The team at C⁴Derpillar have set these goals for the 2015 Hackaday Prize:

- Develop an open-source Capillary Electrophoresis (CE) Capacitively-Coupled Contactless Conductivity Detection (C⁴D) platform for under USD $500.

- Demonstrate the effectiveness of the platform by developing an affordable water testing unit capable of taking automated measurements of nutrient levels in a water system.

- Effectively communicate our use of open-source technology and academic research to contribute back to the open community and establish a public global monitoring network.

Semifinal Update

As of 22/9/2015, we have received and assembled the exciter and detector PCBs and are in the process of prototyping the plumbing of the system in order to conduct a trial separation!

So far we've written code to control our programmable function generator and have tested our voltage amplifier circuitry. We have also written code that lets us run various 'diagnostics' over serial such as dumping the output from the ADC and resetting the device.

Using a digital potentiometer to control the excitation voltage is proving problematic as we could not even get it to show on the I2C bus! At the moment, we are using a fixed resistor to yield ~50V as the excitation signal.

Our next task is to diagnose a fault within our solid state relays (they won't turn on so we can't do a trial separation!) and start characterising the output signal from the system (noise floor of the signal, standard error, SNR). Fortunately, the detection circuitry (the meat of the whole project) appears to be operating within parameters, so all we need to do now is push some liquid down a tube - something that proved elusive all of Sunday night :(

After this is taken care of, it's time to put the unit into appropriate housing (so that it is portable), start developing a nicer user interface (cloud data storage and administration) and conduct a shedload of tests on the device.

At the moment, the project looks like it will stay within budget (more details to come in detailed costings).

Below is our short video for the Semifinal round, showing some hyperlapses of us building various parts of the system. Stay tuned for the next instalment, which will feature a full Electrophoretic separation of river water and finally demonstrate just how innovative our device is!

What problem are we solving?

The United Nations Secretary General Ban Ki-moon states that every year, more people are killed by unsafe water, than all forms of violence, including war. It is thought that the primary source of water pollution is inadequately managed industrial and agricultural waste. This disproportionately affects developing countries, which are industry-rich but lack the resources to effectively police strict environmental regulations.

The Executive Director of the United Nations Environmental Programme concedes that the lack of resources for monitoring and assessment make it difficult to obtain a global picture of water quality. Whilst the technology exists to analyse chemical levels in water, these processes suffer from significant limitations. Traditional techniques, such as ICP-AES and ICP-MS use expensive (USD $50, 000 - $0.5mil), complex machines that require the supervision of an expert operator. These operational requirements make it impossible to obtain regular readings over a wide range of remote monitoring sites, limiting the conclusions we can draw from water quality data.

The same publication laments that traditional methods lack the spatial and temporal resolution to draw effective conclusions regarding water quality. This information gap is not only an issue in developing countries, as the Animas river incident of August, 2015 has shown us. An accidental spill of from an abandoned mine by the US Environmental Protection Agency led to the release of 3 million gallons of industrial waste which affected 3 states. The EPA was criticised for delaying the release of an analysis conducted on the water while confusion existed in the community as to the safety of the bright yellow water. Eventually it was revealed that the water contained high levels of arsenic, cadmium and lead. Towns were advised that the water was unfit for consumption, after a large, unknown number of residents unwittingly exposed themselves going about their daily activities.

These compounds are not easily removed from the body and accumulate; causing ailments such as birth defects, intellectual impairments and degenerative diseases like osteoporosis. It is a fundamental belief of our research group that access to potable water sources is an inalienable human right. This coincides with legislative instruments such as the European Union Drinking Water Directive, which mandates water quality parameters for EU member states. Unfortunately, the Directive does not require sources serving less than 50 people to adhere to the guidelines. This is reflective of the high level of resourcing current analysis methods require.

Animas River: before and after.

Where does C⁴derpillar fit in?

By reproducing a ~USD $40, 000 ($12, 000 used) Capillary Electrophoresis device for under USD $500 and implementing several advances from the academic and open source communities, we aim to make it a simple process for citizen scientists (and academics) to exploit the unique advantages CE offers. We aim to generate high resolution environmental data for the first time and are particularly interested in using big data processing techniques with this high quality data to devise unique solutions to water pollution challenges.

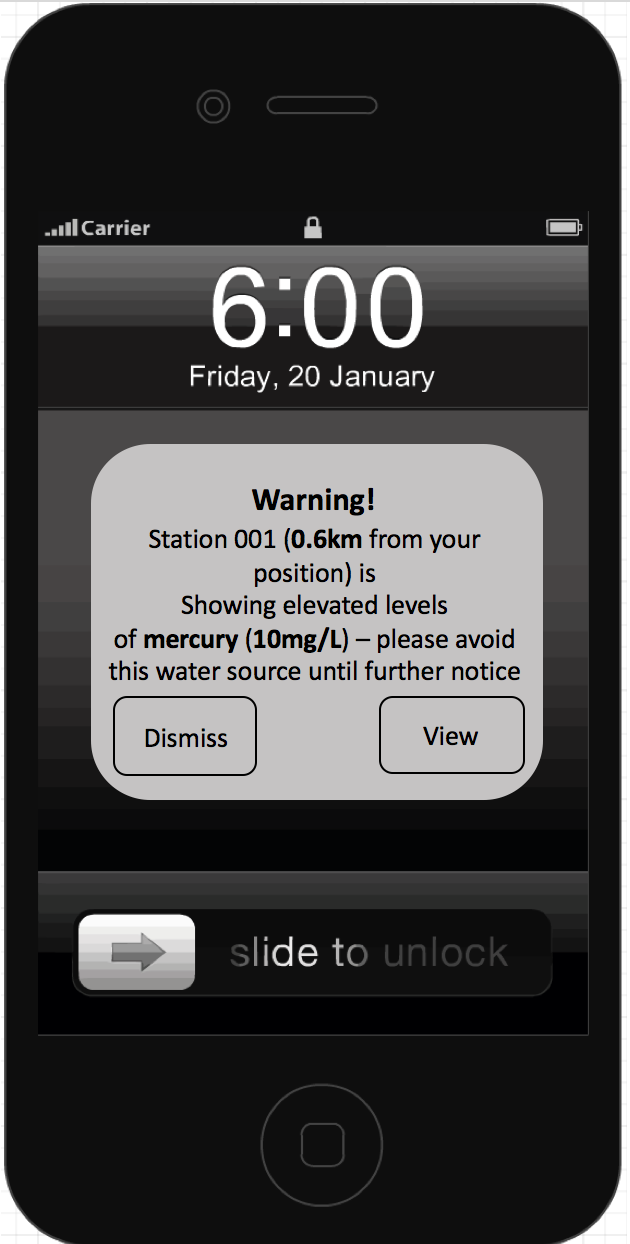

Imagine a system that sent push notifications to warn villagers that their drinking water was contaminated with arsenic from an illegal waste dump, while at the same time drawing the attention of social media, leading to the apprehension of the offenders by the community.

A unique advantage of C⁴derpillar is its simple design and ability to be powered by solar, allowing extended operation at remote sites. The impact of widespread access to an affordable, automated chemical monitoring system is a paradigm shift from our current complicated and onerous measurement processes. Technology such as this in the hands of the average citizen empowers the population to take ownership of the environment, leading to large scale improvements in economic and health outcomes.

If a C⁴Derpillar system was implemented along the Animas river, citizens would have had access to independent real-time information and be equipped to make informed decisions to limit their exposure.

The applications of CE are not limited to the detection of pollutants in water; C⁴derpillar was designed to be a modular total analysis platform, capable of extending the functionality of several critical pieces of open source laboratory equipment. Run a 'virtual gel' on some of your OpenPCR product; automatically process hundreds of samples using Opentrons, or identify that suspicious peak with the RamanPi. Upon completion of our reference implementation, we aim to interface with these technologies in order to create a low cost Chain Termination (Sanger) DNA Sequencer, with minimal modification to the reference platform.

What is C⁴derpillar?

C⁴Derpillar came to be when we discovered that there were no accessible detection systems for taking automated measurements of water quality, particularly nutrient levels, for monitoring our fish tanks. We discovered a simple and accurate technique for separating ions in a solution called Capillary Electrophoresis (CE) [wiki]. We propose solutions to several significant challenges involved with detecting dissolved solids with Capacitively-Coupled Contactless Conductivity Detection (C⁴D). C⁴D detection is able to accurately identify and quantify most chemicals of interest. Realising the potential of an open-source C⁴D CE platform for a global community of citizen scientists, we began our journey as C⁴Derpillar.

Read more in our Project Log: Introduction.

Read more about how CE works in Project Log: What is Capillary Electrophoresis (CE)?

Our system uses the property of electrolytic conductivity [wiki] to measure the concentration of ions in a solution. Using Capillary Electrophoresis (CE), individual ions can be separated and then specifically identified by their migration speeds in an electric field. Contact with the solution traditionally hindered the development of conductivity detection based CE, while the expense and difficulty of light-based (UV) detection is prohibitive for amateurs. We suggest the Capacitively-Coupled Contactless Conductivity Detection (C⁴D) technique which provides a simple, low-cost and highly accessible method for wirelessly detecting ions separated by CE.

Read more about our implementation of C⁴D in our Project Log: Detection.

System Design of C⁴Derpillar

When developing C⁴Derpillar, we aim to adhere to 4 core design principles:

- Open design - allowing even novice operators to produce laboratory-grade measurements.

- Low cost (< USD $500) - making it accessible to developing countries.

- High reproducibility and sensitivity - to provide meaningful, high quality readings.

- Cloud connectivity - to harness the power of big data analysis in water quality management for the first time.

Where are we at the moment?

As of 18 August, 2015, we have ordered the parts required to make the Sampling/flow injection analysis, power supply, separation, detection and control systems. While we brave the shipping time to Australia, we 3D printed (thanks to 3Dhubs) a syringe pump assembly and ran some tests driving it with a NEMA 17 stepper motor. A (long) video of the endeavour can be found below:

We are spending the majority of our spare time optimising the PCB design for the C⁴D detector and upgrading our documentation to a standard where it can be uploaded.

What is the analysis procedure for C⁴Derpillar?

- The system is automatically purged with dilute sodium hydroxide.

- Sample is acquired from an auto-sampler or provided by a user.

- Separation buffer, including background electrolyte is mixed with the sample and guided into the separation system.

- The separation system splits the sample into ionic bands, allowing for the measurement of individual chemicals by C⁴D detection.

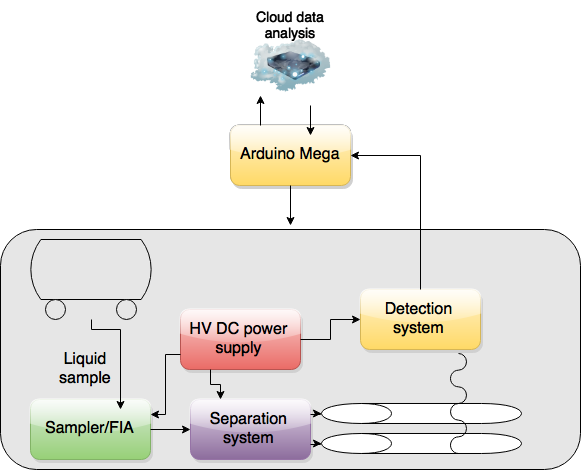

- Measurements are captured by a microcontroller and sent to a computer by USB or uploaded to a Cloud-based data analysis system, which also allows remote administration of the device.

The C⁴Derpillar can be considered as 6 discrete functional units that work together to conduct the analysis. Construction will be conducted on each section concurrently, with the aim to produce a functional prototype by 14 September, 2015. Information about the design of these units can be found below.

Sampling/Sequential injection Analysis (SIA) system

Information regarding the Sequential Injection Analysis system can be found in: Project Log: SIA Design Document

This system is responsible for acquiring a sample for analysis. The sample can be acquired automatically from a source such as a river or provided by a user through an injection port connected to a syringe pump. Our syringe pumps use doctek's 3D printed Simple Syringe Pump, powered by a NEMA 17 stepper motor.

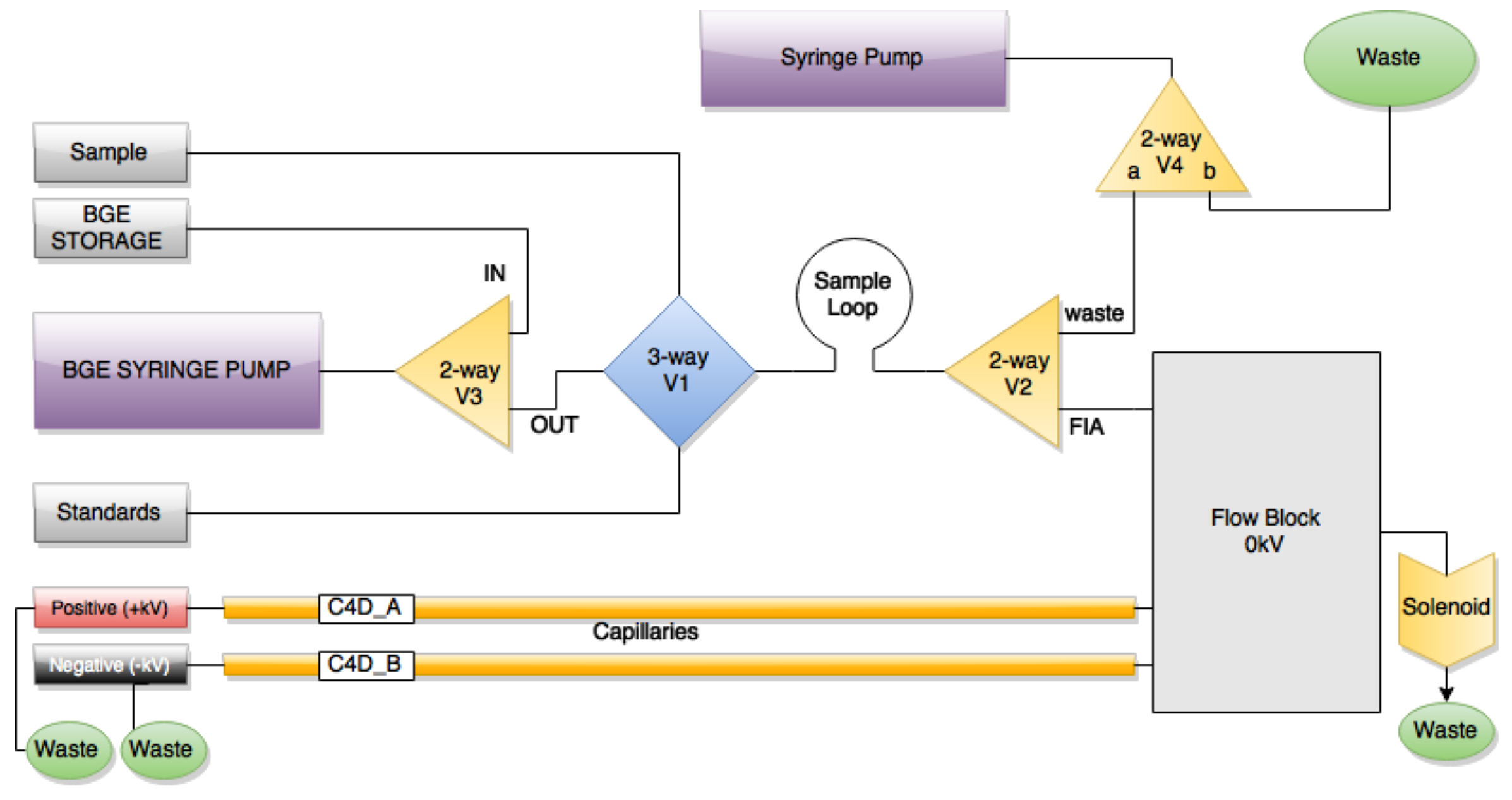

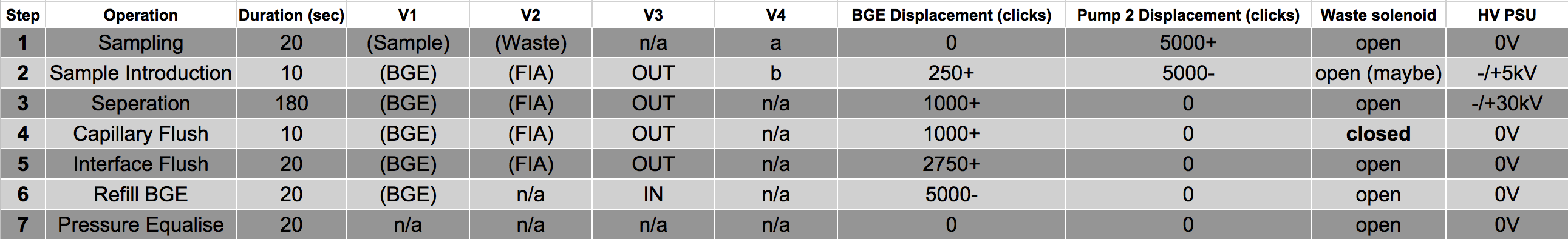

Once a sample is taken into the sample reservoir, the Flow Injection Analysis (FIA) system is responsible for mixing a known amount of sample with the separation buffer and directing it through the capillary at flow rates ranging from 1-100μL/min.

Fluid actuation will be achieved by a combination of NResearch 2-way and Bio-Chem 3-way flow selection valves, connected by 1/16" PTFE and silicon tubing. PTFE and silicon was chosen as they are chemically inert, preventing contamination due to analytes adhering to the walls of the tubing. Sample is then introduced into a 3D printed flow block that distributes it into the separation system.

A schematic of the Sampling/flow injection analysis system is shown below:

The following table shows the switching states of various components as the system performs an analysis run. This will come in handy when designing the controller logic:

HV DC Power supply

The power supply needs to deliver high voltage/low current DC. A +5kV potential is applied for a few seconds during the injection phase to facilitate the loading of ions into the capillary. In the separation phase, a user-selectable voltage between 5-30kV is applied for the duration of the analysis run, usually ~20 minutes. Usually the current draw is around 20μA, due to the high resistance of the separation buffer.

Ideally, to allow for the simultaneous separation of anions and cations, we want a centre tapped supply, capable of providing -0-30kVDC and +0-30kVDC lines. To achieve this in our prototype unit, we will use a neon sign transformer and selectable voltage multiplier circuits.

As the neon sign transformer is powered by mains AC, it will prove difficult to integrate into a safe, portable system. We are researching alternative methods for making a supply powered by 12VDC.

If anybody has any suggestions for overcoming this challenge, we have opened a stack - please help us!: https://hackaday.io/page/1173-hv-dc-power-supply-options-30kv20ua

Separation system

Read more in Project log: What is Capillary Electrophoresis (CE)?

The separation system is responsible for separating substances into individual bands to be 'seen' by the detection system. C⁴Derpillar achieves this with Capillary Electrophoresis (CE), which involves applying HV DC across 2 capillary tubes, one for positively charged ions and one for negatively charged ions.

By adjusting the separation buffer, C⁴Derpillar is capable of measuring a wide range of chemicals in liquid samples, including:

Thankfully, CE is a mature analysis technique and a large number of published separation buffers exist for most analytes of interest. We aim to develop simple, non-toxic buffer systems which can be distributed as pre-measured sachets for beginner users.

Read more about the separation buffer chemistry in Project log: Separation chemistry

Detection system

Information about our design can be found in Project Log: Detector System Design Document

Traditional CE systems used UV-based detection methods to detect separated bands of ions migrating through the capillary. These systems are not suitable for amateurs due to their significant cost and complexity. C⁴Derpillar uses a low cost, wireless conductivity detection method (C⁴D). C⁴D measures the conductivity of the solution inside the capillary using two electrodes that sleeve the capillary tube. Several designs for these detectors are described in the literature.

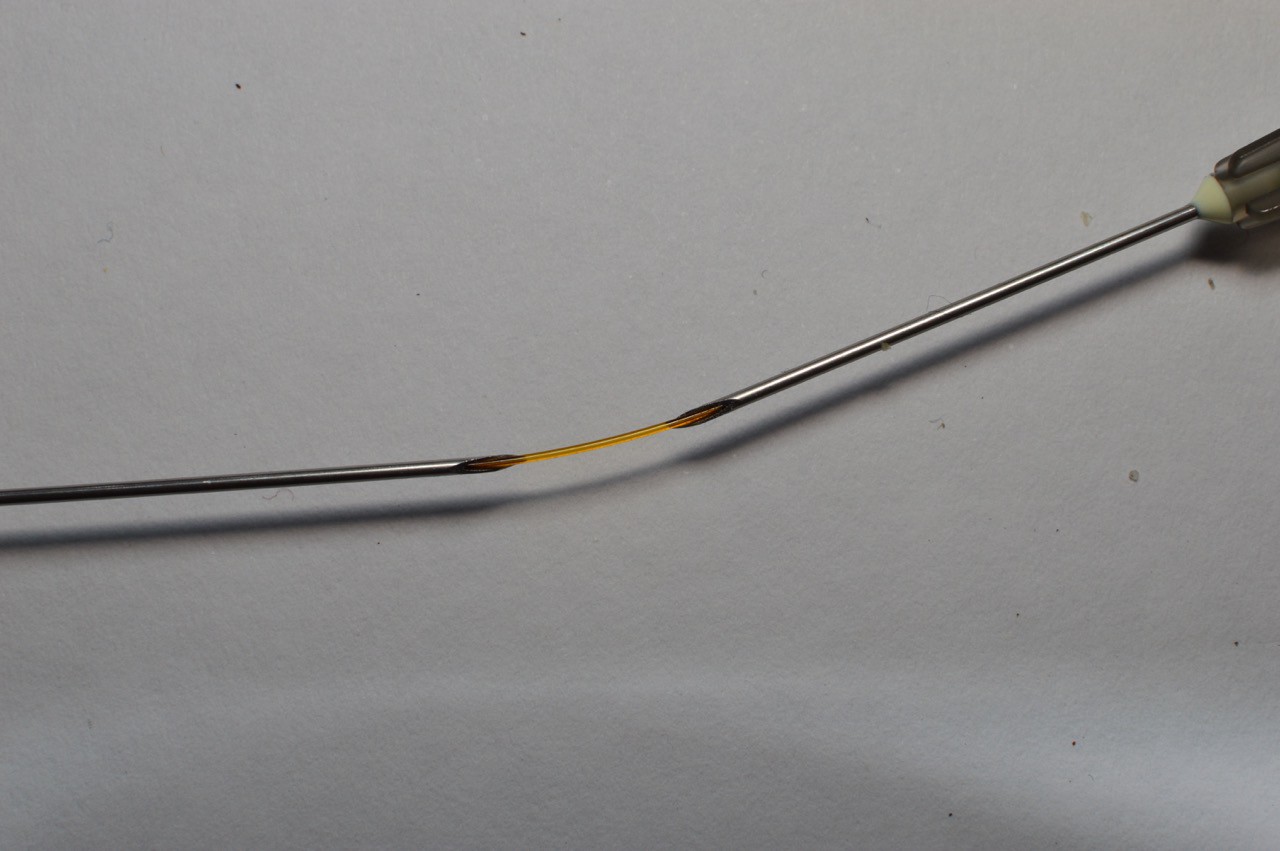

In our design, we achieved this on a budget by sleeving the 375μm OD capillary with a 400μm ID syringe, which can be seen below:

Our particular electrode configuration features an additional electrode constantly measuring pure sample buffer. Phase cancelation is used to remove the background signal from the final reading, significantly enhancing the sensitivity of the detector. This arrangement is usually referred to as a referenced C⁴D detector detector and provides several advantages, including abolishing the need to operate the device at a constant temperature - a key constant that limits the portability of current techniques.

More information about how the C⁴D detection system works can be found at Project log: Conductivity Detection.

Control system

C⁴Derpillar will be controlled by an Arduino Mega. This allows us to interface with the injection system and HV PSUs (via the analogue pins), and the detector function generator (digital pin).

The signal from the 2 C⁴D detectors is captured by 2 ADS1259 (24-bit, 14kSPS), ADCs and written onto an SD card, along with information such as the GPS location and working parameters of the system. This can be transferred to a computer or uploaded to the Cloud via Wi-Fi/GPRS. As the amount of data transmitted is small, global data roaming SIM cards represent a versatile way of providing a low cost, universal connectivity solution for the platform. The design of the communications system will be completed once we have produced an operational prototype. Candidate GPRS modules include the MG2639 GPRS/GPS Shield.

The controller will be configured over USB using the open source Instrumentino library for python and Arduino, which contains many handy functions for operating the Arduino as a python-controlled PID controller. Instrumentino also allows for the rapid development of powerful cross-platform graphical user interfaces and integration with our Cloud analysis system.

Data analysis system

By storing the data in the cloud, we can use tools such as Google Fusion Tables and the Google Maps API to design an interface that allows users to perform complex analyses on their data and share geotagged readings with the public. Users should be able to subscribe to public sensors and obtain real-time warnings about selected chemical levels (e.g. arsenic, lead or cadmium as in the Animas river spill).

Content licensing and attribution

doctek's 3D printed Simple Syringe is licensed under a Creative Commons Attribution-ShareAlike 3.0 Unported Licence. This implies that we must release any developments upon this design under the same licence.

Instrumentino is released under the GNU General Public Licence where enables us to modify it for use in our application.

Brett Walker

Brett Walker