This projects has continued to grow and I am very pleased that the first few sales have started to fund other projects related to this. I recently finished my upgraded resin dispenser which is working flawlessly. I had two more molds machined and have tripled my production rate. As the production rate increases bottle necks have been found that slow things down. One of these is the heating of the molds. I originally mounted two heater coils into the mold and connected those to an arduino and a solidstate relay. This works fine for a single mold and I left the design open to be able to control 3 such molds. However, now that I have been working on this project I see that this might not be the best way to go.

First, it requires me to mount the heaters into the mold. As I get more molds this means that each one would have an additional $16 worth of heaters and a thermocouple built in. It does not make sense to do it this way. So my current plan is to separate the heating from the mold. This is actually quite common in injection molding machines.

Another problem with having a single control box to run 3 sets of heaters was that they must all be close together or have long wires running around. A hotplate fixes this as well. It will be slightly more expensive because I will use 3 micro-controllers but these parts are not very expensive.

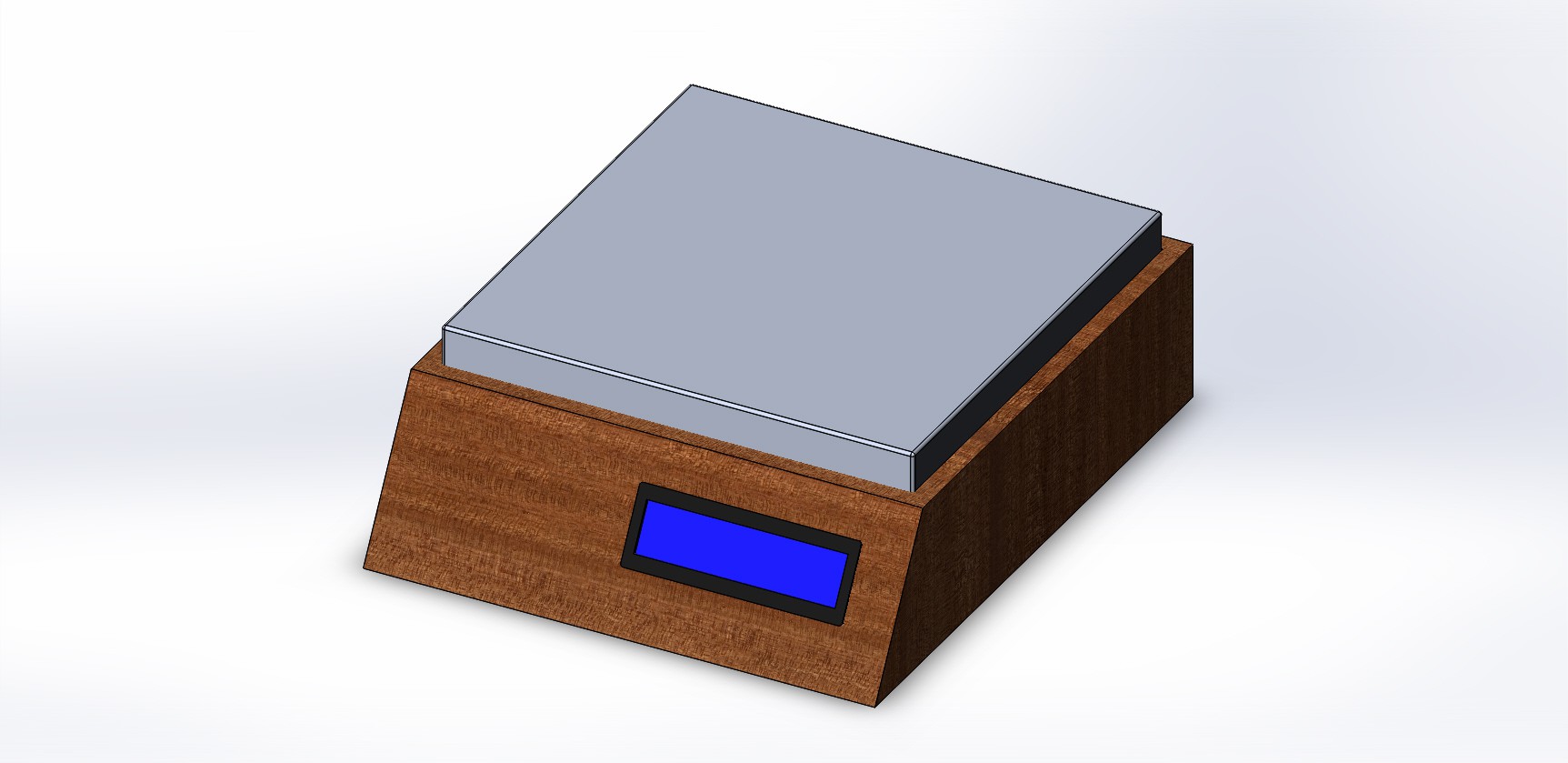

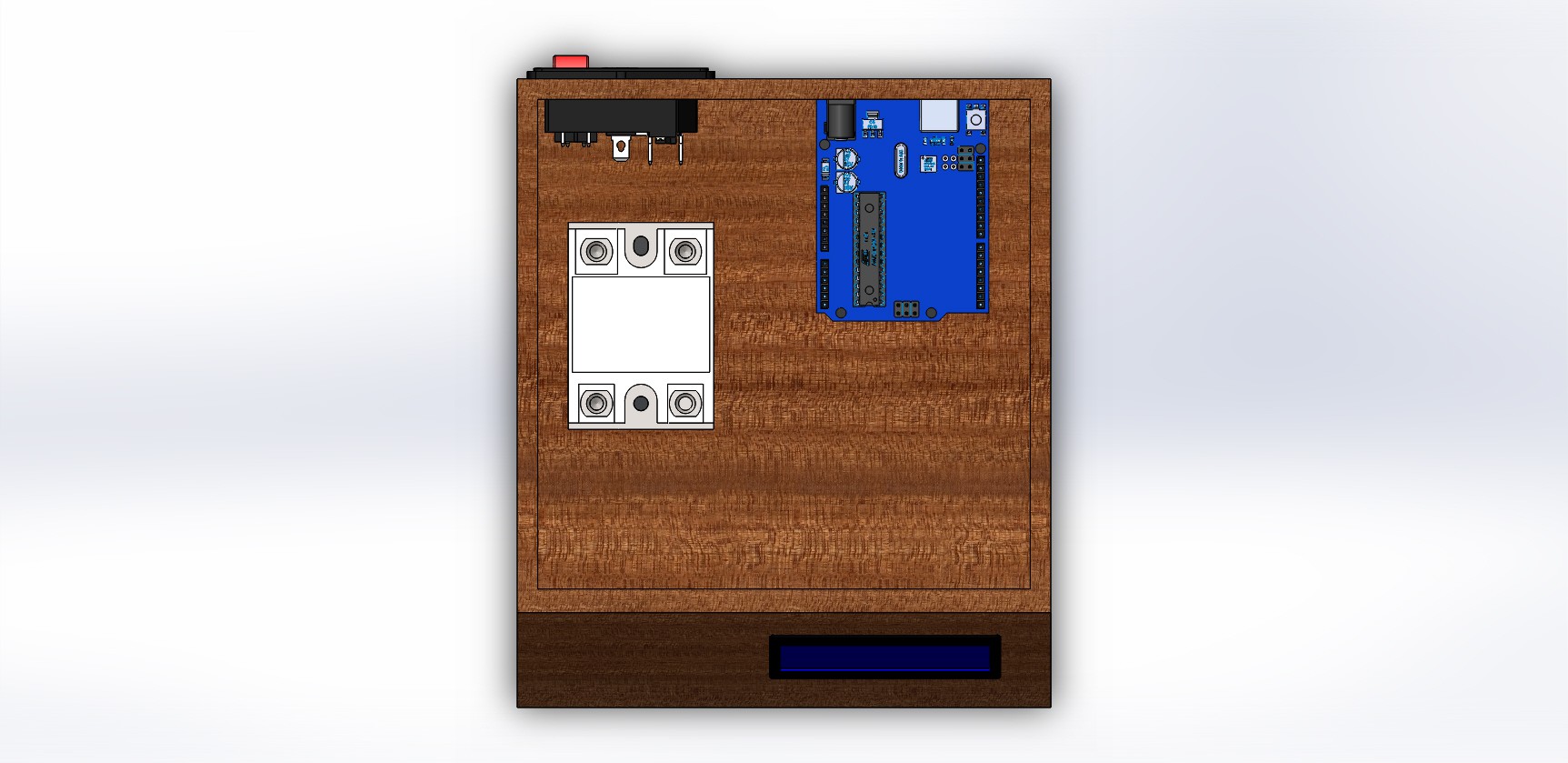

I made an new project for the hotplate and you can check it out here:

And here is a quite computer rendering while I wait for the parts to arrive.

jupdyke

jupdyke

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.