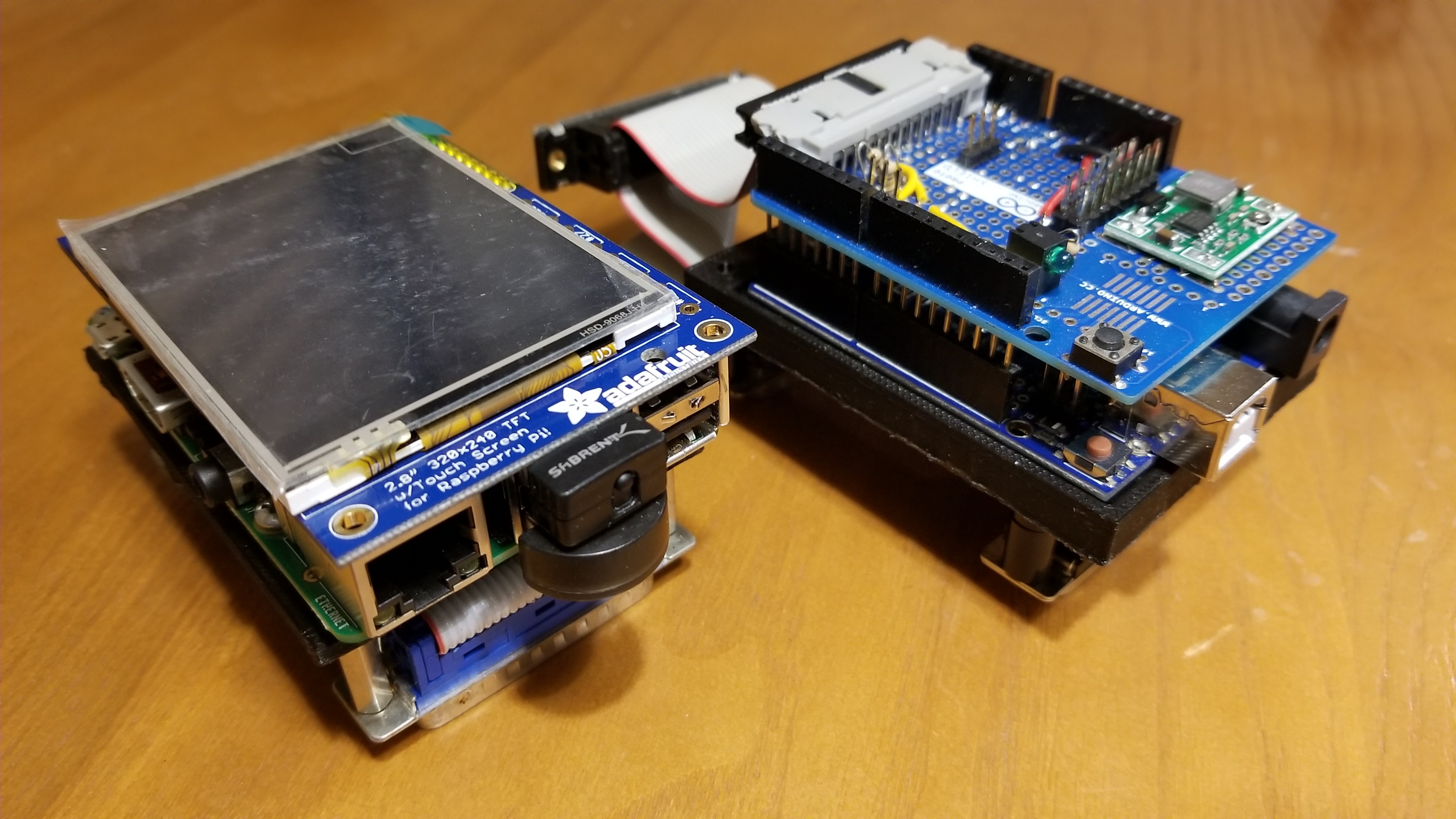

The footprint will allow for all sorts of small-form-factor computing devices to run atop a power tool battery. The new pull request includes STL files for Raspberry Pi devices & full-size Arduino devices... with support for more devices coming soon. Each of the holes in the STL file designs are compatible with M3 screws or Imperial #6 screws. Screws & standoffs can be purchased at many PC or RC part supply stores.

Since there are 2X 30VDC pins on DB-25 connectors & 1X 30VDC pins on DE-9 connectors, the configuration shown above can accommodate up to 30VDC at up to 30A. Please make sure to check the new PR (again at http://retrospec.cc/new) for new pin specs for high-current D-Sub connectors (with some accommodating up to 60VDC at up to 80A & some soon which will accommodate 60VDC at up to 160A).

This PR is a big bold step for this little free modular framework.

William

William

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.