It's been a crazy week since my last update. I've started with the HTML5 webpage, I haven't gotten as far as I'd have liked to due to a busy schedule. I have been working out a lot of the design challenges, particularly with the CO2 / LED systems. The nutrient delivery system is mostly complete in terms of the design however I have been struggling to make sure all the fittings are uniform to avoid unnecessary pressure fluctuation in the lines.

- CO2 SYSTEM

The Carbon-Dioxide enrichment system not only keeps the plants inside of EDEN alive, it bulks them up allowing more growth to occur. Without a fresh supply of CO2 the plants will eventually wither away like my girlfriend's failed attempt to grow flowers in her window. The most basic way of supplying CO2 is by having good ventilation so outdoor air can circulate and replenish the CO2 concentration. This is easy to implement - however is less effective. Atmospheric carbon-dioxide levels are not ideal for plant growth, even with all the fuss about climate change. There is also the challenge of keeping the air temperature just right, the humidity right, the pressure right, and the nasty pollutants out. Because of that, relying on ventilation varies too much to achieve controlled results like other alternatives offer.

EDEN will use 24 oz CO2 tanks. The tanks I have selected for this project are actually paintball tanks in order to allow ease of refills. Theoretically I expect the tanks to last the duration of the grow, if they run out - they can be refilled during the sleep cycles since plants use light to absorb CO2. I have invested a good amount of confidence in these tanks after seeing them used in aquaponics projects, with some users actually complaining that their aquarium plants are getting too big.

CO2 tanks for paintball guns typically are around 800-1000 psi, overpowering most of the electronically controlled gas solenoids I've found for the project. I've found a low pressure regulator which will drop the pressure down to around 100 psi, however I must do extensive testing to make sure it's not going to vent CO2 outside of the gas lines. It has been a challenge to ensure all fittings match up perfectly, but progress is being made.

I'm going with a cheaper CO2 sensor like the MG-811 and coupling it with a pressure sensor to determine the right flow intervals. Something to note is that a full tank releasing gas for 5 seconds is going to be quite different from a low tank releasing gas for 5 seconds because of a pressure drop. The pressure sensor will detect drops which helps to calculate how long to keep the solenoid open and when the tank is low. The role of the CO2 sensor is to determine the overall demand.

- LED Array

The LEDs are closely tied to the CO2 System. From my research I have come to the conclusion that the CO2 absorption rates increase as the amount of light increases. Initially when I learned of CO2 enrichment I became skeptical of greenhouse gases because plants thrive at higher levels, until I realized that the amount of light would not increase to accommodate those absorptions. The LED array must be powerful enough to provoke higher CO2 consumption.

Many hydroponics projects use crazy expensive lights, with claims of 'full spectrum' and gigantic power consumption being used as marketing standards. LEDs are not only more power efficient, they allow for targeting the spectrum of light that chlorophyll captures and uses for photosynthesis. Our optical sense tells us these huge HID arrays are bright, but plants have a different sense of optics.

This week I found an LED supplier in China that is selling 3W LEDs with pcbs for around $35 per hundred. I'm anxiously trying to order these ASAP so they arrive before THP deadlines. They are 440-470nm (Blue/Royal Blue) and 610-660nm (Red/Deep Red), and emit about 70 lumens of brightness each. I expect to use around 300-400 LEDs. 900-1200 watts of light is quite a bit, but my logic behind that amount is due to the idea that not all of those LEDs will be active at once. They can be, but I intend to separate the LEDs into stands of 12. These strands will be regulated by a converter with a switch that can customize the spectrum the plants receive. The light that is optimal for early stages of growth differs from the light that is optimal in later phases. I want to allow custom LED profiles, but I intend to do a few presets - like power saver, phase based, maximum growth, maximum brightness.

- Power

Driving all of those LEDs, sensors, solenoids, and other electronics is going to take a pretty decent power supply. I calculate a demand for around 1500 watts maximum, and for now I've decided to go with a decent desktop PC power supply.

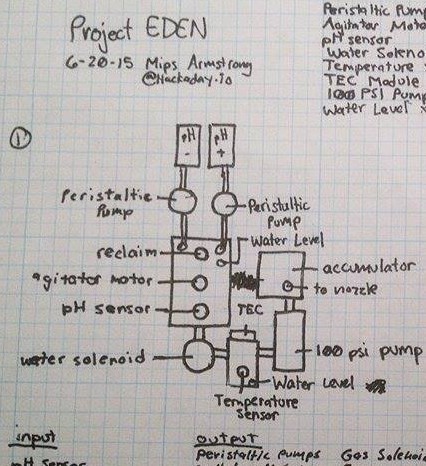

I will use my TI MSP430 for the LED controller, and an Arduino Due for just about everything else. I am going to spend most of this next week bouncing between web design and double checking that the fittings for everything are compatible. Next weekend I will be doing more work in the realm of circuit design. Here's a glimpse at the nutrient system.

sadhana

sadhana

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.