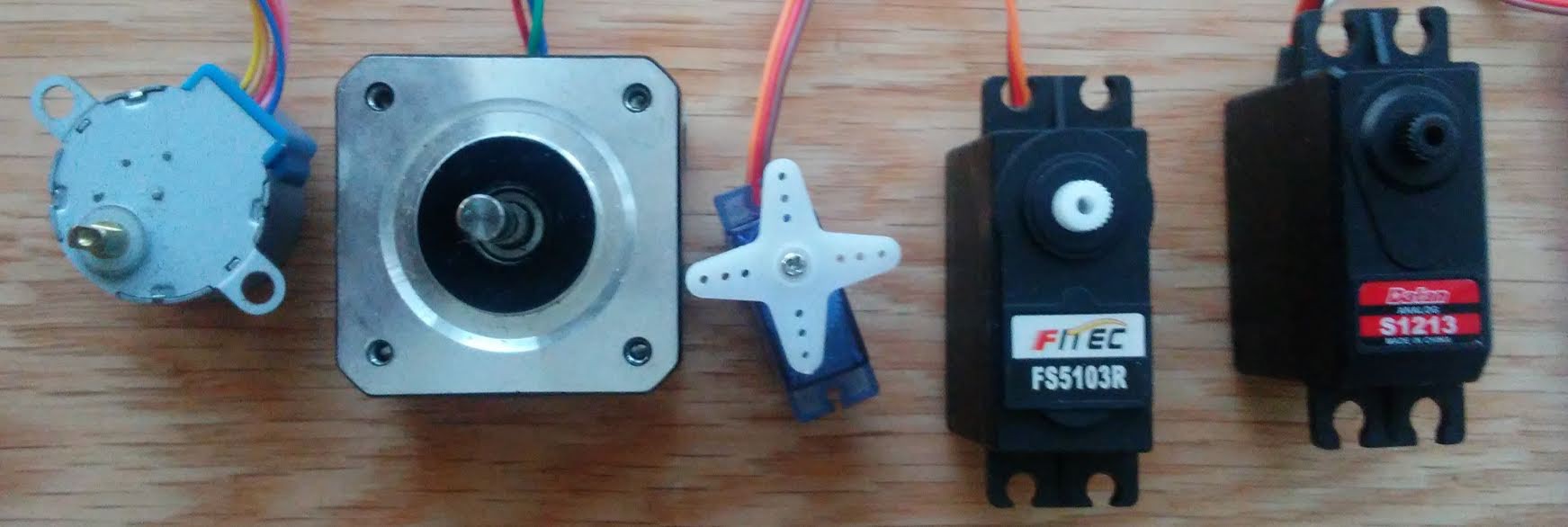

We have experimented with several stepper and servo motors to control FED, and we found one that works well for dispensing pellets. This log will describe a bit of our experience and what to look for if you want to choose a different motor for a pellet dispenser.

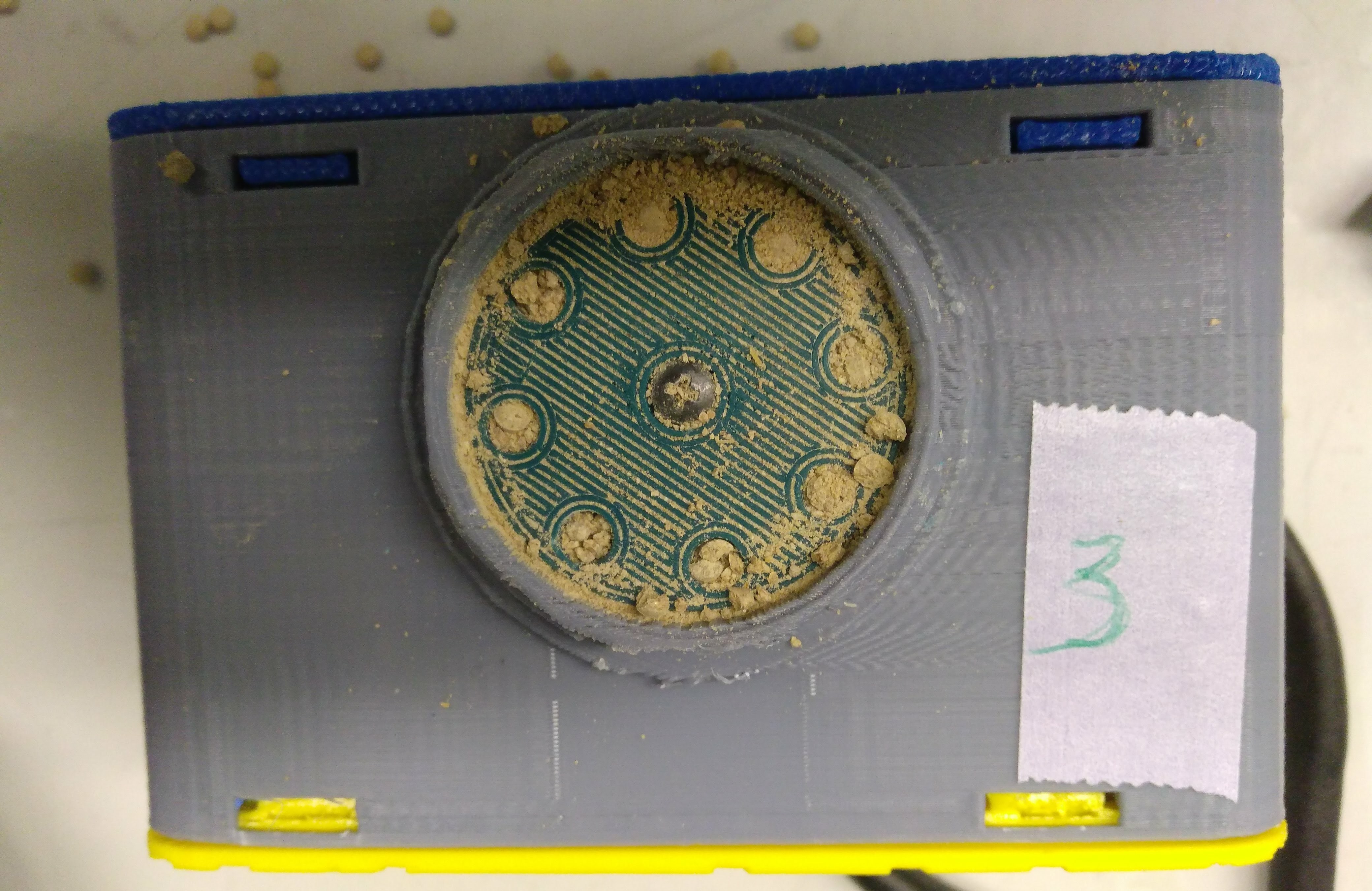

We needed to find a balance between having a motor that is strong enough to move the pellet disk, but also weak enough to not grind up pellets if it encounters resistance. Grain pellets disintegrate very easily, and create dust that can gum up the works. While stepper motors are a bit more complicated to control than servos (they require a driver board), we found that they are a better choice as all of the servos we tried would grind up pellets and result in pellet jams. They would typically work for a couple of hours, but after 1-2 days they would look like this

Obviously this FED can no longer dispense until it is unclogged. So if you want to experiment with different motors, or designing a different pellet dispenser altogether, we recommend choosing a geared stepper motor that will stall when it encounters resistance, rather than powering through and pulverizing the pellet. While this can take a bit longer to dispense a pellet, we coded the motor to try dispensing 10 times, and then perform a big movement to dislodge any jammed pellets.

As one final point, if you use sucrose pellets they are much harder than the grain pellets and are therefore more resistant to crushing and jamming.

Lex Kravitz

Lex Kravitz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

We are also observing the crushing after about 12-18 hours. Am using Bio-serv F0071 Dustless Precision Pellets® Rodent, Purified - 20mg. Dustless is ironic :) Suspect what happens is that when there are many pellets and some dust, the motor doesn't move on individual dispensing movements -- so the stepper then does the full revolution to unjam, and then we start to see food pile up in the exit port, but not quite make it to the photodetector. -- to solve we used a filing tool to smoothen out the inside of the exit port and clean out the excess plastic from the shapeways fab.

Are you sure? yes | no