Last night I met up with my friend who is going to cut out the profiles on his CNC machine. His machine is a vintage monster (V. Alberti Edit 3000), usually used to cut out large pieces for his furniture business, not really suited to the fiddly work I was presenting. There is a limit of 800 lines of g-code in a program, which means that the the splines and crazy curves that SolidWorks generated when I converted the drawing to DXF needed to be optimised.

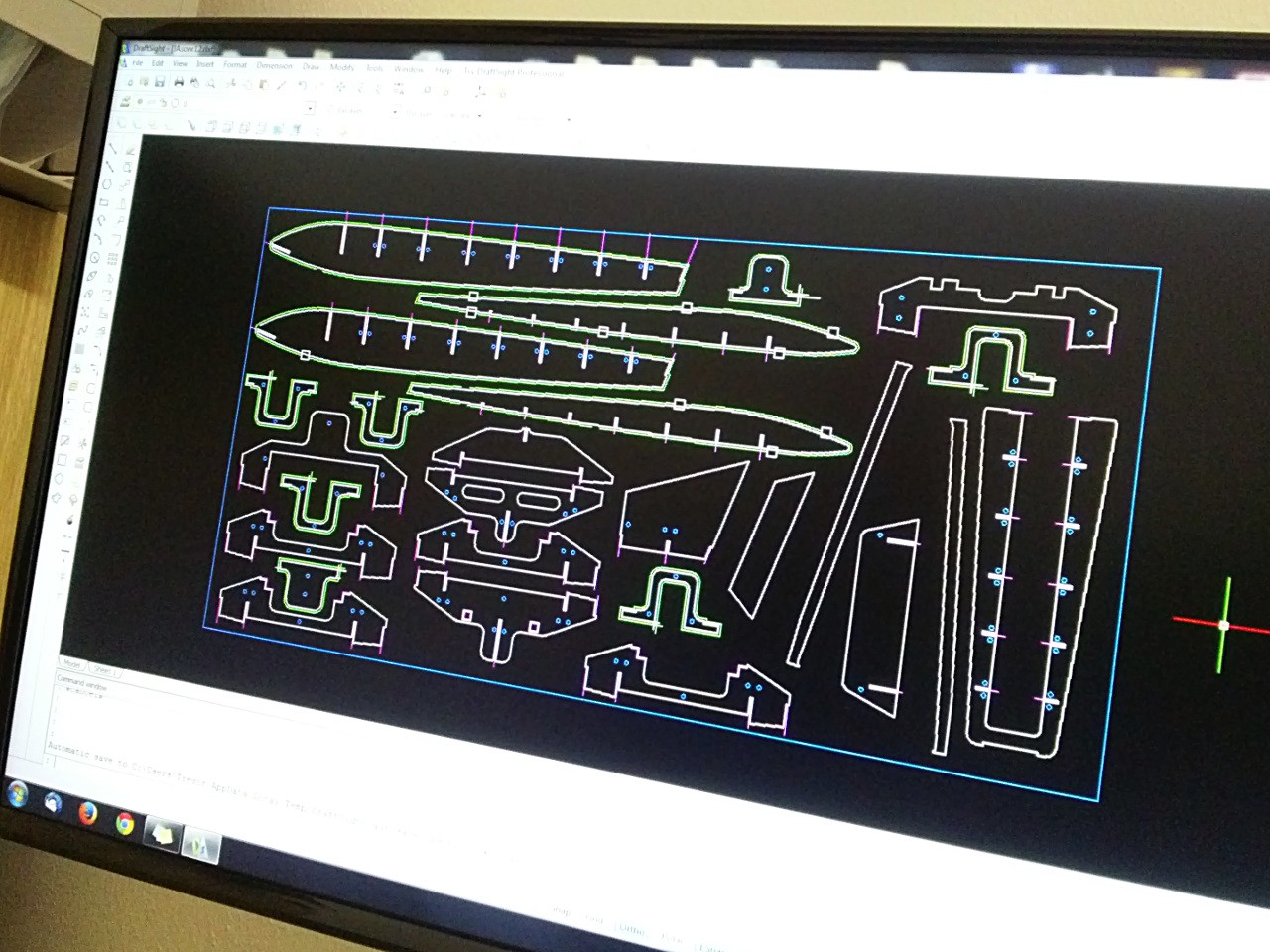

After a couple of hours of work with DraftSight we had approximated all of the splines with radii and generated about half of the toolpaths. The majority of the shapes will be cut out with a 6mm cutter, while the notches and 90' corners will use the 3mm cutter. There are holes all over the show which will be used to screw the profiles down the the wasteboard beneath, since the CNC machine only has suction cups for holding large boards.

There is still some work to be done before the program is ready to run, but it is close! I'd kept my poor friend at work until 10pm, so it was time to release him, but not before we took our vintage RC cars out for a run in the street outside the factory. These little beasties were actually what got us both back into the RC hobby, so the boat owes something to them.

Ossum

Ossum

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.