I've been makeing some sutble changes to the PF. I changed the orbit and added some weapondry to the various lanes to fill in some "empty" space created by removing the rollover switches.

I also did the initial CAD work on getting a CNC-ready Playfield.

My next step is to see if I can source some inserts from Pinball Resource. I'll need to do this before I commit to keeping the same sized inserts as on the original.

finished the CNC work on the Playfield as I have a 1pm reservation on the Techshop.ws CNC machines for Saturday. Earlier this week I got some Russian Birch in 4x8 sheet to create the PF on. The veneers/cores look to be dense and high quality which should yield a good looking PF.

The CNC simulation yielded this rendering (click for full size image):

The simulator says 44minutes of machine time – but I’m guessing it’s gonna be longer than that.

I used Sketchup 8 to create the files (easiest 3D software I can barely use). Once I had the file created in Sketchup; I exported the model to a 3D model in DAE format. Then I used Meshlab 1.3.0 to convert the .dae into an .stl which could be read by Cut3D. Here’s the models as the look in MeshLab:

Once I had the tool paths figured out; I imported the .v3d file into Cut2D and aligned it in the file. The simulation shows me this:

This should allow me to cut, drill, and carve the PF in one "session" on the shopbot. Simulation told me 1hr 7minutes... but I'm skeptical.

I couldn’t figure out why the Ball lane path is “etching” the non-lane wood. I tried a couple of things but they didn’t seem to make it better – only worse. So; I plan on leaving the 1/4” ball mill a little higher when it’s cut to try and avoid the etches.

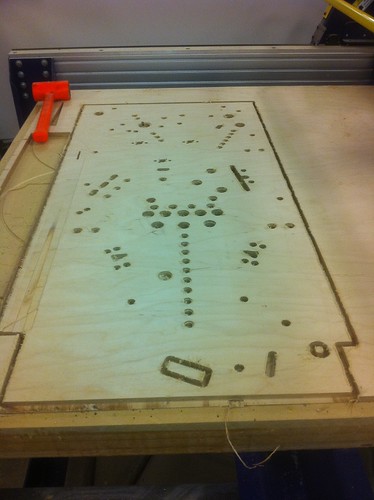

11/22/2013... this happened at techshop.ws:

I <3 me some CNCing.

So yeah... me is happy:

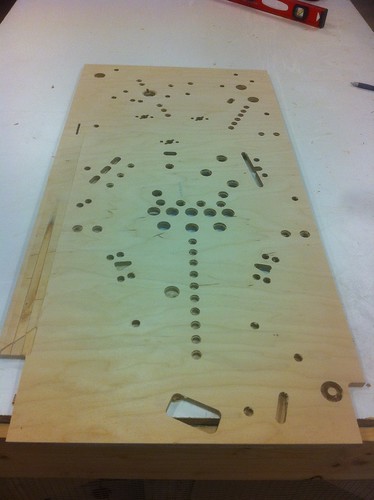

11/24/2013:

I had another 4hour block on the CNC machine at techshop... I finished up drilling the holes in the PF:

I also flipped the PF and CNCed out the proximity slots on the underside of the PF:

I have about 7 hours total in the PF including setup and actual CNC time.

I cleaned the wood "fuzzies" from the top of the PF with a wire brush attachment on my dremel. There is currently Primer grey on the underside of the PF... trying to dry in this cold as$ texas night. Yes; I know your not suppose to paint below 50F... but I really don't have a lot of choice if I'm going to meet the TPF'14 deadline.

zittware

zittware

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.